Axial Piston Hydraulic Motors And Pumps Market Research, 2033

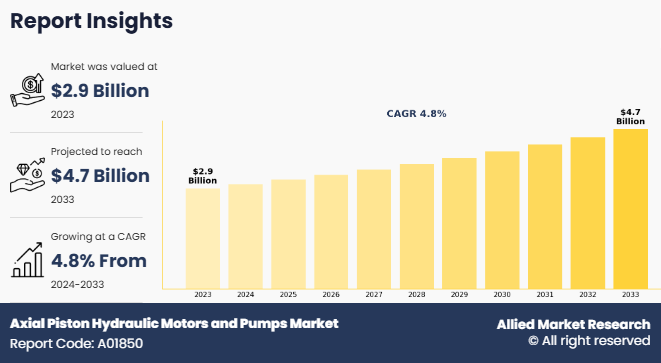

The Global Axial Piston Hydraulic Motors And Pumps Market size was valued at $2.9 billion in 2023, and is projected to reach $4.7 billion by 2033, growing at a CAGR of 4.8% from 2024 to 2033. Axial piston hydraulic motors and pumps are key components in hydraulic systems and are widely used for converting fluid energy into mechanical power. These devices operate on the principle of axial piston movement, where a series of pistons are arranged in a cylindrical block. In pumps, the pistons push hydraulic fluid through the system, generating high pressure to move machinery or vehicles. In motors, the flow of hydraulic fluid forces the pistons to rotate, producing mechanical energy to drive mechanical systems. These devices are highly efficient, compact design, and versatility in applications such as construction equipment, automotive, and industrial machinery. They come in fixed or variable displacement types, offering varying levels of control overflow and pressure to suit diverse operational needs.

Key Takeaways:

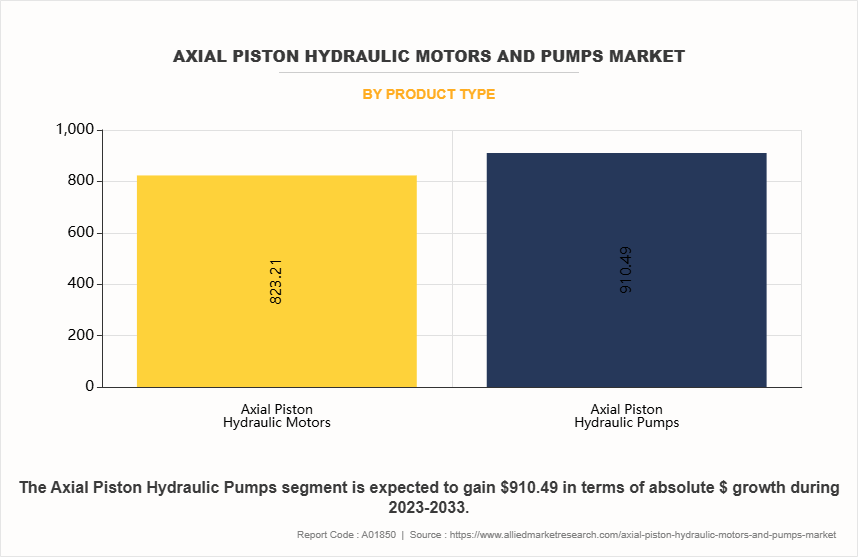

On the basis of product type, the axial piston hydraulic pumps segment dominated the axial piston hydraulic motors and pumps market share in terms of revenue in 2023. However, axial piston hydraulic motors are anticipated to grow at the fastest CAGR during the forecast period.

