Methacrylate Monomers Market Research, 2031

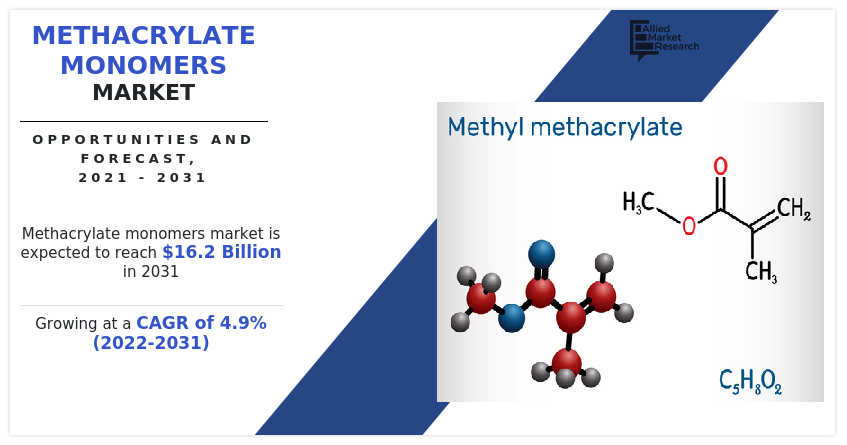

The global methacrylate monomers market was valued at $10.1 billion in 2021, and is projected to reach $16.2 billion by 2031, growing at a CAGR of 4.9% from 2022 to 2031.

Methacrylate monomers are common industrial monomers that easily form polymers owing to its highly reactive double bonds. Various derivatives of methacrylate monomers exist such as methyl methacrylate, butyl methacrylate, ethyl methacrylate, allyl methacrylate, glycidyl methacrylate, cyclohexyl methacrylate, stearyl methacrylate, and others. They find application in a wide range of end-use sectors including automotive, architectural, paints & coatings, electronics, and others.

Rise in population coupled with rapid urbanization has surged the growth of the architecture & construction sector in both developed and developing economies such as the U.S., China, India, and others where methacrylate monomers are widely used as a binder for concrete admixtures, reactive road making, industrial flooring, and liquid waterproofing applications. For instance, according to a report published by National Investment Promotion and Facilitation Agency, the infrastructure activities accounted for 13% share of the total foreign direct investment (FDI) inflows in 2021. This is expected to boost the demand for methacrylate monomers in the growing building & construction sector. Furthermore, factors such as surge in disposable income, technological upgrades, and spurring rise in original equipment manufacturers (OEMs) have led the automotive sector to witness a significant growth where methacrylate monomers are used in manufacturing automotive paints, illuminated light displays, and others. For instance, according to a report published by India Brands Equity Foundation, the domestic automobile production increased by a compound annual growth rate (CAGR) of 2.36% from 2016-20 with 26.36 million vehicles being manufactured in India in 2020.

However, there are several side-effects associated with the use of methacrylate monomer. For instance, exposure to methacrylate monomer causes moderate skin irritation and slight eye irritation. Furthermore, inhalation of mist or vapor can cause lung, throat, and nose irritation, and can be fatal if exposed beyond concentration limits. These factors may restrain customers from using methacrylate monomers; thus hampering the market growth.

On the contrary, factors such as rise in population coupled with emergence of advanced polymers have made customers more linear toward using polymer-based products. Furthermore, polymer offers various significant advantages such as low cost, lightweight, high strength, and increased lifecycle that make several end use sectors use polymers as a building block in product manufacturing where methacrylate monomers are used in production of homo- and copolymers in polymer sector. This is anticipated to foster the popularity of methacrylate monomers in the growing polymer sector; thus, creating lucrative opportunities for the market.

