Etching Chemicals Market Research, 2032

The global etching chemicals market was valued at $1.7 billion in 2022 and is projected to reach $3.0 billion by 2032, growing at a CAGR of 5.9% from 2023 to 2032.

Report Key Highlighters:

- The etching chemicals market study covers 20 countries. The research includes a segment analysis of each country in terms of both value ($million) and volume (kilotons) for the projected period 2023-2032.

- The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and to assist stakeholders in making educated decisions in order to achieve their most ambitious growth objectives.

- Over 3,700 product literature, annual reports, industry statements, and other comparable materials from major industry participants were reviewed to gain a better understanding of the market.

Chemicals used in the etching process are referred to as etching chemicals, often known as etchants. In the process of etching, the material is deliberately removed from a substrate's surface to produce the desired patterns, textures, or structures. Etching chemicals are specially designed to interact with the substance being etched while protecting the surroundings. Etching chemicals can be classified into various types based on their composition and intended application. Common types of etching chemicals include acid-based etchants, alkaline etchants, solvent-based etchants, and plasma etchants.

Acid-based etchants contain acids as their primary component. These etchants are frequently employed in a variety of industries for processes involving the selective removal of materials and surface modification. The substance being etched and the acids in acid-based etchants react, making the targeted portions easier to dissolve or remove. Acid-based etchants include substances such as hydrochloric acid, nitric acid, and sulfuric acid. For etching or cleaning materials that are delicate to acid-based etchants, or in situations where alkaline solutions have unique advantages, alkaline etchants are effective. Alkaline etchants include substances such as potassium hydroxide and sodium hydroxide.

The most popular etching method in the electronics sector is termed as "chemical etching" or "wet etching," which involves removing the undesired material with the help of a chemical solution called an etchant. The material being etched determines the best etchant to use. The etchant is applied to the substrate's surface during the etching process, where it interacts or dissolves the exposed material only. Depending on the requirements of the application, several etching techniques, such as immersion, spraying, or spin coating, might be used.

Overall, etching is a critical process in the electronics industry for creating patterns, channels, and structures required for the production of electronic components. It enables the miniaturization and integration of electronic devices and plays a vital role in the manufacturing of integrated circuits (ICs), printed circuit boards (PCB), and various other electronic products.

Increased demand for electric vehicles is driving the demand for etching chemicals.

The automotive industry is increasingly focusing on alternative power sources, such as fuel cells and batteries, for electric and hybrid vehicles. Fuel cell and battery components such as electrodes and current collectors are made using etching chemicals. The performance and efficiency of these energy storage systems are improved by the desirable microstructures and surface qualities that are produced during the etching process. In automobile systems, sensors and actuators play a crucial role in enabling operations, including engine monitoring, emission control, braking, and airbag deployment.

Microelectromechanical systems (MEMS) technology is frequently used in these components to produce accurate shapes and patterns on silicon surfaces. For the creation of MEMS devices, etching agents such as buffered oxide etchants (BOEs) are frequently utilized. In addition, etching chemicals are widely used in the jewelry industry to create designs and patterns on metals such as gold, silver, and platinum.

Furthermore, the aerospace industry requires a wide range of components, each with unique geometries, materials, and tolerances. Etching is a highly versatile manufacturing process that can produce parts from a wide range of materials, including stainless steel, copper, and nickel alloys. Moreover, the process can produce parts with a wide range of geometries, including complex shapes, deep cavities, and thin walls, making it an ideal choice for producing a variety of aerospace components. Thus, increase in application of etching chemicals acts as a key growth driver of the global market.

However, numerous etching chemicals are harmful to the environment, which is expected to hamper the market growth. If not handled properly, the disposal of etching solutions and trash produced during the procedure can be risky. Contamination of land, water supplies, and air can result from chemical spills or inappropriate handling. To address these issues, efforts are being made to create more ecologically friendly etching procedures and chemicals.

For various materials, different etching chemicals are required. The adaptability of the method may be constrained by the fact that not all materials can be etched using the same etchant. It may be more difficult to generate the necessary patterns or structures on some materials due to the limited etching possibilities available.

