Table Of Contents

Yerukola Eswara Prasad

Koyel Ghosh

Discovering the Power of Superalloys: Transforming High-Performance Applications

Superalloys are highly advanced metals known for their exceptional strength, ability to withstand high temperatures, and resistance to chemicals. They are typically composed of at least two elements, with a primary alloying element being nickel, cobalt, or nickel-iron. These alloys have a specific crystal structure called austenitic face-centered cubic. They have been primarily developed for use in aerospace and power industries. Superalloys consist of a combination of metallic elements, as well as additives such as metalloids or nonmetals. They fall into three main categories: nickel-based, iron-based, or cobalt-based.

Some Key characteristics of superalloys are as Follows

- High Temperature Resistance: Superalloys can withstand elevated temperatures without losing their mechanical properties, making them suitable for applications in high-temperature environments.

- Excellent Mechanical Strength: These alloys maintain their strength and structural integrity at both high and low temperatures, providing durability and reliability in extreme conditions.

- Corrosion and Oxidation Resistance: Superalloys exhibit resistance to corrosion and oxidation, which is crucial for applications in aggressive environments where exposure to chemicals or atmospheric conditions may occur.

- Creep Resistance: Superalloys resist deformation under prolonged exposure to high temperatures, a property known as creep resistance. This is particularly important in applications where materials are subjected to constant stress at elevated temperatures.

- Fatigue Resistance: These alloys demonstrate resistance to fatigue, ensuring long-term performance under cyclic loading conditions.

The demand for superalloys has showcased significant growth by increasing penetration in different end-use industries such as aerospace & defense, automotive, power generation, oil and gas and so on. To observe the growth in the superalloys industry, we need to observe and analyze certain parameters that will provide insights into the demand perspective.

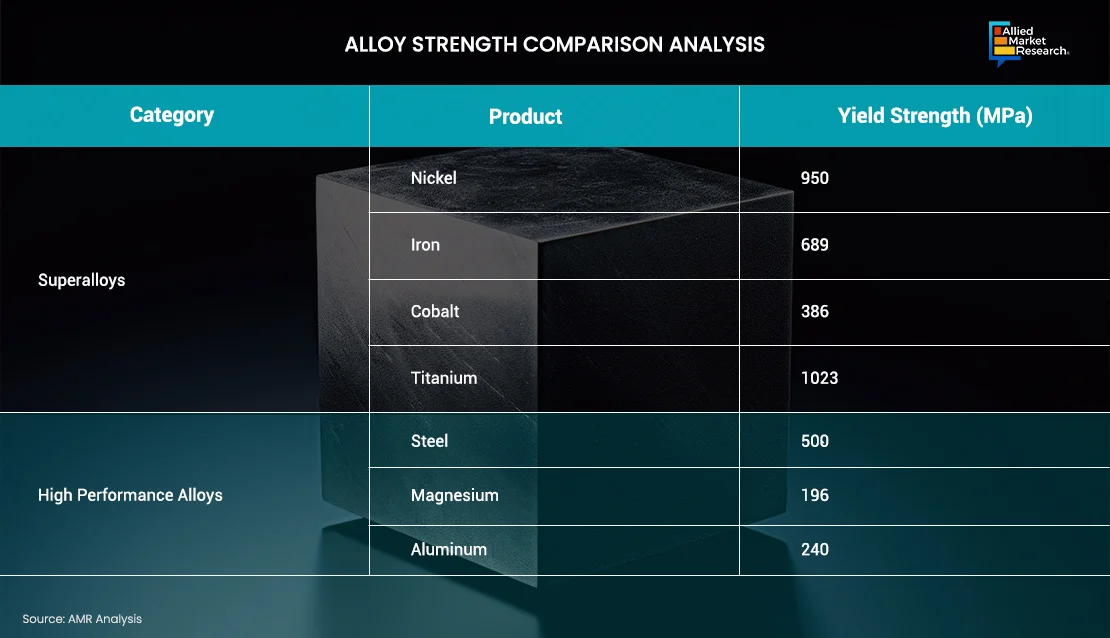

Strength Comparison Analysis (Superalloys V/S Substitutes)

Superalloys possess remarkable strength characteristics, making them well-suited for demanding applications in high-temperature and corrosive environments. The strength of these materials is often assessed through various parameters, including tensile strength, yield strength, and creep resistance. High strength property in superalloys is of huge importance as the corresponding component encounters high temperatures, creeps, fatigue, corrosion, and so on.