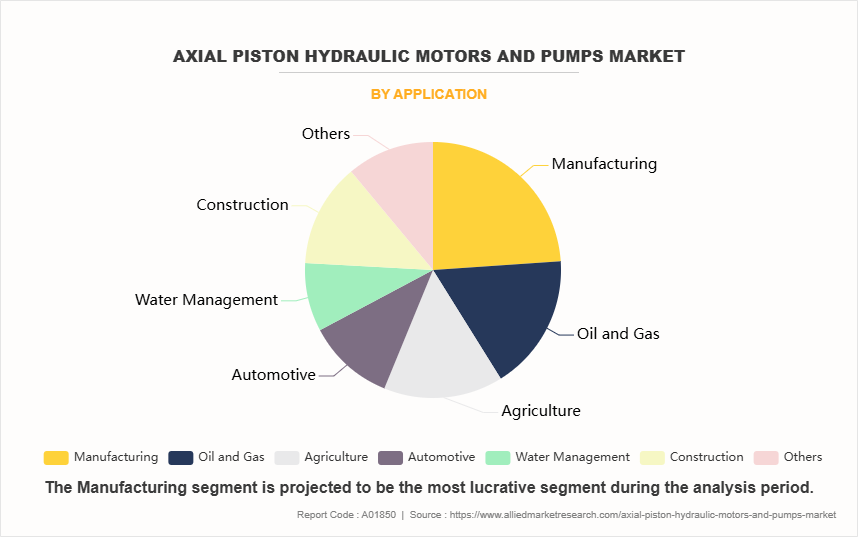

On the basis of application, the manufacturing segment dominated the axial piston hydraulic motors and pumps market trend in terms of revenue in 2023. However, construction segment is anticipated to grow at the fastest CAGR during the forecast period and is anticipated to grow at the highest CAGR during the forecast period.

Segment Overview

The axial piston hydraulic motors and pumps market overview is segmented into product type, application and region.

On the basis of product type, the market is divided into axial piston hydraulic motors, and axial piston hydraulic pumps. In 2023, axial piston hydraulic pumps dominated the market in terms of revenue. However, Axial Piston Hydraulic Motors is also projected to have the highest CAGR during the forecast period. Axial piston hydraulic motors play a pivotal role in various industries, offering efficient power transmission across diverse applications. In construction, they are integral to the operation of excavators, bulldozers, and loaders, delivering the reliability needed for demanding tasks. In agriculture, these motors drive critical machinery such as tractors, harvesters, and irrigation systems, ensuring productivity and precision. In the automotive sector, they enhance functionality in power steering systems and convertible tops.

On the basis of application, the market is segregated into manufacturing, oil and gas, agriculture, automotive, water management, construction, and others. In 2023, the manufacturing segment dominated the market in terms of revenue however construction segment is projected to have the highest CAGR during the forecast period due to Increasing infrastructure development worldwide, urbanization, and government investments in large-scale construction projects fuel the demand for efficient and reliable hydraulic systems. Axial piston hydraulic motors and pumps are preferred for their compact design, high-pressure capability, and precision control, making them indispensable in heavy machinery such as excavators, cranes, and loaders.

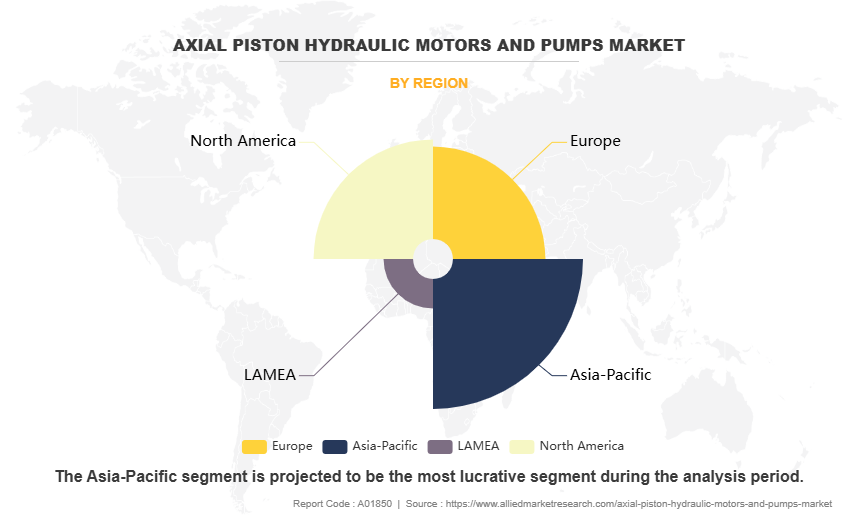

On the basis of region, it is analyzed across North America (the U.S., Canada, and Mexico), Europe (the UK, Germany, France, Italy, and the rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and rest of Asia-Pacific), LAMEA(Latin America, Middle East and Africa). In 2023, Asia-Pacific dominated the market in terms of revenue and is expected to witness the highest CAGR during the forecast period due to The increasing infrastructural investments across the Asia-Pacific region are driving the demand for construction machinery, including cranes, drills, bulldozers, and tractors, to facilitate the lifting and handling of heavy materials. Hydraulic axial piston motors and pumps play a crucial role in enabling these machines to efficiently and safely transport materials from one location to another.

Competitive Analysis

The key players in the axial piston hydraulic motors and pumps market are HAWE Hydraulik SE., Liebherr Group, Linde Hydraulics GmbH And Co. KG, Bucher Group, Danfoss, HYDAC International GmbH, Jiangsu Hengli Hydraulic Co., LTD., POCLAIN, Parker Hannifin Corp, Bosch Rexroth AG.(ROBERT BOSCH GmbH), THM Huade, Kawasaki Precision Machinery (Kawasaki Heavy Industries), Bondioli & Pavesi S.p.A.. Product launch and acquisition business strategies were adopted by the major market players in 2023.

