3D Ceramic Printer Market Insight, 2032

The global 3D ceramic printer market was valued at $1.9 billion in 2022, and is projected to reach $12.7 billion by 2032, growing at a CAGR of 21.4% from 2023 to 2032.

A 3D ceramic printer is a specialized type of 3D printer designed to create three-dimensional objects using ceramic materials. It operates on the principles of additive manufacturing, where objects are built layer by layer, based on a digital 3D model. Unlike traditional ceramic manufacturing methods, which involve shaping and firing clay or other ceramic materials, 3D ceramic printing offers a more precise and efficient way to produce intricate ceramic components.

Expanding applications of ceramics in aerospace, automotive, and healthcare sectors acts as a major driver in the market. In addition, growing awareness of the benefits of 3D printing for ceramics among manufacturers is fueling the growth of the market. However, size limitations and scale-up challenges for large ceramic object and technical challenges in handling ceramic pastes and powders during printing is restraining the growth of the market. On the contrary, increased adoption of 3D ceramic printing in the consumer goods and home decor industries is expected to propel the market growth in upcoming years. In addition, growing market for artistic and creative ceramic designs using 3D printing technology is anticipated to create lucrative opportunities for 3D ceramic printer market in future.

The report focuses on growth prospects, restraints, and trends of the 3D ceramic printer market analysis. The study provides Porter’s five forces analysis to understand the impact of various factors such as bargaining power of suppliers, competitive intensity of competitors, threat of new entrants, threat of substitutes, and bargaining power of buyers on the 3D ceramic printer market outlook.

Segment Review

The 3D ceramic printer market is segmented into component, technology, end user, and region. By component, the market is classified into solution and service. By technology, it is bifurcated into binder jetting, fused deposition modelling (FDM), selective laser sintering (SLS), stereolithography (SLA), laminated object manufacturing (LOM), and others. By end user, the market is categorized into aerospace, automotive, healthcare, architecture, consumer goods, art, casting mold, and others. Region-wise, the market is analysed across North America, Europe, Asia-Pacific, and LAMEA.

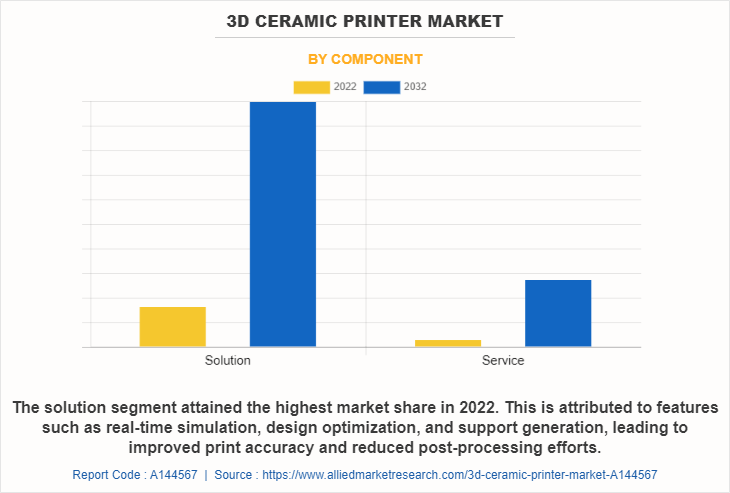

By component, the solution segment attained the highest 3D ceramic printer market share in 2022. This is attributed to features like real-time simulation, design optimization, and support generation, leading to improved print accuracy and reduced post-processing efforts. Further, solutions that enable the integration of ceramics with other materials like metals and polymers are gaining popularity.

Region wise, North America dominated the 3D ceramic printer market size in 2022. This was attributed to region's strong aerospace sector which is leveraging 3D ceramic printers for prototyping, rapid tooling, and manufacturing lightweight and high-temperature-resistant ceramic components. Further, the healthcare industry in North America has been exploring various applications of 3D ceramic printing, including patient-specific implants, dental restorations, surgical guides, and medical devices.

