Composite Process Material Kits Market Research, 2031

The global composite process material kits market was valued at $109.4 million in 2021, and is projected to reach $196.5 million by 2031, growing at a CAGR of 6.3% from 2022 to 2031. Composite process material kits is made up of two components that have different chemical and physical properties. When they are combined, they form a material that is specialized to perform a certain function, such as becoming stronger, lighter, or electrically resistant. They can also help to increase strength and stiffness. They are preferred over traditional materials because they improve the qualities of their basic materials and are useful in a variety of situations.

Open mold composites are processed using an automated robotic arm, prepreg tape made of fiber/polymer resin, heat, and pressure. In Automated Tape Laying (ATP), a robotic arm is actively operated to lay prepreg tape over the mold while also applying pressure and heat to the material to cure the resin and consolidate the fibers, respectively. The lamination is continued by repeating this process. The primary benefit of using ATP is the ability to produce highly customized parts because each tape can be positioned at various angles depending on the required load directions.

However, the composite process material kits market growth is being constrained by composite process materials because of their disadvantages, including stringent environmental regulations, higher costs, and limits on waste disposal. The management of composite end-of-life waste is also under scrutiny due to the growing use of life cycle assessment as a criterion for material selection in several sectors. For instance, the UK, where it is alleged that 90% of waste now goes to landfills, presents substantial societal and industrial difficulties that the business must address.

Fabric layers are trimmed to the correct proportions and then put within the lower half of the rigid mold in resin transfer molding (RTM). By enclosing the fabric preform in a stiff top mold, the preform is compressed until it reaches the appropriate thickness. To saturate the fabric preform, a resin is pumped into the mold under positive injection pressure. By shutting the intake valve, the injection is stopped once the resin reaches the vent and it has been confirmed that the fabric preform is fully impregnated. The composite item is ready to be demolded once it achieves its green strength.

The key players profiled in this composite process material kits market forecast report include Airtech Advanced Materials Group, Aerovac Composites One, Shanghai Leadgo-Tech Co., Ltd., Diatex SAS, InCom Group, Metyx Composites, GEFiM, Pro-Vac Vacuum Consumables, Velocity Composites plc, and Solvay S.A.

