Collaborative Robot Market Research, 2032

The global collaborative robot market was valued at $1.4 billion in 2022, and is projected to reach $27.4 billion by 2032, growing at a CAGR of 36.3% from 2023 to 2032.

A collaborative robot, also known as a cobot, is a type of robotic designed to work alongside humans collaboratively. Unlike normal industrial robots that are regularly caged or separated from humans due to safety concerns, collaborative robots are specifically designed to operate in close proximity to humans without causing harm. The defining characteristic of collaborative robots is their ability to interact and collaborate with human workers. They are equipped with various sensors, such as force sensors and vision systems, that enable them to perceive and respond to their environment.

Collaborative robots are typically programmed to perform tasks that require physical interaction, such as handling objects, assembly, or machine tending. Collaborative robots are designed to prioritize safety and are built with features that limit the risk of injury to humans. They have built-in security mechanisms, such as force & torque limiting, speed reduction, and collision detection, which allow them to notice the presence of humans and automatically adapt their behavior to prevent accidents.

There has been a rising demand for automation solutions owing to the increase in demand for automation in industries worldwide to improve productivity and efficiency. Collaborative robots provide a flexible and cost-effective automation solution, especially for small and medium-sized firms (SMEs) that may additionally not have the resources or knowledge to implement traditional industrial robots. Collaborative robots are equipped with advanced sensors and safety features that enable them to detect and respond to human presence, ensuring safe collaboration. This flexibility allows cobots to be easily integrated into existing production lines or workspaces without the need for extensive modifications.

Collaborative robots are designed to be user-friendly and accessible, even for those without extensive robotics expertise. Many cobots have intuitive interfaces and programming methods, such as teach pendant systems or graphical user interfaces, making it easier for operators to set up and operate them. The combination of flexibility, ease of use, safety, and adaptability has made collaborative robots a popular choice for industries looking to enhance productivity and efficiency through automation. These factors are anticipated to have a positive impact on the collaborative robot market outlook in the coming years.

The high initial cost of collaborative robots is expected to be a restraint for the collaborative robot market growth. The upfront investment required to implement collaborative robots includes not only the cost of the robot itself but also additional costs such as integration, training, and maintenance. Moreover, the cost of collaborative robots can vary depending on factors such as payload capacity, functionality, and the level of customization required for specific tasks. For small and medium-sized enterprises (SMEs) with constrained budgets, the high initial cost can make it challenging to justify the investment in collaborative robots, especially if the anticipated return on investment is not immediately apparent. SMEs may prefer to allocate their resources to other areas of their business or opt for traditional robots or manual labor, which may have lower upfront costs.

Cobots are designed to be user-friendly and can be easily programmed by operators without extensive programming knowledge. This feature allows to quickly reprogram the robots to perform different tasks, eliminating the need for specialized programming expertise or external support. This flexibility enables businesses to respond swiftly to changing production needs, reducing downtime, and increasing overall efficiency. Cobots can seamlessly switch between different tasks, making them highly adaptable to changing manufacturing requirements. Traditional industrial robots often require significant reconfiguration and downtime when switching tasks, whereas cobots can be rapidly reprogrammed to perform new operations. This ability enables manufacturers to optimize production lines, accommodate product variations, and efficiently handle short production runs or customized orders. Moreover, the flexibility of cobots allows for streamlined production lines. The flexibility offered by cobots in the manufacturing industry is estimated to drive the collaborative robot market demand in the coming years.

Competitive Analysis

The key players profiled in the collaborative robot market report include Universal Robots A/S, ABB, Fanuc Corporation, Denso Corporation, Techman Robot Inc., Omron Adept Technologies Inc., Doosan Robotics, Epson Robors, Robert Bosch GmbH, and F&P Robotics AG. For instance, in March 2021, Comau S.p.A. launched a cost-effective cobot named Racer-5 suitable for packaging and warehousing. This advanced cobot works at an industrial speed of up to 6 m/s and has a 5kg payload capacity.

