Aerospace Robotics Market Outlook, 2030

The global aerospace robotics market size was valued at $2.9 billion in 2020, and is projected to reach $9.2 billion by 2030, growing at a CAGR of 12.69% from 2021 to 2030. Aerospace robotics is a robotic technology used to manufacture aircraft in aerospace industry. Aerospace robots are utilized for various tasks, including engine drilling holes, manufacturing, welding metal parts, and painting airframes. Various positive aspects of aerospace robotics technology, including high precision, flexible automation, capacity to conduct repeatable operations, and high-speed production are critical in aircraft manufacturing.

Increase in need for efficient manufacturing of aircraft, surge in use of robotics to handle aircraft order backlog, and rise in labor cost boost demand for robotic solutions, machines, and equipment for aircraft manufacturing. However, high costs associated with installation of robotic systems and lack of skilled workforce limit adoption of robotic systems in aerospace industry.

On the contrary, technological advancements, including artificial intelligence (AI), Internet of Things (IoT), cloud computing & 3D vision technology, and high paced growth in aerospace industry are expected to provide lucrative growth opportunities for the aerospace robotics industry in future.

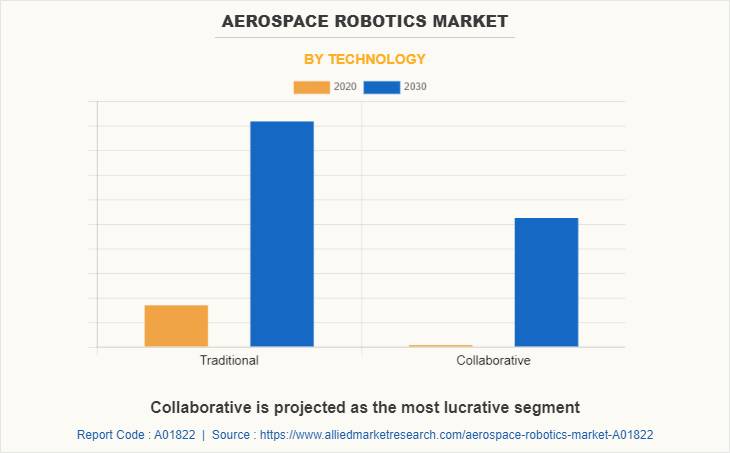

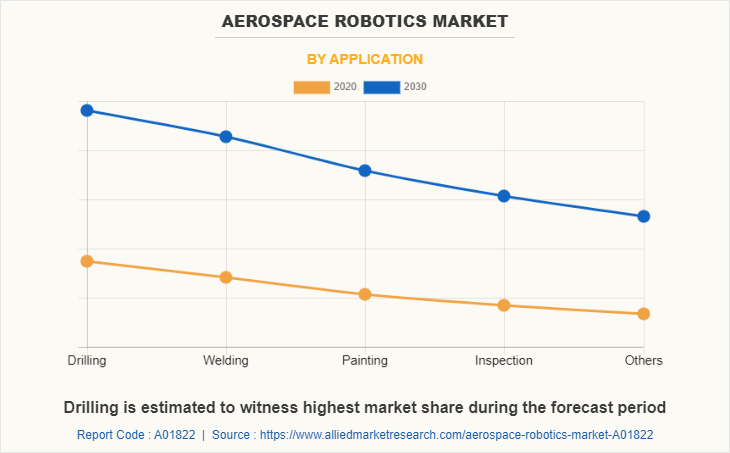

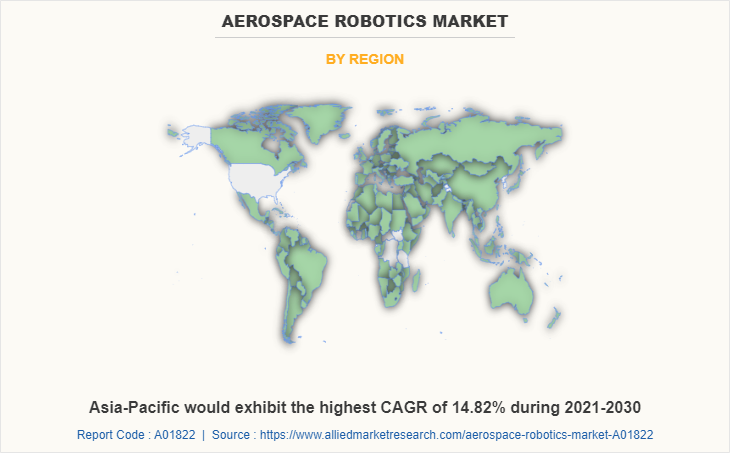

The aerospace robotics market is segmented on the basis of technology, application, type, and region. Depending on technology, it is segmented into traditional and collaborative. According to application, it is bifurcated into drilling, welding, painting, inspection, and others. As per the type, it is categorized into articulated, cartesian, and others. Region wise, it is analyzed across North America (the U.S., Mexico, and Canada), Europe (the UK, Germany, France, and rest of Europe), Asia-Pacific (China, India, Japan, and rest of Asia-Pacific), and LAMEA (Latin America, Middle East, and Africa).

The key players profiled in this aerospace robotics market report include ABB, AV & R, Electroimpact Inc., Fanuc Corporation, JH Robotics, Inc., KUKA AG, Mitsubishi Electric Corporation, OC Robotics, Universal Robots A/S, and Yaskawa Electric Corporation.

Increase In Need For Automation For Efficient Aircraft Production

Aerospace companies focus on automation of operational processes to reduce cost, save time, deliver high-quality products, and increase productivity to meet stiff competition. Aerospace robots automate internal processes and reduce workload of employees by working in collaboration with workers for better efficiency. Several companies, including Boeing Company, GKN Aerospace, Pratt & Whitney, and Airbus focus on deploying robots for manufacturing process of aerospace components. For instance, in October 2019,

Airbus started its highly automated fuselage structure assembly line for A320 Family aircraft in Hamburg. The new facility features 20 robots, a new logistics concept, automated positioning by laser measurement, and a digital data acquisition system. Furthermore, in 2019, the Boeing Company reported that technologists in South Carolina used artificial intelligence (AI) to drive assembly efficiency. The AI solution is being used to support fuselage section assemblies for Boeing 787.

