Superplasticizers Market Research, 2031

The global superplasticizers market was valued at $9.7 billion in 2021, and is projected to reach $19.1 billion by 2031, growing at a CAGR of 7.2% from 2022 to 2031.

Report Key Highlighters:

- The superplasticizers market study covers 20 countries. The research includes a segment analysis of each country in terms of both value ($million) and volume (kilotons) for the projected period 2021-2031.

- The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and to assist stakeholders in making educated decisions in order to achieve their most ambitious growth objectives.

- Over 3,700 product literature, annual reports, industry statements, and other comparable materials from major industry participants were reviewed to gain a better understanding of the market.

- The superplasticizers market is highly fragmented, with several players including Arkema, BASF SE, Beijing Dongke United Technologies Co.,Ltd, CHRYSO, Enaspol a.s., GCP Applied Technologies Inc., MAPEI, Rhein-Chemotechnik GmbH, Sika AG, and Tripolarcon Pvt Ltd. Also tracked key strategies such as acquisitions, product launches, mergers, expansion etc. of the players operating in the superplasticizers market.

Superplasticizers are chemical admixtures that are added to concrete to improve workability and fluidity while maintaining strength and durability. They are known as high-range water reducers as they may significantly reduce the water content of concrete while retaining its flowability. Superplasticizers disperse cement particles and reduce surface friction between the particles and the mixing water. They lower the viscosity of the slurry, making them easier to flow and allowing the concrete to be placed and cemented more efficiently.

Superplasticizers are frequently employed in the production of high-strength concrete and self-consolidating concrete, where the concrete must be placed in small areas or around complex reinforcing structures. The superplasticizer's dosage depends on the cement type and the desired level of workability. The dosage is typically expressed as a percentage of the weight of the cement and the recommended dosage ranges from 0.5% to 3% by weight of the cement. The superplasticizer is added to the concrete mixture during the mixing process, typically after adding water and cement. The mixing time should be adjusted to ensure proper dispersion of the superplasticizer in the mixture.

Superplasticizers can respond to changes in the environment or conditions during the curing process. For example, in February 2023 a team of researchers in Japan developed a superplasticizer that can respond to changes in temperature, pH, or other factors to optimize the strength and durability of the concrete. This type of superplasticizer could help improve the overall quality and consistency of concrete and could be particularly useful for large-scale construction projects.

Consumers have increased interest in developing more sustainable and environmentally friendly superplasticizers. The natural materials such as energy crops, agricultural crop residues, forestry residues, algae, and others can be extracted from waste streams generated by the forestry or agricultural industries, making them a potentially more sustainable alternative to synthetic superplasticizers.

Growth in preference for precast concrete in the construction industry drives the growth of superplasticizers market.

Precast concrete has become increasingly popular in the construction industry due to its advantages over traditional cast-in-place concrete. It is created in a controlled environment, usually in a factory, and is transported to the construction site to be installed. Precast concrete is highly durable and can withstand the effects of weathering and natural disasters better than other materials, making it a popular choice for structures such as bridges, tunnels, and buildings in earthquake-prone areas. On June 1, 2021, Endeavor Business Media announced the launch of Smart Buildings Technology, a new brand dedicated to bringing integrated intelligence to new construction and existing commercial buildings.

However, high cost of superplasticizers is expected to hinder the growth of superplasticizers market. Superplasticizers are mostly used in the construction industry to improve the flowability and pumpability of concrete and reduce water content in the mixture. They are more expensive than other types of concrete admixtures, however, offer unique benefits such as increased workability and reduced water content. As per the Federal Highway Administration, on average, the cost of superplasticizers ranges from $0.50 to $2.50 per pound, or $1.10 to $5.50 per kilogram, depending on the type, manufacturer, quantity purchased, and location of the buyer.

