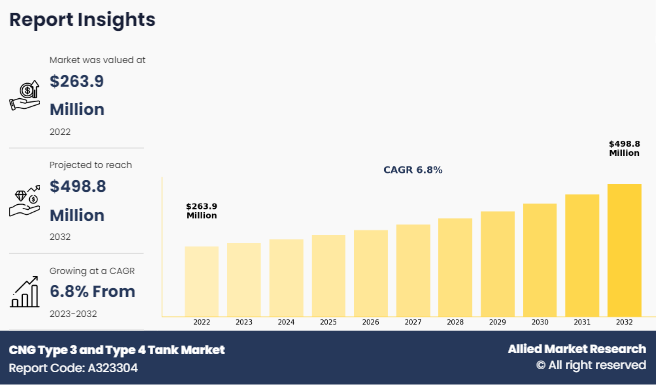

The global CNG type 3 and type 4 tank market size was valued at $263.9 million in 2022, and is projected to reach $498.8 million by 2032, growing at a CAGR of 6.8% from 2023 to 2032.

Key Takeaways

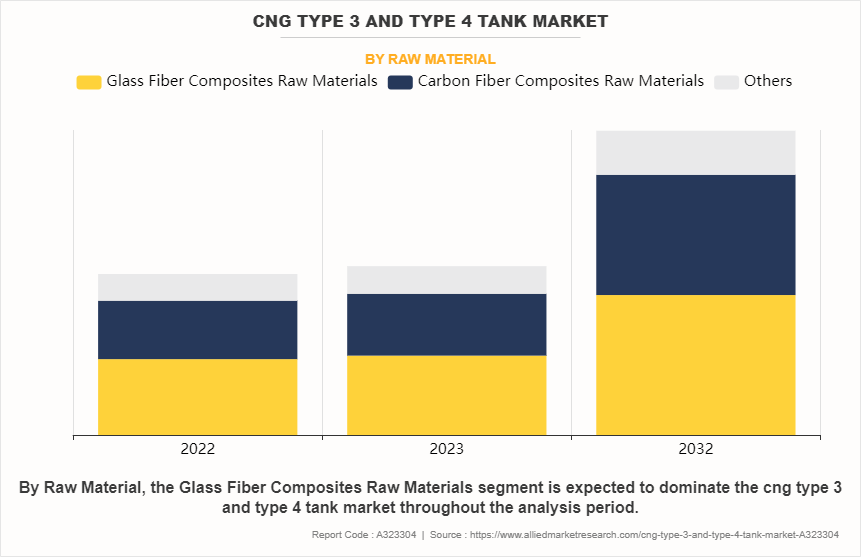

- On the basis of raw materials, the glass fiber composites raw materials segment held the largest share in the CNG type 3 and type 4 tank market size in 2022.

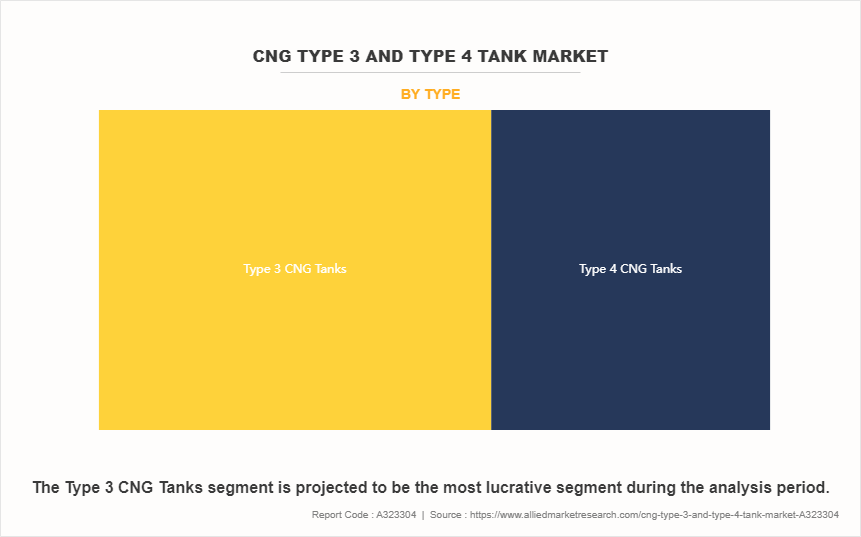

- By type, the type 3 CNG tanks segment held the largest share in the market in 2022.

