Painting Robots Market Research, 2034

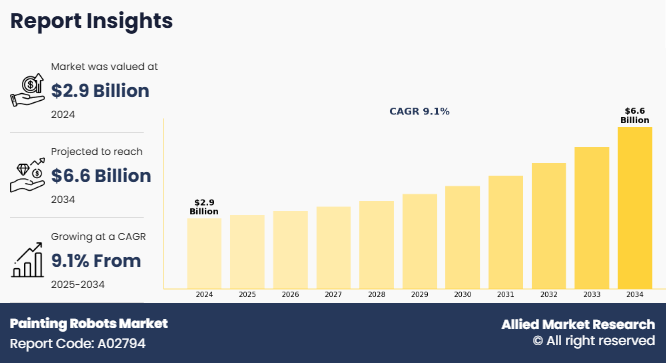

The global painting robots market was valued at $2.9 billion in 2024, and is projected to reach $6.6 billion by 2034, growing at a CAGR of 9.1% from 2025 to 2034.

Painting robots are programmable, automated robotic systems designed to apply paint or coatings on surfaces with high precision, consistency, and efficiency. Equipped with articulated arms, spray guns, and control units, these robots are commonly used in industrial applications such as automotive, aerospace, and general manufacturing.

Key Takeaways

- The Painting Robots Market Size covers 20 countries. The research includes a segment analysis of each country in terms of value ($Billion) for the projected period 2023-2033.

- More than 1,500 product literatures, industry releases, annual reports, and other such documents of major decorative coatings industry participants along with authentic industry journals, trade associations' releases, and government websites have been reviewed for generating high-value industry insights.

- The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and to assist stakeholders in making educated decisions to achieve their most ambitious growth objectives.

The rise in demand in automotive industry majorly drives the growth of the painting robots market, as these robots can apply paint and coating consistently on each part without wasting materials. Further, reliability, capability, and precision of the program helps paint large areas accurately within optimized time. Thus, the requirement of highly skilled painters is reduced. These factors majorly boost the growth of the painting robots market. However, high product and installation cost hinders the Painting Robots Marketgrowth.

The painting robots market is experiencing growth owing to the increase in adoption across key industrial sectors**. One of the primary drivers of the market is the increasing demand for automation in high-volume and precision-dependent industries, particularly the automotive sector. Painting robots offer exceptional consistency in finish quality, reduced paint wastage, shorter cycle times, and enhanced safety for workers by minimizing exposure to toxic fumes. In modern automotive production, robotic systems are capable of achieving transfer efficiency rates of up to 95%, significantly reducing material consumption and overspray losses. These capabilities directly translate into operational cost savings and improved environmental compliance, making robotic painting solutions highly attractive to automakers seeking leaner production and greener practices.

In addition, growing concerns about workplace safety and stringent environmental regulations related to volatile organic compounds (VOCs) have further reinforced the case for robotic painting systems. Regulatory frameworks such as the European Union’s Industrial Emissions Directive and the U.S. EPA’s National Emission Standards for Hazardous Air Pollutants (NESHAP) impose strict limits on VOC emissions, prompting manufacturers to replace manual spraying methods with closed-loop robotic systems. Painting robots, by design, limit the release of harmful chemicals into the environment, aligning well with corporate sustainability goals and industry mandates. The demand for robotic painting solutions is expected to rise steadily as more manufacturers across sectors adopt ESG frameworks and decarbonization initiatives**.

However, high initial installation costs and the complex integration of robotic systems into legacy production lines remain key challenges. A full robotic painting setup—including robotic arms, control software, paint circulation systems, and safety enclosures—can be cost-prohibitive for small and medium-sized enterprises (SMEs), especially those operating in cost-sensitive developing economies. In addition, the specialized skillsets required for programming, operating, and maintaining these robots often result in increased dependence on system integrators and automation consultants, which can further delay adoption timelines. Although return on investment (ROI) for robotic painting is generally favorable in the long term, the significant upfront capital requirements continue to hinder adoption among manufacturers with limited automation experience or resources.

Nevertheless, several emerging opportunities are fosteiring the growth of the Painting Robots Market. The shift toward customized production and the rise of Industry 4.0 have created demand for flexible, intelligent robotic systems capable of handling high-mix, low-volume product lines. In industries such as aerospace, electronics, furniture, and metal fabrication, manufacturers are increasingly deploying compact and collaborative painting robots that can adapt to varying shapes, sizes, and coating specifications with minimal human intervention. Integration of technologies such as artificial intelligence (AI), machine learning (ML), and industrial Internet of Things (IIoT) is enhancing the adaptability and efficiency of these systems. Smart painting robots can now auto-adjust spray paths based on part geometry, monitor coating thickness in real time, and conduct predictive maintenance to minimize downtime.