On the contrary, the rapid emergence of new technologies, such as flexible electronics, organic electronics, and nanotechnology, opens up new avenues for the application of etching chemicals. These technologies often require innovative etching processes to achieve precise patterns and structures on unconventional substrates. Etching chemical manufacturers can explore these emerging fields and develop tailored solutions to meet the unique demands of these technologies.

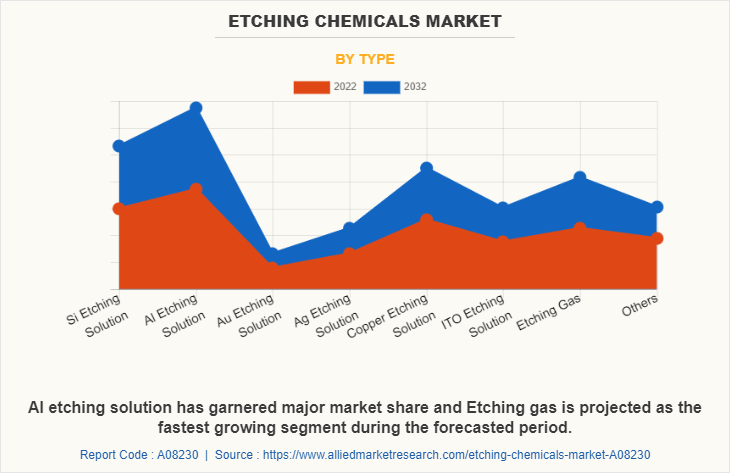

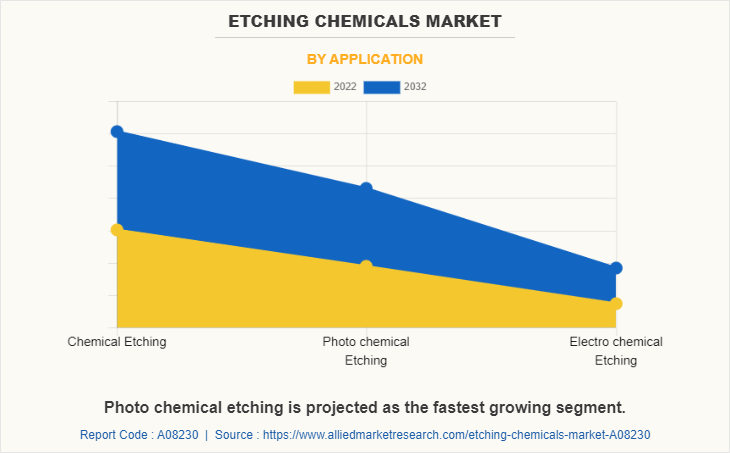

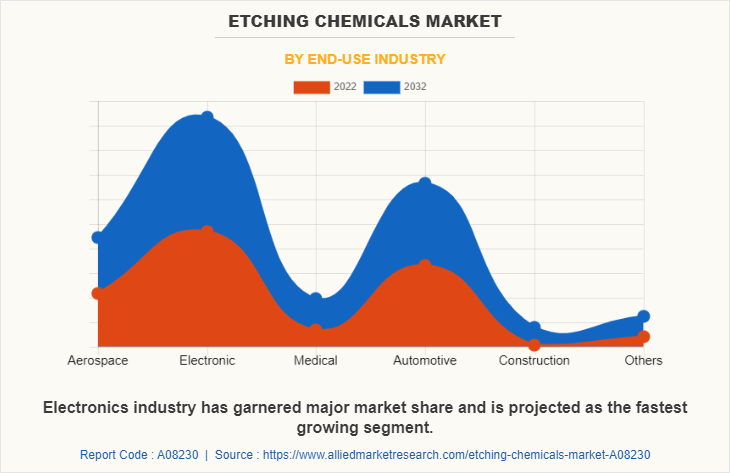

The global etching chemicals market is segmented into type, application, end-use industry, and region. On the basis of type, the market is divided into SI etching solution, AL etching solution, AU etching solution, AG etching solution, copper etching solution, ITO etching solution, etching gas, and others. By application, it is classified into chemical etching, photochemical etching, and electrochemical etching. Depending on the end-use industry, it is segregated into aerospace, electronics, medical, automotive, construction, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

The major players operating in the global Etching Chemicals market include Solvay, SACHEM, INC., ZEON CORPORATION, ADEKA CORPORATION, Nagase ChemteX Corporation, BASF SE, DAIKIN INDUSTRIES, Ltd., KANTO KAGAKU, Stella Chemifa Corporation, Mitsubishi Chemical Corporation.