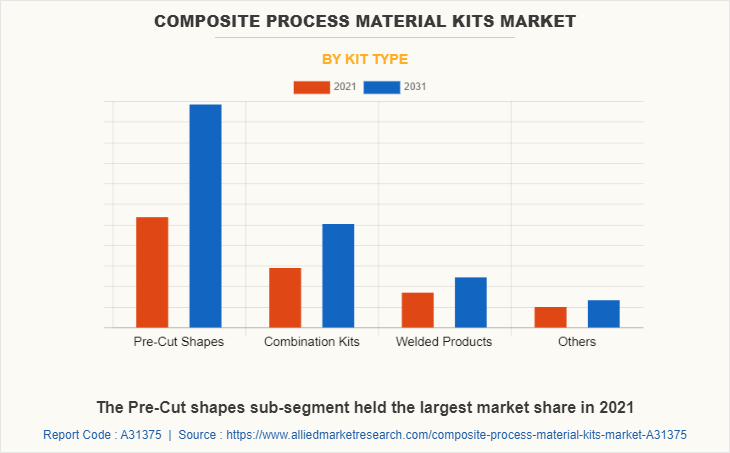

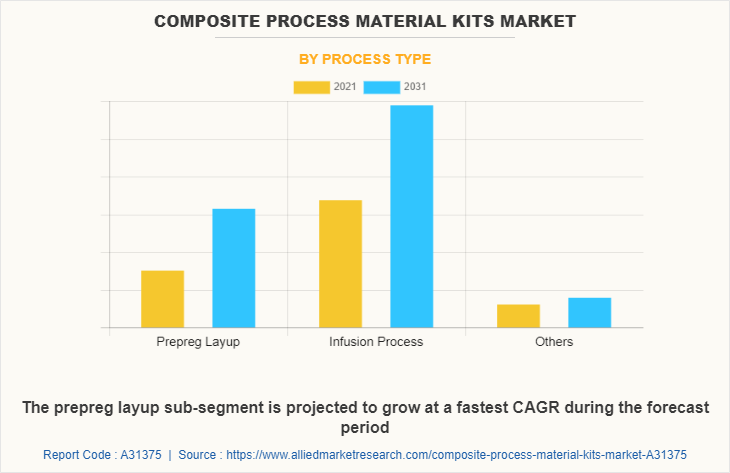

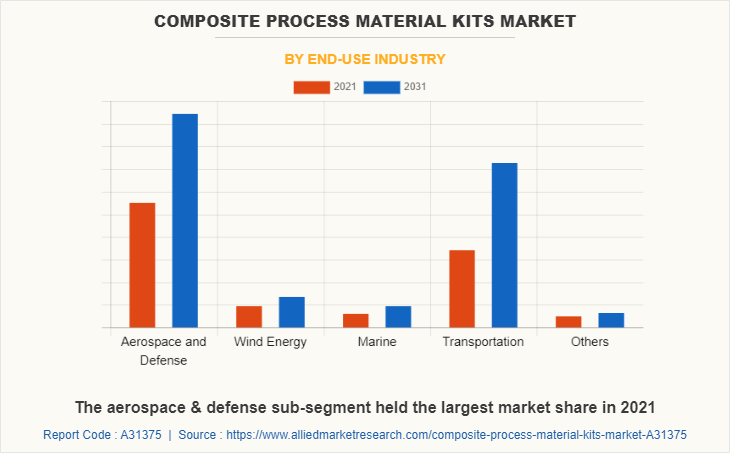

The global composite process material kits market is segmented on the basis of kit type, process type, end-use industry, and region. By kit type, the market is classified into pre-cut shapes, combination kits, welded products, and others. As per process-type, the market is divided into prepreg layup, infusion process, and others. According to end-use industry, the market is classified into aerospace & defense, wind energy, marine, transportation, and others. Region wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The composite process material kits market is segmented into Kit Type, Process Type and End-use Industry.

By kit type, the pre-cut shapes sub-segment dominated the market in 2021. Pre-cut kits are the most common form of kit on the market, but welded kits are expected to grow at the fastest rate over the next few years. Pre-cut-shaped kits are used to create the blades of wind energy. Because they are easy to handle, less mechanical lifting equipment is required, which ultimately cuts expenses. The cloth must be first pre-cut into patterns to assist the fiber architecture. After the materials are spread out across a surface, a mandrel rolls over them, compressing and reducing them. These are predicted to be the major factors affecting the composite process material kits market size during the forecast period.

By process type, the infusion process sub-segment dominated the market in 2021. Infusion molding is a cutting-edge technique for producing composite materials. Dry reinforcements must first be placed in a mold that is sealed with a vacuum bag before being impregnated with resin, which is poured into the mold and sucked up by the depression it produces. A higher fiber rate, a better strength-to-weight ratio, the capacity to produce large components in a single step, and product reproducibility are all benefits of using a certain amount of resin. These are predicted to be the major factors affecting the composite process material kits market size during the forecast period.

By end-use industry, the aerospace and defense sub-segment dominated the global composite process material kits market share in 2021. Weapon systems, ships, spacecraft, and military hardware are produced by aerospace and defense (A&D) corporations. Even though the demands of the public enterprises frequently dictate the objectives for product development, they sell their products to both public and private enterprises. Some of these businesses were created as a result of P3s or the privatization of government operations, and many of them are state-owned or at least partially state-influenced, which will certainly start opening new opportunities for growth for the sub-segment during the forecast period.

By region, North America dominated the global market in 2021. The need in the industry for composite process materials in North America is expected to hold the greatest market share during the next five years. The region has been a leader in the advanced composites industry as a result of the presence of several small to large-sized OEMs, molders, process material suppliers, and raw material suppliers. The market for composite process materials looks to be expanding favorably due to the variety of types, manufacturing flexibility, and widespread utilization in several applications.