Moreover, regional market dynamics further underscore the potential for expansion. In Asia-Pacific, countries such as China, Japan, South Korea, and Taiwan are not only major consumers of painting robots but are also emerging as key manufacturers. These nations have made significant investments in automation infrastructure and are home to some of the largest global players in robotics technology. China, in particular, has established itself as a global hub for industrial robots through policy support, domestic R&D, and expanding manufacturing capacity. Simultaneously, countries like India, Vietnam, and Indonesia are witnessing growing adoption due to their expanding automotive and general manufacturing bases. In the LAMEA region, Brazil, Mexico, and the UAE are also exploring the use of painting robots in response to increased demand for export-quality production and the modernization of industrial plants.

The competitive landscape is witnessing developments that reflect the increasing interest in this space. Manufacturers are actively focusing on product innovation, such as lightweight robotic arms, faster control systems, and energy-efficient drive motors. Some are introducing modular and plug-and-play solutions to attract small manufacturers looking for scalable automation tools. For instance, in January 2024, FANUC introduced a new line of compact painting robots specifically designed for tier-2 automotive and industrial parts suppliers, featuring built-in AI-driven path optimization and energy-saving features that reduce power consumption by up to 20% compared to earlier models.

Despite these positive trends, challenges persist. Integration complexities, especially in retrofitting older plants, and the global shortage of robotics engineers remain barriers to widespread deployment. Furthermore, while developed markets such as North America, Western Europe, and Japan have achieved high penetration of robotic painting systems, developing markets are still catching up due to limited access to training, infrastructure, and financing options.