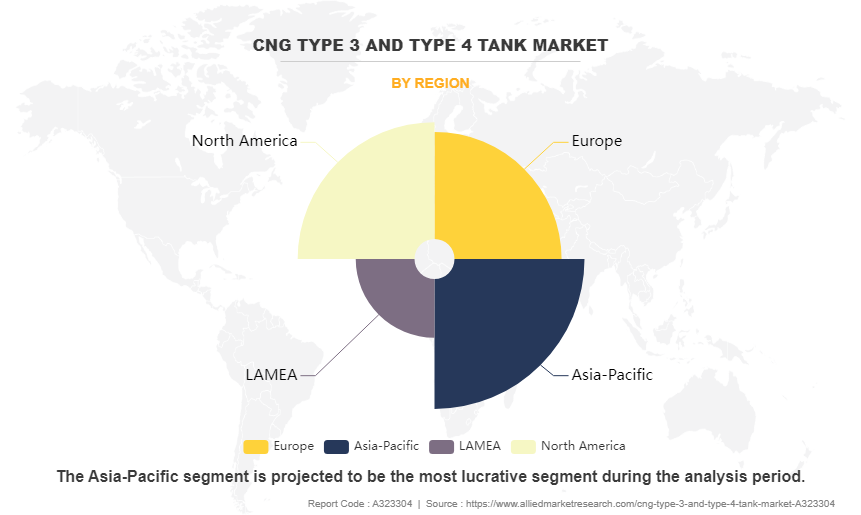

- On the basis of region, Asia-Pacific held the largest market share in 2022.

The CNG (Compressed Natural Gas) type 3 and type 4 tank market covers the production, distribution and use of specialized storage vessels designed for compressed natural gas applications. These tanks are essential in storing and transporting natural gas especially in sectors such as automotive, transportation and industrial applications where it is used as a fuel. Different technological solutions for compressed natural gas storage are represented by type 3 and 4 tanks. Metal liner wrapped with composite material such as carbon fiber, glass fiber or combination of both is commonly used in construction of type three tanks which gives them strength and durability while keeping their weight low overall. In contrast to this type, fully composite structure i.e., plastic liner reinforced by carbon fibers or other high strength materials is used in making type 4 tanks; these offer great advantages over traditional metal lined ones like better weight saving abilities coupled with higher pressure capacities & corrosion resistance properties.

CNG type 3 and type 4 tank market in the U.S.

It has been noted that there is a significant increase in demand for CNG (Compressed Natural Gas) type 3 and type 4 tanks market share in U.S. driven by a number of factors, such as the rise in the number of natural gas vehicles (NGVs) within the transportation sector, the need for greener and more sustainable fuel options and government measures to popularize natural gas.

U.S. has taken the lead in advocating for use of natural gas as a viable substitute to conventional oil-based fuels especially in transport industry hence leading to upsurge requirements for CNG tanks specifically those falling under type three or four due their lightweight nature coupled with ability store at high pressures which makes them suitable for NGVs.

This region's growth is driven by a combination of factors, including a well-established natural gas infrastructure, supportive government policies, and a strong emphasis on reducing emissions from the transportation sector. Major automakers in this region have embraced CNG technology, offering a wide range of CNG-powered vehicles to cater to both commercial and consumer markets. Stringent emission regulations and the push for cleaner transportation solutions have created a favorable environment for the adoption of CNG vehicles and, consequently, the demand for type 3 and type 4 tanks. According to the CNG Type 3 and Type 4 tank market forecast, technological advancements are expected to drive innovation and competitiveness in the industry.

Moreover, Canada based companies have developed advanced CNG tank system. For instance, in November 2022, Westport Fuel Systems successfully developed and tested a conformable Compressed Natural Gas (CNG) tank technology. This innovative solution aims to reduce transportation emissions in the Canadian truck market and within the natural gas industry.

The project focused on various aspects, including development, design verification, safety certification, vehicle integration, and testing of the CNG storage technology. Test results confirmed that the full-scale design was highly adaptable to meet packaging requirements and showcased a 50% improvement in packaging compared to conventional cylinders. Therefore, mature CNG infrastructure coupled with strict guidelines towards adoption of type 3 and type 4 CNG tank in North America, is anticipated to drive growth in the CNG type 3 and type 4 tank market share in the region during the forecast period.

