Anti-corrosion Coating Market Research, 2033

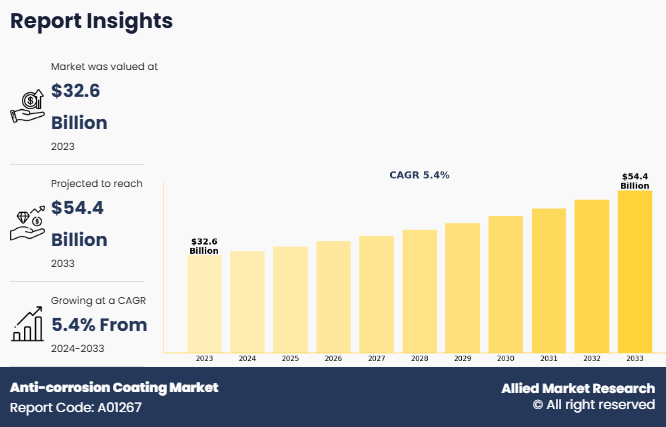

The global anti-corrosion coating market was valued at $32.6 billion in 2023, and is projected to reach $54.4 billion by 2033, growing at a CAGR of 5.4% from 2024 to 2033. Increase in demand for infrastructure development and rise in focus on sustainable coatings are key drivers of growth in the anti-corrosion coating market. Infrastructure projects such as bridges, highways, pipelines, and buildings require robust protective solutions to withstand environmental challenges and extend asset lifespans, leading to higher demand for anti-corrosion coatings. Moreover, the global push towards sustainability has spurred the development and adoption of eco-friendly coatings that reduce volatile organic compound (VOC) emissions and environmental impact without compromising on performance.

Introduction

Anti-corrosion coatings are protective layers applied to metal surfaces to prevent or slow down the process of corrosion caused by environmental factors such as moisture, chemicals, and temperature fluctuations. These coatings act as a barrier, shielding the underlying material from exposure to corrosive elements, thereby extending the lifespan and maintaining the structural integrity of the object or surface. Anti-corrosion coatings are made from various materials such as paints, powders, and specialized chemical formulations, and are commonly used in industries such as automotive, marine, construction, and manufacturing to safeguard metal components from deterioration.

Key Takeaways

- The global anti-corrosion coating market has been analyzed in terms of value ($Million). The analysis in the report is provided on the basis of type, technology, end-use industry, 4 major regions, and more than 15 countries.

- The global anti-corrosion coating market report includes a detailed study covering underlying factors influencing industry opportunities and trends.

- The anti-corrosion coating market is fragmented in nature with few players such as AkzoNobel N.V., PPG Industries, Inc., Sherwin-Williams Company, BASF SE, Nippon Paint Holdings Co., Ltd., Hempel A/S, Axalta Powder Coating Systems GmbH, Kansai Paint Co., Ltd., Sika AG, and 3M.

- The report facilitates strategy planning and industry dynamics to enhance decision making for existing market players and new entrants entering the industry.

- Countries such as China, the U.S., India, Germany, and Brazil, hold a significant share in the global anti-corrosion coating market.

Market Dynamics

Increase in demand for infrastructure development is a significant driver for the growing need for anti-corrosion coatings. As governments and private sectors worldwide invest in building and upgrading infrastructure such as bridges, roads, railways, ports, and high-rise buildings, the importance of protecting these structures from environmental wear and tear becomes paramount. Infrastructure projects involve the use of materials such as steel, iron, and concrete, all of which are vulnerable to corrosion when exposed to moisture, chemicals, and temperature fluctuations. Anti-corrosion coatings provide an essential solution to safeguard these materials from corrosion, which leads to structural failure, costly repairs, and safety hazards. All these factors are expected to drive the demand for the anti-corrosion coating market during the forecast period.

However, volatile organic compound (VOC) emissions and their associated environmental impact present a significant challenge to the growth of the anti-corrosion coating market. Traditional anti-corrosion coatings contain solvents that release VOCs during application and curing. These emissions contribute to air pollution, smog formation, and have harmful effects on human health, such as respiratory problems and other illnesses. As a result, governments and regulatory bodies across the globe have implemented stringent regulations to limit VOC emissions, which has placed pressure on manufacturers to modify their formulations and reduce reliance on solvent-based coatings. Compliance with these regulations requires extensive investment in research, reformulation, and changes to manufacturing processes, all of which increase costs and slow product adoption. All these factors hamper the anti-corrosion coating market growth.