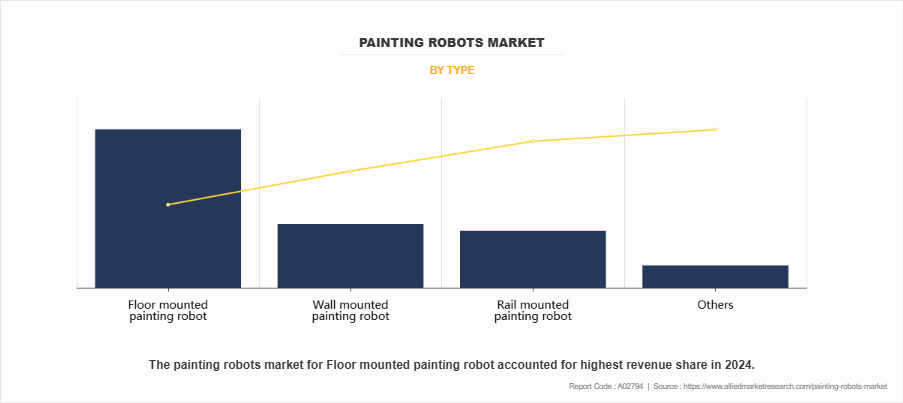

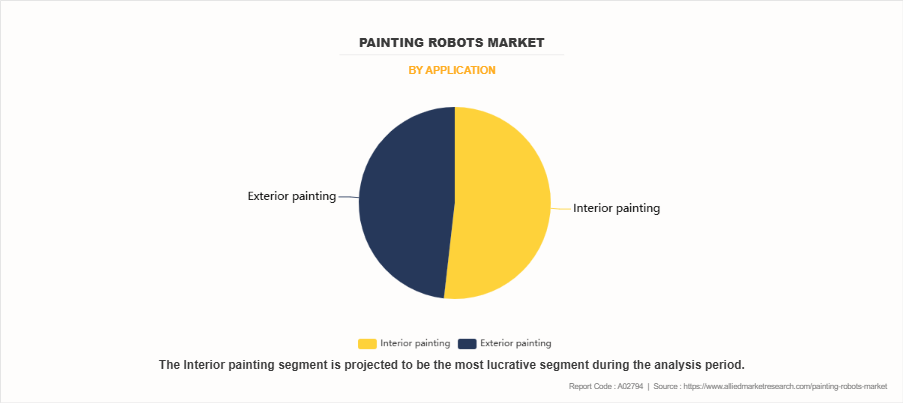

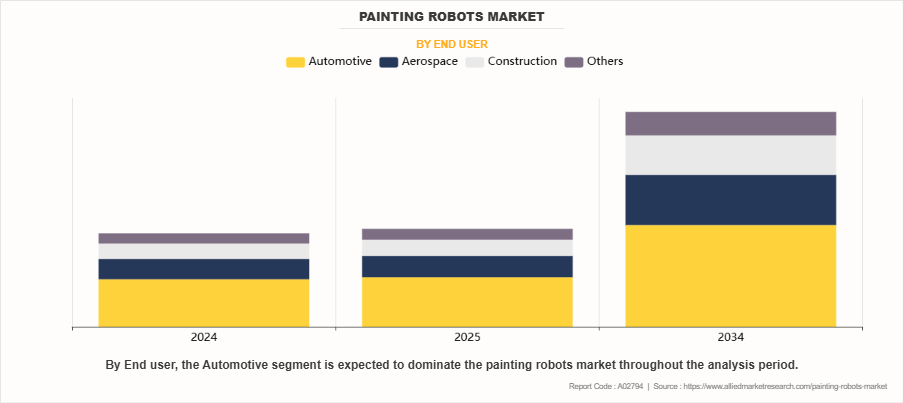

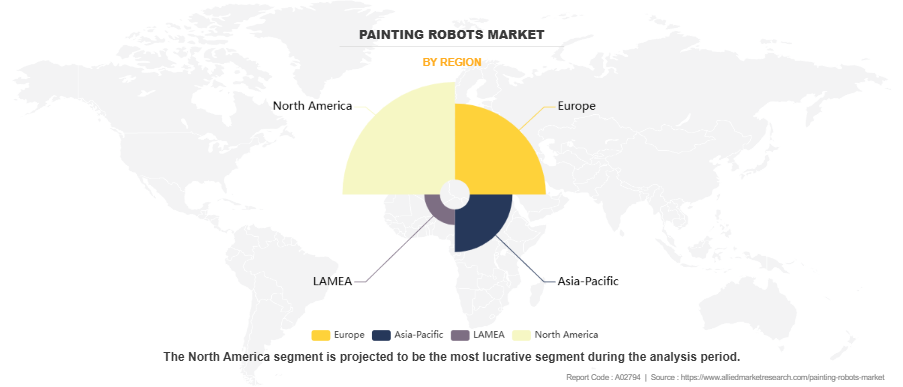

The painting robots market is segmented on the basis of product type, application, end user, and region. Based on product type the market is categorized into floor mounted painting robots, wall mounted painting robots, rail mounted painting robot, and others. Depending on application, the market is bifurcated into interior painting and exterior painting. By end user, the market is divided into automotive, aerospace, construction, and others**. Region-wise, the market is analyzed across North America (the U.S., Canada, and Mexico), Europe (UK, Germany, France, Italy, and rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and rest of Asia-Pacific), and LAMEA (Latin Ameria, Middle East & Africa).

By Type

The floor-mounted painting robot segment dominates due to its superior stability and ability to handle heavy payloads, making it ideal for large-scale industrial painting operations. Unlike other types, these robots can support extended arms and reach difficult surfaces with precision. Their robustness allows for continuous operation in high-volume manufacturing environments without significant wear or downtime. Additionally, floor-mounted robots can be customized with multiple axes and advanced control systems, enabling complex paint trajectories. Their adaptability across automotive, aerospace, and industrial equipment applications ensures consistent quality, reduced labor costs, and efficient paint usage, cementing their leading position in the Painting Robots Market.

By Application

The interior painting segment leads because of the increasing demand for high-quality, aesthetically pleasing finishes in residential, commercial, and industrial interiors. Automated painting ensures uniform coverage, reduces human error, and minimizes material wastage. Rising construction activity, urbanization, and interior remodeling projects globally drive adoption. Moreover, interior surfaces often require multiple layers of coating with precise color matching, which painting robots efficiently deliver. The need for faster project turnaround without compromising on quality further enhances robot usage. Integration with smart sensors and AI-based systems allows for adjustments in real time, making interior painting robots highly efficient and cost-effective compared to manual methods.

By End User

The automotive segment dominated the global maket in the year 2024 and is likely to remain dominant during the Painting Robots Market Forecast period. Consistency, precision, and speed are critical in automotive painting, where even minor defects can affect aesthetics and corrosion resistance. Robots reduce labor dependency, lower rework rates, and enhance throughput while ensuring uniform paint thickness across complex surfaces. The trend towards electric vehicles, customized finishes, and multi-layer coatings further boosts demand. Automotive manufacturers benefit from improved environmental compliance as robots optimize paint usage and reduce overspray. The combination of operational efficiency, high-quality output, and cost savings makes this segment the largest consumer of painting robots globally.

