Composite Preforms Market Research, 2031

The global composite preforms market was valued at $239.3 million in 2021, and is projected to reach $433.1 million by 2031, growing at a CAGR of 6.1% from 2022 to 2031.

Report Key Highlighters

- The composite preforms market is consolidated in nature among companies such as include Kümpers Composites, C and J Antich, SAERTEX Group, Sigmatex, Axis Composites Limited, Albany International Corp, T.E.A.M., Inc., and Eurocarbon B.V.

- The study contains qualitative information such as the market dynamics (drivers, restraints, challenges, and opportunities), and Porter’s Five Force Analysis across North America, Europe, Asia-Pacific, LAMEA regions.

- The segment analysis of each region and country in terms of value ($million) and volume (tons) during the forecast period 2021-2031 is covered in the composite preforms market report

- Latest trends in global composite preforms market such as product development, undergoing R&D activities, and strategies adopted by key players are analyzed across 22 countries in 4 different regions.

Composite preforms are essentially fibers of selected composition arranged in varying 2D and 3D forms to build the required shape. Nowadays composite preforms are preferred over traditional materials, such as aluminum, steel, iron, and more, due to their low weight, high durability, and corrosion resistance. Composite preforms find wide applications in global metallurgical, aerospace & defense, and heavy mechanical industries as they are the basic raw material to these industries and have high potential to be customized.

The aerospace industry is one of the fastest-growing sectors globally owing to the rise in demand for air travel, advanced technology, rise in disposable income, improvement in the standard of living, international trade promotion, and emerging economies that have enhanced the performance of the overall aerospace industry. The 3D woven composite preforms with Z-direction reinforcement are mainly used in landing gears and engine turbine blade applications. This factor is expected to boost the market during the forecast period.

However, strict industrial requirements and the inability of certain composites to meet the technical requirements of composite preforms is expected to hamper the market growth. Also, rising prices of raw materials may restrain the market growth. On the contrary, the rapid installation of AI technology systems for monitoring ships and high growth in the sea trade businesses in recent years has enhanced the performance of the overall marine industry.

Composite preforms have great scope in the marine sector where they are used for manufacturing watercraft, submersibles, offshore structures, and other marine structural components. In addition, it is an economical solution for manufacturing complex shapes due to which several key players are actively engaged in the production process of composite preforms. These factors are fostering the potential sales of composite preforms market in the marine industry; thus, offering the most lucrative opportunities for the market.

Aerospace followed by the automotive industry is expected to be the major consumer of composite preforms during the forecast period. In addition, emerging economies along with R&D projects of numerous space agencies such as NASA, ESA, and ISRO provide excellent opportunities for composite preforms.

The report segments the composite preforms market on the basis of structure type, product type, fiber type, application, and region. Based on structure, it is classified into One-D, Two-D, and Three-D. By product type, it is divided into stitching, braiding, knitting, and weaving. Based on fiber type, it is categorized into carbon, glass, and others. By application, it is divided into automotive, consumer goods, infrastructure, marine, medical, aerospace & defense. Region wise, it is studied across North America, Europe, Asia-Pacific, and LAMEA.

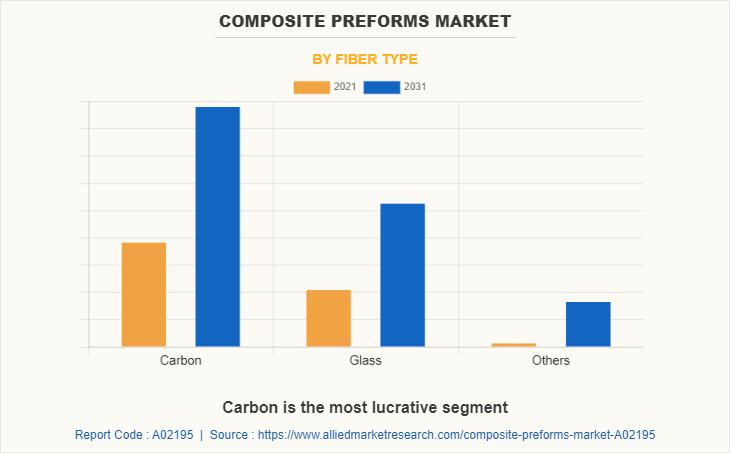

In 2021, the carbon segment was the largest revenue generator, and is anticipated to grow at a CAGR of 6.4% during the forecast period. Carbon fiber preforms are used in both commercial aircraft and military applications for a number of years and their usage is expanding into automotive and consumer goods components. This factor is the major key market trend in the global composite preforms market for carbon fiber.

