IoT in Manufacturing Market Insights: 2030

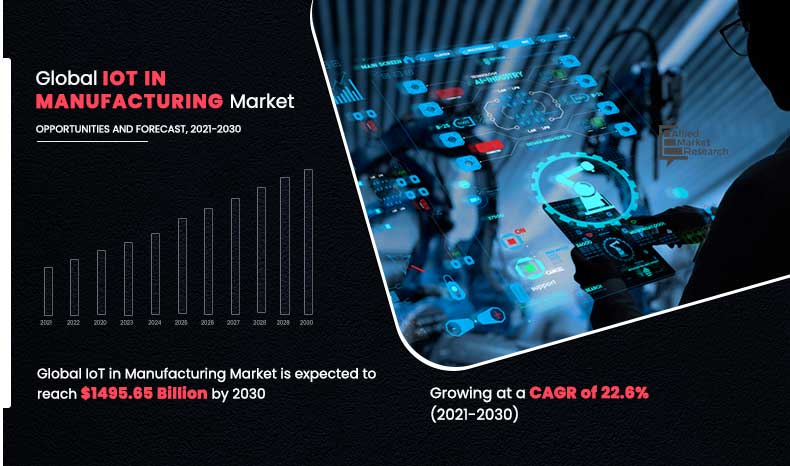

The global IoT in manufacturing market size was valued at USD 198.25 billion in 2020, and is projected to reach USD1,495.65 billion by 2030, growing at a CAGR of 22.6% from 2021 to 2030.

Advancements in technologies such as smart sensors and virtual & augmented reality as well as low operational cost boost the growth of the global IoT in manufacturing market. In addition, rise in demand for real-time asset monitoring positively impacts the growth of the market. However, inadequate IT infrastructure is hampering the market growth. On the contrary, introduction to connected operational intelligence and surge in adoption of cloud-based deployment model are expected to offer remunerative opportunities for expansion of the market during the forecast period.

Internet of Things (IoT) is a network of interconnected devices that enable communication and transfer of data by use of embedded sensors. IoT in manufacturing provides various applications such as real-time asset monitoring, connected operational intelligence, and fleet management.

Depending on application, the predictive maintenance segment garnered the largest share in 2020, and is expected to continue this trend during the forecast period as predictive maintenance helps to optimize resource management by sending technicians with the right parts, which notably contributes toward the IoT in manufacturing market growth. However, the cognitive process and operation management segment is expected to witness highest growth in the upcoming years, owing to it helps the manufacturers to identify defects during production. This technique is predominantly adopted in the U.S. has emerged to reduce inspection time and facilitate continuous process improvement.

Region wise, the IoT in manufacturing market size was dominated by North America in 2020, and is expected to retain its position during the forecast period, owing to abundance of business analytics solutions vendors such as SAP SE and IBM Corporation, thus aiding the growth of the IoT in manufacturing market. However, Asia-Pacific is expected to witness significant growth during the forecast period, owing to the fact that enterprises in Asia-Pacific are focusing on enhancing their management system and increasing their overall efficiency to stay competitive in the market.

The report focuses on growth prospects, restraints, and analysis of the global IoT in manufacturing market trends. The study provides Porter’s five forces analysis to understand the impact of various factors, such as bargaining power of suppliers, competitive intensity of competitors, threat of new entrants, threat of substitutes, and bargaining power of buyers on the global IoT in manufacturing market share.

Segment Review

The global IoT in manufacturing market is segmented into component, application, and region. On the basis of component, the market is divided into software and services. Depending on application, the market is classified into predictive maintenance, asset performance management, quality management, cognitive process & operations management, supply chain management, and others. Region wise, it is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The global IoT in manufacturing market is dominated by key players such as Cisco Systems Inc., Hitachi Ltd., IBM Corporation, Microsoft Corporation, PTC Inc., Robert Bosch GmbH, SAP SE, Software AG, Texas Instruments, and Zebra Technologies. These players have adopted various strategies to increase their market penetration and strengthen their position in the IoT in manufacturing industry.

COVID-19 impact analysis

The IoT in manufacturing market has witnessed significant growth in past few years and continued to grow during outbreak of the COVID-19 pandemic. This is attributed to implementation of lockdown by governments in majority of the countries and rise in adoption of work-from-home culture across all industries. In addition, increase in acceptance of data gathered through smart devices during the lockdown to monitor and maintain the overall manufacturing life cycle has expanded the prospects of the market.

By Component

Softwate segment is projected as one of the most lucrative segments.