Moreover, robots are used for various applications in aerospace industry, including drilling, painting, sealing, inspection, and engine fabrication. Large number of activities can be executed in less duration of time by robots in comparison with man power.

In addition, robot deployment by aerospace companies is growing, due to robotic systems being able to do repetitive tasks, including drilling a large number of holes in aircraft parts, welding of metal parts, and painting, which reduces costly rework. These factors propel growth of the adoption of robotic systems for efficient aircraft production. For instance, large and complex jigs are required for manual drilling process whereas, robots perform seamless drilling procedures without the help of jigs and fixtures.

Growth In Use Of Robotics To Handle Aircraft Order Backlog

Aircraft manufacturers including Airbus, Boeing Company, and others witness manufacturing backlog, owing to increase in number of aircraft orders and growth in number of passengers across the globe. For instance, according to the Airbus’s annual report 2020, in December 2020, backlog of 7,184 aircraft commercial orders was observed. Furthermore, as per the Boeing Company’s annual report 2020, backlog of more than 4,000 commercial airplane orders was reported.

Robotic devices used in the aerospace industry help in automated drilling and fastening operations, including welding, material handling, and aircraft parts handling. The aerospace robotics machines are flexible and lighter compared to the existing manufacturing machines.

Robotic devices help human operators in performing complex and repetitive manufacturing processes. Several industries, including automotive and aerospace adopt automation and robotic systems to speed up their production with maintaining quality to cover backlogs. For instance, in February 2022, according to the Association for Advancing Automation (A3), 39,708 robots sold in North America in 2021, a 14% over the previous high in 2017 and 28% increase over 2020.

Moreover, aerospace companies, including Airbus Group, Bombardier Inc., and the Boeing Company implement automation and robotics technologies in their manufacturing processes for development of humanlike robotic technology that can perform complex manufacturing tasks and are capable of working in hard-to-access parts of aircraft and handle a backlog of orders.

Lack Of Skilled Workforce

Unavailability of skilled labor for development and implementation of robotics technology hinder the growth of the aerospace robotics market. Existing workers in manufacturing sector, including automotive and aerospace industries lack the skills required for operating advanced robotic devices.

Technological Advancements

Aerospace robotics market is expected to significantly grow in future, owing to introduction of new technologies. Advancements, including Internet of Things (IoT), 3D vision technology, artificial intelligence, and cloud computing enhance the features of robotic devices used in aerospace industry.