Furthermore, carbon fiber preforms offer various significant properties such as easier designs, lower costs as compared to continuous fiber composites, and potential for near zero waste, which in turn has surged the demand for carbon fiber preforms in aerospace & defense, automotive, industrial, and other end-use sectors. Moreover, the rise in the upgradation of fighter jets and modern armored fighting vehicles (AFVs) where carbon fiber preform is widely preferred as a lightweight material for producing various components is expected to fuel the demand for carbon fiber preform during the forecast period.

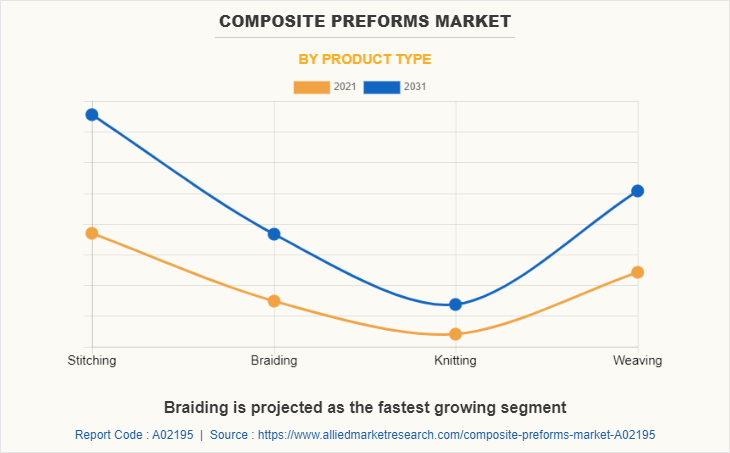

By product type, the stitching segment dominated the global market in 2021, and is anticipated to grow at a CAGR of 6.3% during forecast period. Stitching technique is often regarded as a direct approach to enhance the strength of composite preforms. It involves high-tensile strength sewing yarn, usually made from carbon, glass, or Kevlar, through the layers of composites using an industrial sewing machine. It is a low-cost technique for improving the stiffness and damage tolerance of composites preforms. These factors altogether have surged the usage of stitched composite preforms among several end-use sectors such as aerospace & defense, sporting, automotive, and others.

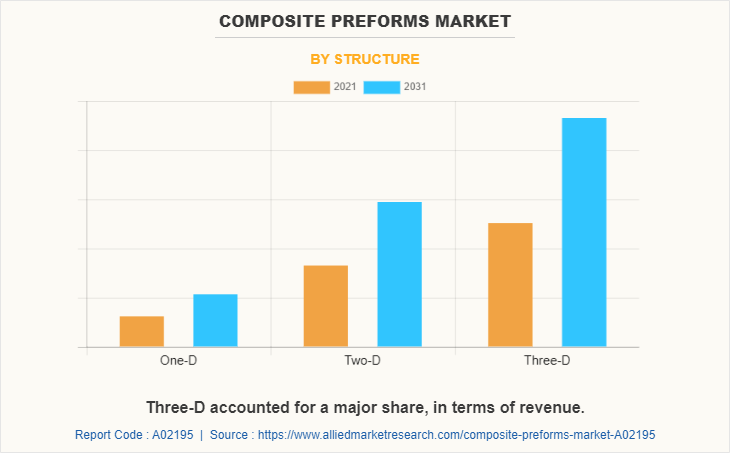

In 2021, the three-D segment was the largest revenue generator, and is anticipated to grow at a CAGR of 6.4% during the forecast period. Three-dimension woven composite preforms offer numerous advantages such as weight reduction, reduced crack risk, lower production time, and cost reduction. These factors altogether have surged the utilization of three-dimensional composite preforms among various end-use sectors such as aerospace & defense, automotive, and others.

Furthermore, three-dimensional composite preforms offer weight reduction and recyclability, which in turn has surged its demand among lightweight vehicle manufacturers. Moreover, three-dimensional composite preforms offer many structural and weight advantages over traditional steel and injection molded automotive parts, which in turn is expected to fuel the demand for three-dimensional composite preforms among the growing automotive sector.