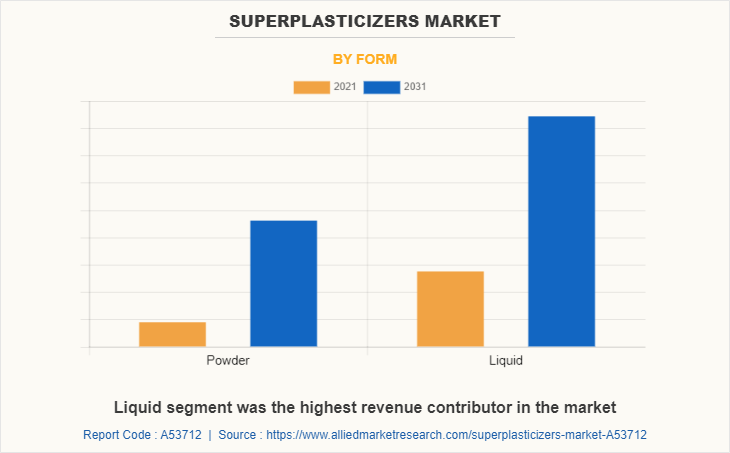

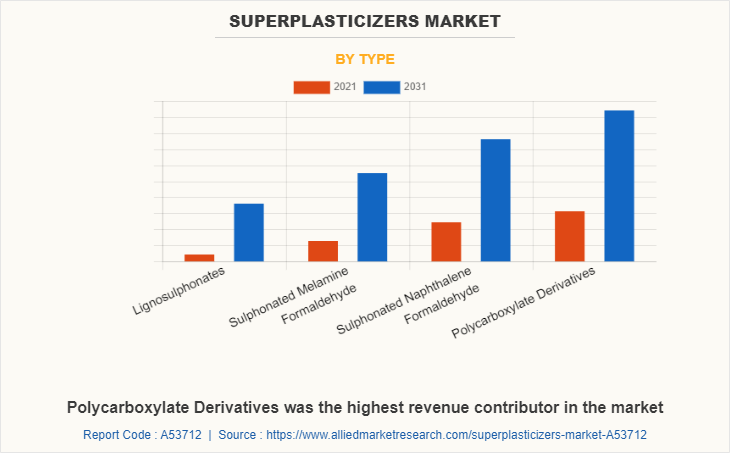

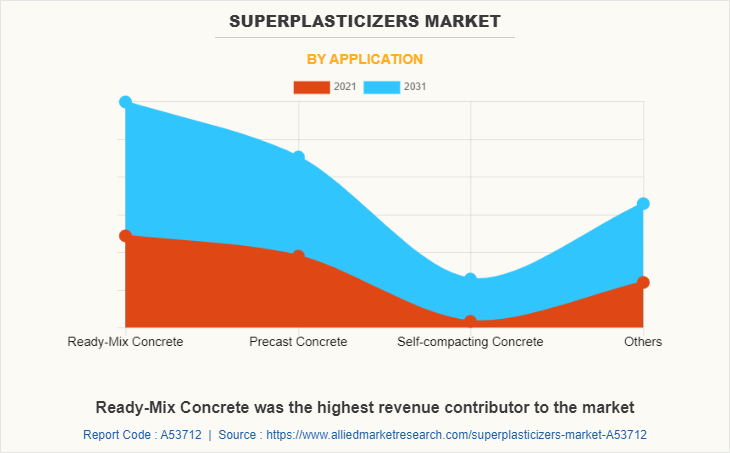

The superplasticizers market is segmented into form, type, application, and region. On the basis of form, the market is bifurcated into powder and liquid. On the basis of type, it is categorized into lignosulphonates, sulphonated melamine formaldehyde, sulphonated naphthalene formaldehyde, and polycarboxylate derivatives. On the basis of application, the market is classified into ready-mix concrete, precast concrete, self-compacting concrete, and others. Region wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

Liquid superplasticizers are chemical additives used in the construction industry to improve the workability and strength of concrete. They reduce the amount of water needed to achieve the desired consistency, resulting in a stronger and more durable final product. Liquid superplasticizers can help reduce the amount of shrinkage in concrete, resulting in a more stable and durable final product. They can also increase the workability of the concrete, making it easier to apply and shape into decorative designs.

