Conductive Coatings Market Overview:

Global Conductive Coatings Market size was valued at $15,120 million in 2016, and is expected to reach at $24,360 million by 2023, growing at a CAGR of 6.8% from 2017 to 2023. Conductive coatings are applied on an electronic-base substrate to protect it from electromagnetic radiation interference resulting in product deterioration and rendering it useless. The added advantages of easy handling and coating on surface of materials of variable size and shape make it a much widely accepted method to prevent harmful interference.

The global conductive coatings market is segmented based on material, application, and geography. Based on material, it is categorized into conductive polymers and organics, carbon nanomaterials, nanometals and related, metal compounds, metals, and conventional carbon. According to applications, it is classified into ESD/antistatic coatings, EMI/RFI coatings, solid state lighting, displays, photovoltaic cells, fuel cells, capacitors and supercapacitors, and batteries. Geographically, it is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Conductive Coatings Market Segmentation

Conductive Coatings Market By Application

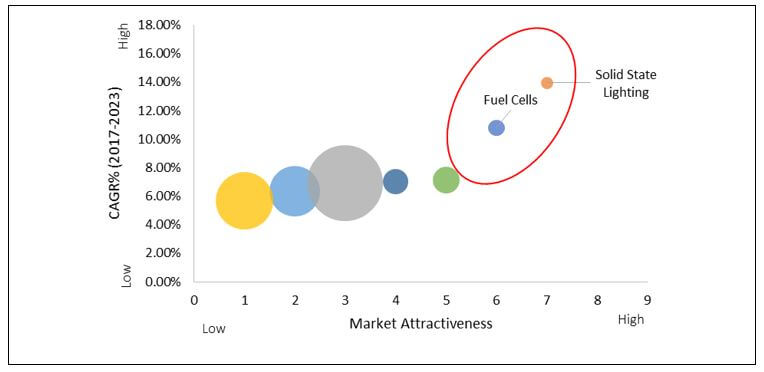

The EMI/RFI coatings application is anticipated to be the top investment pocket, owing to rise in demand for electronics from the huge volume of population in Asia-Pacific. In addition, short service life resulting in periodic replacement cycles and dropping prices of electronics devices makes it an attractive strategy to enter into the conductive coatings market. Moreover, the photovoltaic cells application is anticipated to be the second alternative of market players due to the growth in demand for use in achieving shielding effect from unwanted electromagnetic interference, thus enhancing the conductivity of the cells.

Top Investment Pockets, By Application

Conductive Coatings Market By Region

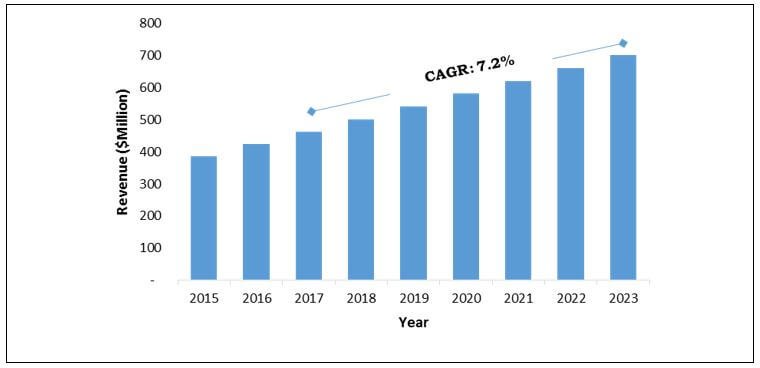

Brazil is an active conductive coatings market in LAMEA. It is a developing economy with abundant raw materials, development of ports to ease out transportation, and increase in number of educated population, which make it an ideal location for new entrants. Companies are establishing manufacturing bases to target an established customer base and expand their conductive coatings market.

Brazil Conductive Coatings Market, 2015-2023 ($Million)

Key players operating in the market include PPG Industries Inc., Henkel, Akzonobel N. V., Axalta Coating Systems, 3M Company, Dai Nippon Printing, Abrisa Technologies, Acree Technologies Inc., Carclo PLC., and Cima Nanotech.

The other key players in the conductive coatings market (not included in the report) are Clearjet, Gentex Corp., Hitachi Chemical Co. Ltd., Inktec, Intlvac Thin Film Corp., Jtouch Corp., and JX Nippon Mining & Metals Corp.

Key Benefits for Conductive Coatings Market:

Porter’s five forces analysis helps analyze the potential of buyers & suppliers and their conductive coatings market share for building strategies.

- It outlines the current trends and future scenario of the conductive coatings market size from 2016 to 2023 to understand the prevailing opportunities and potential investment pockets.

- Major countries in four major regions, namely, North America, Asia-Pacific, Europe, and LAMEA have been mapped according to their individual revenue contribution in the conductive coatings market analysis at regional and country level.

- The key drivers, restraints, and opportunities and their detailed impact analyses are elucidated in the study.

- The profiles of key players along with their contribution in conductive coatings market growth are enlisted in the report.

Conductive Coatings Market Report Highlights

| Aspects | Details |

| By Material |

|

| By Application |

|

| By Geography |

|

| Key Market Players | AXALTA COATING SYSTEMS, CIMA NANOTECH, ACREE TECHNOLOGIES INC., DAI NIPPON PRINTING, CARCLO PLC, ABRISA TECHNOLOGIES, 3M COMPANY, AKZONOBEL N.V., HENKEL, PPG INDUSTRIES INC. |

Analyst Review

Conductive coatings are used in protection of machines and equipment from harmful radiation interference. They are an easy solution for professionals to achieve regulatory compliance for electromagnetic compatibility (EMC). They are advantageous due to their low cost, high-grade performance, and ready adaptability with various substrates.

The carbon nanomaterials as a material for making conductive coatings has witnessed significant growth rate due to the enhancement of properties that are offered. Carbon nanotubes offer permanent electrical conductivity. Easy embedding into the matrix provides enhanced surface conductivity and volume conductivity. Low density and high surface area reactivity make it a suitable alternative to the conventional materials used. R&D activities in nanotechnology have opened new opportunities for nanomaterials.

Asia-Pacific is the most active region in electronics and optics industry, experiencing steady growth, owing to its favorable government policies supporting foreign investment. Rise in disposable income and steady growth of electronics industry in Asia-Pacific have driven the conductive coatings market. China dominates the market, owing to a strong manufacturing base and availability of a large volume of population resulting into a strategic leader across the market. India is also witnessing strong growth in the market due to the availability of skilled labor and friendly governmental policies.

Loading Table Of Content...