Copper Smelting Market Research, 2031

The global copper smelting market was valued at $1.4 billion in 2021, and is projected to reach $2.0 billion by 2031, growing at a CAGR of 3.8% from 2022 to 2031.

Copper smelting is a type of process that includes the separation of elemental copper from copper concentrates through multiple sulfide oxidizing process. Primarily, copper ore concentrates are mined and stored and then separated depending on copper grade. The separated copper ore is further differentiated on the basis of formulation quality and later transferred into flash smelting furnaces. Flash smelting includes refining of copper ore inside flash furnace in presence of oxygen-enriched air. The copper is oxidized quickly and later melted followed by refining process. The copper produced through a functioning flash smelting process consists of 65% slag and a mixture of iron oxide, silica, and other compounds.

Traditional copper smelting process tends to generate and emit large toxic gas emission. Thus, several key-players in the copper smelting industry are adopting functioning flash smelting process is driving the demand of the global market. Majorly, functioning flash copper smelting process is used owing to its economic factors and production of high-quality electrolytic copper. In addition, use of functioning flash smelter increases mining efficiency and boosts recovery of by-products from copper ore. All these factors have escalated the demand of the global market. Copper cathodes are utmost important in the semiconductor industry.

However, high production cost associated is anticipated to hamper the market growth. Conversely, acid furnace smelting includes leaching of ore with use of ammonia or sulphuric acid in order to extract blister copper. Acid furnace smelting of copper is a continuous and multi-step smelting process that produces blister copper. Blister copper is a partial purified copper with blister surface formed during acid smelting process. Blister copper is mainly used for production of Tel (C2H5)4Pb tetra ethyl lead. This Tel (C2H5)4Pb tetra ethyl lead is further used to increase the efficiency of petroleum products or used as petroleum additive. In addition, it can also be used in automotive batteries, paints & pigments, and solder products. This factor has escalated the demand for blister copper. Moreover, blowing of oxygen during acid smelting tends to remove sulfur content in the form of sulphur dioxide that further produces high-quality blister copper. All these factors are collectively driving the demand for copper smelting.

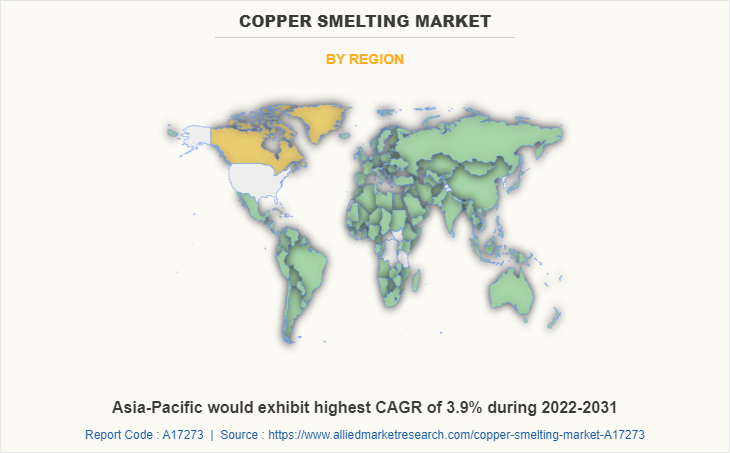

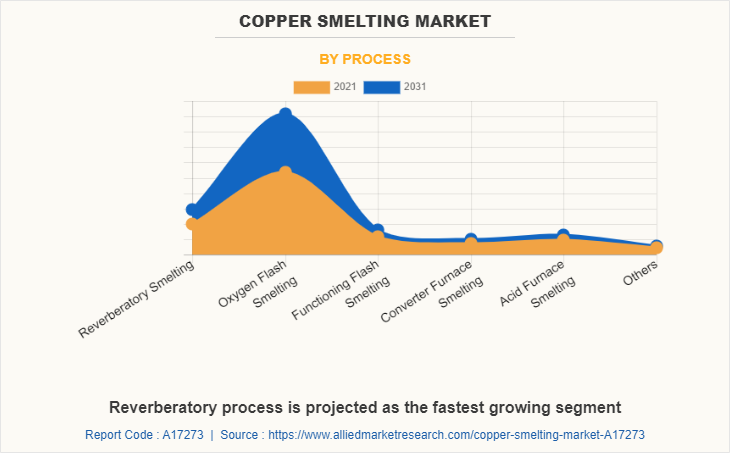

The copper smelting market is segmented on the basis of process, and region. On the basis of process, the market is categorized into reverberatory smelting, oxygen flash smelting, functioning flash smelting, converter furnace smelting, and acid furnace smelting. Region wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

The global copper smelting market profiles leading players that include Aditya Birla Management Corporation Pvt. Ltd., ASARCO (American Smelting and Refining Company), Aurubis AG, Dhanvanti Engineering, Glencore, Hindustan Copper Limited, KGHM, Southern Copper Corp, Teck Resources Ltd., and Vedanta Limited. The global copper smelting market report provides in-depth competitive analysis as well as profiles of these major players.