The key players that operate in the global 3D ceramic printer market include as 3D Systems, Inc, Voxeljet AG, Admatec BV, Lithoz, Wasp S.r.l., Tethon 3D, 3dceram, Prodways, DeltaBots, and Nanoe. These players have adopted various strategies to increase their market penetration and strengthen their position in the 3D ceramic printer industry.

Top Impacting Factors

Advancements in Printing Technology

The 3D ceramic printer market is driven by constant advancements in printing technology. As 3D printing technology improves, ceramic printers become more efficient, precise, and accessible. Innovations in print head design, material deposition methods, and slicing algorithms contribute to faster printing speeds and enhanced print quality. These developments attract more users, including artists, designers, and manufacturers, expanding the market. Further, the development of new ceramic materials compatible with 3D printing fuels market growth. Researchers and material manufacturers constantly explore novel ceramic compositions and blends suitable for 3D printing processes. These advancements expand the range of applications and drive the adoption of 3D ceramic printers across different industries.

Furthermore, the key players in the market are increasingly introducing new products to acquire a higher market share. For instance, in April 2023, Austrian ceramic 3D printing company Lithoz and Germany-based glass manufacturer Glassomer have launched a new 3D printing material called LithaGlass, a high-performance fused silica glass. With the introduction of LithaGlass, both firms have accelerated advancements in ceramics, glass, and 3D printing. LithaGlass is expected to have important consequences for a variety of industries. Thus, the advancements in printing technology is propelling the growth of the market.

Decrease in Labor Costs and Time Saving

3D ceramic printers streamline the manufacturing process by reducing labor costs and saving time. Automated printing eliminates the need for manual handling, cutting down on labor-intensive tasks. In addition, rapid prototyping and fast iteration cycles enable quicker product development, making 3D ceramic printing an attractive choice for businesses seeking efficiency gains. Further, for niche markets and limited production runs, 3D ceramic printing offers cost-effective solutions. Unlike traditional manufacturing, which often incurs significant setup costs for small-batch production, 3D ceramic printing allows for on-demand manufacturing without expensive tooling. This capability enables businesses to enter niche markets with lower financial risks.

Growing Use of 3D Ceramic Printers in Various Industries

The versatility of 3D ceramic printing fosters its adoption in numerous industries. From architecture, aerospace, and automotive to healthcare and art, 3D ceramic printers find applications in a wide range of fields. These printers enable the creation of complex geometries and functional ceramic components, driving their integration into various industrial processes. Further, the demand for personalized and customized ceramic products is on the rise, driving the growth of 3D ceramic printers. Consumers and businesses seek unique, tailor-made ceramic items that cannot be easily mass-produced using traditional manufacturing processes. 3D ceramic printers allow for intricate designs and varied shapes, enabling customization at a cost-effective rate. Thus, the growing use of 3D ceramic printers in various industries in fueling the growth of the market.

Market Landscape & Trends

One of the key factors propelling the 3D ceramic printer market growth is the introduction of new products in 3D ceramic printer market. For instance, in February 2023, SprintRay Inc., an industry leader in digital dentistry and 3D printing solutions announced the U.S. commercial launch of their Ceramic Crown 3D printing ecosystem, a complete solution set to transform same-day, chairside delivery of ceramic dental restorations. It enabled full end-to-end definitive chairside crown fabrication in less than 45 minutes, delivering tangible financial and time-saving benefits to both patients and providers.

Furthermore, the continuous developments and innovations in the market are expected to create lucrative opportunities for 3D ceramic printer market to grow during the forecast period. For instance, in April 2023, Austrian ceramic 3D printing company Lithoz and Germany-based glass manufacturer Glassomer launched a new 3D printing material called LithaGlass, a high-performance fused silica glass. Lithoz’s Lithography-based Ceramic Manufacturing (LCM) 3D printing technology is the only method able to 3D print LithaGlass with precision and complexity. The composite slurry, which has a quartz glass base, is expected to have a significant impact in the field of ceramics and 3D printing.

Moreover, some advancements are seen in enabling the 3D printing of ceramics along with other materials in a single process. This capability have opened up new possibilities for creating functional and multi-functional ceramic components with embedded sensors, electronics, or even other materials like metals or polymers.