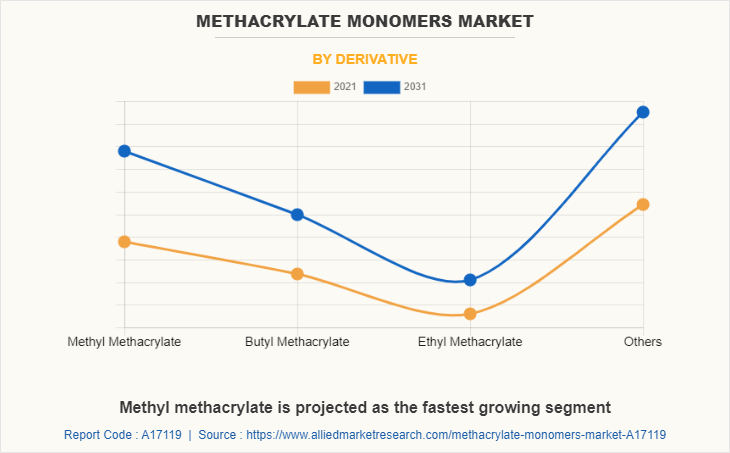

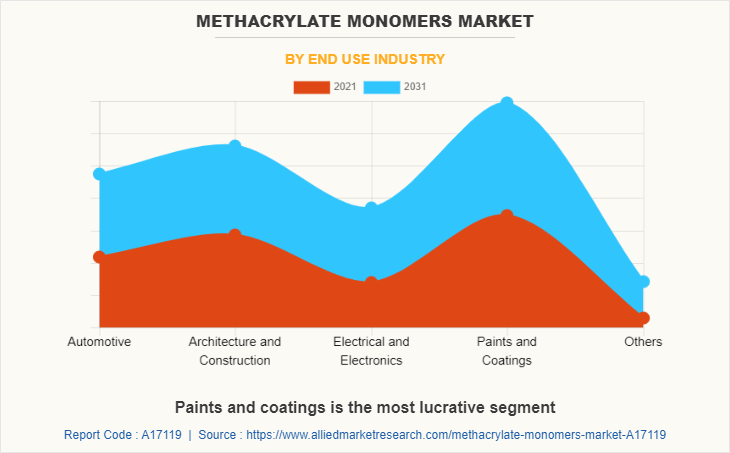

The methacrylate monomers market is segmented on the basis of derivative, end use industry, and region. On the basis of derivative, it is divided into methyl methacrylate, butyl methacrylate, ethyl methacrylate, and others. On the basis of end use industry, the market is classified into automotive, architecture & construction, electrical & electronics, paints & coatings, and others. Region wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

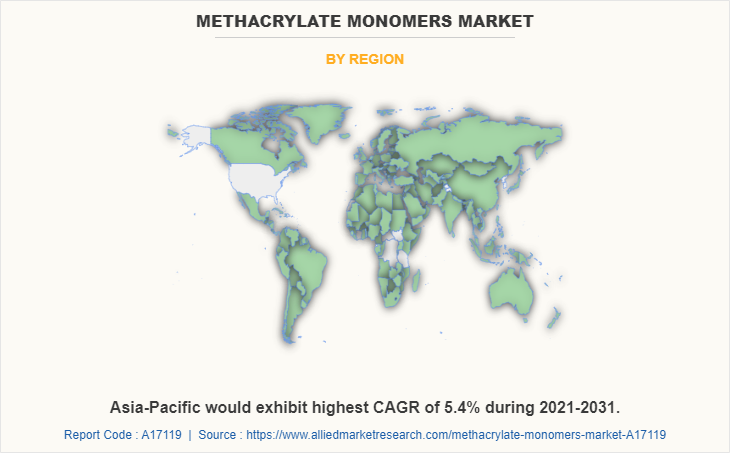

The Asia-Pacific methacrylate monomers market is projected to grow at the highest CAGR of 5.4% during the forecast period and accounted for 37.50% of methacrylate monomers market share in 2021. This is attributed to the rise in building & construction, automotive, electronics, and other sectors have enhanced the performance of the methacrylate monomer in the Asia-Pacific region. In addition, China's consumer electronics sector is increasing rapidly, which in turn has enhanced the performance of the methacrylate monomer market in the region. According to a report published by the United Nations Statistics Division, China witnessed around 28.7% of the global manufacturing output for consumer electronic products in 2019. Moreover, countries such as India and Australia have witnessed a rapid increase in automotive sectors where methacrylate monomer –based extruded acrylic sheets are used in taillights, thermoplastic mirrors, and other places of cars. This may boost the growth of the methacrylate monomers market in Asia-Pacific. For instance, according to a report published by the Indian Ministry of Commerce and Industry, the automotive sector in India is expected to grow at a compound annual rate (CAGR) of 5.9% by 2025.

By derivative, the methyl methacrylate segment is anticipated to grow at a highest CAGR of 5.4% during the forecast period. This is attributed to increase in young population coupled with rise in disposable income that has led the automobile sector to witness a significant growth where methyl methacrylate-based acrylic sheets are widely used in tail-lights, instrument clusters, and other electronic components. In addition, the surge in import export activities in both developed and developing economies has surged the demand for various commercial vehicles, where methacrylate monomer-based acrylic sheets are used in glasses, instrument clusters, armrests, and other automotive parts.

