Automated Material Handling Equipment Market Overview:

Automated Material Handling Equipment Market size was valued at $22,520 million in 2014 and is expected to reach $39,060 million by 2022. Continuous rise in demand for automation in industries has revolutionized the adoption of automated material handling equipment. With the advent of technologies such as robotics, wireless technologies, and driverless vehicles, the automated material handling equipment market has witnessed significant growth over the last few years.

Major players in automated material handling industry focus on the development of affordable, small, compact, and energy-efficient material handling solutions to reach a wider customer base. Recent boom in e-commerce is a major driver for the materials handling systems, with widespread demand for process automation worldwide. E-commerce industry players aim on improving the quality of their service through minimal waste generation. In developing nations, industrialization and modernization primarily support the market growth.

Increased need for automation in industries such as e-commerce, automotive, and food & beverages due to reduced operational costs, improved supply chain process, and reduced labor costs drive the AMH equipment market growth. Moreover, increase in industrial production in emerging nations, such as China, India, and Mexico demands automated conveyor systems, transport equipment and industrial equipment thereby boosting the market growth. However, high initial installation cost of automated material handling equipment poses a major threat to the automated material handling equipment.

Segment Overview:

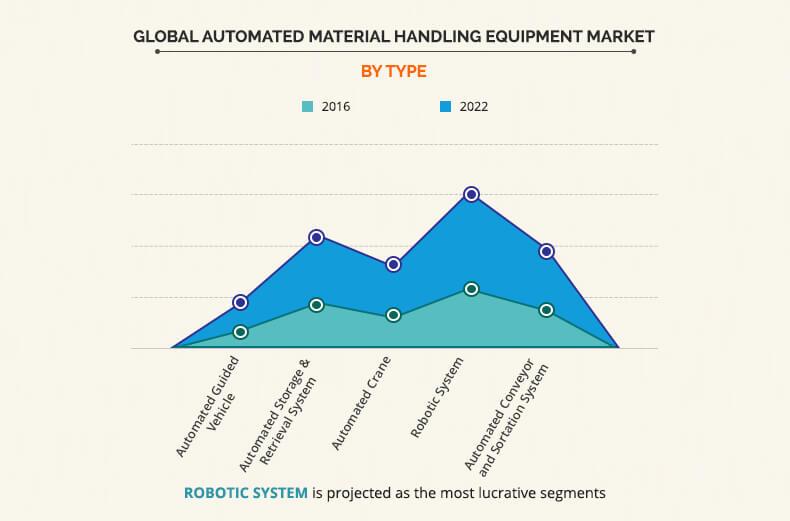

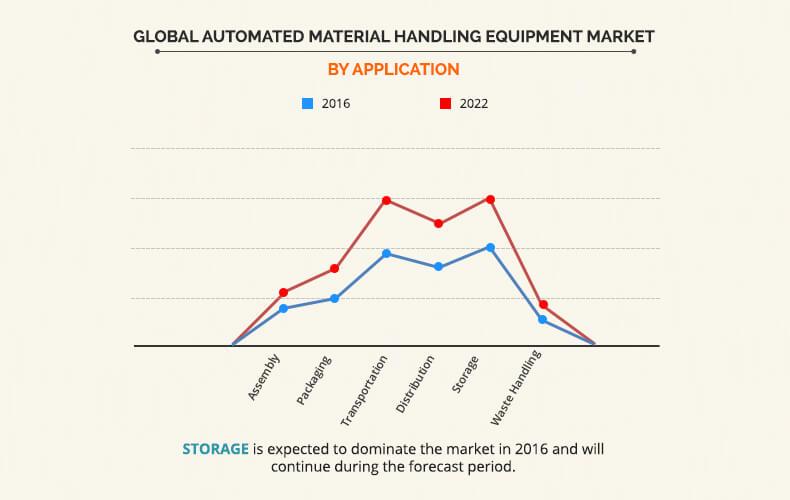

The automated material handling manufacturing industry is segmented based on product type, system type, component, application, industry vertical and geography. Based on product type, market is segmented into automated guided vehicle, automated storage and retrieval system, automated crane, robotic system, and automated conveyor & sortation system. By system type it is divided into, unit load material handling system and bulk load material handling system. Based on application, market is segmented into assembly, packaging, transportation, distribution, storage, and waste handling. By Industry vertical, it is divided into automotive, chemical, rubber & plastic, aviation, semiconductor and electronics, e-commerce, food & beverages, metal, and heavy machinery.

