High-Temperature Honeycomb Sandwich Materials Market Research, 2030

The global high-temperature honeycomb sandwich materials market size valued at $0.4 billion in 2020, and is projected to reach $1.0 billion by 2030, growing at a CAGR of 10.5% from 2021 to 2030.

The high-temperature honeycomb sandwich materials market is segmented into Type, Application and Technology.

Honeycomb sandwich is made from three layers in which a low-density core is injected between two relatively thin layers, giving it superior mechanical properties with minimal weight. The global demand for high temperature honeycomb sandwich materials is increasing, owing to their lightweight nature and superior mechanical performance. Resin transfer molding has the potential to minimize manufacturing cost of high temperature honeycomb sandwich parts. Resin transfer molding sandwich honeycomb parts are manufactured by controlling resin flow during infusion with scrims of different weights.

Various aircraft are manufactured for commercial and defense purposes. According to an article published by simpleflying.com, in the year 2022, Airbus is expected to exceed its monthly production of 65 planes, with the target of 75 jets in 2022. In these aircraft, honeycomb is used in their structure to provide better strength and stiffness along with less weight. Moreover, growth in the defense sector in various developed and underdeveloped countries drives the high temperature honeycomb sandwich market. In addition, commercial aircraft delivery is expected to rise in the future, which, in turn, increase aircraft production. This is beneficial for increasing high temperature honeycomb sandwich materials market share in aerospace and aircraft industry.

However, high production cost and high raw materThis is beneficial for increasing high temperature honeycomb sandwich materials market share in aerospace and aircraft industry. ials cost restrain the growth of the market. Conversely, increase in popularity of LED honeycomb and 3D printing to manufacture honeycomb panels is expected to provide lucrative growth opportunities for the market. LED displays use honeycomb panels, permitting them to be lighter while giving more pixel effects. High temperature honeycomb sandwich panels can be produced with 3D printers; however, they are currently in the research stage and anticipate to impact the industry to grow significantly once commercialized.

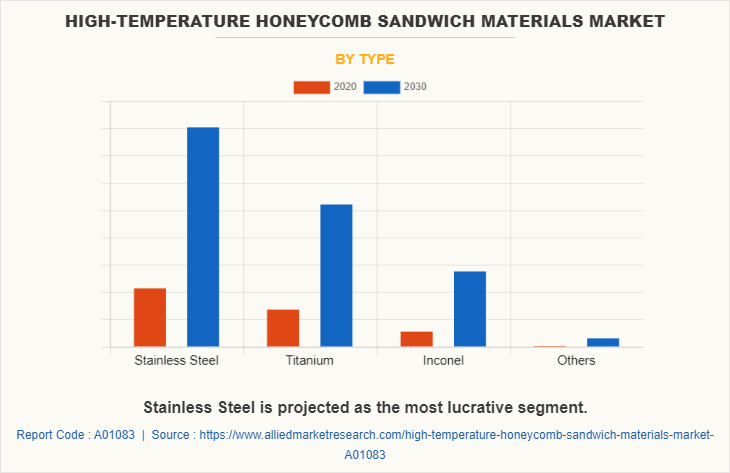

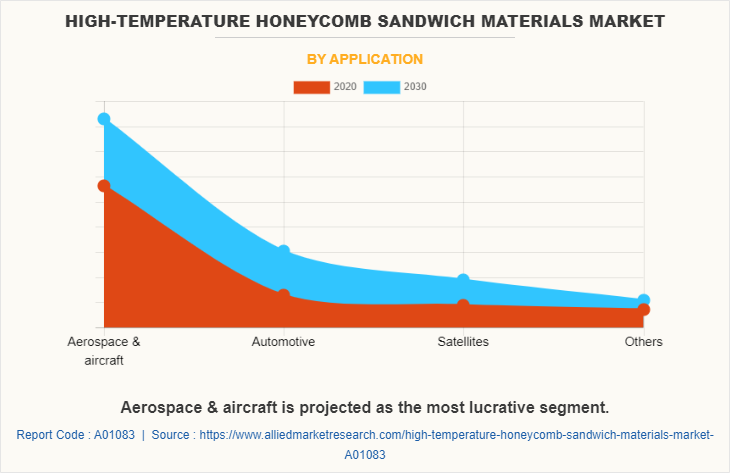

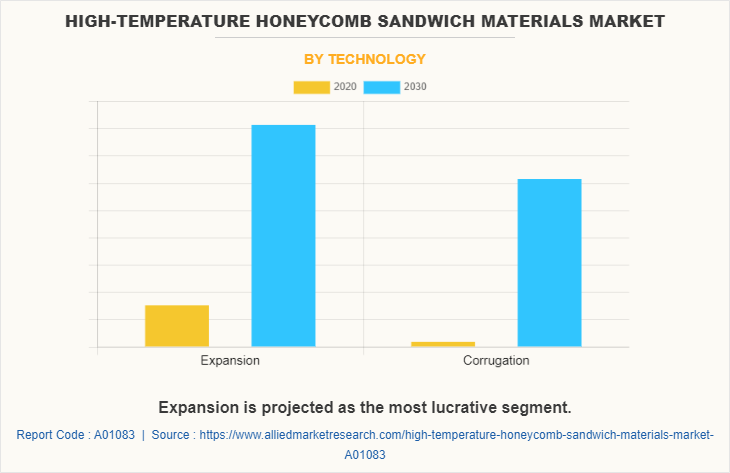

The high temperature honeycomb sandwich materials market is segmented on the basis of type, application, technology, and region. Depending on type, it is segregated into stainless steel, titanium, inconel, and others. According to application, it is classified into aerospace & aircraft, satellites, automobiles, and others. As per the technology, it is categorized into expansion and corrugation. Region-wise, it is analyzed across North America, Europe, Asia-Pacific, and LAMEA. The high temperature honeycomb sandwich materials market share is analyzed across all significant regions and countries.

