Abrasive Paper Market Research, 2032

The global abrasive paper market size was valued at $4.4 billion in 2022, and is projected to reach $6.6 billion by 2032, growing at a CAGR of 4.3% from 2023 to 2032.

Report Key Highlighters:

- The global abrasive paper market has been analyzed in terms of value ($Million). The analysis in the report is provided on the basis of type, abrasive grain, application, 4 major regions, and more than 15 countries.

- The global abrasive paper market report includes a detailed study covering underlying factors influencing the industry opportunities and trends.

- The abrasive paper market is fragmented in nature with few players such as 3M, Bosch Limited, Deerfos, Hermes Schleifmittel GmbH, Klingspor AG, Mirka Ltd, MISUMI Corporation, Saint-Gobain, sia Abrasives Industries AG, and VSM AG.

- The report facilitates strategy planning and industry dynamics to enhance decision making for existing market players and new entrants entering the abrasive paper industry.

- Countries such as China, U.S., India, Germany, and Brazil hold a significant share in the global abrasive paper market.

Abrasive paper is a coated abrasive material used for various surface preparation, finishing, and material removal applications. It consists of abrasive grains or particles that are securely bonded to a backing material such as paper, cloth, or fiber. The abrasive particles on the surface of the paper are responsible for the abrasive action. It is widely used in woodworking, metalworking, automotive refinishing, and other industries where precise material removal or surface finishing is required. It is available in various grit sizes, each denoting the coarseness or fineness of the abrasive particles.

The surge in metal fabrication and metalworking industries has significantly contributed to the escalating demand for abrasive paper. As these industries experience rapid growth and expansion, the need for efficient surface preparation, finishing, and material removal increases the demand for abrasive paper. Abrasive paper, with its versatile and abrasive composition, emerges as a critical tool in addressing the intricate requirements of metalworking processes. Furthermore, the demand for abrasive paper in metalworking extends beyond traditional manufacturing processes to include tasks such as metal surface finishing, polishing, and deburring. All these factors increase the demand for the abrasive paper market during the forecast period.

However, volatility in raw material prices poses a considerable challenge for abrasive paper manufacturers as it led to increased production costs and profit margins. Abrasive grains are a significant component subject to market dynamics such as global supply and demand fluctuations, geopolitical events, and changes in extraction and processing costs. These factors result in sudden and unpredictable spikes in raw material prices that make it challenging for manufacturers to plan and budget effectively. All these factors hamper the abrasive paper market growth.

Rise in global emphasis on sustainable and eco-friendly practices has significantly impacted various industries such as the abrasive paper sector. As environmental consciousness grows, there is an increase in focus on adopting sustainable abrasives, creating notable opportunities within the abrasive paper market. Traditional abrasive materials often involve minerals such as aluminum oxide or silicon carbide, which have environmental implications during extraction and manufacturing. In response to this, manufacturers are exploring alternative, eco-friendly materials and production processes that align with sustainability goals. This shift toward sustainable abrasives addresses environmental concerns and caters to a market increasingly influenced by conscientious consumption. All these factors are anticipated to offer new growth opportunities in abrasive paper market forecast.