Factors such as the increase in adoption of natural gas in the automotive industry, rise in environmental awareness and, advancements in composite materials are anticipated to boost growth of the global CNG type 3 and type 4 tank during the forecast period. However, intense competition, the high cost of composite tanks, stringent regulatory approvals, and an increase in use of Adsorbed Natural Gas (ANG) are expected to hinder growth of the market during the forecast period. Moreover, growth in demand from developing countries and low cost of CNG compared to crude oil derivative fuels are anticipated to create opportunities for market growth in the future.

Segment Review

The CNG type 3 and type 4 tank market is segmented into raw material, type, and region. By raw material, it is divided into glass fiber composites raw materials, carbon fiber composites raw materials, and others. By type, it is categorized into type 3 CNG tanks, and type 4 CNG tanks. By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

- On the basis of raw materials, the glass fiber composites raw materials segment held the largest share in the CNG type 3 and type 4 tank market in 2022.

- By type, the type 3 CNG tanks segment held the largest share in the market in 2022.

- On the basis of region, Asia-Pacific held the largest market share in 2022.

By Raw Material

On the basis of raw materials, the glass fiber composites raw materials segment generated maximum revenue in 2022, owing to rise in demand for cost-effective and reliable CNG tank solutions. As the adoption of CNG vehicles expands globally, particularly in emerging economies, the need for affordable tank options has become a driving force in this market.

By Type

On the basis of type, the type 3 CNG tanks segment generated maximum revenue in 2022 as these tanks strike a balance between weight savings and affordability, making them suitable for a wide range of CNG vehicle applications. The growing demand for cleaner transportation solutions and the expansion of CNG refueling infrastructure in regions such as Asia-Pacific and Europe is driving the demand for Type 3 tanks.

By Region

Based on region, Asia-Pacific dominated the CNG type 3 and type 4 tank market in 2022, owing to rapid urbanization, growing environmental concerns, and the need for affordable and cleaner transportation solutions. Countries such as China, India, and Thailand have witnessed surge in CNG vehicle adoption, fueling the demand for advanced CNG tank technologies.

Competitive Analysis

Some of the major companies that operate in the global CNG type 3 and type 4 tank market are Anhui Clean Energy Co., Ltd., Beijing Tianhai Industry Co. Ltd., Everest Kanto Cylinders Ltd., Faber Industrie S.P.A, Fiba Technologies, Hexagon Agility, Luxfer Group, Quantum Fuel Systems Technologies Worldwide Inc, Worthington Industries, Indoruss Synergy Pvt. Ltd., Santek, Shandong AUYAN New Energy Technology Co., Ltd., Time Technoplast Ltd., Hanwha Solutions, Shanghai Metal Corporation, Beijing SinoCleansky Technologies Corp., and Weifang Hengsheng Gas Co.

Increase in adoption of natural gas in the automotive industry

Natural gas vehicles are high mileage vehicles which provide higher fuel range for various applications. The advantages of natural gas as a transportation fuel are its domestic availability, widespread distribution infrastructure, and reduced greenhouse gas emissions over conventional gasoline and diesel fuels.

CNG vehicles store natural gas in tanks and cylinders where it remains in a gaseous state under pressure. The driving range of natural gas vehicles is less than that of comparable diesel or gasoline vehicles, due to lower energy density of natural gas, hence, extra storage tanks/cylinders can increase the range. Thus, multiple benefits associated with natural gas fuel its adoption in the automotive industry, which, in turn, notably contributes toward the CNG type 3 and type 4 tank market growth.

Rise in environmental awareness

Automobiles are a major source of ozone, particulate matter, and other smog-forming pollutants. The dangers of air pollution to one's health are enormous. Poor air quality exacerbates respiratory illnesses such as asthma & bronchitis, raises the risk of life-threatening disorders such as cancer, and costs the health-care system a lot of money. Particulate pollution is responsible for up to 30,000 deaths prematurely each year. Vehicles, engines, and motorized equipment that emit exhaust and evaporative pollutants are illustrations of these sources. Vehicles utilized on roadways for passenger or freight transportation are considered on-road sources. Vehicles, motors, and equipment used for construction, agriculture, recreation, and a variety of other applications are examples of off-road sources. To reduce the environmental impact of the vehicle sector, governments all over the world have passed strict environmental restrictions. For instance, a group of 21 state attorneys general, the District of Columbia, and several large U.S. cities encouraged the U.S. government to implement stringent automobile emission laws in September 2021. Automobile manufacturers create alternative fuel-powered vehicles that provide a greener driving experience with little or no hazardous emissions.

