CNC Controller Market Research, 2033

The Global CNC Controller Market was valued at $3.2 billion in 2023, and is projected to reach $7.2 billion by 2033, growing at a CAGR of 8.3% from 2024 to 2033.

CNC (Computer Numerical Control) controllers are essential components in modern CNC machines for automating the control of machine tools. They interpret G-code and other programming languages to precisely control the movement of machinery, enabling the production of complex parts with high accuracy and repeatability. CNC controllers are used in various industries, including automotive, aerospace, electronics, and woodworking. They come in different configurations, such as open-loop and closed-loop systems, and can control multiple axes, from simple 2-axis setups to advanced multi-axis systems. The integration of advanced technologies like AI, IoT, and machine learning is enhancing the capabilities of CNC controllers, making them more efficient and reliable.

The CNC controller market is experiencing significant growth driven by the increasing demand for automation and precision in manufacturing processes. Key factors influencing the market dynamics include technological advancements, industry-specific requirements, and regional economic conditions. Technological innovations, such as the integration of AI, motion control, and IoT, are enhancing the functionality and efficiency of CNC controllers, enabling real-time monitoring, predictive maintenance, and process optimization. These advancements are particularly beneficial in high-precision industries like aerospace, automotive, and medical devices, where the demand for complex and accurate parts is high.

Industry-specific requirements also play a crucial role in shaping the market. For instance, the automotive industry demands high-speed and high-precision machines for mass production, while the aerospace sector requires controllers capable of handling complex geometries and tight tolerances. The medical device industry, on the other hand, emphasizes precision and reliability for producing intricate components. These diverse requirements drive the development of specialized CNC controllers tailored to meet the needs of different sectors.

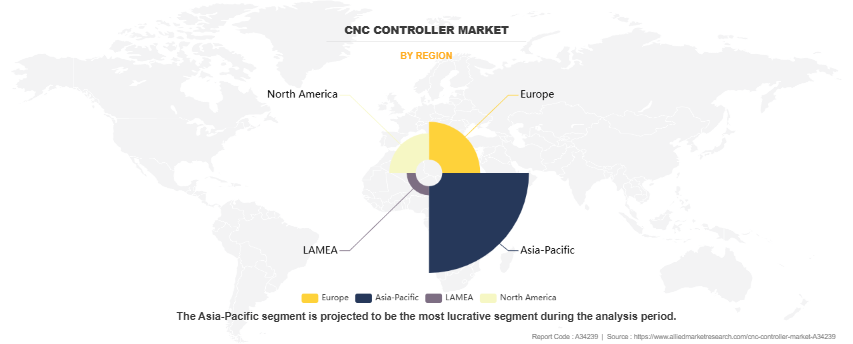

Regional economic conditions and industrial policies significantly impact the market. In developed regions such as North America and Europe, the focus is on advanced manufacturing technologies and high-end CNC systems. In contrast, emerging economies in Asia-Pacific are witnessing rapid industrialization and increasing adoption of CNC technology, driven by the need for cost-effective and efficient manufacturing solutions. Government initiatives promoting industrial automation and smart manufacturing further boost the market in these regions.

In recent years, the CNC controller market growth has revealed a steady growth trajectory driven by advancements in automation and precision engineering. Over the past decade, the market has seen significant technological innovations, including the integration of AI, IoT, and machine learning, which have enhanced the functionality and efficiency of CNC controllers. The demand for high-precision manufacturing in industries such as aerospace, automotive, and medical devices has further fueled market expansion. In addition, the increasing adoption of CNC technology in emerging economies, coupled with government initiatives promoting smart manufacturing, has contributed to the robust growth of the CNC controller industry globally.

Segment Overview

The CNC controller market forecast is segmented into Technology, Control Architecture, Axis Type, and Region.

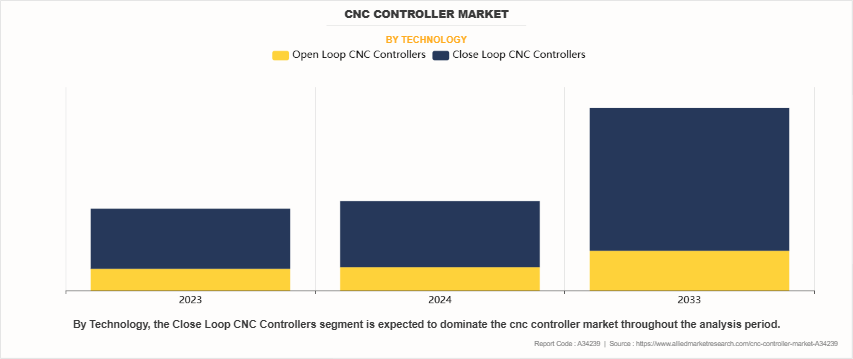

By technology, the CNC controller market outlook is segmented into Open-Loop CNC Controllers and Closed-Loop CNC Controllers. Closed-Loop CNC Controllers hold the largest market share due to their higher accuracy and efficiency in controlling machine operations.