By Region

North America region had the dominating Painting Robots Market Share due to its advanced manufacturing infrastructure and high automation adoption. The region houses leading automotive, aerospace, and industrial equipment manufacturers, all of which invest heavily in robotics to improve productivity and maintain competitive advantage. Supportive government initiatives, research and development facilities, and access to cutting-edge technology accelerate deployment. Additionally, labor costs incentivize automation to reduce dependence on manual painting. High awareness of quality standards, stringent environmental regulations, and increasing focus on sustainable manufacturing practices further drive the adoption of painting robots. These factors collectively make North America the largest and most advanced Painting Robots Industry for painting robots.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the painting robots market analysis from 2024 to 2034 to identify the prevailing painting robots market opportunities.

- The Painting Robots Marketresearch is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the painting robots market segmentation assists to determine the prevailing Painting Robots Market Opportunity.

- Major countries in each region are mapped according to their revenue contribution to the global Painting Robots Industry.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the Painting Robots Market Outlook players.

- The report includes the analysis of the regional as well as global painting robots market trends, key players, market segments, application areas, and Painting Robots Market Growth strategies.

Painting Robots Market Report Highlights

| Aspects | Details |

| Market Size By 2034 | USD 6.6 billion |

| Growth Rate | CAGR of 9.1% |

| Forecast period | 2024 - 2034 |

| Report Pages | 300 |

| By End user |

|

| By Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | Durr Group, Stubli International AG, Kawasaki Robotics, CMA Robotics Spa, YASKAWA ELECTRIC CORPORATION, FANUC CORPORATION, Krautzberger GmbH, ABB, Epistolio Srl, KUKA AG |

Analyst Review

According to the perspectives of CXOs of the leading companies in the market, increasing demand for painting robots in the automotive industry drives market growth in the Asia-Pacific region. The automotive sector, with its high-volume production lines and strict quality standards, continues to adopt painting robots for their precision, repeatability, and ability to reduce paint wastage. Industry leaders have observed that these robots help achieve up to 30% savings in paint consumption due to improved transfer efficiency and reduced overspray. Moreover, their consistent performance and reduced cycle times contribute significantly to productivity gains.

However, high installation costs and expensive product prices are expected to hamper market growth. CXOs point out that the initial capital required for deploying robotic painting systems—especially those with advanced features like multi-axis control, vision systems, and AI-based programming—can be a deterrent for small and mid-sized enterprises. In addition, integration challenges with existing manual or semi-automated production lines further elevate the cost and complexity, delaying adoption in price-sensitive regions.

Moreover, emerging countries such as Japan, China, South Korea, and Taiwan are inclined towards manufacturing painting robots. According to industry executives, these nations are not only key adopters but are also heavily investing in R&D and local production to meet rising domestic and global demand. The presence of major robot manufacturers and automation solution providers in these regions accelerates innovation and helps reduce costs through localized supply chains. Furthermore, rising labor costs and stricter environmental regulations are pushing manufacturers in these countries to adopt robotic painting solutions to improve compliance and reduce operational hazards.

However, the need for painting robots is expected to grow in the Asia-Pacific and LAMEA regions during the forecast period. CXOs emphasize that rising industrialization, increased focus on workplace safety, and the shift towards sustainable manufacturing practices are key drivers behind this anticipated growth. In countries within the LAMEA region, especially those undergoing manufacturing expansion, painting robots offer a viable solution to address labor shortages and maintain consistent quality in mass production. Industry leaders also note a growing trend among manufacturers to upskill their workforce to manage and maintain robotic systems, further supporting the adoption of painting automation.

The global painting robots market was valued at $2,859.5 million in 2024, and is projected to reach $6,571.7 million by 2034, registering a CAGR of 9.1% from 2025 to 2034.

From 2024-2034 would be forecast period in the market report.

$2.8 billion is the market value of Painting robots market in 2024.

2024 is base year calculated in the Painting robots market report.

Durr Group, FANUC CORPORATION, Epistolio Srl, Krautzberger GmbH, YASKAWA ELECTRIC CORPORATION are the top companies hold the market share in Painting robots market.

Loading Table Of Content...

Loading Research Methodology...