Advanced Composites Market Research, 2031

The global advanced composites market size was valued at $34.0 billion in 2021 and is projected to reach $88.7 billion by 2031, growing at a CAGR of 10.2% from 2022 to 2031. The advanced composites market is driven by rise in demand in the aerospace and aircraft industry, where lightweight, high-strength materials are essential for improving fuel efficiency and performance. In addition, increase in demand for ceramic matrix composites, known for their high heat resistance and durability, further boosts the market growth, particularly in high-temperature applications such as aerospace, defense, and energy sectors.

REPORT KEY HIGHLIGHTERS:

- The advanced composites market has been analyzed in both value and volume. The value of the advanced composite market is analyzed in millions while the volume is analyzed in kilo tons.

- Global advanced composites market is fragmented in nature with many players such as Toray Industries, Inc., Koninklijke Ten Cate NV, Teijin Limited, Hexcel Corporation, SGL Group, Cytec Solvay Group, Owens Corning, E. I. Dupont De Nemours, Huntsman Corporation, Momentive Performance Materials Inc. Also tracked key strategies such as product launches, acquisitions, mergers, expansion etc. of various manufacturers of Advanced Composites.

- Covered the detailed list of manufacturers by application of advanced composite market. It covers the product information, application, and geographical presence of the companies.

- Conducted primary interviews with raw material suppliers, wholesalers, suppliers, and manufacturers of advanced composite market to understand the market trends, growth factors, pricing, and key players competitive strategies.

- Included more than 20 countries in the report which covers market volume as well as market value for all the countries of advanced composite market report.

Advanced composites materials have high specific strengths and stiffness, which when combined with automatic manufacturing technologies allow for the fabrication of lightweight and cost-effective composite structures. The replacement of metal alloys with advanced composite materials, in general, reduces a structure’s mass by 20–30%. These are referred to as "advanced composite materials", in contrast to the composite materials that are frequently used, including reinforced concrete or even concrete itself. The high-strength fibers are also low-density while occupying a large fraction of the volume.

"Numerous industrialists are aware of that advanced composites can be utilized to improve conventional materials like metal and wood to produce stronger yet lighter-weight alternatives. Advanced composites are replacing metal components in many applications, particularly in the weight-critical products produced in the aerospace industry. There is an increase in the growth of the advanced composite market owing to the high demand for advanced composites in a broad range of industries such as the aerospace & defense, sporting goods, marine, medical, wind energy, and transportation industries, as these offer a high strength to weight ratio and high heat resistance."

Advanced composites are offering a competitive advantage to industries that have formerly used steel or aluminum constructions. Advanced composites are no longer limited to aerospace, high-performance marine, and wind energy applications. Advanced composites are being used on building facades, medical uses, truck cabins, and a variety of other applications. The global demand for fuel-efficient and lightweight vehicles, particularly in the aerospace and defense sectors, is one of the factors driving the advanced composite market. Furthermore, future market opportunities are anticipated to emerge from new technological advancements in the wind energy sector, as well as other industries such as automobile battery enclosure.

Increased sales of vehicles will drive the demand of high demand for advanced composites, which will boost the market advanced composites growth for the projection period. During the forecast period, rising auto sales are anticipated to boost worldwide industry growth. Countries like India, China, the U.S., and Brazil are principally responsible for the increase in global vehicle sales. Furthermore, rapid expansion in specialized manufacturing industries such as medical devices and wind energy is anticipated to support industrial growth in these areas. Hence, rapid industrialization in Brazil, Russia, India, China & South Africa (BRICS) is expected to drive industrial advanced composites demand, which, in turn, is expected to complement the global advanced composites market sector growth.

High demand in the aerospace and aircraft industry

Aerospace has always been an industry of technological revolution. Aerospace engineering has ac the promoter for the development of advanced engineering materials. with the development of transport vehicles for space travel and the next generation of supersonic aircraft in development, the industry continues to drive innovation to new heights. The advanced material development depends on their properties such as strength, stiffness, damage tolerance, density, and corrosion resistance, at ambient and high temperatures. Manufacturers demand high-performance, cost-effective material solutions to solve complex problems and eliminate risk. Reduced take-off weight of an aircraft, space vehicle, or satellite directly affects the amount of fuel burned, causing enormous economic and ecological benefits with lightweight design.

