Blanking Machine Market Research - 2030

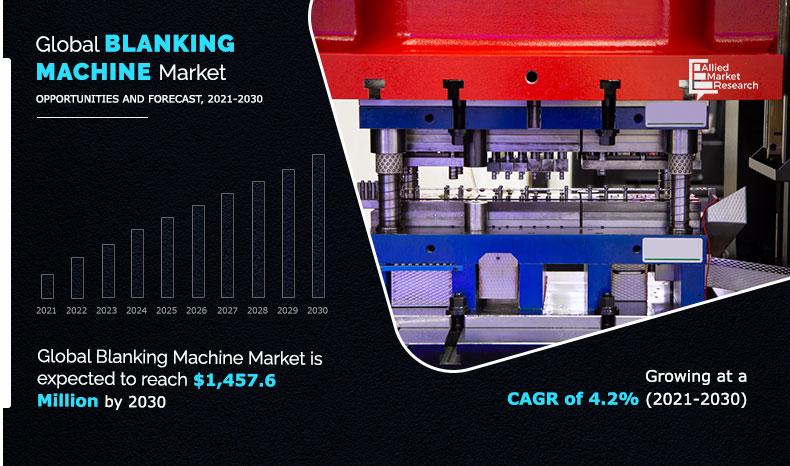

The global blanking machine market size was valued at $927.9 million in 2020, and is expected to reach $1,457.6 million by 2030, with a CAGR of 4.2% from 2021 to 2030.

Blanking machine is used to cut, and shear metal material, and rubber for making innovative products. Blanking machine cuts the material or piece of metal in attractive and customizable shapes, and sizes. It is used to make strip material for packaging materials, electrical appliance packaging, airbags for automobile, and precision smartphone accessories. It is rigid and accurate.

There is a rise in the adoption of blanking machines by various end users such as automotive, aerospace, defense, and other sectors as these machines are highly efficient and highly productive. This rise in adoption boosts the of the global blanking machine market growth. The urban population is projected to rise by 2050; thereby, fueling the demand for mobiles, cars, and electronics devices, which in turn, increases the demand for blanking machine to make precision components. This fosters the market growth. Rise in infrastructure activities in developing countries such as India, Brazil, and others is expected to drive the demand for blanking machine, which fuels the growth of the blanking machine.

Blanking machines offer various advantages such as high-speed cutting, precise and consistent shapes, minimal material waste, and the ability to handle a wide range of material thicknesses and sizes. In addition, it is used in various end-user industries such as automotive, aerospace, electronics, appliances, and others where cutting sheet metal is required in an efficient manner. Depending on the level of automation and production requirements, Blanking machines can be manual, semi-automatic, or fully automatic. A wide variety of materials can be processed, including metals such as steel, aluminum, and brass, as well as non-metallic materials such as plastics and rubber. Moreover, the adoption of automation and Industry 4.0 technologies in the manufacturing process is expected to drive the blanking machine market growth during the forecast period.

An increase in urbanization and industrialization in emerging countries such as Germany, France, the U.S., and others drives the demand for automotive vehicle. This is expected to fuel the demand for blanking machine to make precision component such as airbag, car door, and others thereby, driving the growth of the global market. For instance, degree of urbanization in the U.S. increased by 0.4% from 2017 to 2019.

In addition, blanking machine is used in various industry verticals such as automotive, aerospace, and defense, owing to rise in demand for blanking machine. The healthcare industry in various countries such as the UK, the U.S., and India is growing at a significant pace, due to increase in investments in this sector by government. For instance, in 2018, the UK Government spent $252.9 billion on the healthcare industry. This is expected to drive the demand for blanking machine market, owing to features such as highly efficient, rigid, and high revolution per minute (rpm).

However, fluctuation in foreign currencies and volatile economic condition in the developing economies are anticipated to hamper the growth of the global blanking machine. Furthermore, growth in machinery and equipment manufacturing sector is anticipated to provide lucrative opportunities for the growth of the global blanking machine.

Major players such as Komori Corporation, Hagel Automation GmbH, and Jet Pack Machinery Pvt Ltd, are engaged in offering new blanking machines to the market, to improve the product portfolio of blanking machine products. For instance, in January 2020, Komori Corporation developed a new auto pile turner Apressia AT 120H at a private show in Japan. It is best suitable for blanking machines. It has a maximum stack height of 2,000 mm. it has a pallet clamp function that enables pallet and paper-centering options. It has various features such as easy touch panel operation, sound safety measures, and machine support. Such strategies are anticipated to provide lucrative opportunities for the growth of the blanking machines market.

By Product Type

Mechanical segment is projected to grow at a significant CAGR

Segment Overview

The blanking machine market is segmented on the basis of product type, material, end user, and region. On the basis of product type, the market is divided into hydraulic, pneumatic, and mechanical. Mechanical segment generated the highest revenue in 2020. On the basis of material, the market is divided into steel, aluminum, alloy, and others. Steel segment dominated the market in 2020. On the basis of end user, the market is categorized into automobile industry, aerospace industry, home applications, and others. Automobile segment generated the highest revenue in 2020.

