Automotive Plastics Market Research, 2033

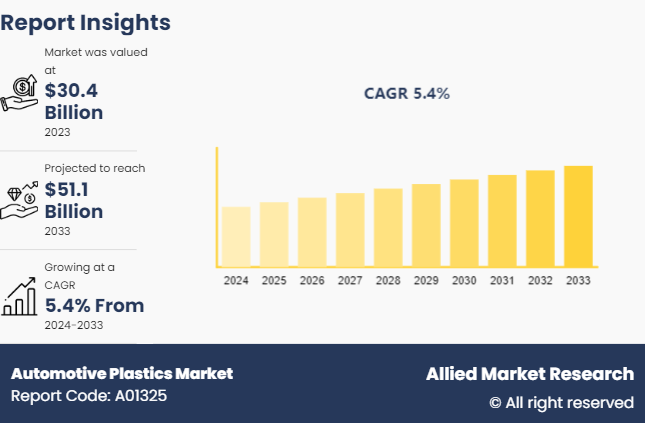

The global automotive plastics market was valued at $30.4 billion in 2023, and is projected to reach $51.1 billion by 2033, growing at a CAGR of 5.4% from 2024 to 2033.

Market Introduction and Definition

Automotive plastics refer to a broad category of synthetic materials used in the manufacturing of various components within vehicles. These materials include polymers such as polypropylene polyurethane, polyethylene, Polyvinyl Chloride, Acrylonitrile Butadiene Styrene, and others. Automotive plastics are valued for their versatility, lightweight nature, durability, and ability to be molded into complex shapes that makes them ideal for a wide range of applications in automobiles.

Key Takeaways

The automotive plastics market study covers 20 countries. The research includes a segment analysis of each country in terms of value ($Billion) for the projected period 2023-2033.

More than 1,850 product literatures, industry releases, annual reports, and other such documents of major automotive plastics industry participants along with authentic industry journals, trade associations' releases, and government websites have been reviewed for generating high-value industry insights.

The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and to assist stakeholders in making educated decisions to achieve their most ambitious growth objectives.

Key Market Dynamics

As the automotive industry continues to evolve, plastics manufacturers have been developing innovative solutions to meet the changing needs of automakers. These advancements have led to the creation of high-performance plastics that offer superior properties such as enhanced strength, durability, and heat resistance that makes them suitable for various automotive applications. All these factors are expected to drive the demand for the automotive plastics market during the forecast period.

However, the production of automotive-grade plastics requires specific polymers, additives, and reinforcing materials, which are expensive compared to traditional materials such as metal. Products composed of plastic are essential to ensure that the plastics meet the stringent performance, safety, and durability requirements of the automotive industry. Some of the dominant polymers used in automotive plastics are polypropylene and polyethylene. Henceforth, stringent regulations over the use of plastics are a prime factor expected to hamper the growth of the automotive plastics market during the forecast period.

EVs operate on high-voltage electrical systems which require proper insulation to ensure safety and reliable performance and engineered plastics with high dielectric strength provide effective insulation for battery packs wiring harnesses and other electrical components. These plastics help to prevent short circuits, reduce the risk of electrical fires and maintain the overall integrity of the EV's electrical system. In addition, the increase in demand for safe and reliable EVs drives the need for advanced plastic materials that meet these insulation requirements. All these factors are anticipated to offer new growth opportunities for the automotive plastics market during the forecast period.

Market Segmentation

The automotive plastics market is segmented by type, application, and region. Based on type, the market is classified into polypropylene (PP) , polyurethane (PU) , polyvinyl chloride (PVC) , acrylonitrile butadiene styrene (ABS) , polyamide (PA) , polystyrene (PS) , polyethylene (PE) and others. By application, the market is divided into dashboards, engine covers, door handles, wheel covers, bumpers, plug connectors, knobs and fittings, and others. Region-wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

China- the Dominant Automotive Hub Expected to Boost the Automotive Plastics Demand

China is the world's largest automotive market and a major manufacturer of vehicles. The use of plastics in automotive production has significantly contributed to the growth of China's automotive industry. China has a robust plastic manufacturing sector, which supports the production of various automotive components such as interior trim, exterior panels, and engine components. In addition, China's automotive plastic sector is characterized by continuous innovation and technological advancements. Automotive plastics manufacturers invest in research and development to improve the quality, durability, and performance of plastic materials used in vehicles. All these factors expected to drive the demand for automotive plastics market in China throughout the forecast period.

Competitive Landscape

The major players operating in the automotive plastics market include Knauf Industries, BASF SE, SABIC, Arkema, LG Chem, Dow, Exxon Mobil Corporation., Asahi Kasei Corporation., DuPont, Celanese Corporation, and others.

Recent Key Strategies and Developments

In September 2022, Citroën and BASF introduced the all-electric concept car oli [all-ë], showcasing significant weight and resource savings. BASF, with a longstanding commitment to sustainability, highlighted key initiatives such as Chem Cycling for better plastic recycling and the biomass balance method, replacing fossil resources with renewables in production.

