Blow Molded Plastics Market Research, 2032

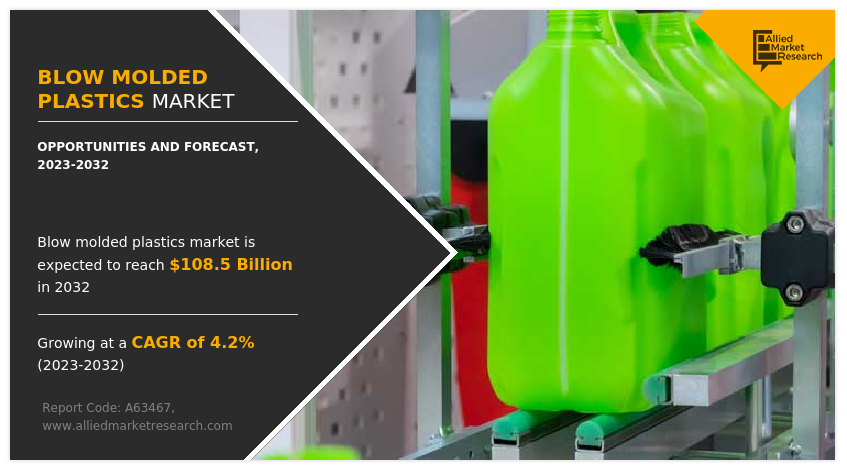

The global blow molded plastics market size was valued at $72.6 billion in 2022 and is projected to reach $108.5 billion by 2032, growing at a CAGR of 4.2% from 2023 to 2032. The growing demand for lightweight materials in the automotive industry is a key driver for the blow-molded plastics market, as automakers increasingly prioritize fuel efficiency, reduced emissions, and improved performance through the use of lighter components.

Key Report Highlighters:

1. The report depicts detailed insights into the blow molded plastics industry trends and new growth opportunities.

2. The report provides a complete analysis of the market status across key regions and more than 15 countries across the globe in terms of value ($ Million) and volume (Tons).

3. The report identifies the blow molded plastics market growth segments and emerging application areas.

4. The report provides competitive dynamics by evaluating business segments, product portfolios, target market revenue, geographical presence, and key strategic developments by prominent manufacturers.

Introduction

Blow molded plastics refer to a type of plastic product that is manufactured using the blow molding process, a versatile and efficient method for creating hollow plastic components. This process involves inflating a heated plastic material within a mold to form a specific shape, creating seamless, hollow structures with uniform wall thickness. The technique is widely used for mass production of various plastic items due to its cost-effectiveness, precision, and ability to produce complex geometries.

Blow molding is a type of plastic-forming process for creating hollow plastic products made from thermoplastic materials. The process involves heating and inflating a plastic tube known as a parison or preform. The parison is placed between two dies that contain the desired shape of the product. Air is then supplied to expand the tube causing the walls to become thinner and conform to the shape of the mold. Once the blowing process is complete, the product is then cooled, ejected, trimmed, and prepared for the secondary processes.

Market Dynamics

Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. Different manufacturing plants can employ additional processes such as additional cooling or heating cycles and additives and colorants compounding. These additional processes depend on the design and intended application of the final product.

The packaging industry is one of the primary drivers of blow-molded plastics demand. Blow-molded plastic containers, bottles, and jars are widely used for packaging various products such as beverages, food items, personal care products, and household chemicals. The growth in the consumer goods sector, changing lifestyles, and increasing demand for convenience packaging have significantly contributed to the demand for blow-molded plastics.

Blow-molded plastics are extensively used in the automotive industry for manufacturing components such as fuel tanks, air ducts, bumpers, dashboards, and interior trims. The automotive industry's constant pursuit of lightweight materials to improve fuel efficiency and reduce emissions has led to increased adoption of blow-molded plastics. While blow-molded plastics offer numerous advantages, their impact on the environment, particularly in terms of plastic waste and pollution, has become a significant concern. Increasing awareness about plastic pollution and the need for sustainable alternatives have led to regulatory measures and consumer preferences shifting toward more environmentally friendly options. This has put pressure on industries to explore alternative materials and reduce their reliance on traditional blow-molded plastics.

Increased demand from the packaging industry

Blow-molded plastics offer convenience and functionality in packaging applications. They can be molded into various shapes and sizes, allowing for custom designs that meet specific packaging requirements. Additionally, blow-molded plastic containers are lightweight, durable, and resistant to impact, making them ideal for protecting and preserving a wide range of products. Blow-molded plastics are versatile and can be used for packaging a wide range of products, including beverages, food items, personal care products, household chemicals, and more. They can be manufactured in different forms, such as bottles, jars, canisters, and closures, to cater to diverse packaging needs across industries. These factors are expected to boost the demand for blow-molded plastics.

In addition, blow-molded plastics offer cost advantages compared to alternative packaging materials. The manufacturing process is efficient, allowing for high production volumes at a relatively low cost per unit. Additionally, the lightweight nature of blow-molded plastic containers contributes to cost savings in transportation and logistics. Consumer preferences have evolved toward convenience, safety, and sustainability. Blow-molded plastics meet these expectations by offering easy-to-use packaging formats, secure closures, and recyclability.