Anti-coatings offer superior corrosion resistance, enhanced durability, and a range of other beneficial properties, such as self-healing and hydrophobicity. Advancements in coatings help end-use industries to protect their assets in harsh environments, thus extending the lifespan of structures and reducing maintenance costs. For instance, advancements in nanotechnology have enabled the creation of ultra-thin, high-performance coatings that provide exceptional protection against moisture, chemicals, and extreme temperatures. These next-generation coatings are particularly useful in industries such as oil and gas, marine, and construction, where exposure to harsh elements accelerate corrosion and degradation. All these factors are anticipated to offer new growth opportunities for the anti-corrosion coating market during the forecast period.

Segments Overview

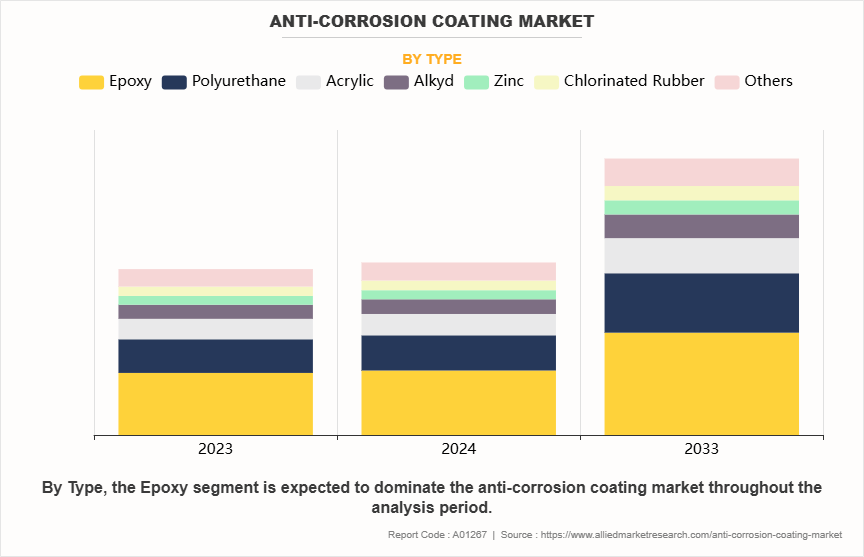

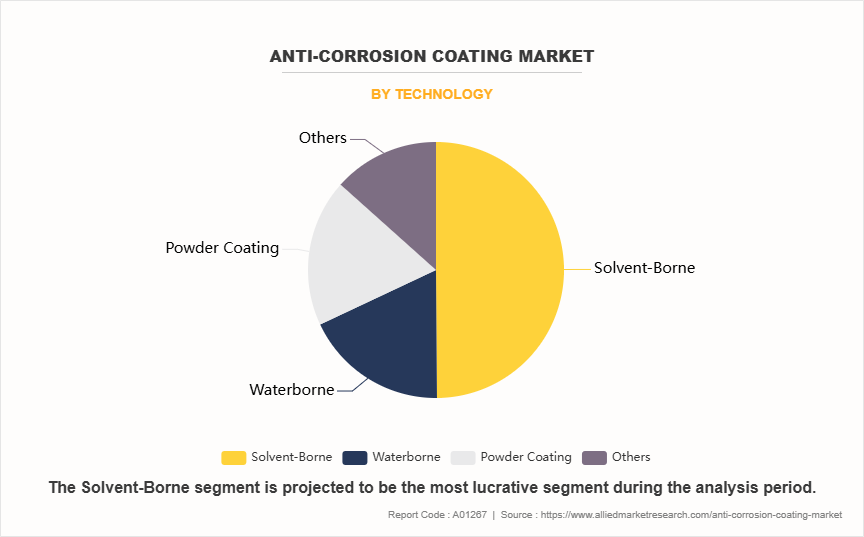

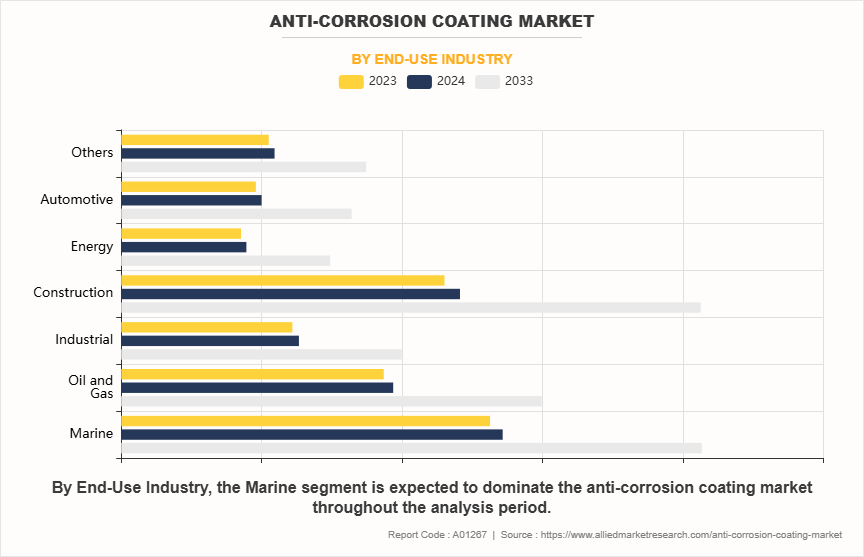

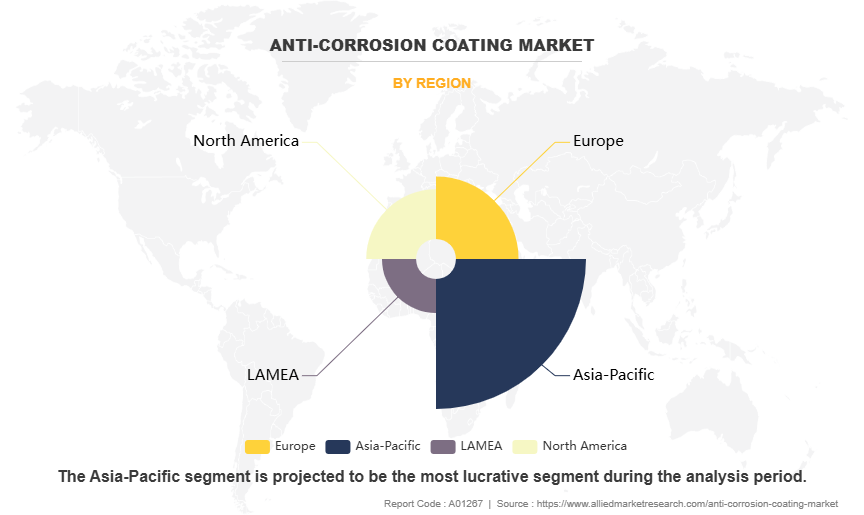

The anti-corrosion coating market is segmented on the basis of type, technology, end-use industry, and region. On the basis of type, the market is segmented into epoxy, polyurethane, acrylic, alkyd, zinc, chlorinated rubber, and others. On the basis of technology, the market is classified into solvent-borne, waterborne, powder coatings, and others. On the basis of end-use industry, the market is segmented into marine, oil & gas, industrial, construction, energy, automotive, and others. Region-wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