In March 2022, Covestro AG launched two polycarbonate compounding production lines at its Greater Noida facility near New Delhi, India. These additions aim to address the increasing need for compounded plastics, especially in the automotive, electrical, and electronics sectors.

Industry Trends

According to the China Association of Automobile Manufacturing (CAAM) , the production of new electric vehicles (NEVs) in China saw a substantial year-on-year increase of 96.9% in December 2022. This rapid growth in the electric vehicle market is anticipated to boost the demand for automotive plastics in the country.

According to the Society of Indian Automobile Manufacturers (SIAM) , the country witnessed a significant increase in the production of passenger vehicles. For instance, the production of passenger vehicles reached 3, 650, 698 for 2021-2022, representing an increase of 19% compared to 2020-21, positively impacting the demand for automotive plastics in the region.

Automotive Industry Outlook

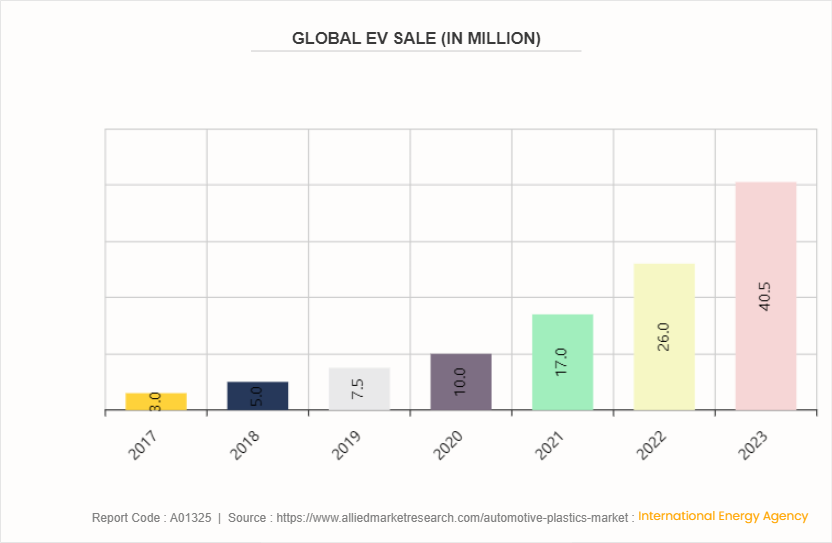

The rapid increase in global electric vehicle (EV) sales as indicated by the progression from 3 million in 2017 to 40.5 million in 2023, has a profound impact on the automotive plastic market. This is driven by the need for lightweight and durable materials, has significant growth in the demand for automotive plastics. From 2017 to 2023, the EV market experienced an exponential increase, with sales escalating from 3 million units in 2017 to 40.5 million units in 2023. This surge is reflective of the broader shift towards sustainable and energy-efficient transportation solutions. The adoption of EVs is a key factor propelling the demand for automotive plastics. Plastics play a crucial role in reducing vehicle weight which in turn enhances the energy efficiency and driving range of EVs. In addition, the automotive industry has intensified its focus on incorporating high-performance plastic components.

Key Sources Referred

Plastics Europe

Invest India

International Renewable Energy Agency (IREA)

India brand Equity foundation (IBEF)

National Institute of Standards and Technology (NIST)

Plastics Industry Association

Society of Plastics Engineers

American Chemistry Council

Key Benefits For Stakeholders

This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the automotive plastics market analysis from 2024 to 2033 to identify the prevailing automotive plastics market opportunities.

The market research is offered along with information related to key drivers, restraints, and opportunities.

Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

In-depth analysis of the automotive plastics market segmentation assists to determine the prevailing market opportunities.

Major countries in each region are mapped according to their revenue contribution to the global market.

Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

The report includes the analysis of the regional as well as global automotive plastics market trends, key players, market segments, application areas, and market growth strategies.

Automotive Plastics Market Report Highlights

| Aspects | Details |

| Market Size By 2033 | USD 51.1 Billion |

| Growth Rate | CAGR of 5.4% |

| Forecast period | 2024 - 2033 |

| Report Pages | 340 |

| By Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | DuPont, SABIC, Exxon Mobil Corporation, Arkema, Knauf Industries, Dow Inc., BASF SE, Celanese Corporation, Asahi Kasei Corporation, LG Chem |

Growing demand for electric vehicles (EVs), increased adoption of lightweight materials are the upcoming trends of Automotive Plastics Market in the world.

Asia-Pacific is the largest regional market for Automotive Plastics.

Bumper segment is the leading application of Automotive Plastics Market.

$51.1 billion is the estimated industry size of Automotive Plastics by 2033.

Knauf Industries, BASF SE, SABIC, Arkema, LG Chem, Dow, Exxon Mobil Corporation., Asahi Kasei Corporation., DuPont, and Celanese Corporation are the top companies to hold the market share in Automotive Plastics

Loading Table Of Content...