Segment Overview

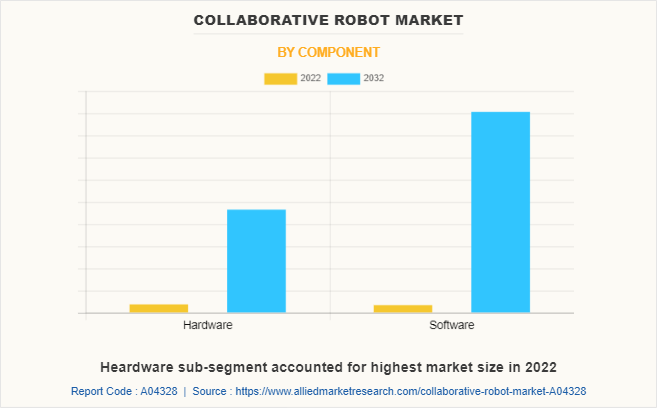

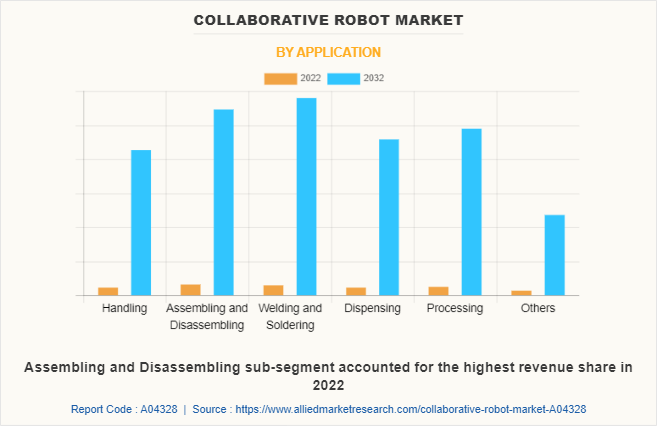

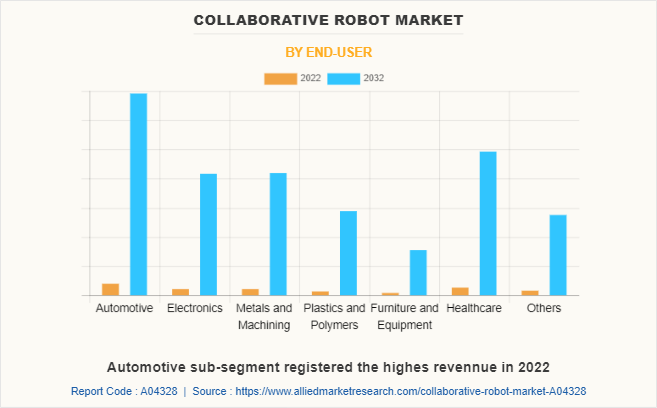

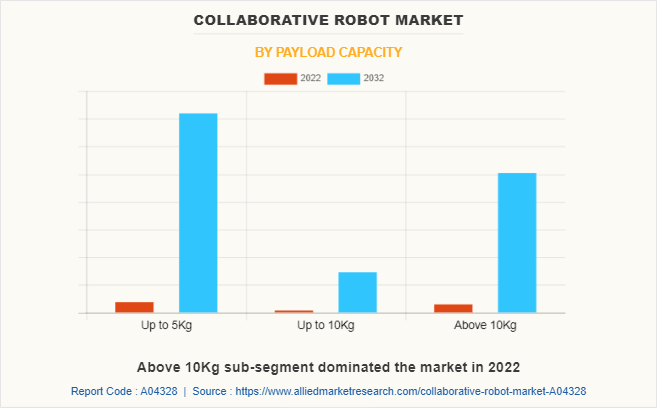

The collaborative robot market is segmented on the basis of component, application, end-user, payload capacity, and region. By component, the market is divided into hardware and software. By application, the COBOT market is classified into handling, assembling & disassembling, welding & soldering, dispensing, processing, and others. By end-user, the collaborative robot market is classified into automotive, electronics, metals & machining, plastics & polymers, furniture & equipment, healthcare, and others. By payload capacity, the collaborative robot market is classified into up to 5kg, up to 10kg, and above 10kg. By region, the COBOT market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