COVID-19 pandemic has had a significant impact on the 3D ceramic printer industry, owing to surge in demand for medical equipment, including ventilators and PPE (personal protective equipment). 3D printing, including ceramic 3D printing, played a significant role in rapidly producing some of these essential items, showcasing the potential of additive manufacturing during emergencies. Further, disruptions in global supply chains led some industries and governments to reevaluate their dependence on overseas manufacturing. This shift towards more localized production presented opportunities for 3D ceramic printing, allowing for on-demand manufacturing and reduced transportation times. However, the pandemic caused disruptions in global supply chains, affecting the availability of raw materials and components necessary for 3D ceramic printers. This led to delays in manufacturing and shipping, impacting the overall production capacity of 3D printers. Thus, the pandemic had a moderate impact on 3D ceramic printer industry.

Key Benefits for Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the 3D ceramic printer market analysis from 2022 to 2032 to identify the prevailing 3D ceramic printer market opportunity.

- The market research is offered along with information related to key drivers, restraints, and opportunities in the 3D ceramic printer market forecast.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the 3D ceramic printer market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global 3D ceramic printer market trends, key players, market segments, application areas, and market growth strategies.

3D Ceramic Printer Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 12.7 billion |

| Growth Rate | CAGR of 21.4% |

| Forecast period | 2022 - 2032 |

| Report Pages | 1021 |

| By Component |

|

| By Technology |

|

| By End User |

|

| By Region |

|

| Key Market Players | 3D Systems, Inc., Prodways, Tethon 3D, Nanoe, Lithoz, Voxeljet AG, Admatec BV, 3dCeram, DeltaBots, WASP S.r.l. |

Analyst Review

The 3D ceramic printer market is going through a major transformation in the ceramics industry, revolutionizing traditional ceramic manufacturing processes. By combining additive manufacturing principles with ceramic materials, these innovative printers offer unprecedented design freedom, material diversity, and reduced lead times. Further, the 3D ceramic printer market has experienced significant growth over the past few years, driven by advancements in printing technology, increasing demand for customized ceramic products, and a growing emphasis on sustainability and reduced waste in manufacturing processes.

The COVID-19 outbreak had a significant impact on the 3D ceramic printer market and has boosted the 3D ceramic printer market owing to increasing demand from healthcare sector globally. Moreover, during this global health crisis, the technological advancements in the 3D ceramic printer industry have automated long and hectic processes. This, as a result, has promoted the demand for 3D ceramic printer, thereby accelerating the revenue growth.

Furthermore, the 3D ceramic printer market is at the forefront of a transformative shift in ceramic manufacturing. With its ability to create complex, customized, and sustainable ceramic products, technology has transformed industries and drives innovation. As the market grows, continuous R&D efforts, coupled with strategic collaborations, are expected to propel the 3D ceramic printer market into new lucrative opportunities of ceramic manufacturing.The key players in the 3D ceramic printer market are 3D Systems, Inc, Voxeljet AG, Admatec BV, Lithoz, Wasp S.r.l., Tethon 3D, 3dceram, Prodways, DeltaBots, and Nanoe. Major players operating in this market have adopted various strategies that include business expansion and partnerships to reduce supply and demand gaps. With increase in awareness and demand for 3D ceramic printer across the globe, major players have collaborated on their product portfolio to provide differentiated and innovative product.

The upcoming market trends of 3D Ceramic Printer Market include advancements in 3D printing technology, growing adoption in the aerospace and healthcare industries, expanding applications in architecture and construction, and research and development of new ceramic materials.

At a CAGR of 21.4%, the 3D Ceramic Printer Market will expand from 2023 - 2032.

Advancements in printing technology Decrease in labor costs and time saving Growing use of 3D ceramic printers in various industries

The 3D ceramic printer market analysis includes top companies operating in the market such as 3D Systems, Inc, Voxeljet AG, Admatec BV, Lithoz, Wasp S.r.l., Tethon 3D, 3dceram, Prodways, DeltaBots, and Nanoe.

Loading Table Of Content...

Loading Research Methodology...