Carbon Fiber Thread Market Research, 2032

The global carbon fiber thread market size was valued at $1.6 billion in 2022, and is projected to reach $2.7 billion by 2032, growing at a CAGR of 5.3% from 2023 to 2032.

Report key highlighters

- Quantitative information mentioned in the global carbon fiber thread market includes the market numbers in terms of value (USD Million) with respect to different segments, pricing analysis, annual growth rate, CAGR (2023-32), and growth analysis.

- The analysis in the report is provided based on product type and end-use industry. The study will also contain qualitative information such as the market dynamics (drivers, restraints, opportunities), Porter's Five Force Analysis, key regulations across the region, and value chain analysis.

- A few companies, including SGL Carbon, Hexcel Corporation, Mitsubishi Chemical Carbon Fiber and Composites, Inc., TEIJIN LIMITED, TORAY INDUSTRIES, INC., Solvay, Beijing Konfitex Technology Co., Ltd., Formosa Plastics Corporation, ZhongAo Carbon, and KUREHA CORPORATION, hold a large proportion of the carbon fiber thread market.

- This report makes it easier for existing market players and new entrants to the carbon fiber thread business to plan their strategies and understand the dynamics of the carbon fiber thread market industry, which ultimately helps them make better decisions.

Carbon fiber threads are thin strands or filaments consisting mostly of carbon atoms that are extremely strong, lightweight, and have a high tensile strength. A precursor substance such as polyacrylonitrile (PAN), pitch, or rayon is selected as part of the production of carbon fiber threads. If PAN is used, it goes through a polymerization process, and PAN fibers are generated by spinning a PAN solution or melting into filaments. After that, the precursor fibers are stabilized by being subjected to an appropriate temperature in an atmosphere free of oxygen. After stabilization, the fibers undergo carbonization, where they are heated to temperatures beyond 1000°C in a controlled environment with little oxygen. By removing non-carbon components and converting the fibers into carbon-rich material, this technique produces carbon fiber threads with excellent strength and light in weight.

The surge in the demand for lightweight and high strength materials in various end-use industries including aerospace and automobile, drives the carbon fiber thread market.

Carbon fiber threads are used in aircraft to reduce weight, boost fuel efficiency, improve structural integrity, and enhance performance. Due to these benefits, carbon fiber is an ideal material to meet the demanding standards of the aerospace sector. They are employed in building the wings, fuselages, tail sections, and empennage components of aircraft. Lightweight constructions remain durable and have structural integrity because of their superior strength to weight ratio. The production of interior parts including seats, panels, and cabin fittings involves use of carbon fiber threads.

Furthermore, control surfaces including ailerons, elevators, and rudders are made using carbon fiber threads. Due to its small weight, carbon fiber contributes to increased maneuverability and reduced total drag, which improves aircraft control and fuel efficiency. Owing to these excellent uses of carbon fiber threads in the aerospace industry, the carbon fiber thread market will expand significantly during the forecast period.

The demand for lightweight materials in automobile sector is boosted due to several factors such as improved fuel efficiency, reduced emissions, enhanced performance, safety advancements, cost savings, and the growth of electric and hybrid vehicle segments. Carbon fiber threads are used to produce lightweight vehicle structures, such as body panels, chassis components, and frames. In comparison to more conventional materials such as steel, its high strength-to-weight ratio enables significant weight reduction, which boosts performance and fuel economy. These also provide a premium and sporty appearance while reducing weight, enhancing the overall aesthetic, and improving the vehicle's performance.

In addition, carbon fiber threads are used in the manufacturing of battery enclosures for hybrid and electric automobiles. The safety and protection of the vehicle's battery pack is ensured by the exceptional structural integrity and stiffness provided by carbon fiber. Carbon fiber threads are also used in the production of vehicle suspension parts such as control arms, stabilizer bars, and springs. These parts benefit from the high strength and rigidity of carbon fiber, which improves handling and enhances ride quality. Thus, due to these great uses of carbon fiber threads in the automobile sector, the carbon fiber thread market share is expected to witness a tremendous boost during the forecast period.

The rise in demand for renewable energy due to the adverse effects of conventional energy sources, such as fossil fuels on the environment, led to the increase in usage of various renewable energy sources, particularly wind energy.

