Tungsten Electrode Market Research, 2030

The global tungsten electrode market was valued at $103.8 million in 2023, and is projected to reach $123.8 million by 2030, growing at a CAGR of 2.6% from 2024 to 2030.

Market Introduction and Definition

A tungsten electrode is a crucial component in various industrial processes, particularly in welding. Tungsten electrodes come in various compositions, with the most common being pure tungsten or alloys blended with other elements such as thorium, cerium, or lanthanum. Each composition offers unique advantages, such as improved stability of the arc, increased resistance to contamination, and enhanced longevity. The selection of a specific tungsten electrode composition depends on the welding process, material, and desired outcome, highlighting the versatility and adaptability of tungsten in meeting diverse industrial requirements. The tungsten electrodes find extensive application in both direct current (DC) and alternating current (AC) welding processes, further underscoring their versatility. Whether used in tungsten inert gas (tig) welding, plasma arc welding (paw) , or other specialized techniques, tungsten electrodes contribute significantly to the precision and efficiency of the welding operation.

The aerospace industry extensively relies on tungsten electrodes for welding critical components such as aircraft fuselages, engine parts, and structural components. TIG welding with tungsten electrodes ensures the integrity and strength of welds in aerospace applications, where precision and reliability are paramount. Moreover, tungsten electrodes are used in the manufacture and repair of spacecraft, satellites, and other aerospace equipment due to their ability to weld various metals and alloys effectively.

In the automotive industry, tungsten electrodes find applications in welding chassis, engine components, exhaust systems, and body panels. TIG welding with tungsten electrodes enables automakers to achieve high-quality welds with minimal distortion, ensuring the structural integrity and longevity of vehicles. Additionally, tungsten electrodes are used in the fabrication of electric vehicle batteries, where precision welding is crucial for assembling battery cells and modules.

Key Takeaways:

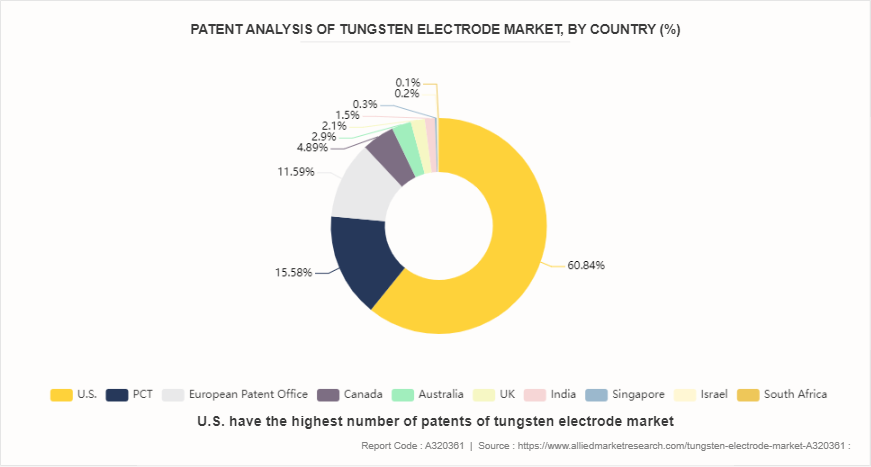

The tungsten electrode magnet industry covers 20 countries. The research includes a segment analysis of each country in terms of value ($million) for the projected period (2024-2030) .

The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of the global tungsten electrode market overview and to assist stakeholders in making educated decisions to achieve their growth objectives.

Over 3,700 product literature, annual reports, industry statements, and other comparable materials from major industry participants were reviewed to gain a better understanding of the tungsten electrode market size.

The tungsten electrode market share is highly fragmented, with several players including Diamond Ground Products, Astaras, Inc., Weldstone, Winner Tungsten Products Co. Ltd., Huntingdon Fusion Techniques, Metal Cutting, BGRIMM, Advanced Materials Science & Technology Co., Ltd., Sunrain Tungsten, and ATTL Advanced Materials Co., Ltd. Also tracked key strategies such as acquisitions, product launches, mergers, and expansion of the players operating in the tungsten electrode market growth.

