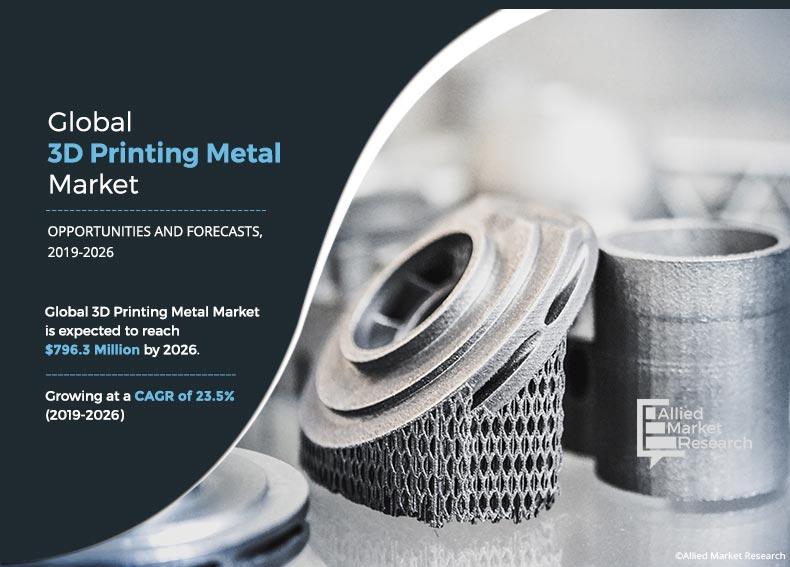

3D Printing Metal Market Outlook - 2026

The global 3D printing metal market size was valued at $147.2 million in 2018 and is projected to reach $796.3 million by 2026, growing at a CAGR of 23.5% from 2019 to 2026. The 3D printing is a process of developing three-dimensional object from a computer-aided design (CAD) model. This is done by adding material layer by layer, which is also known as additive manufacturing. Metals used for 3D printing are called 3D printing metals. 3D printing materials are used to manufacture solid objects. These materials are of different types such as plastics, metal, ceramics, and other materials. They are used by designers, engineers, architects, surgeons, and other professionals to make representative models for clients and students.

Despite the fact that thermoplastics attracted the most consideration in the beginning of 3D printing, the 3D material choices keep on developing. These advancement in 3D printing technology is expected to drive the growth of the market. The 3D printing metal market growth is further driven by Additive Manufacturing (AM) technology which utilizes metals, earthenware production, glass, composites, plastics, paper, and bio-inks for printing. In 2017, NASA declared the effective testing of an igniter made of different metal alloys. This bi-metallic capacity could lessen rocket motor expenses by 33% and fabricate time by one-half. In several applications, metals and metal combinations have been progressive in AM and 3D printing.

The global 3D printing metal market is expected to register substantial growth in the near future due to rapidly growing industries such as Aerospace & defense, healthcare, and automotive. Metal materials are expected to dominate the market in terms of growth rate during the forecast period. However, high cost associated with the techniques and materials is expected to restrict the market growth.

Segment Overview

The global 3D printing metal market is segmented based on type, form, end-user and region.

3D Printing Metal Market By Type

On the basis of type, the market is segmented into steel, titanium, aluminum, nickel and others. The aluminum segment was the highest contributor to the global market, and steel segment is estimated to grow with the highest CAGR during the forecast period. The increasing use of aluminum 3D printing in automotive application is expected to drive the growth of the market. Aluminum is ideal for strong, light and precise metal parts. Hence, its application is increasing in automotive industries. The product ranges from spare parts to components of RC cars and gadgets. On the other hand, 3D printed steel enables manufacturing of parts for very technical applications that usually perform better than those manufactured by traditional methods.

By Type

Other metal is projected as the fastest growing segment.

3D Printing Metal Market By Form

Based on form, the global 3D printing metal market is bifurcated into powder and filament. The powder segment was the highest contributor to the market and the filament segment is estimated to grow with the highest CAGR during the forecast period. The growing use of metal powder-based 3D printing in applications such as aerospace, medical and rapid tooling areas. In the 3D printing materials market, plastic in the form of filament is the most dominantly material. Among all the thermoplastics available in the market around 80% of them are available in the form of filaments. Some other materials such as metal, lay wood, paper, and others are also available in the form of filaments.

By Form

Filament segment is projected as the fastest growing segment.

3D Printing Metal Market By End User Industry

Based on end-user, the global 3D printing metal market is segmented into consumer products, Aerospace & Defense and defense, automotive, healthcare, and others. The automotive segment was the highest contributor to the market and aerospace & defense segment is estimated to grow with the highest CAGR during the forecast period. Automotive industry is the early adopter of the 3D printing technology. In the automotive industry manufacturers primarily use the technology for prototyping rather than parts manufacturing owing to large production volumes. Advancement in current technology will allow greater penetration of 3D printing in the areas of making automotive parts cheaper, lighter, and faster.

By End-user Industry

Aerospace and Defense segment would exhibit an CAGR of 25.8% during 2019-2026.