Robotic systems accounted for dominant share of the global market in 2015 and is anticipated to consolidate its position during the forecast period, owing to reduced operating costs and advent of energy efficient robotic systems. In addition, storage application accounted for the largest market share due to increased storage capacity, improved inventory control system, reduced labor cost, and security. Automated conveyor systems accounted for one fifth of the market share in 2015, and is likely to reach $7,596 million by 2022 at a CAGR of 6.5%. Among industries, aviation industry is expected to witness the highest growth due to increased usage of automated material handling equipment in manufacturing and assembling of aircraft.

Top Impacting Factors for AHM Equipment Market

Increase in need for automation

With the increase in need for automation in industrial and transport equipment, the use of automated material handling equipment has multiplied significantly. Organizations adopt robotics systems to automate their processes to deliver high quality products, increase their manufacturing capabilities, serve customers better, and efficiently manage their processes. This factor pushes organizations to adopt AMH equipment and further strengthens the market. The effect of this factor is moderate at this stage; however, it is expected to increase in near future.

Technological advancements

With the advent of new technologies, better and efficient automated solutions are being offered in the market. The automated material handling equipment such as robotic systems perform tasks with higher accuracy and precision and help to reduce operational cost. New technologies such as vision automated guided vehicle provide increased throughput, ensure safety, and helps reduce labor costs. Introduction of advanced technologies result in enhanced quality and flexible automated systems which would strengthen the market in the future. The effect of new technologies is moderate in the AHM equipment market, and its impact is expected to increase in near future, owing to increasing adoption of automated material handling equipment in e-commerce industry to shorten the delivery time of products to customers.

Emerging Markets

Currently, the emerging economies including China, India, and Mexico witnessed a slow penetration in the automated material handling equipment industry; however, with the various technological advancements and increase in innovations in robotic systems, the demand for automated systems would rise in the future. However, higher efficiency of these equipment coupled with stringent government policies regarding cleanliness and hygiene, would increase the adoption of automated material handling equipment such as conveyer systems in the e-commerce, food & beverages, and automotive industry in the near future.

High initial investment

The initial cost required for the set up and integration of the automated material handling equipment is high, which limits the use of these equipment in heavy manufacturing organizations. Industries with high labor costs are anticipated to use robotic systems and automated guided vehicles to reduce their labor costs and produce high quality products. Industries, such as automotive and electronics, where precision and accuracy play a major role, use automated systems to meet international quality standards. However, with new emerging technologies, and growth in competition in the market, the initial costs of automated material handling equipment would reduce in the future.

Key players operating in the global automated material handling equipment market are Daifuku Co. Ltd., Siemens AG, Bosch Rexroth, Murata Machinery Ltd., Swisslog Holding AG, SSI Schaefer AG, Dematic Group S.A.R.L, Toyota Industries Corporation, JBT Corporation and Bastian Solutions, Inc.

KEY BENEFITS

- This report provides an in-depth analysis of the global automated material handling equipment industry trends and future estimations to elucidate the potential investment pockets in the market.

- The report provides a quantitative analysis from 2014 to 2022 to enable the stake holders to capitalize on prevailing market opportunities.

- The current trends and future forecasts aid to determine the overall market potential and single out profitable trends.

- Recent developments, key market players, and market shares are listed in the report to study the competitive scenario of the market.

- Porter’s five forces model of the industry illustrates the potency of the buyers and suppliers.

- Value chain analysis provides a clear understanding on the roles of the stakeholders involved.