The growing emphasis on sustainability presents an opportunity for blow-molded plastics to evolve and offer more eco-friendly solutions. Research and development efforts are focused on developing biodegradable or compostable materials for blow molding, reducing the environmental impact of plastic waste. Companies that can offer sustainable alternatives or incorporate recycled content in blow-molded plastics may gain a competitive advantage.

The global blow-molded plastics market is segmented into types, materials, end-use industry, and regions. On the basis of type, the market is classified into injection blow molding, extrusion blow molding, and others. By materials, the market is segmented into polyethylene, polyethylene terephthalate (PET), polypropylene (PP), polyamide (PA), polycarbonate (PC), polyvinylchloride (PVC), and others. As per the end-use industry, it is categorized into medical, packaging, building & construction, automotive & transportation, electrical & electronics, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

The major players operating in the global blow molded plastics market include Dow, Inpress, Plastic Forming Company, Inc., Garrtech Inc., Creative Blow Mold Tooling, Custom-Pak, Inc., APEX Plastics, Gemini Group, Comar, and DuPont.

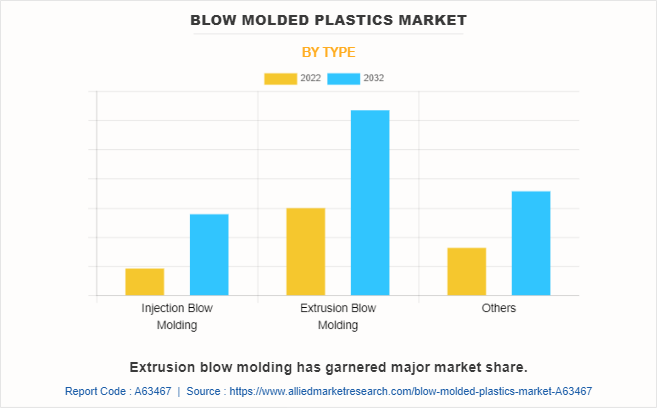

Blow Molded Plastics Market, By Type

Extrusion blow molding has garnered more than one-fourth of the market share. Extrusion blow molding produces lightweight yet durable plastic products. This characteristic is particularly beneficial for applications such as packaging, where lightweight containers reduce transportation costs and minimize environmental impact. Despite their lightweight, extrusion blow-molded products exhibit excellent structural integrity and can withstand the rigors of handling and transportation. In addition, extrusion blow molding can contribute to environmental sustainability. The process allows for the use of recycled plastic materials, reducing the dependence on virgin resins and promoting the circular economy. Additionally, the lightweight nature of extrusion blow molded products can contribute to reduced carbon emissions during transportation.

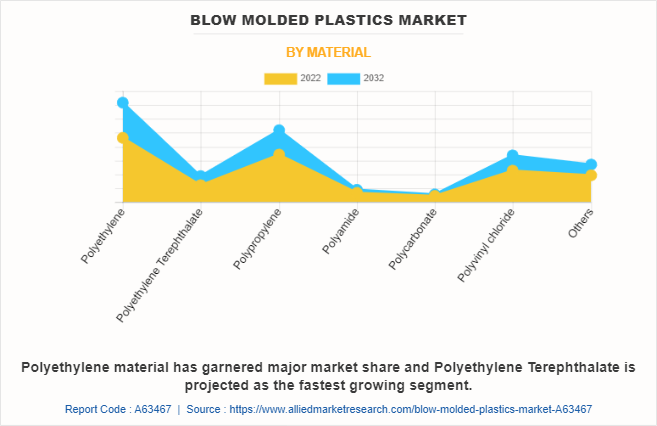

Blow Molded Plastics Market, By Material

The polyethylene segment has garnered one-third of the blow molded plasticsmarket share in 2022. Polyethylene blow molded products are lightweight, which offers advantages in terms of transportation costs, fuel efficiency, and ease of handling. The lightweight nature of polyethylene makes it particularly suitable for applications in the packaging industry, where weight reduction is desired to minimize environmental impact and optimize logistics. Polyethylene blow molded products find extensive applications across various industries. They are commonly used for manufacturing bottles, containers, drums, tanks, automotive components, toys, and household products. The versatility of polyethylene allows for the production of different shapes, sizes, and designs to meet specific application requirements.