Carbon fiber threads are ideal to produce wind turbine blades because of their exceptional light weight. By utilizing carbon fiber, it is possible to lower the blades' overall weight while yet maintaining their structural integrity. The turbine components experience less mechanical stress due to the decreased weight, which also increases energy efficiency. Also, the strength and stiffness of carbon fiber threads are remarkable. This makes it easy for wind turbine blades to handle the dynamic loads and stresses that are experienced during operation, such as intense winds and turbulence.

The longer lifespan of the turbine is a result of the carbon fiber's greater strength-to-weight ratio, which ensures the blades' toughness and fatigue resistance. Furthermore, the corrosion resistance of carbon fiber is far higher than that of conventional materials such as steel. In difficult circumstances such as coastal regions where exposure to seawater and corrosive substances is higher, wind turbines are frequently placed in offshore wind farms. The risk of corrosion-related damage is reduced by using carbon fiber threads in the blade structure, which leads to fewer maintenance needs and a longer service life.

In addition, manufacturers may construct complicated blade shapes and improve aerodynamic performance because of the design flexibility provided by carbon fiber threads. The material may be bent and shaped into a variety of geometries, allowing designers to obtain aerodynamic profiles, increase energy absorption, and reduce noise production. This adaptability encourages the development of wind turbine systems that are more effective and productive. Moreover, the less weight enables installation easier and requires less labor and equipment, which lowers installation costs overall. Thus, owing to these factors, the usage of carbon fiber thread in the manufacturing of wind turbine blades boosted the growth of the market.

The cost of carbon fiber threads is higher compared to traditional materials like steel or aluminum restraining the markets’ growth. The higher production costs, including raw materials and manufacturing processes, can limit their adoption in cost-sensitive industries and applications, thus reducing demand for carbon fiber threads. The raw material used for producing carbon fiber is commonly polyacrylonitrile (PAN) or pitch, which is processed through a complicated series of stages to become carbon fiber. Precursor materials themselves can be expensive and processing them takes specialized tools and expertise. In addition, there are several steps involved in the production of carbon fiber, including spinning, stabilization, carbonization, and surface preparation. Temperature, pressure, and other variables must be carefully regulated during each phase.

Advanced technology and machinery are used during the complex, energy-intensive manufacturing process, which also contributes to the final cost. Moreover, carbon fiber is produced in much smaller quantities than other common materials like steel or aluminum. Although the demand for carbon fiber has grown recently, it still has not reached the same level as that for more conventional materials. Higher unit costs are the result of lower production quantities because economies of scale are not fully utilized. All these factors hamper the growth of the market.

Sustainable and eco-friendly materials have become more popular as environmental issues have gained attention. Carbon fiber threads help to cut down on fuel use and emissions, which is in line with sustainability objectives and environmental standards due to their low weight and high energy efficiency in transportation-related applications, which created an excellent opportunity for the market expansion. Carbon fiber threads' reduced weight makes it possible to produce lighter parts for automobiles or wind turbine blades. Less energy is needed to carry and move structures with a lower weight. Because of this, carbon fiber-using products use less energy and emit fewer greenhouse gases over their lifespan.

In addition, products made up of carbon fiber typically last longer, requiring fewer replacements or repairs. Because of their increased longevity, these products require less material and energy overall to produce and maintain, resulting in a more resource-efficient use of resources. Thus, Due to these factors, the sustainability of carbon fiber threads has created a lucrative growth opportunity for the market.