Advanced ultrasonic and metrology inspection technologies used in robots help in performing operations, including delamination, cracks, and fastener inspections during assembly process in aircraft manufacturing industry.

In addition, advanced industrial robots can communicate with others for improved manufacturing process, owing to development of Internet of Things (IoT). For instance, in July 2021, Airbus introduced its new fully automated solar array production for aircraft and spacecraft. This new project combines 18 separate robots that work together to build solar cells in a seamless manner. Furthermore, in 2019, Airbus acquired MTM robotics, an industrial automation company for expanding advanced robotics capabilities within its manufacturing processes.

Moreover, robots are used for building various complex shapes of aircraft components using 3D printing. For instance, In January 2022, the Boeing Company developed the first 3D printed flight critical part for spin during test flights. In addition, in 2020, according to The Boeing Company’s 4th quarter report 2019, more than 70,000 3D-printed production parts fly through Boeing commercial and defense programs

Key Benefits For Stakeholders

This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the aerospace robotics market analysis from 2020 to 2030 to identify the prevailing aerospace robotics market opportunities.

The aerospace robotics market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the aerospace robotics market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global aerospace robotics market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global aerospace robotics market trends, key players, market segments, application areas, and aerospace robotics market growth strategies.

Aerospace Robotics Market Report Highlights

| Aspects | Details |

| By Technology |

|

| By Application |

|

| By Type |

|

| By Region |

|

| Key Market Players | Mitsubishi Electric Corporation, KUKA AG, ABB, Universal Robots A/S, JH Robotics, Inc., Electroimpact Inc., Fanuc Corporation, Yaskawa Electric Corporation, OC Robotics, AV&R |

Analyst Review

Increase in need for automation for efficient aircraft production and growth in labor cost contribute to growth of the market. The articulated robots segment dominated the aerospace robotics market and is expected to maintain its dominance during the forecast period. However, the demand for other types of robots, including cylindrical, Selective Compliance Articulated Robot Arm(SCARA), spherical, and parallel is expected to grow significantly among the aircraft manufacturing companies during the forecast period, due to several features, including omni-directions movements, locomotion with minimal friction, and constrained spaces.

Moreover, major players in the market developed and launched advanced robotic devices to cater wider customer base across various nations. For instance, in March 2022, Fanuc Corporation launched the new CRX-5iA, CRX-20iA/L, and CRX-25iA collaborative robots, the latest additions to its popular CRX series that includes the CRX-10iA and CRX-10iA/L collaborative robots. In addition, in November 2021, Fanuc Corporation launched the new LR-10iA/10 robot designed for machine tending and variety of picking applications. This new FANUC LR-10iA/10 industrial robot has fully enclosed structure features built-in airlines for easy integration.

Furthermore, technological advancements in robotic devices such as internet of things (IoT), 3D vision technology, artificial intelligence, and cloud computing attracts major market players in the aerospace industry, which, in turn, boost the adoption of aerospace robotics machines and equipment.

The aerospace robotics market is segmented on the basis of technology, application, type, and region. Depending on technology, it is segmented into traditional and collaborative. According to application, it is bifurcated into drilling, welding, painting, inspection, and others. As per the type, it is categorized into articulated, cartesian, and others. Region wise, it is analyzed across North America (the U.S., Mexico, and Canada), Europe (the UK, Germany, France, and rest of Europe), Asia-Pacific (China, India, Japan, and rest of Asia-Pacific), and LAMEA (Latin America, Middle East, and Africa).

The global aerospace robotics market valued at $2.85 billion in 2020, and is projected to reach $9.19 billion by 2030, registering a CAGR of 12.69% between 2021 and 2030

The leading companies operating in the aerospace robotics market are ABB, Fanuc Corporation, KUKA AG, and Yaskawa Electric Corporation

The report sample for global aerospace robotics market report can be obtained on demand from the website

Technology, Application, and Type are the key segments covered in the report on aerospace robotics

By technology, the aerospace robots are classified into traditional and collaborative

The company profiles of the top players of the market can be obtained from the company profile section mentioned in the report. This section includes analysis of top ten player’s operating in the industry along with their last three-year revenue, segment revenues, product offerings, key strategies adopted, and geographical revenue generated

High efficiency of robots in aerospace industry, faster aircraft manufacturing processes are the major opportunities in aerospace robotics industry

Loading Table Of Content...