Impact of COVID-19 on the Global Composite Process Material Kits Industry

- COVID-19 has negatively impacted various industries such as automotive that has led to a drastic decline in automotive sales. As composite process material kits are widely used in automotive manufacturing, there was a significant reduction in the composite process material kits demand globally.

- For instance, in the construction sector, some projects have been postponed or canceled owing to a lack of labor, raw materials, and human resources as well as worker and traveler concerns around the COVID-19 virus. In the same way, spark-ignition engines in the car industry employ kits for composite process material.

- The market share of composite process material kits has been impeded during the pandemic, nevertheless, by disruptions in the exports of Chinese car components as well as the closing of automotive assembly and production facilities.

- Economic slowdown has affected the setup of new composite process material kits projects across the world as majority of government fundings were diverted toward healthcare sector owing to rapid spread of the COVID-19 virus, impacting the market to a great extent.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the composite process material kits market analysis from 2021 to 2031 to identify the prevailing composite process material kits market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the composite process material kits market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global composite process material kits market trends, key players, market segments, application areas, and market growth strategies.

Composite Process Material Kits Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 196.5 million |

| Growth Rate | CAGR of 6.3% |

| Forecast period | 2021 - 2031 |

| Report Pages | 280 |

| By Kit Type |

|

| By Process Type |

|

| By End-use Industry |

|

| By Region |

|

| Key Market Players | metyx composites - telateks a.s., Pro-Vac Vacuum Consumables, Velocity Composites plc, airtech advanced materials group, solvay, Shanghai Leadgo-Tech Co., Ltd., GEFiM, Aerovac Composites One, diatex sas, incom group |

Analyst Review

The light weight of composite materials is one of its principal benefits, along with other advantages. Composite materials have the potential to dramatically reduce the weight of an airplane, enhancing both performance and fuel efficiency. Strict environmental laws, increased costs, and waste disposal caps are just a few of the drawbacks of composite process materials that are restricting the industry. Additionally, due to the expanding use of life cycle assessment as a component of the material selection process in several sectors, composite end-of-life waste management is being closely examined. In the defense sector, sophisticated composite materials will also be used and used more often. Although many of these innovative applications will be in the form of aircraft components due to their strength and light weight, as was previously noted, there are still other unique applications that will benefit the military sector. Modern vehicle armor is available for both personal security and military applications ranging from new, technologically advanced bulletproof personal protective suits which are anticipated to provide remunerative opportunities for key players to maintain the pace of the composite process material kits market in the upcoming years.

Among the analyzed regions, North America is expected to account for the highest revenue in the market by the end of 2021, followed by Asia-Pacific, Europe, and LAMEA. Rapid industrialization and urbanization are the key factors responsible for leading position of North America and Asia-Pacific in the global composite process material kits market.

The composite materials are widely used in the aerospace and defense sector, and thus, this creates favorable demand for composite material process kits. Additionally, high performance and cost effectiveness of composite materials bring in more end users and open up lucrative opportunities for the growth of the composite material process kits market in the forecast period.

The major growth strategies adopted by composite process material market players are investment and agreement.

Asia-Pacific will provide more business opportunities for the global composite process material kits market in the future.

Airtech Advanced Materials Group, Aerovac Composites One, Shanghai Leadgo-Tech Co., Ltd., Diatex SAS, InCom Group, Metyx Composites, GEFiM, Pro-Vac Vacuum Consumables, Velocity Composites plc, and Solvay S.A. are the major players in the composite process material kits market.

Pre-cut shapes sub-segment of the kit type segment acquired the maximum share of the global composite process material kits market in 2021.

Aerospace & Defense and Transportation are the major customers of the global composite process material kits market.

The report provides an extensive qualitative and quantitative analysis of the current trends and future estimations of the global composite process material kits market from 2021 to 2031 to determine the prevailing opportunities.

Loading Table Of Content...