The Asia-Pacific copper smelting market size is projected to grow at the highest CAGR during the forecast period, and accounted for a major market share in 2021 with 63% share in the global market. The increasing establishments of chemical manufacturing, biomedical, aerospace, and other industrial units has led the industrial sector in Indonesia to witness a significant growth, wherein copper smelting technology finds application in various industrial and mechanical process owing to its high strength, permeability, and resistant to corrosion. For instance, according to a report published by the Indonesian Investment Coordinating Board (BKPM), the manufacturing industry in Indonesia (including chemical, pharmaceutical, and traditional medicine industry) is witnessing rapid growth, owing to increasing utilization of various consumer goods. This is expected to enhance the performance of the copper smelting market in the Asia-Pacific region.

In 2021, the oxygen flash smelting segment was the largest revenue generator, and is anticipated to grow at a CAGR of 3.9% during the forecast period. Oxygen flash smelting includes production of blister copper through oxidation of copper-iron sulphide. Oxygen flash smelting produces casted copper wire. Cast copper wire are used across several industries owing to its material strength, durability, and corrosion resistance.

The demand for cast copper rods across power & communication cables, household electrical wire, power distribution transformers, and magnets have escalated the demand for oxygen flash smelting of copper thereby augmenting the demand of the global market. Key-players in the copper smelting market are introducing innovative flash smelting technology process that offers low energy consumption, minimal emission, and high recovery of unsmelted copper is another considerable factor driving the demand of the global market. Blowing of oxygen during copper smelting significantly increases smelting capacity of copper ore and produces high grade copper.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the copper smelting market analysis from 2021 to 2031 to identify the prevailing copper smelting market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the copper smelting market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global copper smelting market trends, key players, market segments, application areas, and market growth strategies.

Copper Smelting Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 2 billion |

| Growth Rate | CAGR of 3.8% |

| Forecast period | 2021 - 2031 |

| Report Pages | 200 |

| By Process |

|

| By Region |

|

| Key Market Players | American Smelting and Refining Company, Glencore, Southern Copper Corp., Vedanta Limited, KGHM, Teck Resources Ltd., Hindustan Copper Limited, Aurubis AG, Aditya Birla Management Corporation Pvt. Ltd., Dhanavanti Engineering |

Analyst Review

The global copper smelting market is expected to exhibit high growth owing to its use in textile and building & construction application. Acid furnace smelting includes leaching of ore with use of ammonia or sulfuric acid in order to extract blister copper. Acid furnace smelting of copper is a continuous and multi-step smelting process that produces blister copper. Blister copper is a partial purified copper with blister surface formed during acid smelting process.

Blister copper is mainly used for production of Tel (C2H5)4Pb tetra ethyl lead. This Tel (C2H5)4Pb tetra ethyl lead is further used to increase the efficiency of petroleum products or used as petroleum additive. In addition, it can also be used in automotive batteries, paints & pigments, and solder products. This factor has escalated the demand for blister copper thereby driving the demand of global market. Moreover, blowing of oxygen during acid smelting tend to remove sulfur content in form of sulfur dioxide that further produces high-quality blister copper.

Oxygen flash smelting includes production of blister copper through oxidation of copper-iron sulphide. Oxygen flash smelting produces casted copper wire. Cast copper wires are used across several industries owing to their material strength, durability, and corrosion resistance. In addition, the demand for cast copper rods across power & communication cables, household electrical wire, power distribution transformers, and magnets. These are the upcoming trends of copper smelting market in the world

Blister copper is the leading application of copper smelting

Asia-Pacific is the largest regional market for copper smelting

The global copper smelting market was valued at $1.4 billion in 2021, and is projected to reach $2 billion by 2031, growing at a CAGR of 3.8% from 2022 to 2031.

Aditya Birla Management Corporation Pvt. Ltd., ASARCO (American Smelting and Refining Company), Glencore, and Hindustan Copper Limited

Loading Table Of Content...