Automated Material Handling Equipment Market segmentation

By Product Type

- Automated guided vehicle

- Automated storage and retrieval system

- Automated crane

- Robotic system

- Automatic conveyor and sortation system

By System Type

- Unit load material handling system

- Bulk load material handling system

By Component

- Hardware

- Software

- Services

By Application

- Assembly

- Packaging

- Transportation

- Distribution

- Storage

- Waste Handling

By Industry Vertical

- Automotive

- Chemical, rubber & plastic

- Aviation

- Semiconductors & electronics

- E-commerce

- Food & Beverages

- Healthcare

- Others(energy, metal, and heavy machinery)

By Region

- North America

- U.S.

- Mexico

- Canada

- Europe

- Germany

- UK

- France

- Rest of Europe

- Asia-Pacific

- China

- India

- Japan

- Rest of Asia-Pacific

- LAMEA

- Latin America

- Middle East

- Africa

Key Players

- Daifuku Co. Ltd.

- Siemens AG

- Bosch Rexroth

- Murata Machinery Ltd.

- Swisslog Holding AG

- SSI Schaefer AG

- Dematic Group S.A.R.L

- Toyota Industries Corporation

- JBT Corporation

- Bastian Solutions, Inc.

Other companies mentioned in the report:

- Jungheinrich AG

- KUKA AG

- KION Group AG

- Xuzhou Heavy Machinery Co., Ltd.

- Manitowoc Company, Inc.

- Informatik GmbH

- Eisenmann AG

- Columbus McKinnon Corporation

- Crown Equipment Corporation

- Viastore Systems GmbH

Automated Material Handling Equipment Market Report Highlights

| Aspects | Details |

| By PRODUCT TYPE |

|

| By SYSTEM TYPE |

|

| By COMPONENT |

|

| By APPLICATION |

|

| By INDUSTRY VERTICAL |

|

| By GEOGRAPHY |

|

| Key Market Players | BOSCH REXROTH, TOYATA INDUSTRIES CORPORATION, MURATA MACHINERY, LTD., BASTIAN SOLUTIONS, INC., DEMATIC GROUP S.A.R.L., JBT CORPORATION, SWISSLOG HOLDING AG, SSI SCHAFER AG, DAIFUKU CO. LTD., SIEMENS AG |

Analyst Review

The automated material handling systems reduce the labor cost and enhance the workflow and production quality of a process. Automotive, chemical, food & beverage, electronics, healthcare, and aviation industries incorporate AMH equipment to reduce cost, save time, and deliver better quality products. The global automated material handling equipment market has witnessed steady growth across the globe due to increase in automation trends among the various manufacturing industries. With the increase in demand for automated material handling equipment such as automated guided vehicle, automated storage & retrieval systems, automated crane, robotics systems and automated conveyor and sortation systems the market players are developing innovative and technologically advanced material handling systems to enhance their market reach. Automated conveyor systems accounted for one fifth of the market share in 2015, and is likely to reach $7,596 million by 2022 at a CAGR of 6.5%. Acquisition is the most adopted strategy by these market players to increase their market share in the global automated material handling equipment manufacturing industry. For instance, Dematic Group S.A.R.L acquired NDC Automation, a leading provider of Automated Guided Vehicles (AGVs) and Software to provide highest quality AGV solutions to customers. This acquisition would enhance the company’s offering in storage equipment and logistics IT technologies.

Europe dominates the market owing to presence of major industry players including Siemens AG, Bosch Rexroth, Swisslog Holding AG, SSI Schaefer AG, and Dematic Group S.A.R.L. In fact, Germany accounted for the highest market share in this region. Asia-Pacific on account of demand from China, India, Japan, and other developing countries pose lucrative opportunities for market players. LAMEA is expected to grow at a steady CAGR during the forecast period, with growth in developing nations such as Brazil. Key players operating in the market include Daifuku Co. Ltd., Siemens AG, Bosch Rexroth, Murata Machinery Ltd., Swisslog Holding AG, SSI Schaefer AG, Dematic Group S.A.R.L, Toyota Industries Corporation, JBT Corporation, and Bastian Solutions, Inc.

Loading Table Of Content...