Region wise, the blanking machine market analysis is conducted across North America (the U.S., Canada, and Mexico), Europe (the UK, France, Germany, Italy, and rest of Europe), Asia-Pacific (China, Japan, India, Australia, and rest of Asia-Pacific), and LAMEA (Latin America, the Middle East, and Africa). In 2020, Asia-Pacific was the highest contributor to the global blanking machine market share, and is anticipated to secure a leading position during the forecast period.

By End-user

Automobile segment generated the highest revenue in 2020.

Competition Analysis

Key players profiled in this report include AMADA CO Ltd, Hagel Automation GmbH, Autoprint Machinery Manufacturers Pvt Ltd, Hubei Tri-ring Metalforming Equipment Co Ltd, Jet Pack Machines Pvt Ltd, Komori Corporation, Precision Surfacing Solutions (Lapmaster Wolters), Schuler AG, Torontech Inc., and Ueshima Seisakusho Co Ltd.

Major players such as Komori Corporation, Hagel Automation GmbH, and Jet Pack Machinery Pvt Ltd, are engaged in offering new blanking machine to the market, for improve the product portfolio of blanking machine products. For instance, in January 2020, Autoprint Machinery Manufacturers Pvt Ltd launched a new small version of Checkmate 50 at Pamex 2020 which is held between 6 and 9 January 2020, at Bombay Exhibition Center in Mumbai. It has dimension of 250X300mm length, and can run at maximum speed of 250 m/min.

By Region

Asia-Pacific holds a dominant position in 2020, with a highest CAGR of 4.9% during the forecast period.

Key Benefits For Stakeholders

- The report provides an extensive analysis of the current blanking machine market trends and future estimations.

- Extensive analysis of global blanking machine is conducted by following key product positioning and monitoring of the top competitors within the market framework.

- In-depth market analysis is conducted by constructing market estimations for the key market segments between 2021 and 2030.

- A comprehensive analysis of all the regions is provided to determine the prevailing opportunities.

- The global blanking machine market forecast analysis from 2021 to 2030 is included in the report.

- The key market players within the global blanking machine market are profiled in this report and their strategies are analyzed thoroughly, which help understand the competitive outlook of the global market.

Blanking Machine Market Report Highlights

| Aspects | Details |

| By Product Type |

|

| By Material |

|

| By END USER |

|

| By Region |

|

| Key Market Players | Komori Corporation, Torontech Inc., HUBEI TRI-RING METALFORMING EQUIPMENT CO.,LTD, Autoprint Machinery Manufacturers Pvt. Ltd., Precision Surfacing Solutions (Lapmaster Wolters), Schuler AG, Ueshima Seisakusho Co., Ltd, AMADA CO., LTD, JET PACK MACHINES PVT. LTD., Hagel Automation GmbH |

Analyst Review

The global blanking machine market has witnessed huge demand in Asia-Pacific region followed by Europe & North America. The highest share of the xx market is attributed to the increase in demand for blanking machine in automotive and aerospace sectors.

Blanking is a process of cutting or shearing a blank or piece of metal in appropriate shape or design. Blanking machine is used to stamp, cut, and shear metal material. Blanking machine is used in various industries such as automotive, electrical, electronics, pumps, valves, aerospace, defense, home appliances, and many others sectors. It helps reduce setup costs, reduce production time, and minimize positioning errors. A rise in demand for blanking machines in industrial and manufacturing sector globally fuels the growth of the blanking machine market.

Moreover, major players such as Lapmaster Wolters, Schuler AG, and others are adopting acquisition as a key developmental strategy to improve the product portfolio of the blanking machine product. For instance, in February 2019, Precision Surfacing Solutions (PSS) subsidiary of Lapmaster Wolters acquired Wafering Division of Meyer Burger Technology Ltd. The acquisition aimed to improve the product portfolio of blanking machine products. All such instances drive the growth of the global blanking machine market.

However, fluctuation in raw material prices and foreign currencies is anticipated to restraint the growth of the global blanking machine market. Moreover, developments in machinery and equipment manufacturing sectors are anticipated to provide lucrative opportunities for the growth of the global blanking machine market.

The Global blanking machine market size was $927.9 million in 2020 and is projected to reach $1,457.6 million in 2030, growing at a CAGR of 4.2% from 2021 to 2030.

The forecast period considered for the Global blanking machine market is 2021 to 2030, wherein, 2020 is the base year, 2021 is the estimated year, and 2030 is the forecast year.

The base year considered in the Global blanking machine market is 2020.

The report for Global blanking machine market doesn’t provides Value Chain Analysis, but if there is a requirement for the same, it could be added as an additional customization.

On the basis of product type, the mechanical segment is expected to be the most influencing segment growing in the Global blanking machine market report.

Based on material, steel segment generated the highest revenue, accounting for 46.60% of the market share, and is projected to grow at a CAGR of 4.6% from 2021 to 2030.

The report contains an exclusive company profile section, where the leading 10 companies in the market are profiled. These profiles typically cover company overview, geographical presence, and market dominance (in terms of revenue and volume sales).

Asia-Pacific is expected to provide more business opportunities for global blanking machine market in the future.

Loading Table Of Content...