White Goods Coatings Market Research, 2032

The global white goods coatings market size was valued at $5.6 billion in 2022, and is projected to reach $10.2 billion by 2032, growing at a CAGR of 6.2% from 2023 to 2032.

White goods refer to heavy consumer durables or large home appliances, which were traditionally available only in white. Although these goods are presently available in varied colors, they are continued to be called as white goods. They include appliances such as washers & dryers, refrigerators & freezers, dishwashers, microwave ovens, air conditioners, and others. These white goods require coatings that help to increase the durability, improve corrosion & heat resistance, and enhance aesthetic looks of white goods.

White goods manufacturers prefer application of coatings owing to several benefits such as material & functional improvement, high reproducibility, and greater design possibilities. In addition, they help streamline production and reduce environmental impact. Thus, all these factors are driving the growth of the global white goods coatings market. Leading companies in the white goods coatings industry produce coatings that meet all the demanding performance standards.

Furthermore, major companies in the white goods coatings market are producing coatings with a sizable percentage of raw materials that are bio-sourced. For example, Beckers Group, a well-known producer of industrial paint and coil coatings, is constantly investing in R&D to create coatings made from recycled or renewable raw materials.

Changing white goods market and rising demand for aesthetic pre-coatings on white goods

The modern consumer expects environmentally friendly items. Simultaneously, changing lifestyles and rising affluence in emerging nations have increased demand for a better assortment of household appliances to simplify and beautify homes; thus, aesthetics and usefulness are now equally vital.

Coatings are essential products that are used with wide assortment of appliances such as refrigerators, washers & dryers, and cooking appliances. Pre-coating technologies extend the service life of appliances by ensuring quality consistency, visual appeal, and superior performance after embossing. All these factors are contributing towards the white goods coatings market growth.

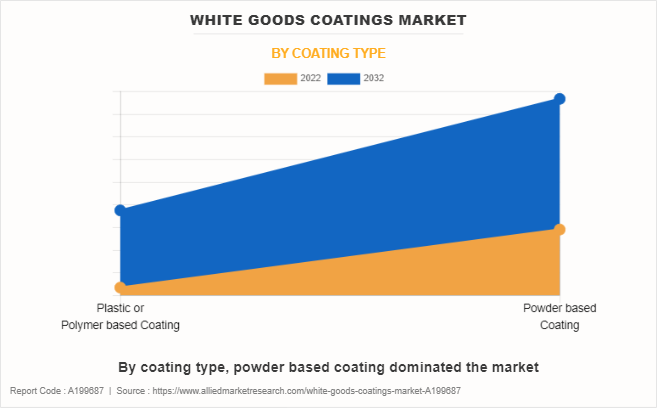

However, disadvantages associated with the use of powder-based coating on white goods is expected to hamper the market growth. Powder-based coatings tend to breakdown over UV rays and require baking process before application, which, in turn, increases application cost. In addition, powder-based coatings should be applied electrostatically and requires use of spray gun. These all factors tend to increase the cost of application, thus limiting the growth of the global market.

On the contrary, improvement in economic conditions is a key factor that contributes toward the growth of the white goods coatings market. In addition, increase in per capita disposable income enhances spending capacity of consumers, leading to rise in expenditure on premium household appliances, which is expected to surge the demand for white goods.

Moreover, rise in spending capacity is anticipated to improve the standard of living, enabling consumers to buy highly advanced and smart featured home appliances, which, in turn, boosts the demand for white goods. Increase in disposable income in developing countries of Asia-Pacific such as India and China has increased the expenditure on white goods. Thus, growing demand for white goods is anticipated to impact directly on the demand for coatings used on these white goods.

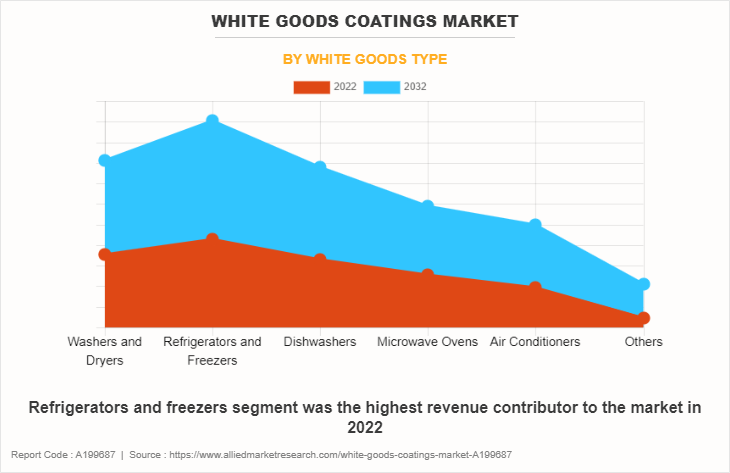

The global white goods coatings market forecast is segmented on the basis of coating type, white goods type, and region. By coating type, the market is bifurcated into plastic/polymer-based coating and powder-based coating. Depending on white goods type, the market is categorized into washers & dryers, refrigerators & freezers, dishwashers, microwave ovens, air conditioners, and others. Region wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Major applications of powder-based coatings include microwave ovens, small kitchen appliances, washers & dryers, and other white goods. These coatings can be used in industrial and domestic white goods, thus making them popular choice in the market. powder coatings that are used on white goods are long-lasting and resistant toward to wear & tear and other environmental effects. Moreover, powder coatings are durable toward high humidity range, UV radiation, and temperature changes, thus making powder coatings an ideal choice on white goods. Hence, a myriad of benefits associated with powder coatings are anticipated to boost the growth of the global market.

