Highly Reactive Polyisobutylene Market Research, 2031

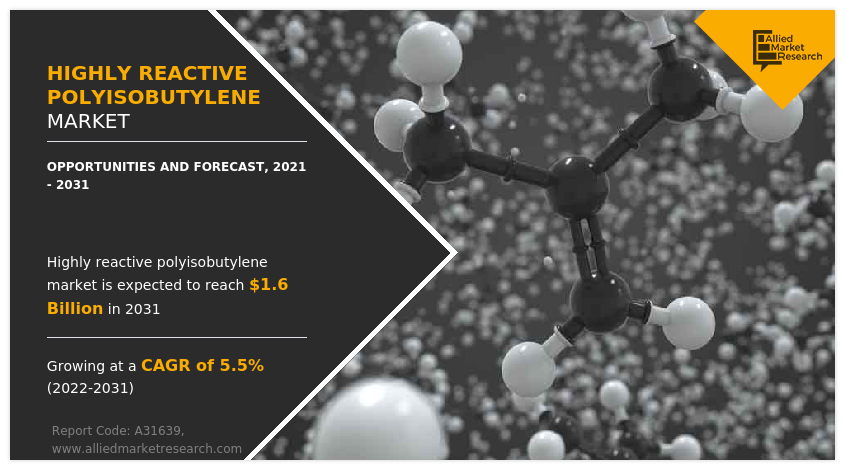

The global highly reactive polyisobutylene market was valued at $1.0 billion in 2021, and is projected to reach $1.6 billion by 2031, growing at a CAGR of 5.5% from 2022 to 2031.

Report Key Highlighters:

- The highly reactive polyisobutylene market has been analyzed in both value and volume. The value of the highly reactive polyisobutylene market is analyzed in millions while the volume is analyzed in kilotons.

- Global highly reactive polyisobutylene market is fragmented in nature with many players such as TPC Group, RB Products Inc., BASF SE, Lubrizol, INEOS, DAELIM Industrial Co. Ltd., Chevron, SPG Prints B.V., Zhejiang Shunda New Material Company Ltd., and KEMAT Polybutenes. Also tracked key strategies such as product launches, acquisitions, mergers, expansion etc. of various manufacturers of highly reactive polyisobutylenes.

- Included more than 20 countries in the report which covers market volume as well as market value for all the segments of the highly reactive polyisobutylene market.

- Covered the detailed list of manufacturers by application of the highly reactive polyisobutylene market. It covers the product information, application, and geographical presence of the companies.

- Conducted primary interviews with raw material suppliers, wholesalers, suppliers, and manufacturers of the highly reactive polyisobutylene market to understand the market trends, growth factors, pricing, and key players competitive strategies.

Highly reactive polyisobutylene (HR-PIB) is a type of oligomer and polymer of isobutylene with varying molecular weights that are utilized as a fuel additive, lubricants (or lube) oil additive, adhesives, and sealant used in industrial application. Highly reactive PIBs have over 80% reactive sites. Due to its higher reactivity, HR-PIB has been replacing conventional isobutylene in applications where it is further chemically converted, especially in the lubricant and fuel additives sector. Highly reactive polyisobutylene is relatively more reactive than conventional polyisobutylene due to the arrangement of the double bonds in the terminal position of the molecule. This leads it to react more quickly, especially when used as a fuel and lubricant additive. HR-PIB is an important intermediate in the manufacture of high-performance fuel and lubricant additives, including additives for sludge prevention. HR-PIB is a commercial polymer that has excellent thermal stability, good flexibility, and impermeability to gases. Furthermore, it offers high resistance to acids, alkalis, and salts. These benefits of HR PIB are projected to drive market growth during the forecast period.

There is an increase in demand for highly reactive polyisobutylene (HR-PIB), owing to major application in the manufacturing of inner tubes of tires, adhesives, sealants in the construction industry and its use in serum vials, injectables, saline bottles, seals for medical packaging, and chewing gum. Furthermore, highly reactive polyisobutylene is an engine oil additive that keep engines clean by dispersing harmful debris generated during operation that can thicken oil, cause wear, and plug the filter. On the other hand, polyisobutylene succinates and their derivatives including succinimides, esters, and others, are molecules that perform a peculiar dispersant performance in a wide range of hydrocarbons products including coatings, petroleum-based and biofuels, oil drilling, and explosives.