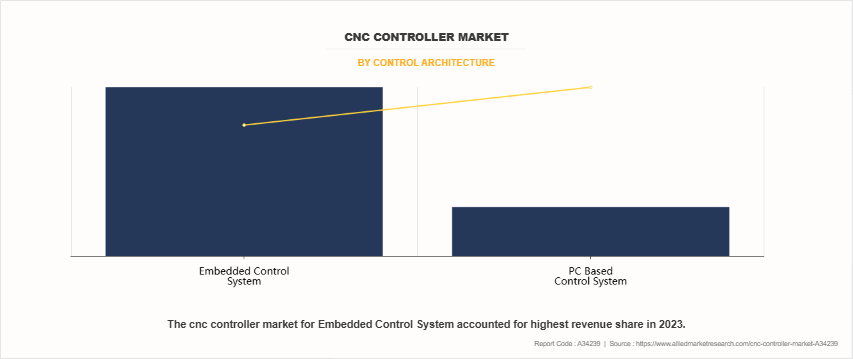

By control architecture, the CNC controller market shareis segmented into PC-based control systems and embedded control systems. PC-based control systems dominate the market because of their flexibility and ease of integration with various software applications.

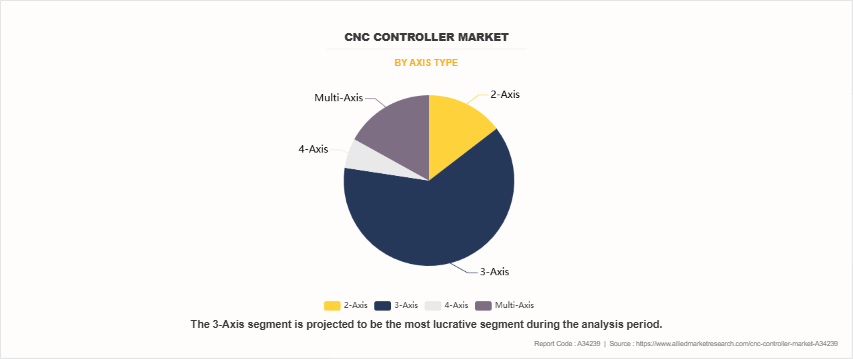

By axis type, the CNC controller market size is segmented into 2-Axis, 3-Axis, 4-Axis, and multi-Axis. Multi-axis CNC controllers lead the market due to their ability to perform complex machining tasks with high precision.

Region-wise, the CNC Controller market opportunity are analyzed across North America (the U.S, Canada, and Mexico), Europe (UK, Germany, France, Italy, and the rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and rest of Asia-Pacific), and LAMEA (Latin America, the Middle East, and Africa). Asia-Pacific dominate the CNC controller industry in 2023, owing to rapid industrialization, an increase in adoption of automation technologies, and significant investments in manufacturing infrastructure.

Competitive Analysis

The key players profiled in the report include Siemens AG, Fanuc Corporation, Mitsubishi Electric Corporation, Bosch Rexroth AG, Haas Automation, Inc., Okuma Corporation, DMG Mori Co., Ltd., Heidenhain Corporation, Fagor Automation, and GSK CNC Equipment Co., Ltd. Market players have adopted various strategies, such as product launch, collaboration & partnership, joint venture, and acquisition, to expand their foothold in the CNC controller market.

Recent Developments in Dry Cable Termination Industry

- In March 2022, Fagor Automation released the CNC8058 Turnkey Package, which is designed to upgrade manually operated machines to fully automated CNC systems. This package features HD graphics, a Windows 10 operating system, and one of the industry's top-rated conversational programming workflows with customizable navigation. The CNC8058 system includes precision ball screws, powerful 31in/lb motors, custom motor brackets, a Fagor Handwheel, and enclosures. Each system is pre-wired and configured for specific machine applications, ensuring full functionality upon delivery. Users can benefit from features such as a high-resolution display, a built-in Fagor CAD/CAM system, DXF to G-Code conversion, and remote CNC support via TeamViewer.

- In May 2024, Fagor Automation and GEKA, announced to boost the digitalization of production processes with the Fagor Digital Suite. The Fagor Digital Suite is a modular digitalization platform designed to enhance manufacturing processes, including those involving CNC controllers. This collaboration aims to integrate advanced digital solutions into CNC systems, thus improving efficiency, precision, and overall productivity in production environments.