The key players operating in the global high temperature honeycomb sandwich materials market include Corex Honeycomb, Eco Earth Solutions, EconCore N.V., Hexcel Corporation, Honylite Private Limited, Pacific Panels, Plascore Inc., Schutz GmbH & co., KGaA, The Gill Corporation, andUlbrich Stainless Steels and Special Metals Inc.

By type, stainless steel segment dominated the global market for high temperature honeycomb sandwich materials in 2020 and is expected to continue its dominance during the forecast period. Depending upon the grade of stainless steel, it can be used in applications where temperature reaches up to 2100 °F. Along with the high temperature application, stainless steel honeycomb offers good heat transfer properties, electromagnetic shielding properties, and heat resistance.

By application, aerospace & aircraft segment provided the largest share of the revenue in 2020. Aerospace and aircraft segment is expected to show lucrative growth over the forecast period and expected to dominate the application segment. Honeycomb is used in structural applications, owing to high stiffness to weight and a high strength-to-weight ratio. Moreover, high temperature honeycomb sandwich tolerate high temperature along with high resistance to corrosion and fatigue. In defense, aircraft with high temperature honeycomb sandwich offers similar advantages to commercial aircraft.

By technology, expansion segment provided the largest share of the revenue in 2020 and is expected to continue its dominance during forecast period. In the expansion process, normally high-temperature honeycomb is manufactured in the low-density range.

Region wise, North America is a significant contributor to the global demand for high temperature honeycomb sandwich materials. high temperature honeycomb sandwich provides great strength while using the minimum amount of material, due to its hexagonal structure. In the U.S., it is widely used in the applications of aerospace and aircraft, satellites, and gas turbines.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the high-temperature honeycomb sandwich materials market analysis from 2020 to 2030 to identify the prevailing high-temperature honeycomb sandwich materials market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the high-temperature honeycomb sandwich materials market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global high-temperature honeycomb sandwich materials market trends, key players, market segments, application areas, and market growth strategies.

COVID-19 Impact on Market

- COVID-19 pandemic banned imports and export, thereby disrupting the supply chain and hampering the high temperature honeycomb sandwich materials market growth.

- There was a huge supply and demand gap due to the COVID-19 pandemic.

- Fluctuation in prices of high temperature honeycomb sandwich materials during COVID-19 was a major hindrance to the market.

- During COVID-19, the demand for high temperature honeycomb sandwich materials decreased in the aerospace and aircraft industry. International travel was banned, owing to lockdown across the globe, which impacted the aerospace and aircraft industry, which, in turn, impacted the market.

High-Temperature Honeycomb Sandwich Materials Market Report Highlights

| Aspects | Details |

| By Type |

|

| By Application |

|

| By Technology |

|

| By Region |

|

| Key Market Players | Corex Honeycomb, The Gill Corporation, Schutz GmbH & co., KGaA, Pacific Panels, EconCore N.V., Honylite Private Limited, Eco Earth Solutions, Ulbrich Stainless Steels and Special Metals Inc, Plascore Inc., Hexcel Corporation |

Analyst Review

According to the CXOs of the leading companies, demand for lightweight & durable materials in aerospace & aircraft and satellite segments for structural applications is rising rapidly which is expected to drive the market over the forecast period. Presently, the satellites industry dominates the high temperature honeycomb sandwich materials market. A high temperature honeycomb sandwich provides space satellites with high stiffness & strength, design flexibility, weight savings, corrosion resistance, and reduced cost as it improves fuel efficiency and safety.

The utilization of sandwich composite materials has increased in recent years, owing to their characteristics such as enhanced performance and sustainable properties. As per the CXOs, the adoption of high temperature honeycomb sandwich materials is the highest in North America, due to increase in demand from end-user industries and a rise in the need for sustainability in materials. In addition, the U.S. military aircraft has the largest fleet in the world and it has a large number of commercial airplanes. These factors are responsible for the potential growth of the high-temperature honeycomb sandwich market in the U.S.

The key players operating in the market include Corex Honeycomb, Eco Earth Solutions, EconCore N.V., Hexcel Corporation, Honylite Private Limited, Pacific Panels, Inc.,Schutz GmbH & co., KGaA

Demand for lightweight & durable materials in aerospace & aircraft and satellite segments for structural applications is rising rapidly which is the key factor for driving the market market over the forecast period

The COVID-19 pandemic disrupted the aerospace & aircraft and automobile industries, resulting in reduced usage of high temperature honeycomb sandwich materials in these industries.

Satellite industry is expected to increase the demand as it provides space satellites with high stiffness & strength, design flexibility, weight savings, and corrosion resistance

Type, application, technology, and region are the segments covered in the report.

The key factor that drive the high-temperature honeycomb market include increase in production of various aircraft and growth in the space industry.

Automotive industry is expected to increase adoption of honeycomb sandwich materials as it is used in various vehicles to reduce the weight of the vehicle & to improve performance

The value of the high-temperature honeycomb sandwich materials is expected to be $1.0 billion in 2030.

Loading Table Of Content...