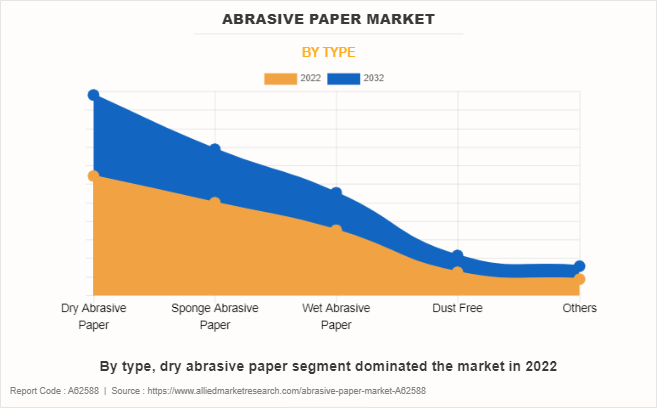

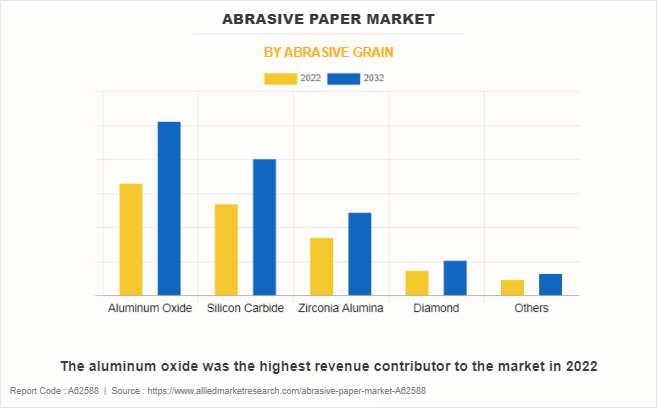

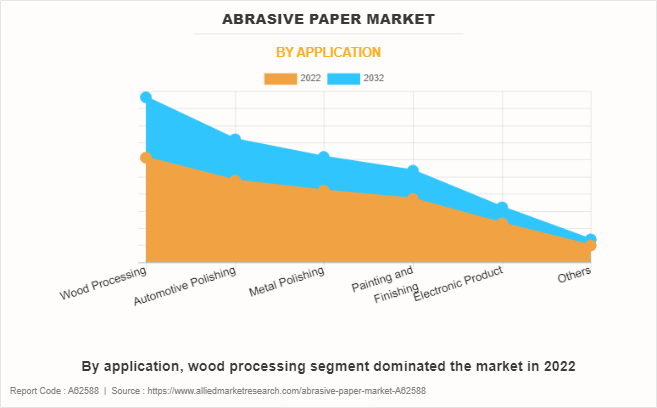

The abrasive paper market is segmented on the basis of type, application, abrasive grain, and region. On the basis of type, the market is divided into dry abrasive paper, wet abrasive paper, sponge abrasive paper, dust free, and others. On the basis of application, the market is segmented into wood processing, metal polishing, electronic product, painting and finishing, automotive polishing, and others. On the basis of abrasive grain, the market is segmented into aluminum oxide, silicon carbide, zirconia alumina, diamond, and others. Region-wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA

Dry abrasive paper segment accounted for one-third of global abrasive paper market share in 2022 and is expected to maintain its dominance during the forecast period. The continuous evolution and innovation in manufacturing processes increase the demand for dry abrasive paper. As industries such as automotive, woodworking, and metalworking, adopt advanced technologies and machinery, the demand for dry abrasive paper with improved abrasion properties, durability, and precision increases. In addition, the compatibility of dry abrasive paper with automated systems and high-speed machinery is crucial for enhancing overall efficiency in industrial applications.

Aluminum oxide segment accounted for less than two-fifths of global abrasive paper market share in 2022 and is expected to maintain its dominance during the forecast period. Aluminum oxide has a crucial role in its prominence in abrasive paper manufacturing. It is available in various grit sizes, enabling the production of abrasive papers suitable for tasks ranging from coarse material removal to fine finishing. This versatility makes aluminum oxide abrasive paper adaptable to diverse applications within industries such as metalworking, woodworking, and automotive, meeting the specific requirements of each task.

Wood processing segment accounted for more than one-fourth of global abrasive paper market share in 2022 and is expected to maintain its dominance during the forecast period. Abrasive papers with their varying grit sizes and compositions, play a crucial role in shaping, smoothing, and refining wooden surfaces, ensuring that the final products meet stringent quality standards.

Asia-Pacific accounted for more than two-fifths of global abrasive paper market share in 2022 and is expected to maintain its dominance during the forecast period. The increase in adoption of advanced technologies and automation in manufacturing processes across Asia-Pacific has led to a higher demand for precision and efficiency in surface treatment. This drives the need for abrasive papers with specific characteristics such as consistent grit size, durability, and suitability for automated machinery.

Key players in the abrasive paper industry include 3M, Bosch Limited, Deerfos, Hermes Schleifmittel GmbH, Klingspor AG, Mirka Ltd, MISUMI Corporation, Saint-Gobain, sia Abrasives Industries AG, and VSM AG.

Apart from these major players, there are other key players in the abrasive paper market. These include Abmast Abrasives Corp, Abrasiflex Pty Ltd, Asahi Diamond Industrial Co.,Ltd., August Rüggeberg GmbH & Co. KG, AWUKO ABRASIVES Wandmacher GmbH & Co. KG, Ekamant, Flexovit, Jiangsu Sanling Abrasive Co., Ltd., Keystone Abrasives, Orient Ceratech, RHODIUS, Tyrolit - Schleifmittelwerke Swarovski AG & Co K.G., Uneeda Enterprizes, Inc., and Winoa.