Advanced composite materials have broad, proven applications, in the aircraft, and aerospace sectors. The use of advanced composite materials in the aerospace sector is growing steadily due to several advantages of composites over metals, such as composites' lightweight, high strength, corrosion resistance, and superior fatigue and fracture properties, as well as multifunctional performances such as SHM and self-assembly.

Advanced composite material is made when two or more different materials are combined together to create superior and unique materials such as reinforcement and matrix material. The reinforcement provides strength and rigidity which helps to support the structural loads. The matrix or the binder helps to maintain the position and orientation of reinforcement and is more brittle, but when these two materials are combined which is lightweight, stiff, strong, and tough. This factor will boost the market growth during the forecast period.

Complex manufacturing processes are a significant restraint on the growth of the advanced composites market. The production of advanced composites, such as carbon fiber-reinforced polymers (CFRPs) and ceramic matrix composites (CMCs), involves intricate procedures that require specialized equipment, skilled labor, and precision. These processes, including lay-up, molding, and curing, are time-consuming and costly, limiting large-scale production. In addition, the need for stringent quality control and testing adds to production delays and expenses. These complexities hinder the market's ability to meet increasing demand, particularly in industries like aerospace and automotive, where cost efficiency and scalability are critical.

Advancements in manufacturing technologies offer significant opportunities for the growth of the advanced composites market by improving production efficiency and reducing costs. Innovations such as automated fiber placement (AFP), additive manufacturing, and 3D printing allow for the precise, rapid production of complex composite structures with minimal material waste. These technologies also enhance scalability, making it easier to meet the growing demand for advanced composites in industries such as aerospace, automotive, and energy. In addition, improved manufacturing processes enable the development of stronger, lighter, and more durable composite materials, opening new applications and driving further adoption across various sectors.

Growing demand for ceramic matrix composites

One of the major applications of ceramic matrix composites in the aerospace industry. The use of ceramic matrix composites in such aircraft parts is due to their high strength-to-weight ratio and low weight. The other major demand is due to the development of fuel-efficient aircraft as well as vehicles. This market will be driven by the production of sports cars and fuel-efficient aircraft. New technologies are being developed through ongoing research and development to develop ceramic matrix composites with a variety of improved features and a greater capacity to provide structural efficiency at lower weights than the current technology. It is expected that this high level of innovation will reduce production cycle time‐¯and reduce composite production costs. The market will grow as a result of the full-fledged application of such technology to meet the demand for lightweight ceramic matrix composites-based products.

The increasing demand for ceramic matrix composites in developing countries, especially in the Asia-Pacific such as China, India, Singapore, and Thailand, will drive advanced composite market growth. Developing countries are adopting ceramic matrix composite-based fuel-efficient aircraft engines. In addition, the ceramic matrix is utilized in other components of aircraft engines, including nozzles, combustor liners, blades, and shrouds. The increased fuel efficiency leads to a reduction in the operational cost of the aircraft. The high economic growth in these countries, along with high urbanization, industrialization, and increased standards of living, also plays a very crucial role in the adoption of fuel-efficient cost-cutting machinery. Thus, it will drive the demand for ceramic composites during the forecast period.