Polycarboxylate derivatives are a popular superplasticizer used in the construction industry to improve the properties of concrete mixes. They have excellent water-reducing properties, high efficiency, and low dosage requirement. Polycarboxylate derivatives are used in industrial buildings to create high-strength, long-lasting, and workable concrete mixes. According to the China Economic and Security Review Commission, government spending on smart city programs in China will exceed $ 38.92 billion in 2023, indicating a nation's propensity towards adopting energy efficiency solutions in construction industry.

Ready-mix concrete is a type of concrete that is produced in a batch plant and delivered to a construction site in a ready-to-use form. Superplasticizers can improve the efficiency and quality of construction projects by making the concrete easier to work with and reducing the need for additional water or additives. Ready-mix concrete can also be used to make structural elements like beams, columns, and walls. These components are frequently constructed off-site before being moved to the construction site and assembled into the final structure.

The Asia-Pacific region is a major consumer of superplasticizers due to the need for stronger and more durable concrete structures, the growing demand for sustainable construction materials, and the increasing use of high-performance concrete in infrastructure projects. The Asia-Pacific construction industry is becoming more concerned with sustainability, and superplasticizers are playing a role in this trend. Superplasticizers can help to minimise carbon emissions and enhance the overall sustainability of construction projects by reducing the quantity of cement and water required in concrete manufacturing.

Major players operating in the global superplasticizers market includes Arkema, BASF SE, Beijing Dongke United Technologies Co.,Ltd, CHRYSO, Enaspol a.s., GCP Applied Technologies Inc., MAPEI, Rhein-Chemotechnik GmbH, Sika AG, and Tripolarcon Pvt Ltd. These players adopted several growth strategies such as partnership and product launch to strengthen their position in the market.

For instance, in June 2021, MAPEI and Elettrondata, a leader in automation systems for the management, production, and control of ready-mix concrete plants, signed a multi-year partnership to provide equipment and services for quality control, production, and transportation of ready-mix concrete. Through this partnership, the entire concrete sector is anticipated to be able to benefit from the total quality process' additional value and advance toward CO2 neutrality.

IMPACT OF COVID-19 ON THE GLOBAL SUPERPLASTICIZERS MARKET

- The COVID-19 pandemic had a significant impact on the global superplasticizers market, which is closely tied to the construction industry due to supply chain disruptions, labor shortages, and delays in project timelines

- The pandemic caused a decrease in construction activity in many parts of the world, leading to a decline in demand for superplasticizers. In 2019, COVID-19 pandemic decreased the sales of construction industry by 25% during the July-September quarter, with NCR and Mumbai metropolitan region sales down by 13% and 9% respectively

- However, the COVID-19 pandemic had a positive impact on the superplasticizers market, as many construction projects were delayed or canceled. This led to an increased awareness of the importance of sustainable and resilient construction practices, leading to an increased demand for superplasticizers materials.

- Turnover in renovation building construction increased by 8.2% in the first quarter of 2020, and the volume of commercial development has increased, reaching an impressive $137.48 billion in 2019.

Historical Trends:

- Superplasticizers, also known as high-range water reducers (HRWRs), are a type of chemical additive that can be used to improve the workability and strength of concrete. They were first developed in the 1960s, and their use has since become widespread in the construction industry.

- In the 1970s, a new class of superplasticizers based on sulfonated melamine-formaldehyde condensates was developed, which offered greater performance and compatibility. These superplasticizers, known as melamine-based superplasticizers, were able to reduce the water content of concrete mixtures by up to 35%, while still maintaining workability and increasing strength.

- Japan created an innovative form of superplasticizer based on a polycarboxylic acid polymer in 2003, which was discovered to be particularly successful in lowering the water content of concrete mixtures while retaining workability and strength.