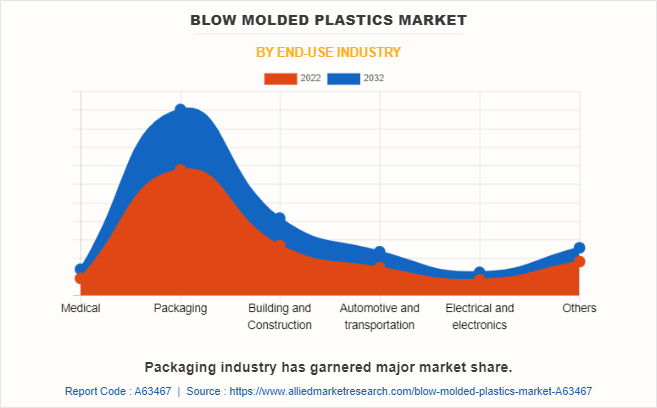

Blow Molded Plastics Market, By End Use Industry

The packaging industry is expected to grow at a CAGR of 4.2% and has garnered major market share in terms of revenue, during the forecast period. Blow-molded plastics provide excellent protection for packaged products. The demand for durable, impact-resistant, and reliable packaging solutions has grown, particularly for products that are vulnerable to damage during transportation or susceptible to contamination. Blow-molded plastics offer the necessary strength and barrier properties to safeguard products and ensure their integrity. Blow-molded plastics find extensive use in the food packaging industry. They are employed to manufacture containers, trays, and tubs for food products, including dairy, sauces, condiments, and ready-to-eat meals. Blow-molded plastic packaging provides a protective barrier, maintains product freshness, and ensures convenience for consumers.

Blow Molded Plastics Market, By Region

Asia-Pacific garnered a share of more than two-fifths in 2022 in terms of revenue and is projected as the fastest-growing segment. The Asia-Pacific region has witnessed rapid urbanization, leading to increased construction activities and infrastructure development. Blow-molded plastics are extensively used in the construction industry for pipes, fittings, tanks, and insulation materials. The growing need for affordable housing, urban infrastructure, and industrial facilities has contributed to the increased demand for blow-molded plastics.

The Asia-Pacific region has a large and rapidly expanding consumer market. The rising middle class and increased disposable income levels have led to increased consumption of various products, including packaged goods, consumer electronics, automotive components, and more. Blow-molded plastics are widely used in these sectors due to their versatility, cost-effectiveness, and ability to meet the demands of a growing consumer market.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the blow-molded plastics market analysis from 2022 to 2032 to identify the prevailing blow-molded plastics market opportunities.

- Market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders to make profit-oriented business decisions and strengthen their supplier-buyer network.

- An in-depth analysis of the blow-molded plastics market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global blow-molded plastics market trends, key players, market segments, application areas, and market growth strategies.

Analyst Review

According to the CXOs of leading companies, the blow molded plastics market is experiencing steady growth globally, driven by various industries such as packaging, automotive, consumer goods, and healthcare. Companies need to stay updated on industry trends, customer demands, and the competitive landscape is crucial. Understanding emerging technologies, materials, and design innovations in blow molding is helping companies to remain competitive and seize market opportunities. The blow-molded plastics industry is subject to various regulations concerning product safety, material standards, and environmental impact. Embracing technological advancements and fostering innovation are crucial in the blow-molded plastics market. Manufacturers need to keep up with emerging and new manufacturing techniques, machinery, and materials that can enhance production efficiency, product quality, and design capabilities to stay competitive in the market. Investing in research and development, collaborating with technology partners, and promoting a culture of innovation within the company can drive growth and differentiation.

Blow Molded Plastics Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 108.5 billion |

| Growth Rate | CAGR of 4.2% |

| Forecast period | 2022 - 2032 |

| Report Pages | 358 |

| By Type |

|

| By Material |

|

| By End-use industry |

|

| By Region |

|

| Key Market Players | Apex Plastics, Comar, Garrtech Inc., Custom-Pak, Inc., Plastic Forming Company, Inc., Inpress, Creative Blow Mold Tooling, Gemini Group, Inc., Dow |

Analyst Review

According to the CXOs of leading companies, the blow molded plastics market is experiencing steady growth globally, driven by various industries such as packaging, automotive, consumer goods, and healthcare. Companies need to stay updated on industry trends, customer demands, and the competitive landscape is crucial. Understanding emerging technologies, materials, and design innovations in blow molding is helping companies to remain competitive and seize market opportunities. The blow-molded plastics industry is subject to various regulations concerning product safety, material standards, and environmental impact. Embracing technological advancements and fostering innovation are crucial in the blow-molded plastics market. Manufacturers need to keep up with emerging and new manufacturing techniques, machinery, and materials that can enhance production efficiency, product quality, and design capabilities to stay competitive in the market. Investing in research and development, collaborating with technology partners, and promoting a culture of innovation within the company can drive growth and differentiation.

Increasing demand from the packaging industry is the upcoming trend of the Blow Molded Plastics Market.

The packaging industry is the leading end-use industry for Blow Molded Plastics Market.

Asia-Pacific is the largest regional market for Blow Molded Plastics.

The global blow-molded plastics market was valued at $72.6 billion in 2022 and is projected to reach $108.5 billion by 2032, growing at a CAGR of 4.2% from 2023 to 2032.

Dow, Inpress, Plastic Forming Company, Inc., Garrtech Inc., and DuPont. are the top companies to hold the market share in Blow Molded Plastics.

Loading Table Of Content...

Loading Research Methodology...