The use of natural gas as a transport fuel has two environmental advantages; for instance, natural gas is a clean burning fuel with very low nitrogen oxides and soot emissions, thus substantially improving the local air quality. In addition to this, natural gas produces less CO2 for every unit of energy consumed by the vehicle. CNG is employed to power passenger cars and city buses.

These vehicles emit 5-10% less CO2 than comparable gasoline-powered vehicles. The recent environmental changes, such as increase in global warming across the globe, have led to rise in awareness among the people to spend the income to buy vehicles powered by natural gas that are less harmful to the environment compared to conventional vehicles. Moreover, governments across the globe have imposed stringent norms for vehicle emission. Increasing government norms related to vehicle emission is expected to propel the demand for CNG vehicles, which in turn is anticipated to boost the market for CNG type 3 and type 4 tank across the globe.

Advancements in composite materials

Advancements in composite materials have played a crucial role in driving the CNG (Compressed Natural Gas) type 3 and type 4 tank market. To store compressed natural gas in vehicles, these types of tanks use advanced composites which are better than steel tanks in several ways. In most cases, type 3 and type 4 tanks are made from composites that include a mixture of high-strength fibers such as carbon fiber or glass fiber, embedded within a polymer resin matrix. This configuration allows for high strength-to-weight ratios so that while still having to meet durability requirements along with pressure handling capacities; they can be lighter than their steel counterparts.

Continuous research and development on composites have resulted in, among others, stronger but lighter weight fiber as well as improved resin systems for more robustness. These developments make it possible for manufacturers to produce CNG cylinders capable of working at higher pressures without adding too much weight thereby improving fuel economy and increasing driving ranges for such vehicles.

Moreover, the use of composite materials in CNG tanks has improved safety features. These materials are highly resistant to corrosion and fatigue, reducing the risk of tank failure or leakage over time. Additionally, composite tanks are designed to release gas gradually in the event of an impact or puncture, minimizing the risk of explosive rupture compared to traditional steel tanks. Advancements in manufacturing processes, such as filament winding and resin transfer molding, have also contributed to the growth of the CNG type 3 and type 4 tank market. These processes allow for precise control over the placement and orientation of the composite fibers, resulting in optimized strength and durability while minimizing material waste and production costs.

Furthermore, as composite materials continue to evolve and become more cost-effective, CNG type 3 and type 4 tanks are becoming increasingly affordable, making them a viable option for a broader range of vehicle manufacturers and consumers. This has opened new market opportunities and facilitated the wider adoption of CNG vehicles, driving the demand for these advanced composite tanks. Overall, the advancements in composite materials have been a driving force behind the growth of the CNG type 3 and type 4 tank industry, enabling the production of lighter, stronger, and safer tanks that meet the evolving needs of the CNG vehicle industry and contribute to more sustainable and efficient transportation solutions.

Increase in use of Adsorbed Natural Gas (ANG)

Compressed natural gas (CNG) cylinders are available in a number of different types, weights, and sizes to suit different applications. Generally, as tanks weight decreases, tanks costs increase. In some cases, tanks are available for lease from vehicle converters or gas suppliers.

Adsorbed Natural Gas (ANG) stores natural gas in a carbon honeycomb structure and eliminates the need for high pressure storage cylinders/tanks. As the gas impacts the system, it is adsorbed into the material where it can be stored at a very low pressure in a solid form. This means it is no longer required to use high pressure cylinders to store the fuel onboard the vehicle. This reduces weight and allows the storage to be custom molded into a huge variety of shapes and sizes. The real advantage of an ANG system is that it is backwards compatible. ANG systems do not require the 3,600 pounds per square inch (PSI) pressure needed for today's CNG vehicles, though they can still use it. An ANG-equipped vehicle can still use the existing CNG network to fill up. While it is true it could dramatically lower the required pressures for an onsite station, they would not be stranded by adopting the new technology. The increase in use of Adsorbed Natural Gas storage technology in vehicles is expected hinder the demand for CNG type 3 and type 4 tank.