- In 2006, a new class of superplasticizers known as viscosity-modifying admixtures (VMAs) was developed, which were designed to improve the workability and viscosity of high-performance concrete mixtures. VMAs are typically based on polymers such as cellulose ethers and polyethylene glycols.

- In 2012, the U.S. developed a new type of superplasticizer based on a polymer called hydroxy alkylated polyacrylamide (HAPA), which was found to be highly effective in reducing the water content of concrete mixtures while still maintaining workability and strength. This new superplasticizer was found to be more environmentally sustainable than traditional superplasticizers based on synthetic polymers.

- Canada produced a novel form of superplasticizer based on a protein isolated from canola seeds in 2018, which was proven to be particularly successful in lowering the water content of concrete mixtures while retaining workability and strength.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the superplasticizers market analysis from 2021 to 2031 to identify the prevailing superplasticizers market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the superplasticizers market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global superplasticizers market trends, key players, market segments, application areas, and market growth strategies.

Superplasticizers Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 19.1 billion |

| Growth Rate | CAGR of 7.2% |

| Forecast period | 2021 - 2031 |

| Report Pages | 350 |

| By Form |

|

| By Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | GCP Applied Technologies Inc., Arkema, Beijing Dongke United Technologies Co.,Ltd, Rhein-Chemotechnik GmbH, MAPEI, Enaspol a.s., Tripolarcon Pvt Ltd., CHRYSO, BASF SE, Sika AG |

Analyst Review

According to the opinions of various CXOs of leading companies, the superplasticizers market is driven by rise in demand from liquid industry. Liquid superplasticizers can be used in the production of decorative concrete, which is a type of concrete that is colored, stamped, or textured to resemble natural stone or other materials. The addition of liquid superplasticizers can increase the workability of the concrete, making it easier to apply and shape into various decorative designs.

Surge in construction and infrastructural activities drive the market growth of superplasticizers market. Superplasticizers are chemical additives used in the construction and infrastructure industries to improve the workability and strength of concrete. They can greatly enhance the fluidity of concrete, allowing it to be easily poured, shaped, and placed in a variety of configurations. Precast concrete components can be designed to meet specific load-bearing requirements.

However, high cost of superplasticizer is expected to restrain industry expansion. Superplasticizers are used in the construction industry to improve flowability & pumpability of concrete and reduce water content. They are more expensive than other concrete admixtures and offer unique benefits such as increased workability and reduced water content.

The Asia-Pacific region is projected to register robust growth during the forecast period. Superplasticizers are becoming increasingly popular in the construction industry in Asia-Pacific due to their ability to reduce the amount of cement and water needed in concrete production. The Airports Authority of India (AAI) is planning to create new airports and expand and upgrade existing airports at a cost of $338 million.

New product developments and technological advancements are upcoming trend of superplasticizers market.

The superplasticizers market is segmented into form, type, application, and region. On the basis of form, the market is bifurcated into powder and liquid. On the basis of type, it is categorized into lignosulphonates, sulphonated melamine formaldehyde, sulphonated naphthalene formaldehyde, and polycarboxylate derivatives. On the basis of application, the market is classified into ready-mix concrete, precast concrete, self-compacting concrete, and others.

The leading application of superplasticizers market are ready-mix concrete, precast concrete, self-compacting concrete, and others.

Asia-Pacific is the largest regional market for superplasticizers market.

Growth in preference for precast concrete in the construction industry is the driving factor of superplasticizers makert.

Arkema, BASF SE, Beijing Dongke United Technologies Co.,Ltd, CHRYSO, Enaspol a.s., GCP Applied Technologies Inc., MAPEI, Rhein-Chemotechnik GmbH, Sika AG, and Tripolarcon Pvt Ltd. are the top companies to hold the market share in superplasticizers market.

The superplasticizers market was valued at $9.7 billion in 2021, and is projected to reach $19.1 billion by 2031, growing at a CAGR of 7.2% from 2022 to 2031.

Loading Table Of Content...

Loading Research Methodology...