Etching gas is projected as the fastest-growing segment during the forecasted period. The etching gas is a technique used to selectively remove material from a surface. The most important gases used presently are halocarbon 14, halocarbon 23, halocarbon 116, and nitrogen trifluoride. These etchant gases react with silicon, silicon dioxide, and silicon nitride. Halocarbons are used to etch silicon compounds, whereas the other chlorine and fluorine compounds are required for etching metallic interconnects.

Photo chemical etching is projected as the fastest-growing segment. Companies use photochemical etching as an economical alternative to laser cutting, water jet cutting, and punching and stamping. During mass production, the technique enables easy modifications and adjustments. The ability to generate precise pieces that are impossible or prohibitive to manufacture using conventional machining methods is the fundamental benefit of this form of machining.

The electronics industry has garnered a major market share and is projected as the fastest-growing segment. Etching is a vital process module, and each wafer goes through a number of etching stages before being finished. Various materials must be etched for the production of semiconductor microdevices, either to remove a complete layer from the surface or to transfer a resist pattern from one layer to another. Thus, the increase in demand for semiconductors in the electronics industry is driving the demand for etching chemicals.

Asia-Pacific region is projected as the fastest growing region. Asia-Pacific has become a global hub for electronics manufacturing, with countries like China, Japan, South Korea, and Taiwan leading the industry. The production of electronic devices, such as smartphones, laptops, and consumer electronics, requires the use of etching chemicals for processes such as PCB production and semiconductor manufacturing.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the etching chemicals market analysis from 2022 to 2032 to identify the prevailing etching chemicals market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the etching chemicals market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global etching chemicals market trends, key players, market segments, application areas, and market growth strategies.

Etching Chemicals Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 3 billion |

| Growth Rate | CAGR of 5.9% |

| Forecast period | 2022 - 2032 |

| Report Pages | 652 |

| By End-use Industry |

|

| By Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | BASF SE, SACHEM, INC., ADEKA CORPORATION, KANTO KAGAKU, Solvay, Stella Chemifa Corporation, DAIKIN INDUSTRIES, Ltd., ZEON CORPORATION, Nagase ChemteX Corporation, Mitsubishi Chemical Corporation |

Analyst Review

According to the insights of the CXOs of leading companies, ensuring the quality and reliability of electronic products is crucial for customer satisfaction and brand reputation. Etching chemicals play a vital role in achieving precise and consistent patterns and structures, which directly impact the performance and functionality of electronic components. The etching chemical industry is continuously evolving, driven by technological advancements and changing market demands. The CXOs further added that collaboration with etching chemical suppliers, research institutions, and industry partners can foster innovation and enable access to the latest etching technologies and solutions. The usage of etching chemicals extends beyond traditional electronics manufacturing. Exploring opportunities to diversify into new industries, such as automotive, aerospace, telecommunications, and energy systems, can open up new revenue streams and expand market presence. Assessing market trends, customer needs, and technological advancements can help identify potential areas for diversification and guide strategic decision-making.

Increasing demand from the automotive industry is the upcoming trend in the etching chemicals Market.

The electronics industry is the leading application for etching chemicals.

Asia-Pacific is the largest regional market for etching chemicals.

The etching chemicals market was valued at $1.7 billion in 2022 and is estimated to reach $3.0 billion by 2032, exhibiting a CAGR of 5.9% from 2023 to 2032.

BASF SE, DAIKIN INDUSTRIES, Ltd., KANTO KAGAKU, Stella Chemifa Corporation, and Mitsubishi Chemical Corporation. are some of the top companies in the etching chemicals market.

Loading Table Of Content...

Loading Research Methodology...