Market Dynamics

Increase in Demand for Construction and Mining Equipment

The increasing demand for construction and mining equipment is significantly driving the axial piston hydraulic motors and pumps market growth. Axial piston hydraulic motors and pumps play a critical role in the operation of heavy machinery, offering better efficiency, precise control, and high power-to-weight ratios. Their ability to operate under high-pressure conditions makes them indispensable for construction and mining applications, where machinery is subjected to rugged terrains and intense workloads. Further, growth in global infrastructure projects, urbanization, and rise in need for minerals and raw materials have fueled the demand for advanced construction and mining equipment. Cities worldwide are investing heavily in infrastructure projects to accommodate growing populations and mitigate climate-related challenges. The concept of sponge cities is gaining traction, integrating permeable surfaces and green spaces to manage stormwater and reduce flood risks. Cities such as Berlin, Vienna, and Leeds are implementing such designs in new developments, which often require advanced hydraulic systems for construction machinery. For instance, Germany’s former Tegel Airport, once Berlin's main international aviation hub, is being redeveloped in an ambitious $8.5 billion project. The transformation is expected to create a new district featuring the Schumacher Quartier, a largely car-free residential area with over 5,000 homes, and The Urban Tech Republic, a campus for students and businesses. Designed to address climate change challenges, the Schumacher Quartier incorporates the innovative "sponge city" model to enhance urban resilience. In mining, the push for automation and efficiency in mineral extraction has increased the adoption of high-performance hydraulic motors and pumps. Axial piston technology provides energy efficiency and durability, reducing operational costs for end users. In addition, technological advancements, such as digital controls and integration with IoT, enhance the performance of these systems, further boosting their demand. This market growth is also supported by stringent emission regulations, which encourage the use of modern, energy-efficient equipment, where axial piston hydraulic motors and pumps excel.

Increase in emphasis on reducing energy consumption

The axial piston hydraulic motors and pumps market is gaining traction as industries prioritize energy efficiency to reduce operational costs and meet sustainability goals. Axial piston hydraulic systems are renowned for their high efficiency, compact design, and superior performance, making them ideal for applications requiring precise control and reduced energy consumption. Governments and industries worldwide are emphasizing energy-efficient technologies to comply with stringent environmental regulations and carbon reduction targets. Axial piston pumps, with variable displacement capabilities, enable precise flow control, minimizing wasted energy during operation. These systems also improve productivity while reducing fuel consumption, especially in energy-intensive sectors such as construction, agriculture, and industrial machinery. For instance, in November 2023, Danfoss, a global leader in mobile and industrial hydraulics and electric powertrain systems, introduced the H1F fixed displacement bent axis hydraulic motor. Engineered for use in both open- and closed-circuit applications, the H1F motor delivers industry-leading efficiency, exceptional reliability, and a space-saving design, setting new standards in hydraulic performance. Adoption of renewable energy systems, such as wind turbines, also fuels the demand, as axial piston hydraulic systems optimize energy conversion and storage. In automotive applications, their integration in hybrid and electric vehicles supports enhanced energy management. The growing awareness of operational efficiency and sustainability is encouraging manufacturers to develop innovative axial piston systems with advanced materials and designs, further driving market growth and positioning the technology as a key component in energy-efficient industrial solutions.

Growth of industrial automation

The rise of industrial automation presents a significant opportunity for the axial piston hydraulic motors and pumps market, driven by the growing demand for efficient and precise hydraulic systems in automated processes. Industries such as manufacturing, construction, mining, and agriculture increasingly rely on automated machinery for enhanced productivity and reduced labor costs. Axial piston hydraulic motors and pumps are integral to these machines, offering high power density, precision control, and durability in demanding environments. Automation technologies such as robotics, CNC machines, and advanced material handling systems require hydraulics to deliver precise motion control and energy efficiency. Axial piston hydraulic systems meet these needs by providing variable speed, torque, and pressure capabilities, making them ideal for applications such as robotic arms, conveyor systems, and injection molding machines. Furthermore, the push for Industry 4.0 integration fosters smart hydraulic solutions, with embedded sensors enabling real-time monitoring and predictive maintenance. This ensures reduced downtime and operational efficiency, further driving adoption. As industries worldwide accelerate automation adoption to stay competitive, the axial piston hydraulic motors and pumps market is expected to witness sustained growth, bolstered by advancements in technology and expanding application areas.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the axial piston hydraulic motors and pumps market analysis from 2023 to 2033 to identify the prevailing axial piston hydraulic motors and pumps market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the axial piston hydraulic motors and pumps market forecast and segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as axial piston hydraulic motors and pumps industry trends, key players, market segments, application areas, and market growth strategies.