Strength Is a Crucial Property in These Alloys Due to Several Key Factors Outlined below

High-Temperature Stability: They are commonly used in applications where exposure to elevated temperatures is unavoidable, such as in gas turbine engines and aerospace components. The ability of superalloys to maintain their strength at high temperatures is crucial for ensuring structural integrity and preventing deformation or failure under thermal loads.

Mechanical Reliability: High-performance applications often involve intense mechanical stresses. The exceptional strength of superalloys allows them to withstand these forces without undergoing plastic deformation or failure. This is particularly important in components like turbine blades, where mechanical reliability is essential for overall system performance.

Creep Resistance: Creep is the gradual deformation that occurs under constant stress at elevated temperatures. Superalloys are designed to exhibit high resistance to creep, ensuring that they can maintain their shape and integrity over extended periods of use in high-temperature environments. This is crucial for components in gas turbines and jet engines, which operate at elevated temperatures for extended periods.

Corrosion Resistance: In addition to high-temperature and mechanical stresses, many high-performance applications involve exposure to corrosive environments. Superalloys are designed to resist corrosion, ensuring that they maintain their strength and structural integrity in aggressive chemical conditions.

Performance in Extreme Environments: Superalloys are often employed in extreme environments, such as in space exploration or deep-sea exploration, where conditions are harsh and unforgiving. High strength ensures that the materials can withstand these extreme conditions without compromising performance.

The above table illustrates the individual alloy strength based on the metal categorization. Titanium and Nickel based alloys showcase the highest strength, which can be utilized in demanding applications such as Aerospace, Power generation, and so on.

In the aerospace industry, the primary applications of superalloys are in turbine blades, turbine discs, engines, and landing gear. Aerospace applications require structure materials that can sustain high stress, resistance to creeping, and high temperature tolerance. They enable the aerospace industry to produce high-performance components, such as jet engines and airframes, via jet engines and airframes. For instance, Materion Corporation introduced AMC® 4632 ALLOY, a powder metallurgy product that refines microstructure and improves mechanical properties, for the aerospace industry.

Enhancing Performance across High-performance Applications

The global aerospace industry has experienced growth, except during the COVID-19 pandemic. Over time, the industry has introduced numerous technological innovations, and superalloys stand out as one of them. Various components and equipment in the aerospace sector utilize these alloys such as engine turbine & blades, compressor blades, nacelles, landing gear, flaperon & wing components, and so on. Superalloys exhibit high temperature resistance, creep resistance, high performance in extreme environmental conditions, making it one of the preferred products in the aerospace industry. Some key areas where they are extensively used in the aerospace industry are discussed below:

- Gas Turbine Engines: Superalloys, particularly nickel-based alloys like Inconel and Waspaloy, are utilized for manufacturing turbine blades and vanes. These components operate in the high-temperature, high-stress environment of gas turbine engines, where the exceptional strength and creep resistance of superalloys are crucial.

- Aircraft Engine Components: They are employed in the fabrication of combustor liners, where they withstand high temperatures and corrosive combustion environments.

- Hot Sections of Jet Engines: They are also used for nozzle guide vanes in the hot sections of jet engines, where they are exposed to extreme temperatures and pressures.

- Aircraft Structural Components: These high-performance alloys are deployed in the manufacturing of exhaust components, including thrust reversers and afterburner sections, where they endure high temperatures and mechanical stresses.

- Space Exploration: Superalloys are exerted in the construction of rocket engines, where they can withstand the high temperatures generated during the combustion of rocket propellants.

- Heat Exchangers: Superalloys enhance aircraft engine efficiency by capturing and reusing heat through regenerative heat exchangers during operation.

- Landing Gear Components: Simultaneously, superalloys are used in landing gear components, such as forged or cast parts, where high strength and durability are essential.

- Aircraft Fasteners: Superalloys may be utilized in manufacturing high-strength fasteners for critical joints in aircraft structures.

- Thrust Reversers: They are employed in components of thrust reversers, which redirect the thrust of the engines to assist in braking during landing.

