Smart Manufacturing Quality Control Systems Market Research, 2032

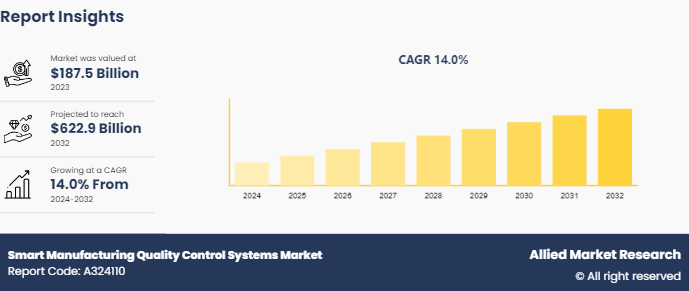

The global smart manufacturing quality control systems market was valued at $187.5 billion in 2023, and is projected to reach $622.9 billion by 2032, growing at a CAGR of 14% from 2024 to 2032. The market is driven by the need for improved product quality, operational efficiency, and the ability to respond swiftly to manufacturing challenges.

Market Introduction and Definition

The smart manufacturing quality control systems market encompasses advanced technologies and solutions designed to enhance the accuracy, efficiency, and reliability of quality assurance processes in manufacturing. This market includes a range of components such as sensors, machine vision systems, and software integrated with artificial intelligence and machine learning to automate defect detection, process monitoring, and data analysis. By leveraging the Internet of Things (IoT) and real-time analytics, these systems enable manufacturers to optimize production, reduce waste, and ensure compliance with quality standards across various industries including automotive, aerospace, electronics, pharmaceuticals, and consumer goods.

Key Takeaways

The smart manufacturing quality control systemss market study covers 20 countries. The research includes a segment analysis of each country in terms of value ($Billion) for the projected period 2023-2032.

More than 1,500 product literatures, industry releases, annual reports, and other such documents of major smart manufacturing quality control systems industry participants along with authentic industry journals, trade associations' releases, and government websites have been reviewed for generating high-value industry insights.

The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and assist stakeholders in making educated decisions to achieve their most ambitious growth objectives.

Key Market Dynamics

The primary driver for the smart manufacturing quality control systems market is the increasing demand for enhanced operational efficiency and product quality in manufacturing processes. As industries strive for greater precision, reduced waste, and compliance with stringent quality standards, smart quality control systems offer advanced solutions through automation, real-time data analysis, and predictive maintenance. The integration of artificial intelligence (AI) and machine learning enhances defect detection and process optimization, making these systems indispensable for manufacturers aiming to stay competitive in a rapidly evolving market. However, the key restraints of the smart manufacturing quality control systems market is the high initial investment required for advanced technology implementation. The cost of acquiring sophisticated hardware, software, and integrating these systems into existing manufacturing processes can be substantial, particularly for small and medium-sized enterprises. Additionally, the complexity of deploying and maintaining these systems can pose challenges, including the need for specialized personnel and ongoing system updates, which may deter some companies from adopting these technologies.

Furthermore, significant opportunity in the smart manufacturing quality control systems market lies in the expansion of Industry 4.0 initiatives and the growing adoption of IoT technologies. As more manufacturers embrace digital transformation and seek to leverage data-driven insights for continuous improvement, there is a rising demand for innovative quality control solutions that offer real-time monitoring, predictive analytics, and seamless integration with existing systems. This trend creates opportunities for growth and innovation in developing scalable and adaptable quality control systems that cater to various industry needs and support the transition to more intelligent manufacturing environments.

Government Role in market

In many countries, regulations mandate rigorous standards for product quality and safety, which directly impact the implementation of smart manufacturing systems. For instance, regulatory bodies may require that manufacturing processes adhere to specific quality control protocols and standards, such as ISO 9001 for quality management systems, which often necessitate the use of advanced technologies for monitoring and compliance.

Additionally, governments may impose regulations related to data privacy and cybersecurity, particularly as smart manufacturing systems rely on vast amounts of data collected through IoT devices and sensors. Compliance with standards like the General Data Protection Regulation (GDPR) in Europe or the California Consumer Privacy Act (CCPA) in the U.S. is crucial for ensuring that data handling practices are secure and meet legal requirements. Moreover, governments may offer incentives, grants, or subsidies to encourage the adoption of advanced technologies, including smart quality control systems, to boost innovation and maintain competitive manufacturing sectors.

Market Segmentation

The smart manufacturing quality control systems market is segmented into component, deployment, industry vertical and region. On the basis of component, the market is divided into solution and services. On the basis of deployment, the market is divided into on-premise and cloud. On the basis of industry vertical, the market is divided into automotive, aerospace & defence, chemicals & materials, healthcare, industrial equipment, electronics, food & agriculture, oil & gas, others. Region wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Regional/Country Market Outlook

In the UK, the smart manufacturing quality control systems market is driven by stringent regulatory standards and a strong emphasis on industrial innovation and sustainability. The UK government supports advancements through initiatives like the Industrial Strategy Challenge Fund, promoting the adoption of smart technologies. In the U.S., the market benefits from a diverse industrial base and significant investment in research and development, supported by various federal programs and incentives for technological advancement. Whereas, Japan's market is characterized by a focus on precision and high-quality manufacturing, supported by strong industry standards and a culture of continuous improvement. Japan’s government and industries are heavily invested in integrating advanced technologies to maintain their competitive edge in global manufacturing.