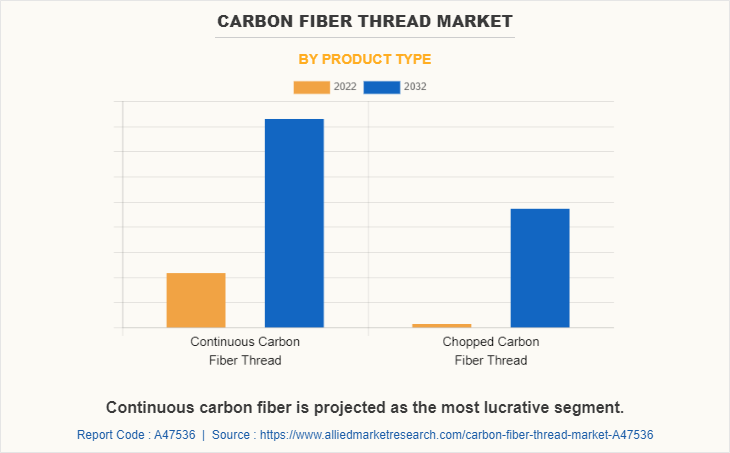

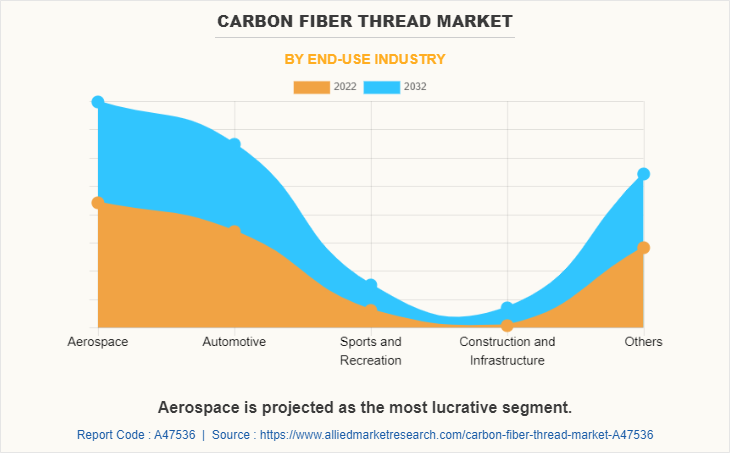

The carbon fiber thread market is divided on the basis of product type, end-use industry, and region. On the basis of product type, the market is classified into continuous carbon fiber thread and chopped carbon fiber thread. Depending on the end-use industry, the market is segregated into aerospace, automotive, sports and recreation, construction and infrastructure, and others. Region-wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The key players operating in the global carbon fiber thread market are SGL Carbon, Hexcel Corporation, Mitsubishi Chemical Carbon Fiber and Composites, Inc., TEIJIN LIMITED, TORAY INDUSTRIES, INC., Solvay, Beijing Konfitex Technology Co., Ltd., Formosa Plastics Corporation, ZhongAo Carbon, and KUREHA CORPORATION. These players have adopted various key strategies including agreement, collaboration, expansion, and partnership to increase their market shares.

The continuous carbon fiber thread segment is leading by product type. Continuous carbon fiber thread is a crucial component in advanced composite materials. These composites, made by combining continuous carbon fibers with resins or thermoplastics, offer superior strength, stiffness, and durability. The trend is towards the increased adoption of advanced composites in industries such as aerospace, automotive, and construction, where high-performance materials are sought after.

The aerospace segment dominated the global market. Carbon fiber thread is a key component in composite materials used in the aerospace industry, such as carbon fiber composites. The advancements in composite material manufacturing techniques, including automated manufacturing processes, have facilitated the efficient and cost-effective production of complex carbon fiber components. These advancements have further fueled the adoption of carbon fiber thread in the aerospace industry.

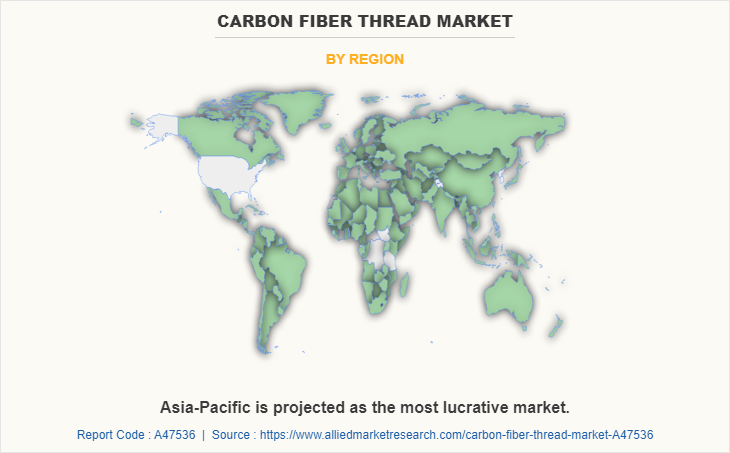

Region-wise, Asia-pacific dominated the market. The automotive industry in the Asia-Pacific region is rapidly expanding, driven by factors such as increasing disposable income, urbanization, and a growing middle class. Carbon fiber thread finds application in the automotive sector for lightweight purposes to enhance fuel efficiency and reduce emissions. As automakers strive to meet stringent environmental regulations and consumer demands for sustainable vehicles, Carbon Fiber Thread becomes a preferred choice for lightweight and high-performance automotive components.