Growing demand for highly reactive-polyisobutylene from lubricants industry

Highly reactive-polyisobutylene is an essential intermediate product for the production of high-performance fuel and lubricant additives, such as fuel detergents or dispersants for engine oils, including additives for sludge prevention. HR-PIB is the basis for high performance lubricant additives that allows for more fuel-efficient engine designs. The lubricant formulations include a low viscosity ester and a high-reactive polyisobutylene polymer with a high level of terminal double bonds that improves viscosity. The high-viscous HR-PIB component with molecular weights of 1000, 1300, and 2300 is eminently suitable for the thickening of lubricants. It is regularly used instead of low viscous stock in high viscous formulations. Presently, a significant quantity of highly reactive polyisobutylene is used in lubrication end-uses such motor oils, industrial lubricants, and metalworking fluids. Thus, increase in demand for lubricants in various end-use industries, particularly the automotive industry, is likely to drive the need for HR-PIB, as it is widely used in the production of lubricants.

According to the International Energy Agency, Lubricant demand in the light vehicle sector mainly consists of engine oil, which accounted for more than 50% of the automotive lubricant demand and 21% of the total lubricant demand in 2015. It is projected that by 2030 the number of light vehicles will reach 1.6 billion (an increase of 500 million from 2015), with an estimated 18% of the total 290 million cars being electric. Thus, the increased demand of lubricants from the automotive industry will drive the demand for HR-PIB during the forecast period. The marketing strategy for highly reactive polyisobutylene (HR-PIB) revolves around the fuel additive industry since HR-PIB is an important intermediate in the manufacture of high-performance fuel additives and lubricant additives, such as fuel detergents or dispersants for engine oils, including additives for sludge prevention.

Surge in demand for HR-PIB in the construction industry as an adhesive and sealant

Highly reactive polyisobutylene offers a number of advantages in the construction industry, as adhesives & sealants owing to its tackiness and stability which make it perfect for various hot melt pressure sensitive adhesives. In addition, surge in industrialization and construction globally is fueling demand for machinery and equipment for production facilities, thus in turn hydraulic fluids and sealants are widely used in these industries. HR-PIB has excellent sealant properties such as reducing shrinkage. Products have beneficial qualities that make them suitable for sealants, such as high degree elongation, moisture resistance, and superior adhesive properties to a variety of substrates. The expanding construction sector is a major contributor in the expansion of the global market for highly reactive polyisobutylene (HR-PIB) due to the increased product use in sealants and adhesives for damp proofing and roof repair.

The growing investment in the construction industry is expected to increase the demand for highly reactive polyisobutylene in adhesive applications. The Middle East, Africa, and Asia-Pacific economies are expected to experience a rise in infrastructure demand as a result of developing road infrastructure, an increase in per capita property ownership, and a surge in purchasing power. This is projected to have an impact on the construction industry of the region, which will then increase demand for highly reactive polyisobutylene during the forecast period.

The highly reactive polyisobutylene market is segmented on the basis of molecular weight, application, and region. By molecular weight, the market is categorized into low, medium, and high. By application, it is divided into adhesives and sealants, lubricants and grease, hydraulic fluids, metal working fluids, and others. Region-wise, it is analyzed across North America, Europe, Asia-Pacific, and LAMEA. Drivers, restraints, and opportunities are explained in the report to understand the market. Further, key strategies adopted by potential market leaders to facilitate effective planning have also been discussed under the scope of the report.

Key players engaged in the development and production of highly reactive polyisobutylene include TPC Group, RB Products Inc., BASF SE, Lubrizol, INEOS, DAELIM Industrial Co. Ltd., Chevron, SPG Prints B.V., Zhejiang Shunda New Material Company Ltd., and KEMAT Polybutenes. These players have adopted product launch, acquisition, and business expansion as their key strategies to increase their highly reactive polyisobutylene market shares.

For instance, in June 2022, INEOS AG started its new 120,000 tonnes per annum Low Viscosity Polyalphaolefin (LV PAO) unit at Chocolate Bayou, Texas. LV PAOs are used in various lubricants such as engine oils, gear oils, transmission fluids, hydraulic fluids, and greases. They are also used in other applications such as processing aids, polymer modification, and cosmetics.

By Molecular Weight

Medium in Highly Reactive Plolyisobutylene is projected as the most lucrative segment.

On the basis of molecular weight, the market is divided into low, medium, and high. The medium segment accounted for the largest market share in 2021, owing to the high demand for medium molecular weight HR-PIB from the automotive and construction industry as it has a broad melting point and low density. Furthermore, it is anticipated to grow during the forecast period primarily due to its application as a reactionary intermediate in lubricant additive manufacturing. It also has a variety of other value-added benefits, such as reduced manufacturing char production and enhanced end lubricant and fuel product performance. Therefore, the medium molecular weight segment is estimated to drive the highly reactive polyisobutylene (HR-PIB) market over the forecast period.