- Environmental Control Systems: Finally, these alloys again play a crucial role in aircraft environmental control systems, ensuring effective temperature control by being used in heat exchangers.

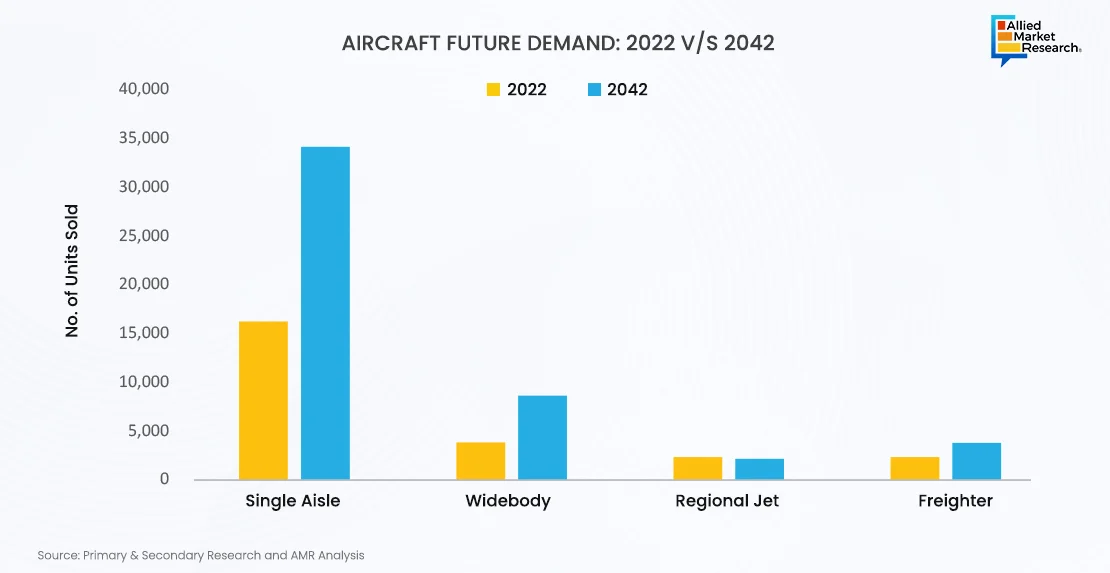

With an increase in the production of various aircraft in the aerospace industry, the demand for superalloys is also anticipated to increase concurrently. Different types of aircraft such as commercial & cargo aircraft, business aircraft, and military aircraft use various superalloy-based components depending on the application specifications. This is due to their inherent cast-ability, stability, high level of strength, and ductility at elevated temperatures.

In the provided data, both Airbus and Boeing experienced a growth of over 10% year-on-year between 2022 and 2023. The surge in passenger demand expected for 2023 is primarily driven by China's reopening to inbound and outbound travel. This increase in travel is anticipated to balance out economic challenges seen in other regions globally. Predictions suggest a significant 21% increase in Revenue Passenger Kilometers (RPKs) this year, followed by a 17% rise in 2024. These growth trends are expected to surpass the global traffic levels of 2019, advancing the recovery timeline by 12 months compared to previous expectations.

The above figures showcase the demand order for various aircraft types until 2042. According to Forecast International, “Airbus had a wild month and received orders for 807 jets (gross orders) from 16 different customers. Turkish Airlines placed a massive order for 220 jets comprised of 150 firm A321neos and 70 firm A350s and Indian carriers IndiGo and Air India placed orders with Airbus and Boeing for 500 and 470 jets, respectively”.

Superalloy manufacturers have the opportunity to broaden their research programs in aerospace, industrial gas turbines (IGT), chemical processing, and automotive markets. This expansion is driven by the goals of reducing costs, improving properties, and enhancing the flexibility of alloy fabrication. Cost reduction efforts in superalloy components are expected to be mainly achieved through computational modeling, particularly in process modeling and the welding of dissimilar component parts. Advances in these research areas will directly benefit the application of superalloys across various industries.

Allied Market Research delves into the intricacies of Superalloys and other related products, as we aim to provide vendors with comprehensive insights into the evolving landscape. We provide in-depth details through highly curated reports that portray technological advancements, market trends, and government initiatives concerning the domain, which in turn help businesses integrate superalloys into their operations. Get in touch with our experts today for further information on the materials and chemicals industry!