Top Impacting Factors

Rise in Demand of Real-time Asset Monitoring

Real-time asset monitoring is one of the major driving factors for IoT in manufacturing. In addition, increase in need to predict asset and equipment failure and minimize unplanned downtime fuel the growth of the IoT in manufacturing industry. Moreover, this application offers instant notifications on asset delivery time and monitors valuable machinery to ensure equipment safety. Further, this method helps monitor devices and machines in real time to prevent manufacturing defect. For instance, Hitachi introduced Hitachi Video Analytics (HVA) to provide operational and business intelligence, which helped the company generate real-time alerts at public places to reduce risk. Thus, rise in demand for real-time monitoring acts as a key driving force of the global IoT in manufacturing market.

By Application

Predictive Maintainence segment is projected as one of the most lucrative segments.

Low Operational Cost

Smart and connected products are critical components in the connected supply chain and smart manufacturing processes. Furthermore, the advent of low-cost connected devices has enabled manufacturers to adopt IoT technologies to lower resource consumption and increase the overall productivity. Moreover, due to low operational cost, several manufacturers prefer to implement IoT applications in machines to maximize the efficiency with reduced cost.

By Region

Asia-Pacific would exhibit the highest CAGR of 25.27% during 2021-2030.

Key Benefits for Stakeholders

- The study provides an in-depth analysis of the global IoT in manufacturing market forecast along with current & future trends to explain the imminent investment pockets.

- Information about key drivers, restraints, & opportunities and their impact analysis on global IoT in manufacturing market analysis is provided in the report.

- The Porter’s five forces analysis illustrates the potency of the buyers and suppliers operating in the IoT in manufacturing Industry.

- The quantitative analysis of the market from 2021 to 2030 is provided to determine the IoT in manufacturing market potential.

IoT in Manufacturing Market Report Highlights

| Aspects | Details |

| By Component |

|

| By Application |

|

| By Region |

|

| By Key Market Players |

|

Analyst Review

IoT is a network of interconnected devices that facilitates the user to communicate and transfer data remotely with the help of embedded sensors. In addition, advancements in technologies such as real time-asset monitoring, predictive maintenance, and connected operational intelligence is expected to boost the IoT solutions in manufacturing sector during the forecast period.

The key providers of IoT in manufacturing market such as Cisco system Inc., Hitachi, Ltd., and SAP SE account for a significant share in the market. With the larger requirement from IoT in manufacturing, various companies are establishing partnerships to increase the IoT in manufacturing capabilities. For instance, in May 2021, Siemens and SAP expanded their partnership to connect plant floor operations, remote condition monitoring conducted by OEMs, and product development via digital twins to facilitate collaboration across an asset’s entire lifecycle. With the partnership, Siemens will begin offering SAP’s Asset Intelligence Network, the SAP Asset Strategy & Performance Management Application, and the SAP Enterprise Portfolio and Product Management package. In turn, SAP will offer Siemens’ Teamcenter software service lifecycle management portfolio.

In addition, with the increase in demand for IoT in manufacturing, various companies are expanding their current services to continue with rise in demand. For instance, in August 2021,?Zebra Technologies announced the intension to acquire antuit.ai, a provider of artificial intelligence (AI)-powered software-as-a-service (SaaS) solutions specific to forecasting and merchandising for the retail and CPG industries. Incorporating antuit.ai’s AI-powered demand forecasting solution into Zebra’s SaaS portfolio will enable retailers and consumer products companies to combine planning, optimize margins, and drive revenue growth. In addition, the acquisition of antuit.ai will further drive our ability to bring the power of AI to customers, and meet the demands of today’s consumer.

Moreover, market players are expanding their business operations and customers by increasing their acquisition. For instance, in May 2021, Cisco Systems announced to acquire Sedonasys Systems, also known as Sedona Systems, a maker of communications technologies. The acquisition will provide Cisco with NetFusion platform, which can automatically discovers, aggregates, and analyzes network data from multiple online systems and optical and IP sources, providing real-time, network-wide data that is then used by different NetFusion products. These products reduce the complexity, cost, time, and resources needed to plan, forecast, and operate the optimal network infrastructure.

The global IoT in manufacturing market size was valued at USD 198.25 billion in 2020, and is projected to reach USD1,495.65 billion by 2030

The IoT in manufacturing market is projected to grow at a compound annual growth rate of 22.6% from 2021 to 2030 reach USD1,495.65 billion by 2030

The global IoT in manufacturing market is dominated by key players such as Cisco Systems Inc., Hitachi Ltd., IBM Corporation, Microsoft Corporation, PTC Inc., Robert Bosch GmbH, SAP SE, Software AG, Texas Instruments, and Zebra Technologies.

Asia-Pacific would exhibit the highest CAGR of 25.27% during 2021-2030

Advancements in technologies such as smart sensors and virtual & augmented reality as well as low operational cost boost the growth of the global IoT in manufacturing market. introduction to connected operational intelligence and surge in adoption of cloud-based deployment model are expected to offer remunerative opportunities for expansion of the market during the forecast period.

Loading Table Of Content...