Philippines Plastic Extrusion Molded Parts Market Overview:

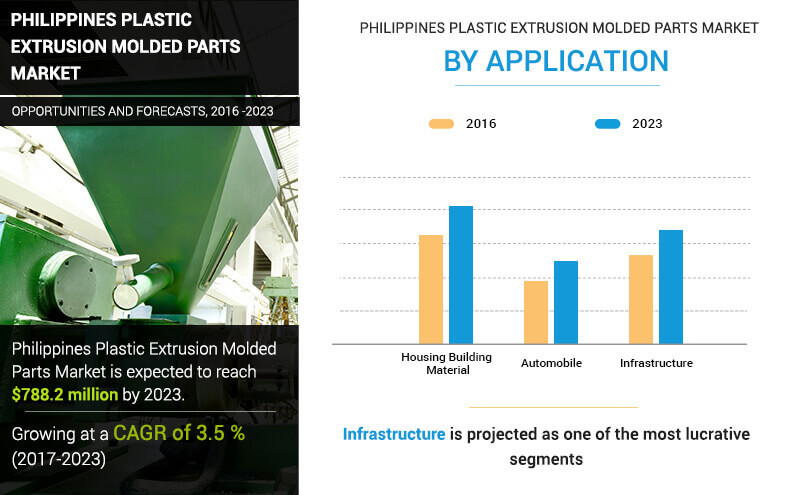

The Philippines Plastic Extrusion Molded Parts Market size was valued at $618.9 million in 2016 to reach $788.2 million by 2023, and is anticipated to grow at a CAGR of 3.5% from 2017 to 2023. Extrusion molding is more versatile when compared with other molding processes with simpler operation. It facilitates the production of large molding parts provided with shorter cycle time. This process enables the development of long parts with a constant cross-section at low costs, from pipe to weather-stripping. It is used to manufacture a range of plastic components such as drinking straws, pipes, curtain tracks, wall components, wall protection components, and automotive parts. Furthermore, it guarantees a smooth finish on the end product and complex shapes can be produced with varying thickness, texture, and colors.

Low cost of feedstock & energy prices and growth in demand for extrusion parts from the construction industry drive the market. However, volatile nature of crude oil prices may hamper the market growth during the forecast period. Moreover, significant growth of plastic industry in Philippines is expected to provide substantial growth opportunity to the industry players in the near future.

The Philippines plastic extrusion molded parts market is segmented based on its applications such as housing building material, automobile, and infrastructure. In addition, the report highlights different factors that impact the growth of the market, such as key drivers, restraints, growth opportunities, and the role of different key players. It presents the quantitative data in terms of both value and volume, which are gathered from the secondary sources such as company publications, Factiva, Hoovers, OneSource, and others. The data is validated after analysis by C-level executives and directors of the companies present in the market.

Top Investment Pockets

Infrastructure is the most lucrative application segment in the market, followed by housing building materials. In infrastructure application, extrusion process is used to manufacture components such as siding, decking, drainage components, and retainers. Increase in investment in infrastructure projects and rise in expenditure for construction is expected to deliver substantial growth opportunity to Philippines plastic extrusion molded parts industry.

Top Impacting Factors

The report emphasizes on the top factors, which directly or indirectly impact the overall market growth. It includes the factors that positively influence the market growth and threats that can hinder or limit the market growth. The impacting factors, which are included in the report are low feedstock & energy prices, growth in demand from construction industry, volatility in crude oil prices, and high growth of plastic industry in Philippines.

The report also comprises of competitors and customers active in the Philippines plastic extrusion molded parts market. Competitors are the key players manufacturing the plastic extrusion molded parts, however, customer include the industries which are using these extruded parts in diverse applications.

The key competitors profiled in the report include Gemphil Electronics Assemblies, Inc., COFTA Moulding Corporation, Indoplas Philippines, KIMIKA Industrial Corporation, Engineered Profiles LLC, The Dow Chemical Company, Bemis Company, Inc., Quanex Building Products Corporation, Royal Group, Inc., Pexco LLC, Bestpak Manufacturing Enterprises, Inc., JM Eagle, Inc., and Royal Group, Inc.

The key customers profiled in the report include Duros Development Corp., Nation Manufacturing and Industrial Products Corporation, Ply Gem Holdings, Inc., Rehau Incorporated, Vision Group, DENSO Corporation, Foton Philippines, Isuzu Philippines Corporation, Mitsuwa Chemical Co., Ltd., Eaton Corporation plc, MHG Asia Pacific, Rehau Incorporated, and Roop Polymers Limited.

Key Market Benefits

- This report provides an extensive analysis of the current and emerging market trends and dynamics of the Philippines plastic extrusion molded parts market.

- In-depth analysis of all applications is conducted by constructing market estimations for key segments between 2016 and 2023, which assist to identify the prevailing opportunities.

- The report assists to understand the strategies adopted by the companies for market expansion.

- This study evaluates the competitive landscape to understand the competitive environment across various competitors and customers in the market.

Philippines Plastic Extrusion Molded Parts Market Key Segments:

By Application

- Housing Building Material

- Automobile

- Infrastructure

Philippines Plastic Extrusion Molded Parts Market Report Highlights

| Aspects | Details |

| By APPLICATION |

|

| By Region |

|

Analyst Review

Extrusion is a process of manufacturing long products of constant cross-section such as rods, sheets, pipes, films, and wire insulation coating. The major advantage of using extrusion to manufacture molding parts is that profiles such as pipes can be made to any length. The plastic extrusion molding is widely adopted in diverse industries owing to its low initial set-up cost, fast setup time, and low production cost.

In 2016, housing building material application segment dominated the Philippines plastic extrusion molded parts industry, which is accounted for nearly half share in total market. In housing building material, extrusion is used to manufacture window casement, wall protection components, and wall trims including other components. Whereas, automobile is the fastest growing application segment, growing at a highest CAGR of 4.2% during 2017 to 2023.

Loading Table Of Content...