3D Printing Metal Market By Region

Geographically, the market is segmented into North America, Europe, Asia-Pacific and LAMEA. North America was the highest revenue contributor and Asia-Pacific is estimated grow with the highest CAGR during the forecast period.

By Region

Asia-Pacific would exhibit an CAGR of 24.2% during 2019-2026.

Competitive Analysis

The key players involved in the global 3D printing metal market includes 3D Systems, Arcam AB, Autodesk, Inc., Stratasys Ltd, The ExOne Company, Hoganas AB, Optomec, Inc., Organovo Holdings, Inc., Ponoko Limited and Voxeljet AG.

In order to stay competitive and increase 3D printing metal market share, these market players are adopting different strategies such as product launch, acquisition, partnership and agreement. In an instance, 3D System entered into partnership with Georg Fischer AG (GF), which enable manufacturers to produce complex metal part within tight tolerances and reduce the total cost of operation, also it provides automation that includes software for enhanced part design, 3D printers, and automated material handling.

Key Benefits for Stakeholders:

- The report outlines the current 3D Printing metal market trends and future scenario of the 3D Printing metal market size from 2018 to 2026 to understand the prevailing opportunities and potential investment pockets.

- Porter’s five forces analysis helps to analyze the potential of buyers & suppliers and the competitive scenario of the industry for strategy building.

- Major countries in the region have been mapped according to their individual revenue contribution in the 3D Printing metal market analysis at the regional and country-level market.

- The key drivers, restraints, and 3D Printing metal market opportunities and their detailed impact analyses are elucidated in the study.

- The profiles of key players along with their key strategic developments are enlisted in the report.

- 3D printing metal market forecast is studied from 2019-2026.

3D Printing Metal Market Report Highlights

| Aspects | Details |

| By Type |

|

| By Form |

|

| By End User |

|

| By Region |

|

| Key Market Players | AUTODESK, INC., OPTOMEC, INC., EXONE COMPANY, ARCAM AB (GENERAL ELECTRIC), STRATASYS LTD, EnvisionTEC, 3D SYSTEMS, ORGANOVO HOLDINGS, INC., HOGANAS AB, PONOKO LIMITED |

Analyst Review

Growth in investment towards research and development, increase in adoption of 3D printing devices, development of low-cost devices, and decrease in the price of materials are driving the demand for 3D printing metal market. Metals are the most widely used 3D printing material across the industry. Significant efforts are made to commercialize new materials to meet the specification of high-end applications. Demand for metals in 3D printing markets is growing significantly owing to a significant upsurge in the demand for desktop printing, whereas demand for metals is growing primarily due to growing penetration in high-end application such as structural parts in automotive and aerospace industry.

The fashion and jewelry sector are two booming sectors where 3D printing is being implemented for producing customized jewelry products. For instance, in the recently held Paris Fashion Week, 2018, the ornaments of one of the dresses showcased were 3D printed using the PolyJet technique. This technique helps to create pieces of high-end resin having smooth surface. 3D printing is also used by the consumer product industry.

The advancements in 3D printing technology are expected to drive the growth of the market. Additive Manufacturing (AM) technology utilizes metals, earthenware production, glass, composites, plastics, paper, and bio-inks for printing. In 2017, NASA declared the effective testing of an igniter made of different metal alloys. This bi-metallic capacity could lessen rocket motor expenses by 33% and fabricate time by one-half. In several applications, metals and metal combinations have been progressive in AM and 3D printing.

The global 3D printing metal market was valued at $147 thousand in 2018 and is projected to reach $796 thousand by 2026, growing at a CAGR of 23.5% from 2019 to 2026.

Product launch is one of the most widely adopted strategy. The 3D System and the Arcam have been actively engaged into the new product launches to gain edge over competitors.

North America is expected to hold the highest share in the market. The rise in application of 3D printing metal in medical sector is expected to drive the growth of the market. Various prosthetic parts and medical instruments are manufactured using 3D printing technology, which have a wide application in the medical market. 3D printing technology is also capable of developing lightweight parts and instruments from various available materials, which increase the demand for 3D printing metal from the aerospace and automobile industry in North America.

Partnership is one of the key growth strategies of 3D printing metal market players. Autodesk entered into partnership with 3D Printing Industry Association (3DPIA), which is decided exertion to advance 3D printing adoption and skills in South Korea.

The key players involved in the global 3D printing metal market includes 3D Systems, Arcam AB, Autodesk, Inc., Stratasys Ltd, The ExOne Company, Hoganas AB, Optomec, Inc., Organovo Holdings, Inc., Ponoko Limited, and Voxeljet AG.

The automotive segment was the highest contributor to the market. Automotive industry is the early adopter of the 3D printing technology. In the automotive industry manufacturers primarily use the technology for prototyping rather than parts manufacturing owing to large production volumes. Advancement in current technology will allow greater penetration of 3D printing in the areas of making automotive parts cheaper, lighter, and faster.

According to industry leaders, significant efforts are made to commercialize new materials to meet the specification of high-end applications. Demand for metals in 3D printing markets is growing significantly owing to a significant upsurge in the demand for desktop printing, whereas there is an increase demand for metals primarily due to rise in penetration in high-end application such as structural parts in automotive and aerospace industry.

Loading Table Of Content...