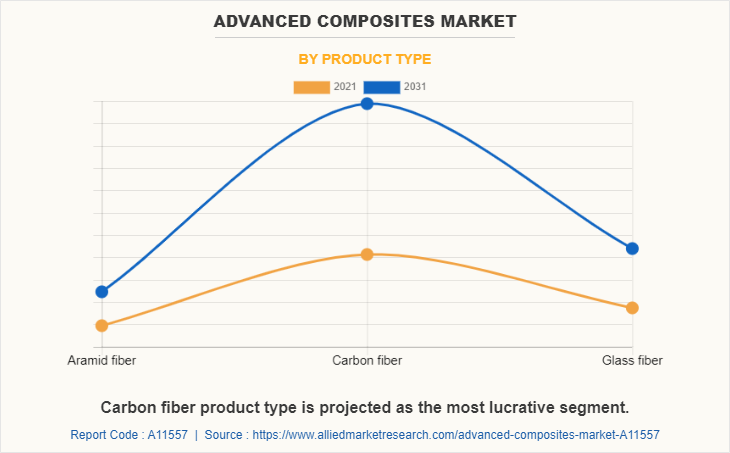

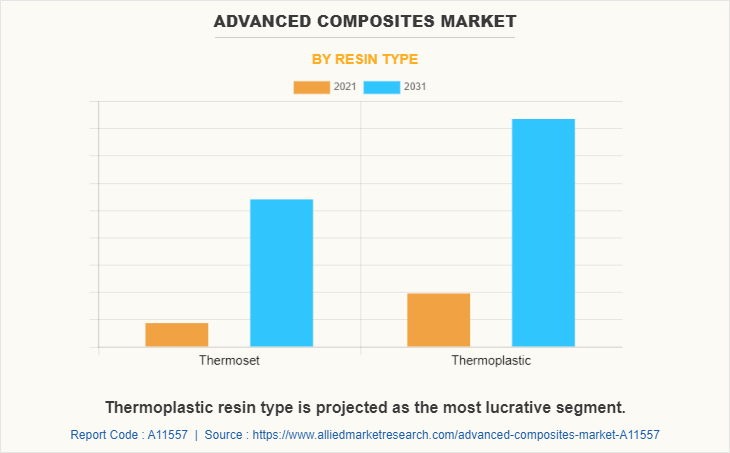

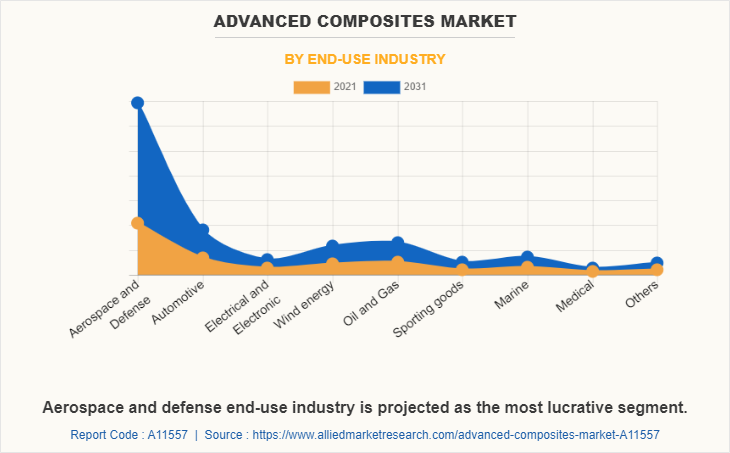

The advanced composite market is segmented on the basis of product type, resin type, end-use industry, and region. On the basis of product type, the advanced composite market is segmented into aramid fiber composites, carbon fiber composites and glass fiber composites. On the basis of resin type, the advanced composite market is segmented into thermosets and thermoplastic. On the basis of the end-use industry, the advanced composite market is segmented into aerospace & defense, thermoplastic, electrical and electronic, wind energy, sporting goods, marine, medical and others. The regional market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The major players operating in the industry include Toray Industries, Inc., Koninklijke Ten Cate NV, Teijin Limited, Hexcel Corporation, SGL Group, Cytec Solvay Group, Owens Corning, E. I. Dupont De Nemours, Huntsman Corporation, Momentive Performance Materials Inc. These players have adopted product launch, acquisition, and business expansion as their key strategies to increase their market shares.

On the basis of type, the market is divided into aramid fiber, carbon fiber, and glass fiber. Carbon fiber composites product type was the largest revenue generator, in 2021 and is anticipated to register a CAGR of 10.3% during the forecast period. Carbon fiber composites offer many properties such as high corrosion resistance, low thermal expansion, and exceptional durability, and are thereby majorly utilized in the production of aerospace parts. Furthermore, increasing aircraft production will further escalate the carbon fiber composites industry expansion over the forecast period.

Advanced Composites Market By Type

The global advanced composites market is divided into thermoset and thermoplastic. The thermoplastic advanced composite was the largest revenue generator, in 2021 and is anticipated to expand at a CAGR of 9.5% during the forecast period. The thermoplastic resin in the advanced composites market is anticipated to boost by increasing demand for fast-curing and sustainable composite materials in the automotive industry. Increasing demand for thermoplastic resin from growing automobile manufacturing and the development of new goods using the product drive adoption.