Market Segmentation

The tungsten electrode market is segmented into product type, application, and region. By product type, the market is divided into pure tungsten, thoriated tungsten, lanthanum tungsten, cerium tungsten, and others. Based on application, the market is categorized into TIG welding, plasma welding, thermal spray and cutting. Region-wise the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Physical Properties of Tungsten Property Value Chemical Abstracts Service (CAS) Number 7440-33-7 Physical Description (physical state at room temperature) Hard, steel-gray to tin-white solid Molecular weight (g/mol) 183.85 Water solubility Insoluble Insoluble Boiling point (o C at 760 mm Hg) 5,900 Melting point (o C) 3,410 Vapor pressure at 2,327o C (mm Hg) 1.97x10-7 Specific gravity/Density at 20/4 o C 18.7 to 19.3

Key Market Dynamics

Innovations in welding technologies, such as Tungsten Inert Gas (TIG) welding, rely heavily on tungsten electrodes, driving the demand for these electrodes. Tungsten's high melting point (3422°C) , excellent electrical conductivity, and resistance to thermal deformation make it an ideal material for welding applications. These properties enable tungsten electrodes to produce a stable arc and consistent heat input, which are essential for achieving precise and strong welds, especially in high-precision industries such as aerospace, automotive, and manufacturing of medical devices. Furthermore, the versatility of TIG welding, which can be applied to a wide range of metals including stainless steel, aluminum, and magnesium, adds to the necessity for high-quality tungsten electrodes. TIG welding technology has further propelled the demand for tungsten electrodes. Advances such as inverter-based power sources have improved the control over the welding process, enhancing the quality and efficiency of welds. These power sources provide better arc stability, which is essential for delicate and intricate welding tasks.

In the construction industry, TIG welding is frequently employed in the fabrication and erection of structural steel frameworks. The precision and strength of TIG welds ensure that the joints and connections in the steel framework are robust and reliable, which is crucial for the overall stability of the structure. TIG welding is also used in the construction of pressure vessels and pipelines, where leak-proof and high-strength welds are mandatory to withstand high pressures and prevent failures. As per Wealth Nation, LLC, in January 2023, the U.S. construction industry's revenue was valued at around $2.8 trillion, with a 12.8% increase from January 2022. The industry's revenue has risen at an annualized rate of 2.7% from 2016 to 2021. Thus, the escalating construction activities drive the growth of tungsten electrodes market.

The expanding automotive and aerospace industries are pivotal drivers propelling the growth of the tungsten electrodes market. As these industries continue to evolve and embrace cutting-edge technologies, the demand for materials with exceptional durability, high melting points, and superior conductivity has intensified, placing tungsten electrodes in a prime position. In the automotive sector, the increasing focus on lightweight materials and advanced manufacturing techniques has led to a surge in the use of tungsten electrodes, especially in welding applications.

Simultaneously, Tungsten electrodes are used to weld various metals and alloys crucial in aerospace, including aluminum, titanium, and stainless steel. Each of these materials presents specific welding challenges, and tungsten electrodes, with their superior properties, help address these challenges effectively. For instance, titanium, widely used in aerospace for its strength-to-weight ratio and corrosion resistance, requires a stable and controlled welding environment. Tungsten electrodes provide the necessary arc stability and control to achieve defect-free welds in titanium components. According to the Aerospace Industries Association (AIA) , the Aerospace and defense industry’s workforce generated $952 billion in combined sales in 2022, a 6.7 percent increase from the prior year. Additionally, the Aerospace and Defense industry generated $418 billion in economic value, which represented 1.65% of total nominal GDP in the U.S. According to the Invest India, India's automotive industry is worth around %222 billion in 2022, while the EV market in India is estimated to be valued at $2 billion by 2023 and $7.09 Bn by 2025. Further, the automotive industry accounts for 8% of all national exports. This sector accounts for 40% of the total $31 Bn of global research and development spending. 1

However, the high initial cost of tungsten electrodes stands out as a substantial restraint in the growth of the market, posing challenges for industries and businesses seeking cost-effective solutions for welding applications. While tungsten electrodes offer unparalleled benefits in terms of durability, high melting point, and superior conductivity, the upfront expenses associated with their acquisition and implementation can be a significant restraint for potential users. Moreover, the complex manufacturing techniques required to produce high-quality tungsten electrodes contribute to the overall cost. The fabrication of tungsten electrodes involves precision machining, often incorporating advanced technologies to achieve the desired specifications. All these factors hamper the growth of the tungsten electrode market.

A notable opportunity for the tungsten electrode market lies in the increase in demand for automated welding systems. Automated welding systems are designed to perform welding operations with minimal human intervention. These systems utilize robotic arms, computer-controlled machinery, and advanced sensors to execute precise and repeatable welding tasks. The primary advantages of automated welding include increased production speed, improved weld quality, reduced labor costs, and enhanced safety. The integration of artificial intelligence (AI) and advanced robotics in welding systems further enhances the precision and adaptability of automated welding. AI-driven systems can optimize welding parameters in real time, improving efficiency and weld quality. In April 2022, ABB introduced the IRB 5710 and 5720 robots, designed for welding and available in eight configurations with payloads from 70 kg to 180 kg and reaching between 2.3 to 3 meters. These robots are versatile, and suitable for tasks such as material handling, machine tending, assembly, and specialized electric vehicle manufacturing processes, including battery module selection and placement, high-precision assembly, and component handling.