Powder coatings are proven to increase the longevity of refrigerators and freezers while also improving the aesthetic look and design of the appliance. Refrigerators and freezers are subjected to various climatic conditions, thus, the durability and resistance to wear and tear are dependent on the coating material. Powder coatings are resistant to chemicals and wear & tear, making them suitable for refrigerators and freezers.

Asia-Pacific is emerging to be one of the fastest growing markets and accounted for major white goods market share. White goods companies operating globally are planning to invest in the emerging countries of Asia-Pacific, including India, China, and Indonesia, owing to growing popularity of the smart and advanced appliances, increasing disposable income, and rising millennial population. Asia-Pacific is projected to grow at the highest CAGR, owing to the constantly expanding infrastructure and real estate sector, where air conditioning is largely demanded. Growing urbanization and high standard of living, especially in the developing countries including India and China, are driving the demand for white goods, which, in turn, is driving the demand for white goods coatings in Asia-Pacific.

The key players operating in the global white goods coatings industry include Axalta Coating Systems LLC, Dymax Corporation, The Sherwin-Williams Company, Akzonobel N.V., IFS Coatings, GMMDL, Tecno Supply, VitraCoat, WEILBURGER Coatings GmbH, and PPG Wörwag Coatings GmbH and Co. KG. In addition, the other value chain players in the white goods coatings market include Peka Chemie, Mader, thyssenkrupp AG, Pulver Inc., Thermaset Ltd, and others.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the white goods coatings market analysis from 2022 to 2032 to identify the prevailing white goods coatings market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the white goods coatings market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global white goods coatings market trends, key players, market segments, application areas, and market growth strategies.

White Goods Coatings Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 10.2 billion |

| Growth Rate | CAGR of 6.2% |

| Forecast period | 2022 - 2032 |

| Report Pages | 290 |

| By Coating Type |

|

| By White Goods Type |

|

| By Region |

|

| Key Market Players | Tecno Supply, VitraCoat, GMMDL, The Sherwin-Williams Company, Dymax Corporation, Axalta Coating Systems LLC., Akzonobel N.V., PPG Wörwag Coatings GmbH and Co. KG, WEILBURGER Coatings GmbH, IFS Coatings |

Analyst Review

According to various CXOs of leading companies, the white goods coatings market is expected to grow at a notable pace during the forecast period due to surge in demand for appliances such as air conditioners, dishwashers, washers & dryers, microwave ovens, and refrigerators. Coatings on white goods provide surface protection, chemical resistance, temperature resistance, mechanical resistance, and smooth surface finishing.

White goods manufacturers employ powder-based coatings on appliances because they are environmentally friendly and provide superior metal covering with effective coverage of sharp edges and weld joints. Thermoplastic powder coatings are high-performance coatings used on air conditioners and dishwashers by household and industrial appliance manufacturers. Polyethylene-based powder coatings are becoming more popular for interior appliance wire applications due to their low cost. Furthermore, due to their superior fluidizing characteristics, high stress-crack resistance, and food contact compliance, they are an ideal coating material for white goods, particularly microwave ovens and dishwashers. Key- layers in the white goods coatings industry offer innovative polyethylene powder-based coating products that offer high-performance as compared to nylon powder coatings. For instance, Axalta Coating Systems offers Talisman coating, which is used for white goods wire working applications. Talisman is a high-performance coating powder with properties like nylon powder. Talisman outperforms nylon in many ways and is a preferred choice for appliance manufacturers trying to decrease material costs while improving the quality of their coated products.

White goods manufacturers employ powder-based coatings on appliances because they are environmentally friendly and provide superior metal covering with effective coverage of sharp edges and weld joints. Thermoplastic powder coatings are high-performance coatings used on air conditioners and dishwashers by household and industrial appliance manufacturers. These are the upcoming trends of White Goods Coatings Market in the world

Refrigerators and Freezers is the leading application of White Goods Coatings Market

Asia-Pacific is the largest regional market for White Goods Coatings

The global white goods coatings market was valued at $5.6 billion in 2022 and is estimated to reach $10.2 billion by 2032, registering a CAGR of 6.2% from 2023 to 2032.

Axalta Coating Systems LLC, Dymax Corporation, The Sherwin-Williams Company, Akzonobel N.V., and WEILBURGER are the top companies to hold the market share in White Goods Coatings.

Loading Table Of Content...

Loading Research Methodology...