Advanced Composites Market By End-Use Industry

The end-use industry covered in the study includes aerospace and defense, automotive, electrical and electronic, wind energy, oil and gas, sporting goods, marine, medical, and others. In 2021, the aerospace and defense end-use industry was the largest revenue generator and is anticipated to register a CAGR of 10.5% during the forecast period. High demand for advanced composite materials from the aerospace industry and the rising need for fuel-efficient aircraft are some of the major factors propelling the growth of the market.

Advanced Composites Market By Region

The Advanced Composite market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. The Asia-Pacific Advanced Composite market size is projected to expand at the highest CAGR of 10.3% during the forecast period. Rising wind energy applications and the increasing demand in the aerospace & defense industry offer an opportunity to the Asia-Pacific advanced composite market.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the advanced composites market analysis from 2021 to 2031 to identify the prevailing advanced composites market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the advanced composites market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global advanced composites market trends, key players, market segments, application areas, and market growth strategies.

Analyst Review

According to the CXOs of the leading companies in the market, Major players in the advanced composite market are focusing on the needs of their customers, which has resulted in a high level of innovation in terms of the product' reduced weight, increased design flexibility, and improved accessibility. Also, the application of advanced composites is growing in many industries, including marine, sports, and construction. The primary driver of market expansion is the growing application in the production of wind turbines and aerospace components. Additionally, carbon fiber composite is anticipated to be the fastest growing market over the projection period owing to increasing penetration of the product in the aerospace industry. The demand for lightweight, fuel-efficient aircraft is anticipated to increase, which will spur the development of improved carbon materials. However, the high cost of the product is expected to restrain the market growth.

The industry is characterized by a high number of new market entrants that are seeking to tap lucrative opportunities in the global market while existing players are entering into strategic collaborations to increase capacities & expand their reach into emerging markets. Joint venture, merger, and acquisition activities in the industry have increased significantly over the past decade. Companies constantly seek to establish long-term contract agreements with trusted partners for sustainable business operations globally.

Advanced composites Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 88.7 billion |

| Growth Rate | CAGR of 10.2% |

| Forecast period | 2021 - 2031 |

| Report Pages | 373 |

| By Product Type |

|

| By Resin Type |

|

| By End-Use Industry |

|

| By Region |

|

| Key Market Players | Huntsman International LLC, Momentive, Hexcel Corporation, ST Advanced Composites, SGL Carbon, Toray Industries, Inc., Owens Corning, TEIJIN LIMITED, DuPont, Solvay |

Analyst Review

According to the CXOs of the leading companies in the market, Major players in the advanced composite market are focusing on the needs of their customers, which has resulted in a high level of innovation in terms of the product' reduced weight, increased design flexibility, and improved accessibility. Additionally, the application of advanced composites is growing in a number of industries, including marine, sports, and construction. The primary driver of market expansion is the growing application in the production of wind turbines and aerospace components. Additionally, carbon fiber composite is anticipated to be the fastest growing market over the projection period owing to increasing penetration of the product in the aerospace industry. The demand for lightweight, fuel-efficient aircraft is anticipated to increase, which will spur the development of improved carbon materials. However, the high cost of the product is expected to restrain the market growth.

The industry is characterized by a high number of new market entrants that are seeking to tap lucrative opportunities in the global market while existing players are entering into strategic collaborations to increase capacities & expand their reach into emerging markets. Joint venture, merger, and acquisition activities in the industry have increased significantly over the past decade. Companies constantly seek to establish long-term contract agreements with trusted partners for sustainable business operations globally.

High demand for advanced composites from the aerospace industry is the key factor driving the global advanced composites market.

Aerospace and defense in the global advanced composites market are projected to increase the demand of advanced composites during the forecast period.

Asia-Pacific is the largest regional market for Advanced composites.

The global advanced composites market was valued at $34.0 billion in 2021, and is projected to reach $88.7 billion by 2031, growing at a CAGR of 10.2% from 2022 to 2031.

The major players operating in the industry include Toray Industries, Inc., Koninklijke Ten Cate NV, Teijin Limited, Hexcel Corporation, SGL Group, Cytec Solvay Group, Owens Corning, E. I. Dupont De Nemours, Huntsman Corporation, Momentive Performance Materials Inc.

The global advanced composites market is segmented on the basis of product type, resin types, end-use industry and region.

Loading Table Of Content...