Key Developmental Strategies Undertaken by Key Players

In November 2021, Toray Industries, Inc. announced that its U.S. subsidiary Zoltek Companies, Inc., will bolster its large-tow carbon fiber (with more than 40,000 filaments) production capacity in 2023. The capacity increase will stabilize supplies to cater to expanding large tow carbon fiber demand. This expansion will boost the carbon fiber thread market growth.

In March 2023, Hexcel Corporation opened a new center of research and technology excellence in Utah, supporting next-generation developments in advanced composites technologies. The 100,000-square-foot building comprises a modern laboratory where company scientists and researchers work with clients on the newest composite developments for industrial, aerospace, space, and defense applications. This expansion will boost the production of carbon fibers leading to the growth of the carbon fiber thread market.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the carbon fiber thread market analysis from 2022 to 2032 to identify the prevailing carbon fiber thread market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the carbon fiber thread market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global carbon fiber thread market trends, key players, market segments, application areas, and market growth strategies.

Carbon fiber Thread Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 2.7 billion |

| Growth Rate | CAGR of 5.3% |

| Forecast period | 2022 - 2032 |

| Report Pages | 197 |

| By Product Type |

|

| By End-Use Industry |

|

| By Region |

|

| Key Market Players | TORAY INDUSTRIES, INC., ZhongAo Carbon, Hexcel Corporation., KUREHA CORPORATION, TEIJIN LIMITED, Mitsubishi Chemical Corporation., Solvay S.A., SGL Carbon, Beijing Konfitex Technology Co., Ltd., Formosa Plastics Corporation |

Analyst Review

According to the opinions of various CXOs of leading companies. Carbon fiber thread is defined as a filament or bundle of fine carbon fibers that have been twisted or spun together to resemble thread. Carbon fibers are made of carbon atoms that have been linked together to form a crystalline structure, giving them exceptional rigidity and strength.

The wide usage of carbon fiber threads in various industries, including aerospace, automotive, renewable energy, sports equipment, and construction drives the markets’ growth. They are employed in the production of a variety of products, including wind turbine blades, sports equipment, vehicle parts, and high-performance structural materials. However, the high production cost for carbon fiber threads, including high price of raw materials, complex manufacturing processes, extensive use of modern equipment and technologies hampers the growth of the market. The rise in demand for sustainable and eco-friendly materials seems a great growth opportunity for the carbon fiber thread market. These are lightweight materials having high strength which reduces the transportation cost and causes less emissions.

The industry is characterized by a high number of new market entrants that seek to tap lucrative opportunities in the global market while existing players enter strategic collaborations to increase capacities & expand their reach into emerging markets. The agreement, collaboration, and expansion activities in the industry have increased significantly over the past decade. Companies constantly seek to establish long-term contract agreements with trusted partners for sustainable business operations globally.

Carbon fiber thread is finding new applications in the infrastructure and construction industry. It is being used to reinforce concrete structures, enhance their strength, and increase their resistance to seismic activities. The use of carbon fiber thread in construction offers advantages such as faster construction time, reduced material requirements, and improved durability.

Aerospace and automotive application are the potential customers of Carbon fiber Thread Market industry.

Asia-Pacific region will provide more business opportunities for Carbon fiber Thread market in the coming years.

The market players are adopting various growth strategies and also investing in R&D extensively to develop technically advanced unique products which are expected to drive the market size.

SGL Carbon, Hexcel Corporation, Mitsubishi Chemical Carbon Fiber and Composites, Inc., TEIJIN LIMITED, TORAY INDUSTRIES, INC., Solvay, Beijing Konfitex Technology Co., Ltd., Formosa Plastics Corporation, ZhongAo Carbon, and KUREHA CORPORATION are the top players in Carbon fiber Thread market.

Loading Table Of Content...

Loading Research Methodology...