By component, the hardware sub-segment dominated the collaborative robot Industry in 2022. The hardware segment growth in the collaborative robot market is driven by continuous technological advancements. As technology progresses, hardware components such as sensors, actuators, grippers, and control systems become more advanced, enabling cobots to perform complex tasks with higher precision and efficiency. The hardware segment has witnessed cost reductions over time, making cobots more affordable for small and medium-sized enterprises (SMEs). Lower hardware costs, along with the potential for increased productivity and return on investment, have encouraged more companies to adopt cobots. Hardware components play a vital role in ensuring the safety of cobots, such as force-torque sensors, collision detection systems, and advanced control algorithms. The emphasis on safety regulations and standards promotes the development and adoption of advanced hardware components in cobots. These are predicted to be the major factors affecting the collaborative robot market size during the forecast period.

By application, the assembling & disassembling sub-segment dominated the global collaborative robot market share in 2022. Assembling and disassembling tasks often require flexibility due to changing product designs, variations, or customization. Cobots provide the ability to quickly adapt to different tasks, reducing the time and effort required for reprogramming or retooling traditional automation systems. Moreover, many industries are facing labor shortages, making it challenging to find skilled workers for repetitive and labor-intensive tasks like assembling and disassembling. Cobots can fill this gap by automating these tasks, reducing the dependency on human labor. In addition, cobots can operate 24/7, increasing productivity and helping to reduce labor costs in the long run. Furthermore, assembling and disassembling tasks can involve handling heavy or hazardous components, leading to safety concerns and potential workplace injuries. Cobots are designed with built-in safety features, such as force sensing, collision detection, and speed reduction, which allow them to work safely along human operators. By integrating cobots into the assembling and disassembling processes, companies can improve worker safety and reduce the risk of accidents.

By end-user, the automotive sub-segment dominated the collaborative robot market in 2022. The automotive industry is one of the leading adopters of automation technology. Collaborative robots, also known as cobots, offer flexibility, safety features, and ease of use, making them ideal for automating various tasks in the automotive manufacturing process. Moreover, collaborative robots are designed to work safely together with humans without the need for extensive safety barriers. In the automotive industry, cobots are used to handle heavy components, perform repetitive tasks, and assist workers in ergonomically challenging jobs. By reducing the risk of workplace injuries and improving ergonomics, cobots contribute to a safer working environment. Collaborative robots offer the advantage of quick and easy reprogramming, allowing manufacturers to adapt their production lines to new models or configurations rapidly. Cobots can be reprogrammed and redeployed for various tasks, making them versatile assets for automotive manufacturers.

By payload capacity, the up to 5kg sub-segment dominated the global collaborative robot market share in 2022. Collaborative robots in the up to 5kg payload capacity are highly flexible and can be easily programmed to perform different tasks. They can handle a wide range of applications, including assembly, packaging, machine tending, pick & place operations, and quality inspection. Furthermore, up to 5kg payload capacity cobots are well-suited for many small and medium-sized enterprises that require automation but may not have floor space or financial resources for larger robots. These cobots can be easily integrated into existing production lines or workstations, providing SMEs with an affordable automation solution. Moreover, technological advancements in robotics, artificial intelligence, and machine learning have contributed to the development of more capable and intelligent collaborative robots. These advancements have improved the performance, reliability, and ease of use of cobots in the up to 5kg sub-segment.

By region, Europe dominated the global collaborative robot market in 2022 and is projected to be the fastest-growing region during the forecast period. The developing manufacturing industry particularly in sectors such as automotive, electronics, and machinery has boosted the Europe collaborative robot market. European countries have been actively promoting and adopting industrial automation technologies to enhance their manufacturing competitiveness. Collaborative robots play a crucial role in this automation drive, as they can work together with human workers, increasing productivity and efficiency. Europe has stringent safety regulations and standards in the workplace. Collaborative robots are designed with built-in safety features such as force sensing, collision avoidance, and power and speed limitations. The focus on worker safety has led to increased adoption of collaborative robots in the region. Furthermore, governments in Europe have implemented various initiatives and funding programs to support the adoption of robotics and automation technologies. These initiatives aim to enhance industrial productivity, promote innovation, and create new job opportunities. Such support from governments encourages the deployment of collaborative robots in various industries.