Growth in demand from developing countries

The demand for automobiles in emerging countries is expected to expand dramatically in future years owing to urbanization and increased industrial activity. Manufacturers are increasingly building production plants in emerging countries due to the rise in demand for automobiles in the region. Developing nations have observed an increase in the production of automobiles owing to factors such as favorable government policies, increasing GDP, and rising consumer spending. Emerging companies and market leaders in many industries throughout emerging nations, such as e-commerce, the food industry, and others, have boosted demand for delivery and transportation solutions, therefore boosting the production of heavy commercial vehicles even further.

With the increase in demand for vehicles, the demand for CNG vehicles is increasing as it is an environment-friendly and cost-effective alternative to petrol and diesel. As a result, governments across various countries in the region are promoting their use of traditional fuels. Owing to this, the CNG vehicles have gained popularity, which in turn is expected to fuel the demand for CNG tanks during the forecast period.

Low cost of CNG compared to crude oil derivative fuels

CNG is a natural gas stored at pressure. The increased pressure allows large volumes of gas to be contained and transported within a given unit of space. It is necessary to compress natural gas for transport. The density of CNG can be reduced by refrigeration and this allows for greater transportation volume. CNG is more environmentally friendly than oil and coal due to lower carbon dioxide (CO2) emissions per unit, less costly per unit of energy, and more readily available domestically in abundant supply. Owing to the precipitous drop in prices for compressed natural gas (CNG), fleets can save a fortune by switching over to these fuels. OEMs such as Freightliner and Thomas Built Bus have jumped into the market. International a U.S. based truck manufacturer now offers the TranStar Class 8 semi that runs on CNG. Owing to this, the low cost of CNG compared to crude oil derivative fuels is fueling the growth of CNG type 3 and type 4 market.

Recent Developments in the CNG type 3 and type 4 tank Industry

- In March 2022, EKC International FZE, a wholly owned subsidiary of Everest Kanto Cylinder Limited announced for setting up a CNG cylinder production facility in Egypt. It established as a joint venture with a local Egyptian partner with majority holding being with EKC FZE.

- In June 2021, Luxfer Holdings PLC signed an agreement with Momentum Fuel Technologies to provide neck mounted GStor Go Type 4 cylinders, one of the major manufacturers of high-pressure composite and aluminum cylinders.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the cng type 3 and type 4 tank market analysis from 2022 to 2032 to identify the prevailing cng type 3 and type 4 tank market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the cng type 3 and type 4 tank market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global cng type 3 and type 4 tank market trends, key players, market segments, application areas, and market growth strategies.

CNG Type 3 and Type 4 Tank Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 498.8 million |

| Growth Rate | CAGR of 6.8% |

| Forecast period | 2022 - 2032 |

| Report Pages | 250 |

| By Raw Material |

|

| By Type |

|

| By Region |

|

| Key Market Players | Luxfer Holdings PLC, Shanghai Metal Corporation, Sinocleansky, Worthington Industries Inc., Hanwha Solutions, Time Technoplast Ltd., Anhui Clean Energy Co., Ltd., Santek, Indoruss Synergy Pvt. Ld., Quantum Fuel Systems LLC, Weifang Hengsheng Gas Co., Ltd., EKC, Hexagon Composites ASA, Shandong AUYAN New Energy Technology Co., Ltd., Faber Italy, FIBA Technologies, Inc., Beijing Tianhai Industry Co., Ltd. |

Anhui Clean Energy Co., Ltd., Beijing Tianhai Industry Co. Ltd., Everest Kanto Cylinders Ltd., Faber Industrie S.P.A, Fiba Technologies, Hexagon Agility, Luxfer Group, Maruti Koatsu Cylinders Ltd, Quantum Fuel Systems Technologies Worldwide Inc., Worthington Industries, Indoruss Synergy Pvt. Ltd., Santek, Shandong AUYAN New Energy Technology Co., Ltd., Time Technoplast Ltd., Hanwha Solutions, Shanghai Metal Corporation, Beijing SinoCleansky Technologies and Corp, Weifang Hengsheng Gas Co.

The global CNG type 3 and type 4 tank market was valued at $263.9 million in 2022, and is projected to reach $498.8 million by 2032, registering a CAGR of 6.8% from 2023 to 2032.

Largest regional market for CNG Type 3 and Type 4 Tank is Asia-Pacific.

Leading application of CNG Type 3 and Type 4 Tank Market Type 3 CNG Tanks.

Upcoming trends of CNG Type 3 and Type 4 Tank Market are growth in demand from developing countries and low cost of CNG compared to crude oil derivative fuels.

Loading Table Of Content...

Loading Research Methodology...