On the basis of type, the market is segmented into epoxy, polyurethane, acrylic, alkyd, zinc, chlorinated rubber, and others. The epoxy segment accounted for less than two-fifths of global anti-corrosion coating market share in 2023 and is expected to maintain its dominance during the forecast period. The growing emphasis on infrastructure development and maintenance drives the demand for epoxy-based anti-corrosion coatings. As many countries prioritize infrastructure upgrades, particularly in developing economies, the need for durable, long-lasting coatings for bridges, highways, and industrial facilities has surged. Moreover, epoxy coatings are also recognized for their cost-effectiveness, providing long-term corrosion protection and reducing the need for frequent maintenance and repairs that makes them a preferable choice for public and private sector projects.

On the basis of technology, the market is classified into solvent-borne, waterborne, powder coatings, and others. The solvent-borne segment accounted for more than half of the global anti-corrosion coating market share in 2023 and is expected to maintain its dominance during the forecast period. Performance characteristics such as high gloss, durability, and resistance to abrasion contribute to the continued popularity of solvent-borne coatings in anti-corrosion applications. These properties are especially valued in industries such as automotive manufacturing, where coatings need to provide both corrosion resistance and aesthetic appeal. In addition, solvent-borne coatings exhibit high resistance to mechanical stresses that makes them ideal for protective purposes on equipment and surfaces exposed to heavy wear and tear.