- In August 2023, The OSP-P500 was designed to enhance user experiences and optimize modern manufacturing operations. It features dual-core processors for increased machine processing power, Digital Twin Technology for precise machining simulations, and robust data protection measures. In addition, it includes Okuma's proprietary ECO suite plus technology, which monitors and balances energy consumption with optimal machining performance.

- In November 2022, Heidenhain'ssubsidiary, Acu-Rite Solutions, launched the dro PWR, for transforming an iPad into a comprehensive digital readout. This innovation offers an intuitive user experience with touchscreen capabilities and dynamic switching between milling, turning, and grinding.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the CNC controller market segments, current trends, estimations, and dynamics of the CNC controller market analysis from 2023 to 2033 to identify the prevailing CNC controller market opportunities.

- The CNC controller market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the CNC controller market segmentation assists to determine the prevailing CNC controller market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global CNC controller market trends, key players, market segments, application areas, and market growth strategies.

CNC Controller Market Report Highlights

| Aspects | Details |

| Market Size By 2033 | USD 7.2 billion |

| Growth Rate | CAGR of 8.3% |

| Forecast period | 2023 - 2033 |

| Report Pages | 334 |

| By Technology |

|

| By Control Architecture |

|

| By Axis Type |

|

| By Region |

|

| Key Market Players | Okuma Corporation., FANUC Corporation, Hurco Companies, Inc., Fagor Automation Corporation, Mitsubishi Electric Corporation, NUM Group, Bosch Rexroth AG, Heidenhain Corporation, Siemens AG, HAAS AUTOMATION, INC. |

Analyst Review

The Computer Numerical Control (CNC) controller market is experiencing significant growth, driven by advancements in automation and increase in demand for precision in manufacturing processes. This growth is primarily fueled by the rising adoption of automation in various industries, including automotive, aerospace, and manufacturing. CNC controllers are essential for enhancing efficiency, precision, and productivity in these sectors.

Continuous improvements in CNC solutions have significantly enhanced the capabilities of CNC machines. Modern CNC controllers offer better precision, faster processing speeds, and more user-friendly interfaces, which are crucial for complex manufacturing tasks. The push towards automation to streamline operations and reduce labor costs is a major driver for the CNC controller market. Automated CNC machines can operate continuously with minimal human intervention, leading to higher productivity and lower operational costs.

The aerospace industry, in particular, relies heavily on CNC technology for producing high-precision components. Similarly, the automotive industry uses CNC machines for manufacturing various parts with high accuracy. The expansion of these industries globally is boosting the demand for CNC controllers. CNC controllers provide the flexibility to produce customized products efficiently. This capability is increasingly important as consumer demand shifts towards personalized products. Industries are leveraging CNC technology to meet these demands without compromising on quality or efficiency.

Despite the positive growth outlook, the CNC controller market faces several challenges. The cost of CNC machines and controllers can be prohibitive for small and medium-sized enterprises (SMEs). This high initial investment can be a barrier to adoption, particularly in developing regions. CNC machines are complex and can experience technical failures, leading to downtime and loss of productivity. Ensuring reliable performance and minimizing downtime is crucial for maintaining operational efficiency. Integrating new CNC controllers with existing machinery can pose compatibility challenges. This issue is particularly relevant for industries with legacy equipment that may not support modern CNC technology.

The future of the CNC controller market looks promising, with several trends expected to shape its growth. The integration of CNC controllers with Internet of Things (IoT) and Artificial Intelligence (AI) technologies is expected to revolutionize the market. IoT-enabled CNC machines can provide real-time data for predictive maintenance, while AI can optimize machining processes for better efficiency and accuracy. As developing countries continue to industrialize, the demand for CNC controllers is likely to increase. Governments in these regions are investing in manufacturing infrastructure, which will drive the adoption of CNC technology. There is a growing emphasis on sustainable manufacturing practices. CNC controllers can contribute to this by optimizing resource usage and reducing waste, thus aligning with global sustainability goals.

In conclusion, the CNC controller market is poised for robust growth, driven by technological advancements and increase in adoption of automation across various industries. While challenges such as high costs and technical issues remain, the integration of new technologies and expansion into emerging markets offer significant opportunities for future development.

he largest regional market for CNC controllers is the Asia-Pacific, driven by rapid industrialization and significant investments in manufacturing infrastructure

Upcoming trends in the CNC controller market include the increased adoption of automation and smart manufacturing, as well as the integration of IoT and cloud-based solutions

The top companies holding significant market share in the CNC controller market are Fanuc Corporation, Siemens AG, and DMG MORI

The leading application of the CNC controller market is in the automotive and aerospace industries, where precision and efficiency are critical.

The CNC controller market was valued at $3,223.2 million in 2023.

Loading Table Of Content...

Loading Research Methodology...