By Application

Lubricants and Grease Application is projected as the most lucrative segment.

By application, it is divided into adhesives and sealants, lubricants and grease, hydraulic fluids, metal working fluids and others. The lubricants and grease segment accounted for the largest revenue share in the global highly reactive polyisobutylene market in 2021. High demand for HR-PIB in high-performance fuel and lubricant additive production is projected to drive market growth during the projection period. Furthermore, HR PIB can be used as a base fluid, but it comes at a higher cost without providing the additional benefit in the application. Furthermore, Lubricants such as engine oils, transmission oils, gear oils, greases, and compressor oils are highly consumed in the automotive, aircraft, marine, and machinery industries. HR-PIB helps enhance the overall performance of lubricants.

By Region

Asia-Pacific is projected as the most lucrative market.

Region-wise, Asia-Pacific accounted for the largest market share in the market and is projected to grow at a CAGR of 6.1% during the forecast period. The increase in construction and automotive markets in countries such as China, India, and Japan has benefited the global highly reactive polyisobutylene market. Furthermore, the rise in industrialization and construction in the Asia-Pacific region is propelling the demand for machinery and equipment for manufacturing facilities, hydraulic fluids and sealants are widely used in these industries.

IMPACT OF COVID-19 ON THE GLOBAL HIGHLY REACTIVE POLYISOBUTYLENE MARKET

One of the main markets for highly reactive polyisobutylene is the automotive industry. In terms of both production and consumption, China is the largest automotive market globally. During COVID-19, the demand for highly reactive polyisobutylene has decreased as a result of a fall in the growth of the highly reactive polyisobutylene market. However, a number of sectors, particularly the automotive sector resumed their operations in the fourth quarter of 2020, which eventually led to an increase in demand for highly reactive polyisobutylene.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the highly reactive polyisobutylene market analysis from 2021 to 2031 to identify the prevailing highly reactive polyisobutylene market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the highly reactive polyisobutylene market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global highly reactive polyisobutylene market trends, key players, market segments, application areas, and market growth strategies.

Highly Reactive Polyisobutylene Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 1.6 billion |

| Growth Rate | CAGR of 5.5% |

| Forecast period | 2021 - 2031 |

| Report Pages | 300 |

| By Molecular Weight |

|

| By Application |

|

| By Region |

|

| Key Market Players | Chevron Corporation, The Lubrizol Corporation, Zhejiang Shunda New Material Co., Ltd., LANXESS, TPC Group, INEOS AG, Kothari Petrochemicals Limited, BASF SE, Daelim Industrial Co. Ltd., KEMAT Polybutenes |

Analyst Review

According to leading CXOs, industries such as electronics, wood, automotive, construction, and aerospace are expected to propel the demand for highly reactive polyisobutylene during the forecast period. Key players including BASF SE, RB Products Inc., and others currently supply highly reactive polyisobutylene in a diverse range of molecular weights. On the other hand, stringent regulation implemented by regulatory bodies due to environmental concerns is likely to hamper the market share during the forecast period. However, the market for highly reactive polyisobutylene exhibits numerous opportunities in the near future due to the significant demand from the automotive, construction, and other industries.

High demand for highly reactive-polyisobutylene from lubricants industry and increased industrial activities drive the demand for highly reactive-polyisobutylene. These are the key factors driving the global highly reactive polyisobutylene market.

Lubricants and grease in the global highly reactive polyisobutylene market are projected to increase the demand of highly reactive polyisobutylene during the forecast period.

The global highly reactive polyisobutylene market is segmented on the basis of molecular weight, applications and region.

The highly reactive polyisobutylene market was valued at $1.0 billion in 2021, and is estimated to reach $1.6 billion by 2031, growing at a CAGR of 5.5% from 2022 to 2031.

The leading players in the market are TPC Group, RB Products Inc., BASF SE, Lubrizol, INEOS, DAELIM Industrial Co. Ltd., Chevron, SPG Prints B.V., Zhejiang Shunda New Material Company Ltd., and KEMAT Polybutenes.

Electronics, wood, automotive, construction, and aerospace are expected to propel the demand for highly reactive polyisobutylene during the forecast period.

After COVID-19 pandemic, as the economies are planned to revive their operations, the demand for highly reactive polyisobutylene is expected to rise globally. With the resuming of business operations and the lifting of lockdown measures globally, the demand for highly reactive polyisobutylene from the downstream industrial lubes and lube additives sectors has begun to increase.

Loading Table Of Content...

Loading Research Methodology...