In 2021, the paints & coatings segment was the largest revenue generator, and is anticipated to grow at a CAGR of 5.1% during the forecast period. This is attributed to the increasing demand for paints & coatings from construction, automotive, and wood industries which in turn have led the paints manufacturing sector to witness an increase in demand where methacrylate monomers are widely used as a prime raw material during paint manufacturing process. Furthermore, increasing trend for high-tech coatings such as cationic coatings, covering all the crevices and corners of multi-faced metal parts, thereby protecting them from corrosion where n-butyl methacrylate is used to impart anti-corrosive properties in coatings may aid the market growth.

The major companies profiled in this report include Arkema S.A., BASF SE, DOW INC, Eastman Chemical Company, Evonik Industries AG, Jamorin International, Kowa Company, Ltd., Merck KGaA, Mitsubishi Chemical Holdings, and TCI America.

IMPACT OF COVID-19 ON THE GLOBAL METHACRYLATE MONOMERS MARKET

- The novel coronavirus is an incomparable global pandemic that has spread to over 180 countries and caused huge losses of lives and the economy around the globe.

- The methacrylate monomers market has been negatively impacted due to the wake of COVID-19 pandemic owing to its dependence on building & construction, automotive, electrical & electronics, and other sectors. According to a report published by Society of Indian Automobile Manufacturers (SIAM), sale of passenger vehicles, commercial vehicles and two‐wheeler vehicles has been declined by 51%, 88%, and 40% respectively in March 2020.

- Moreover, several automotive companies have either shutdown or shrank their operations due to the risk of infections among the workforce where methacrylate monomers is used to produce extruded acrylic sheets used in electronic consoles, tail-lights, and others. This has temporarily hampered the demand for methacrylate monomers market amid the COVID-19 period. According to an article published by The Economic Times, the exports of electronic devices such as computers, smartphones, and others have dipped due to supply chain issues. In addition, the methacrylate monomers market has witnessed a downfall in demand among the construction sectors, owing to temporary halt on various building and construction project amid the COVID-19 period.

- In 2020, methacrylate monomers prices were high in Asia-Pacific. The price rise was due to continued regional demand trends and tight product availability. Firm downstream demand for methacrylate monomers and stronger upstream costs are expected to sustain the price gain.

- However, the healthcare sectors have shown an impressive growth during the COVID-19 period where polymerized methacrylate monomers are used in dentistry and orthopedic surgery. For instance, according to a report published by India Brand Equity Foundation, the healthcare sector is expected to reach $372 billion by 2022, driven by rise in health awareness and surge in income. Furthermore, the building & construction and transportation activities are projected to get back on track and start functioning with full capacity post COVID-19 period, which in turn may enhance the performance of the methacrylate monomers market.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the methacrylate monomers market analysis from 2021 to 2031 to identify the prevailing methacrylate monomers market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the methacrylate monomers market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global methacrylate monomers market trends, key players, market segments, application areas, and market growth strategies.

Methacrylate Monomers Market Report Highlights

| Aspects | Details |

| By Derivative |

|

| By End Use Industry |

|

| By Region |

|

| Key Market Players | BASF SE, Kowa Company, Ltd., Arkema S.A, DOW INC., Merck KGaA, Eastman Chemical Company, MITSUBISHI CHEMICAL HOLDINGS, Jamorin International, Evonik Industries AG, TCI America |

Analyst Review

According to CXOs of leading companies, the global methacrylate monomers market is expected to exhibit high growth potential. Methacrylate monomers are used in producing homo-polymer, copolymer, extruded acrylic sheets, and chemical intermediates in a variety of end-use sectors such as plastics manufacturing, architecture & construction, automotive, and others. Automotive applications that require highly efficient glazing systems, corrosion protection, and temperature resistant properties can be accomplished with the use of methacrylate monomers.

In addition, polymerized methacrylate monomers possesses excellent significant properties such as light & weather resistance, thermal resistance, chemical stability, and corrosion resistance that make it best suited for use as a major base acrylic ester monomer for the production of paint & coatings. CXOs further added that sustained economic growth and development of the architecture & construction sector have increased the popularity of methacrylate monomers.

The Asia-Pacific methacrylate monomers market is the largest market projected to grow at the highest CAGR of 5.4% during the forecast period.

The global methacrylate monomers market is projected to reach $16.2 billion by 2031, growing at a CAGR of 4.9% from 2022 to 2031.

Paints and coatings is the largest end-use application of methacrylate monomers across the globe.

The methacrylate monomers market has been negatively impacted due to the wake of COVID-19 pandemic owing to its dependence on building & construction, automotive, electrical & electronics, and other sectors.

The major companies to hold the market share include Arkema S.A., BASF SE, DOW INC, Eastman Chemical Company, Evonik Industries AG, Jamorin International, Kowa Company, Ltd., Merck KGaA, Mitsubishi Chemical Holdings, and TCI America.

Loading Table Of Content...