Axial Piston Hydraulic Motors and Pumps Market Report Highlights

| Aspects | Details |

| Market Size By 2033 | USD 4.7 billion |

| Growth Rate | CAGR of 4.8% |

| Forecast period | 2023 - 2033 |

| Report Pages | 260 |

| By Product Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | Danfoss, Bosch Rexroth AG.(ROBERT BOSCH GmbH), HAWE Hydraulik SE., Bucher Group, Liebherr Group, Parker Hannifin Corporation, POCLAIN, Kawasaki Precision Machinery (Kawasaki Heavy Industries), HYDAC International GmbH, Linde Hydraulics GmbH And Co. KG, Jiangsu Hengli Hydraulic Co., LTD., Bondioli & Pavesi S.p.A., THM Huade |

Analyst Review

Axial piston hydraulic pumps are used to convert mechanical energy into hydraulic energy; while axial piston hydraulic motors are used to convert hydraulic pressure and flow into angular displacement (rotation) and torque. In addition, axial piston hydraulic motors and pumps are used in various applications including manufacturing, oil & gas, agriculture, automotive, energy & utility, mining, food & beverages, construction, water management, and others (transportation & logistics, maritime, and chemical).

The global axial piston hydraulic motors and pumps market is expected to reach at $1,882 million by 2022, attributed to increase in construction and oil & gas refinery activities globally, enhanced demand for renewable energy, rise of sales in automotive sector, and technological advancements in the design of hydraulic motors and pumps. In addition, improvement of existing machineries and equipment offers significant growth potential for the axial piston hydraulic motors and pumps market.

The axial piston hydraulic motors and pumps market is categorized based on product into axial piston hydraulic motors and axial piston hydraulic pumps. In 2014, the axial piston hydraulic pumps segment was the highest revenue contributor to the market, while axial piston hydraulic motors market is anticipated to witness considerable growth rate during the forecast period.

In axial piston hydraulic motors market, the variable displacement segment accounted for the highest share of revenue in 2014, and is expected to grow at a significant growth rate during the forecast period. In constant displacement axial piston hydraulic motors, the bent axis segment generated maximum revenue in 2014, while the swash plate segment is projected to grow at the highest growth rate of 5.2% during the forecast period.

In 2014, the manufacturing application generated highest share of revenue as compared to others. The market for water management application is anticipated to grow at the highest growth rate, owing to rise in usage of hydraulic pumps and motors in planned cities and towns, innovation in design of axial piston hydraulic motors and pumps, and increase in standards of living in the developing countries.

Asia-Pacific is the dominant region, in terms of revenue, owing to the development in infrastructure, availability of multiple manufacturing facilities, increase in population, significant growth in the GDP of the developing countries, and increase in construction activities, followed by North America and Europe. The Asia-Pacific market is expected to grow at the highest growth rate during the forecast period.

Key market players in the axial piston hydraulic motors and pumps industry have adopted various strategies, such as product launches, partnership, geographical expansion, and strategic alliances to create more awareness about the technological advancements in the design of axial piston hydraulic motors and pumps and increase its adoption across industries.

Increasing demand for energy-efficient systems, rising adoption in construction and agriculture, integration of smart hydraulics are the upcoming trends of Axial Piston Hydraulic Motors and Pumps Market.

The leading application of the Axial Piston Hydraulic Motors and Pumps market is in Manufacturing sector.

Asia-Pacific is the largest regional market for Axial Piston Hydraulic Motors and Pumps.

The Axial Piston Hydraulic Motors and Pumps Market was valued at $2,940.00 million in 2023.

are HAWE Hydraulik SE., Liebherr Group, Linde Hydraulics GmbH And Co. KG, Bucher Group, Danfoss, HYDAC International GmbH, Jiangsu Hengli Hydraulic Co., LTD., POCLAIN, Parker Hannifin Corp, Bosch Rexroth AG.(ROBERT BOSCH GmbH), THM Huade, Kawasaki Precision Machinery (Kawasaki Heavy Industries), Bondioli & Pavesi S.p.A. are the top companies to hold the market share in Axial Piston Hydraulic Motors and Pumps.

Loading Table Of Content...

Loading Research Methodology...