In March 2023, Honeywell expanded its capabilities to help companies achieve automation interoperability in the distribution center (DC) . The company will demonstrate many of its automation solutions and robotics at ProMat 2023 in Chicago, .

In March 2023, Korean electronics major Samsung announced to invest in setting up smart manufacturing capabilities at its second largest mobile phone plant in Noida to make production more competitive.

In Febuary 2022, Advantech, leading provider of industrial Internet of Things (IoT) and edge hardware technology, announced collaboration among Intel, VMware, and ABB to combine technical expertise and foster collaboration on smart grid applications, such as substation virtualization and virtualized protection relay solutions.

Industry Trends:

The increased integration of Artificial Intelligence (AI) and Machine Learning (ML) in smart manufacturing quality control systems represents a significant advancement in how manufacturers ensure product quality and process efficiency. AI and ML technologies enable systems to analyze vast amounts of data in real-time, identifying patterns and anomalies that traditional methods might miss. For example, AI-driven algorithms can predict potential defects before they occur by learning from historical data and recognizing subtle changes in manufacturing processes. This proactive approach not only enhances the accuracy of quality inspections but also reduces downtime and waste by enabling predictive maintenance. For instance, In June 2023, Siemens introduced its AI-driven quality control solution that uses machine learning algorithms to predict defects and optimize manufacturing processes in real time, enhancing accuracy and reducing waste.

The expansion of cloud-based quality control solutions in smart manufacturing represents a significant shift towards leveraging cloud computing to enhance operational flexibility and efficiency. By moving quality control systems to the cloud, manufacturers gain access to scalable, centralized platforms that facilitate real-time data access, analysis, and collaboration across multiple locations. Cloud-based solutions enable seamless integration with other systems and technologies, allowing for more robust data management and easier deployment of updates and new features. For instance, in December 2021, GE Digital released a new manufacturing software suite featuring compatibility with on-premises, cloud, and mixed architecture applications. The new Proficy Smart Factory suite promises to help companies reduce the total cost of ownership (TCO) by 30 percent over five years.

Competitive Landscape

The major players operating in the smart manufacturing quality control systems market include Siemens AG, Honeywell International Inc., Rockwell Automation, Inc., Schneider Electric SE, ABB Ltd., Bosch, Mitsubishi Electric Corporation, Emerson Electric Co., Cognex Corporation, General Electric (GE) Digital and so on.

Recent Key Strategies and Developments

In April 2023, Siemens Digital Industries introduced Industrial Operations X, an open and interoperable portfolio for automating and operating industrial production. The new portfolio is part of Siemens Xcelerator, the open digital business platform comprising a portfolio of software and connected hardware, an ecosystem of partners, and a marketplace.

In April 2023, Stratasys Ltd., a leader in polymer 3D printing, launched its new GrabCAD Print Pro software, with integrated quality assurance functionality from Riven, a recent Stratasys acquisition. GrabCAD Print software manages the print preparation process for Stratasys 3D printers. The new Pro version is designed for manufacturers who need to efficiently produce end use parts and move to production-scale volumes.

In June 2022, Siemens AG has launched an open digital business platform, Siemens Xcelerator, to accelerate digital transformation and value creation for customers of all sizes in industry, buildings, grids and mobility. The business platform makes digital transformation easier, faster and scalable. Siemens Xcelerator includes a curated portfolio of internet of things (IoT) enabled hardware, software and digital services from across Siemens and certified third parties; a growing ecosystem of partners; and an evolving marketplace to facilitate interactions and transactions between customers, partners and developers.

Key Sources Referred

stratasys.com

snicsolutions.com

sap.com

flagssoftware.com

Key Benefits For Stakeholders

This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the smart manufacturing quality control systems market analysis from 2024 to 2032 to identify the prevailing smart manufacturing quality control systems market opportunities.

The market research is offered along with information related to key drivers, restraints, and opportunities.

Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

In-depth analysis of the smart manufacturing quality control systems market segmentation assists to determine the prevailing market opportunities.

Major countries in each region are mapped according to their revenue contribution to the global market.

Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

The report includes the analysis of the regional as well as global smart manufacturing quality control systems market trends, key players, market segments, application areas, and market growth strategies.

Smart Manufacturing Quality Control Systems Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 622.9 Billion |

| Growth Rate | CAGR of 14% |

| Forecast period | 2024 - 2032 |

| Report Pages | 230 |

| By Component |

|

| By Deployment |

|

| By Industry Vertical |

|

| By Region |

|

| Key Market Players | ABB Ltd., BOSCH, Mitsubishi Electric Corporation, Rockwell Automation, Inc., General Electric (GE) Digital, Cognex Corporation, Honeywell International Inc., Emerson Electric Co., Siemens AG, Schneider Electric SE |

The global smart manufacturing quality control systems market was valued at $187.5 billion in 2023 and is projected to reach $622.9 billion by 2032, growing at a CAGR of 14% from 2024 to 2032.

The rise in need for data-driven decision-making and increased demand for operational efficiency are the upcoming trends of the Smart Manufacturing Quality Control Systems Market in the globe.

Growth in Industry 4.0 Adoption is the leading application of the Smart Manufacturing Quality Control Systems Market.

North America is the largest regional market for Smart Manufacturing Quality Control Systems.

Siemens AG, Honeywell International Inc., Rockwell Automation, Inc., Schneider Electric SE, ABB Ltd., Bosch, Mitsubishi Electric Corporation, Emerson Electric Co., Cognex Corporation, General Electric (GE) Digital are the top companies to hold the market share in Smart Manufacturing Quality Control Systems.

Loading Table Of Content...