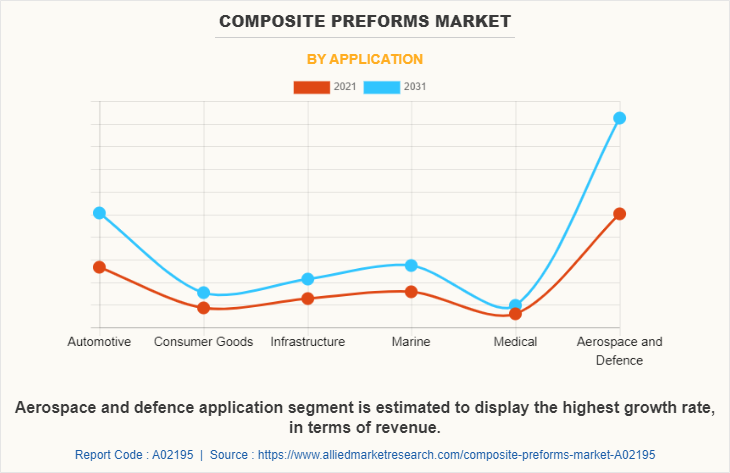

By application, the aerospace and defence segment dominated the global market in 2021, and is anticipated to grow at a CAGR of 6.3% during forecast period. Factors such as increasing air travel activities and increasing aircraft production rate have led the aerospace sector to witness a significant growth where composite preforms are widely used for manufacturing various lightweight components. This is expected to be a key driver for the growth of the composite preforms market for aerospace applications.

Furthermore, countries such as the U.S., China, India, and others are constantly engaged in producing modern fighter jets with advanced armor facilities where composite preforms are widely used as a prime lightweight material for manufacturing various aircraft parts and components.

For instance, according to a report published by Indian Ministry of Defense, Indian Airforce has launched a mega $20 billion Multi-Role Fighter Aircraft (MRFA) program for the development of India’s aerospace ecosystem. This event is projected to surge the demand for composite preforms in the growing aerospace & defense sector; thus, creating lucrative opportunities for the market.

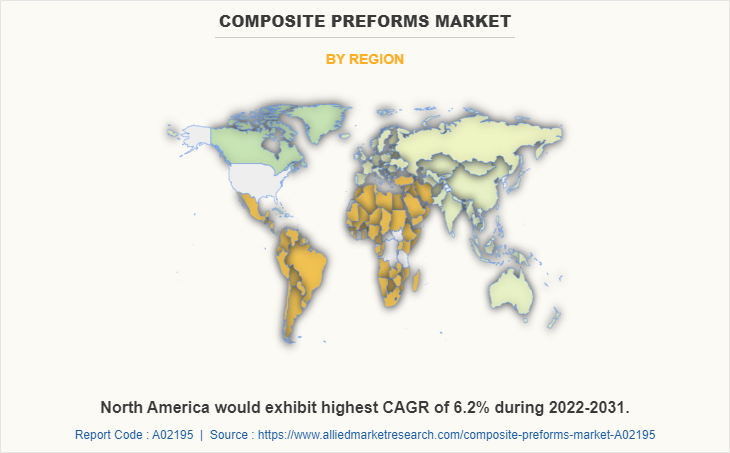

The Asia-Pacific composite preforms market size is projected to grow at the highest CAGR of 6.9% during the forecast period. The rising infrastructure, automotive, aerospace & defense, and other sectors, have enhanced the performance of composite preforms in the Asia-Pacific region. China’s electronic vehicle sector is increasing rapidly, which in turn has enhanced the demand for lightweight composite preforms in the region.

According to a report published by the United Nations Statistics Division, China witnessed around 28.7% of the global manufacturing output for electric vehicles in 2019. Also, countries such as India and Australia are witnessing a rapid increase in the automotive sector, where composite preforms are employed to produce various lightweight vehicle parts.

For instance, according to a report published by the Indian Ministry of Commerce and Industry, the transportation sector in India is expected to grow at a compound annual rate (CAGR) of 5.9%. This is expected to enhance the performance of the composite preforms market in the Asia-Pacific region. Furthermore, the increase in attempts by the governments for producing modern fighter jets is projected to surge the demand for composite preforms to be used as a prime material in manufacturing various jet components; thus, creating remunerative opportunities for the market.