Regional Market Outlook

Region-wise the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. In North America and Asia-Pacific regions, the market is influenced by factors such as technological advancements, the presence of key manufacturing industries, and the demand for high-precision welding processes. Industries such as automotive, aerospace, and energy contribute significantly to the market's growth in this region.

In Europe, countries such as Germany, France, and the UK are prominent consumers of tungsten electrodes. The manufacturing sector, which encompasses automotive, machinery, and metalworking industries, relies heavily on TIG welding and other welding techniques that utilize tungsten electrodes. Additionally, the emphasis on environmental sustainability and energy efficiency in Europe has spurred the adoption of advanced welding technologies, further fueling the demand for high-performance tungsten electrodes.

The Asia-Pacific region, encompassing countries such as China, Japan, India, and South Korea, represents a significant market for tungsten electrodes due to the robust growth of manufacturing and construction activities. Rapid industrialization, urbanization, and infrastructure development in emerging economies drive the demand for welding consumables, including tungsten electrodes, to support fabrication, assembly, and construction processes. Moreover, the automotive and electronics industries in Asia-Pacific rely on precision welding techniques for manufacturing components and assemblies, creating a sustained demand for high-quality tungsten electrodes.

Competitive Analysis

Key market players in the tungsten electrode market include Diamond Ground Products, Astaras, Inc., Weldstone, Winner Tungsten Products Co. Ltd., Huntingdon Fusion Techniques, Metal Cutting, BGRIMM, Advanced Materials Science & Technology Co., Ltd., Sunrain Tungsten, and ATTL Advanced Materials Co., Ltd.

Industry Trends

In January 2022, the Plansee Group finalized an acquisition deal with Mi-Tech Tungsten Metals, a prominent company headquartered in Indianapolis. Mi-Tech, boasting nearly 100 employees, stands as a key player in the U.S. market for tungsten-based products

In September 2021, Kennametal Inc. unveiled KAR85-AM-K, a new tungsten carbide grade designed for metal additive manufacturing. This innovative material offers unparalleled resistance to corrosion, making it ideal for creating durable wear components. However, access to KAR85-AM-K is exclusively available through Kennametal's binder jet 3D printing technology, ensuring the production of fully finished wear parts with exceptional quality and performance.

Public Policies of Tungsten Electrode Market

Thoriated tungsten electrodes fall under the jurisdiction of the U.S. TSCA Inventory. Additionally, thorium dioxide, a component of these electrodes, is subject to reporting obligations outlined in Section 313 of Title III of the Superfund Amendments and Reauthorization Act of 1986 (SARA) and 40 CFR Part 372. In California, thorium dioxide is listed under Proposition 65 as a carcinogen and a reproductive toxicant.

Manufacturers of tungsten electrodes are typically required to provide Material Safety Data Sheets (MSDS) or Safety Data Sheets (SDS) that outline the potential hazards associated with the product and provide guidance on safe handling, storage, and disposal.

Key Sources Referred

Miller Electric Mfg. LLC

U.S. Geological Survey

Mineral Commodity Summaries

American Welding Society

U. S. Environmental Protection Agency (EPA)

Federal Facilities Restoration and Reuse Office (FFRRO)

Key Benefits For Stakeholders

This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the tungsten electrode market analysis from 2024 to 2033 to identify the prevailing tungsten electrode market opportunities.

The market research is offered along with information related to key drivers, restraints, and opportunities.

Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

In-depth analysis of the tungsten electrode market segmentation assists to determine the prevailing market opportunities.

Major countries in each region are mapped according to their revenue contribution to the global market.

Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

The report includes the analysis of the regional as well as global tungsten electrode market trends, key players, market segments, application areas, and market growth strategies.

Tungsten Electrode Market Report Highlights

| Aspects | Details |

| Market Size By 2030 | USD 123.8 Million |

| Growth Rate | CAGR of 2.6% |

| Forecast period | 2024 - 2030 |

| Report Pages | 300 |

| By Product Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | ATTL Advanced Materials Co., Ltd, Advanced Materials Science & Technology Co., Ltd., Astaras, Inc., Diamond Ground Products, Weldstone, Sunrain Tungsten, Huntingdon Fusion Techniques, BGRIMM, Metal Cutting, Winner Tungsten Products Co. Ltd. |

Loading Table Of Content...