Impact of COVID-19 on the Global Collaborative Robot Industry

- The COVID-19 pandemic has had both positive and negative impacts on the collaborative robot market opportunity. The pandemic highlighted the need for automation in various industries, including manufacturing, logistics, and healthcare. The cobot market relies on global supply chains for various components and parts. The pandemic disrupted these supply chains, leading to delays in manufacturing and delivery of cobots. This has affected the availability and deployment of cobots in some cases.

- Various industries faced labor shortages due to travel restrictions, quarantines, and social distancing measures. Cobots helped to fill the gaps by taking over tasks that would typically be performed by human workers, thereby ensuring continuity in production processes. The global economic downturn caused by the pandemic impacted businesses' financial capabilities, leading to budget constraints and reduced investment in automation technologies, including cobots. Some companies postponed or canceled their plans to implement cobot systems due to financial uncertainties.

- Collaborative robots offer a solution for maintaining social distancing in workplaces. By utilizing cobots, companies can limit the number of human workers in close proximity to each other, reducing the risk of virus transmission and ensuring a safer working environment. In certain industries heavily affected by the pandemic, such as hospitality and aviation, the focus shifted from long-term investments in automation to immediate cost-cutting measures and survival strategies. Therefore, the demand for cobots decreased in these sectors.

- The increased awareness of the benefits of automation and the need for social distancing measures have also created new opportunities for the key market players. As the global economy recovers and businesses adapt to the post-pandemic landscape, the demand for collaborative robots is expected to continue growing in the long term.

Key Benefits For Stakeholders

- The report provides exclusive and comprehensive analysis of the global collaborative robot market trends along with the collaborative robot market forecast.

- The report elucidates the collaborative robot market opportunity along with key drivers, and restraints of the market. It is a compilation of detailed information, inputs from industry participants and industry experts across the value chain, and quantitative and qualitative assessment by industry analysts.

- Porter’s five forces analysis helps analyze the potential of the buyers & suppliers and the competitive scenario of the collaborative robot market for strategy building.

- The report entailing the collaborative robot market analysis maps the qualitative sway of various industry factors on market segments as well as geographies.

- The data in this report aims on market dynamics, trends, and developments affecting the collaborative robot market growth.

Collaborative Robot Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 27.4 billion |

| Growth Rate | CAGR of 36.3% |

| Forecast period | 2022 - 2032 |

| Report Pages | 309 |

| By Component |

|

| By Application |

|

| By End-user |

|

| By Payload Capacity |

|

| By Europe |

|

| By Asia-Pacific |

|

| By North America |

|

| By LAMEA |

|

| By Key Market Players |

|

The rising demand for automation is one of the major growth factors of the collaborative robot market. The need for automation in various industries, such as manufacturing, logistics, and healthcare, is driving the demand for collaborative robots. These robots can work alongside human workers safely and efficiently, enhancing productivity and reducing costs, which is estimated to generate excellent opportunities in the collaborative robot market.

Asia-Pacific will provide more business opportunities for the global collaborative robot market in the future.

The major growth strategies adopted by collaborative robot market players are investment and agreement.

The hardware sub-segment of component acquired the maximum share of the global collaborative robot market in 2022.

Universal Robots A/S, ABB, Fanuc Corporation, Denso Corporation, Techman Robot Inc., Omron Adept Technologies Inc., Doosan Robotics, Epson Robors, Robert Bosch GmbH, and F&P Robotics AG are the major players in the collaborative robot market.

The automotive industry is one of the major customers in the global collaborative robot market.

The market for collaborative robots is influenced by the increasing use of technological advancements such as artificial intelligence (AI), and machine learning (ML), which have significantly improved the capabilities of collaborative robots. These robots can now perform complex tasks, adapt to dynamic environments, and interact with humans more intelligently, making them more appealing to businesses, which is estimated to drive the adoption of collaborative robots.

Collaborative robots are finding applications in a wide range of industries, including manufacturing, e-commerce, healthcare, agriculture, and food processing. Their versatility enables them to perform tasks such as assembly, packaging, pick-and-place, quality control, and even interact with patients in healthcare settings, which is anticipated to boost the collaborative robot market in the upcoming years.

Loading Table Of Content...

Loading Research Methodology...