On the basis of end-use industry, the market is segmented into marine, oil & gas, industrial, construction, energy, automotive, and others. The marine segment accounted for around one-fourth of the global anti-corrosion coating market share in 2023 and is expected to maintain its dominance during the forecast period. Stringent regulations and standards imposed by regulatory bodies such as the International Maritime Organization (IMO), drive the adoption of anti-corrosion coatings. Marine vessels must comply with these standards to ensure environmental safety and operational reliability. Coatings that minimize biofouling, prevent rust formation, and reduce maintenance costs, are in high demand, as they help operators meet regulatory requirements and maintain fleet and infrastructure certifications. Moreover, surge in emphasis on eco-friendly and sustainable coatings has accelerated innovation within the sector, leading to the development of low-VOC, non-toxic, and biocide-free solutions that provide effective corrosion protection without harming marine ecosystems.

Region-wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. Asia-Pacific accounted for less than half of the global anti-corrosion coating market share in 2023 and is expected to maintain its dominance during the forecast period. Government regulations and initiatives focused on enhancing safety, which are extending the lifespan of public infrastructure, and reducing environmental impact are significant contributors to market growth. Regulatory bodies are emphasizing the adoption of environment-friendly coatings, such as low-VOC and waterborne formulations, to reduce the release of harmful chemicals into the environment. This regulatory shift has driven technological advancements in eco-friendly anti-corrosion coatings that offer similar protection compared to traditional solvent-based options.

Competitive Analysis

Key players in the anti-corrosion coating market include AkzoNobel N.V., PPG Industries, Inc., Sherwin-Williams Company, BASF SE, Nippon Paint Holdings Co., Ltd., Hempel A/S, Axalta Powder Coating Systems GmbH, Kansai Paint Co., Ltd., Sika AG, and 3M.

Key Benefits for Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the anti-corrosion coating market analysis from 2023 to 2033 to identify the prevailing anti-corrosion coating market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the anti-corrosion coating market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global anti-corrosion coating market trends, key players, market segments, application areas, and market growth strategies.

Anti-corrosion Coating Market Report Highlights

| Aspects | Details |

| Market Size By 2033 | USD 54.4 billion |

| Growth Rate | CAGR of 5.4% |

| Forecast period | 2023 - 2033 |

| Report Pages | 420 |

| By Type |

|

| By Technology |

|

| By End-Use Industry |

|

| By Region |

|

| Key Market Players | Nippon Paint Holdings Co., Ltd., Kansai Paint Co.,Ltd., Hempel A/S, AkzoNobel N.V., 3M, BASF SE, PPG Industries, Inc., Sherwin-Williams Company, Sika AG, Axalta Powder Coating Systems GmbH |

Analyst Review

According to the opinions of various CXOs of leading companies, the anti-corrosion coating market is expected to witness growth during the forecast period owing to increase in demand for infrastructure development and surge in focus on sustainable coatings. As countries across the globe invest in building and upgrading their infrastructure such as bridges, roads, buildings, power plants, and transportation networks, the need to protect these assets from environmental degradation becomes important. Anti-corrosion coatings play a crucial role in preserving the integrity and longevity of these structures by protecting metals and other materials from rust, moisture, and chemical damage. Moreover, rapid urbanization, population growth, and industrialization in developing regions have further amplified the demand for durable infrastructure solutions, creating significant opportunities for the anti-corrosion coating industry to witness growth.

In addition, surge in the focus on sustainable coatings has become a key driver for anti-corrosion coating demand. Environmental regulations and growth in need for eco-friendly products have led industries to seek coatings that minimize their ecological footprint while delivering superior corrosion resistance. Traditional solvent-based coatings contain high levels of volatile organic compounds (VOCs), which contribute to air pollution and present health risks. Moreover, sustainable alternatives such as water-based and low-VOC coatings, offer high performance with reduced environmental impact, aligning with regulatory standards and customer preferences. The push toward greener technologies are evident in sectors such as automotive, marine, construction, and oil and gas, where compliance with environmental mandates and consumer expectations is driving the adoption of eco-friendly anti-corrosion solutions.

The global anti-corrosion coating market was valued at $32.6 billion in 2023, and is projected to reach $54.4 billion by 2033, growing at a CAGR of 5.4% from 2024 to 2033.

Asia-Pacific is the largest regional market for Anti-corrosion Coating.

Marine is the leading application of Anti-corrosion Coating Market.

Technological advancements in coating formulations is the upcoming trends of Anti-corrosion Coating Market in the globe

Key players in the anti-corrosion coating market include AkzoNobel N.V., PPG Industries, Inc., Sherwin-Williams Company, BASF SE, Nippon Paint Holdings Co., Ltd., Hempel A/S, Axalta Powder Coating Systems GmbH, Kansai Paint Co., Ltd., Sika AG, and 3M.

Loading Table Of Content...

Loading Research Methodology...