The global composite preforms market profiles leading players including Kümpers Composites, C and J Antich, SAERTEX Group, bally ribbon mills, Sigmatex, Axis Composites Limited, Albany International Corp, T.E.A.M., Inc., A and P Technology, and Eurocarbon B.V. The global composite preforms market report provides in-depth competitive analysis as well as profiles of these major players.

IMPACT OF COVID-19 ON THE GLOBAL COMPOSITE PREFORMS MARKET

- The composite preforms market has been negatively impacted due to the wake of COVID-19 pandemic. Key factors such as its dependence on infrastructure, automotive, aerospace & defense, industrial, and other end-use sectors have hampered the market growth in 2020. Decrease in the net sales of automotive industry has been observed during the pandemic. For instance, according to a report published by Society of Indian Automobile Manufacturers (SIAM), sale of passenger vehicles, commercial vehicles and two wheeler vehicles declined by 51%, 88%, and 40%, respectively in March 2020.

- However, post COVID-19, the market is growing and sales of automotive have increased. For instance, according to data revealed by Economic Times in August 2022, sales of cars, utility vehicles, and vans have registered 3.7 million units., which is 17-20% higher compared with 2021 year's sales. This has enhanced the performance of the composite preforms market in 2021 and is expected to experience gradual growth.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the composite preforms market analysis from 2021 to 2031 to identify the prevailing composite preforms market opportunities.

- Market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders to make profit-oriented business decisions and strengthen their supplier-buyer network.

- An in-depth analysis of the composite performs market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes an analysis of the regional as well as global composite preforms market trends, key players, market segments, application areas, and market growth strategies.

Composite Preforms Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 433.1 million |

| Growth Rate | CAGR of 6.1% |

| Forecast period | 2021 - 2031 |

| Report Pages | 471 |

| By Fiber Type |

|

| By Product Type |

|

| By Structure |

|

| By Application |

|

| By Region |

|

| Key Market Players | Bally Ribbon Mills, T.E.A.M., Inc., A and P Technology, SAERTEX Group, Kumpers Composites, Sigmatex, Axis Composites Limited, C and J Antich, Eurocarbon B.V., Albany International Corp |

| Other Key Market Players | Wanyou New Materials Technology Co Ltd. Renco Corporation CFPcomposites Sigmatex Limited Link Composites Pvt. Ltd. Albany Engineered Composites Inc. |

Analyst Review

According to CXOs of leading companies, the global composite preforms market is expected to exhibit high growth potential. Composite preforms are widely used in automotive, aerospace & defense, infrastructure, marine, medical, and other end-use sectors. Industrial equipment requires high strength and corrosion protection, and it can be accomplished with the use of composite preforms.

In addition, it is widely used as a prime lightweight material for reducing the weight of vehicles in the automotive industry. Furthermore, composite preforms have great scope in the marine sector where they are used for manufacturing watercraft, submersibles, offshore structures, and other marine structural components. Moreover, increasing awareness for a healthy lifestyle has surged various sporting activities where composite preforms of various designs are used to provide high strength and weight reduction properties as compared to metals in bicycle handlebars, bowling balls, skis, and others. CXOs further added that sustained economic growth and development of the aerospace and defense sector have increased the popularity of composite preforms.

The use of carbon fiber preforms both commercial aircraft and military applications for the number of years and their usage is expanding into automotive and consumer goods components.

The aerospace and defence segment dominated the global market in 2021, and is anticipated to grow at a CAGR of 6.3% during forecast period.

North America accounted for the largest revenue share in the global composite preforms market. The infrastructure sector in the U.S. is increasing rapidly which in turn has increased the demand for composite preforms used use in paneling, renovation, and fire protection purposes.

The composite preforms market \is estimated to reach $433.1 million by 2031.

The leading players in composite preforms market including Kümpers Composites, C and J Antich, SAERTEX Group, bally ribbon mills, Sigmatex, Axis Composites Limited, Albany International Corp, T.E.A.M., Inc., A and P Technology, and Eurocarbon B.V.

Loading Table Of Content...