Historical Trends Of Abrasive Paper:

- In the early 20th century, the industrial production of abrasive paper gained momentum. Companies such as 3M and Norton pioneered the manufacturing processes, introducing coated abrasives with improved backing materials. The innovation provided a more durable and versatile solution for surface preparation in industries such as woodworking and metalworking.

- The mid-20th century witnessed significant advancements in abrasive paper technology. Coated abrasives became more widely accessible, offering a range of grit sizes and backings. This era marked the widespread adoption of abrasive paper in automotive refinishing, construction, and various industrial applications.

- In the late 20th century, advancement was made in the performance of synthetic abrasives such as aluminum oxide and silicon carbide. These materials contributed to improved cutting efficiency, durability, and versatility, expanding the range of applications to include precision grinding, and finishing tasks.

- The late 1990s and early 2000s witnessed a shift towards environmentally friendly abrasive paper solutions. Abrasive manufacturers began exploring water-based adhesives and backing materials, reducing the environmental impact of production processes.

- In the 2010s, abrasive paper technology continued to evolve, with a focus on specialized applications. Abrasive papers tailored for specific industries, such as electronics manufacturing and aerospace, emerged. The market witnessed innovations in microreplication technology, allowing to produce abrasive papers with precisely engineered abrasive patterns.

- The early 2020s marked a phase of ongoing innovation in abrasive and waterproof paper. Manufacturers explored advanced bonding techniques, introducing resin-over-resin bonding for increased durability. Abrasive papers with self-sharpening abrasives and anti-clogging features became prevalent, catering to the demand for efficient and long-lasting surface finishing solutions.

Key Potential Factors That Drive The Abrasive Paper Market Demand:

In the global abrasive paper market, an increasing number of companies have adopted expansion and partnership to expand the market or develop new products. For instance, in August 2023, 3M had inaugurated its first abrasive robotics lab in India, located at its Bengaluru center. 3M utilizes robotic processing in its manufacturing operations and product development within its labs. It also employs emerging technologies such as machine learning to create automation-ready products that perform highly in industrial settings. Also in November 2021, Saint-Gobain abrasives announced new partnership with Dedeco abrasive products. This partnership helps to deliver the most comprehensive abrasives solutions.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the abrasive paper market analysis from 2022 to 2032 to identify the prevailing abrasive paper market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the abrasive paper market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global abrasive paper market trends, key players, market segments, application areas, and market growth strategies.

Abrasive Paper Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 6.6 billion |

| Growth Rate | CAGR of 4.3% |

| Forecast period | 2022 - 2032 |

| Report Pages | 270 |

| By Type |

|

| By Abrasive Grain |

|

| By Application |

|

| By Region |

|

| Key Market Players | MISUMI Corporation, HERMES Schleifmittel GmbH, Bosch Limited, Mirka Ltd, deerfos, 3M, sia Abrasives Industries AG, Klingspor AG, Saint-Gobain, VSM AG |

Analyst Review

According to the opinions of various CXOs of leading companies, the abrasive paper market is expected to grow during the forecast period. Surge in metal fabrication and metalworking industries, and expansion in automotive and aerospace sectors have increased the demand for abrasive paper. Abrasive paper serves as a fundamental tool in surface preparation, finishing, and material removal processes that makes it an essential component in manufacturing and construction activities.

The market growth is driven by expanding industrial applications, where abrasive paper has versatile use in sectors such as automotive, metalworking, woodworking, and electronics. In addition, technological advancements in abrasive materials such as synthetic ceramics abrasives and super abrasives, contribute to improved cutting efficiency and durability which drives the market expansion. The demand for high-precision finishing, driven by industries such as aerospace and electronics, is also a key factor propelling the growth of the abrasive paper market.

The global abrasive paper market was valued at $4.4 billion in 2022, and is projected to reach $6.6 billion by 2032, registering a CAGR of 4.32% from 2023 to 2032.

Wood processing is the leading application of Abrasive Paper Market

Asia-Pacific is the largest regional market for Abrasive Paper

Surge in metal fabrication and metalworking industries and expanding automotive and aerospace sectors are the leading drivers for the Abrasive Paper Market

Integration of abrasives in 3D printing is the upcoming trends of Abrasive Paper Market in the world

Asia-Pacific is the fastest growing region for the Abrasive Paper Market

Key players in the abrasive paper market include 3M, Bosch Limited, Deerfos, Hermes Schleifmittel GmbH, Klingspor AG, Mirka Ltd, MISUMI Corporation, Saint-Gobain, sia Abrasives Industries AG, and VSM AG.

Loading Table Of Content...

Loading Research Methodology...