Curved Steel Market Research, 2032

The global curved steel market was valued at $3.8 billion in 2022 and is projected to reach $5.7 billion by 2032, growing at a CAGR of 4.2% from 2023 to 2032.

Report Key Highlighters:

- The study will contain qualitative information such as the market dynamics (drivers, restraints, opportunities), Porter’s Five Force Analysis, key regulations across the region, and value chain analysis.

- This report makes it easier for existing market players and new entrants to the curved textile business to plan their strategies and understand the dynamics of the industry, which ultimately helps them make better decisions.

- The report provides competitive dynamics by evaluating business segments, product portfolios, target market revenue, geographical presence, and key strategic developments by prominent manufacturers.

- The report facilitates strategic planning and industry dynamics to enhance decision-making for existing market players and new entrants entering the curved steel market.

Curved steel members are produced from straight lengths of material and are bent as per the required specifications given by a bending company. The strength and stability of the steel are unaffected by the bending process. When a form has been correctly curved, without any buckling or localized cracking in the steel, the curved steel member is expected to encounter substantially smaller strains during actual service conditions than those related to the bending operation. Once the bending is complete the curved steel member performs as required.

Steel is highly appealing for AESS (Architecturally Exposed Structural Steel) applications as it can be curved with little distortion. The best bending businesses adhere to internal tolerances and have a quality control system in place before they bend a steel member. The most important piece of information needed to curve a steel element is the bend's radius. The bending technique is determined by the radius requirement. For tighter radii bends, Rotary Draw and Hot Bending are utilized instead of Roll Bending, which is used for wider radii bends. The "hard way" is to bend a member around the strong axis, while the "easy way" is to bend a member around the weak axis. True high-speed steel (HSS) material can be spiral-bent. It is not essential to split HSS before bending and then weld the pieces back together. Other structural components need not be inserted into the HSS material to provide internal support.

Curved steel sections that create a smooth, consistent arc are more aesthetically appealing and less labor-intensive than fabricated sections that need to be welded or spliced together. Straight material and curved material with the same theoretical outside dimensions can be welded together after the bending process. Qualified bending companies can control the amount of deformation or distortion of the bent steel member to ensure proper fit/alignment to the straight member.

Numerous structures have used curved steel sections and numerous award-winning constructions contain curved parts as one of their primary features. Curved structures are ideal for certain types of structures, for example, railway stations, airport terminals, exhibition halls, shopping malls, and sports stadiums. These structures are required in the modern world. Architects are aware of the fundamental qualities and features of steel, and AISC and other business associations work hard to spread awareness about the advantages of steel framing.

As steel-framed structures are often lightweight, foundation loads are reduced. The buildings also go up far more quickly and with less site preparation. The steel is sustainable and nearly 100% recyclable. The addition of precise, slick curved components increases this allure, so the roller bender is crucial to the steel building industry's capacity to compete with other types of construction. These factors are expected to boost the demand for curved steel in the building and construction industry.

The principal advantage of curved structural steel is its aesthetic appeal. Compared to using straight members, it gives architects and designers the chance to express a wider range of forms, making exposed steelwork a desirable option. In public facilities such as airports, railways, retail malls, and recreation centers, curved steel constructions are frequently constructed to give users natural light, a sense of spaciousness & grandeur, and a sense of the building's majesty. This has resulted in building types with large expanses of windows supported by relatively light curved steel trusses or arched frames.

Exposing the arching steelwork to view can improve the perception of internal space even in encased constructions. Even for industrial and distribution buildings, curved roofs can provide an effective solution. Curved roofs avoid the aura of austerity that is often associated with “industrial warehouse” type buildings and may provide a solution that is attractive to local planners. Contrary to some expectations, curved steel structures need not be any costlier than other framed structures.

The additional cost of curving steelwork is usually small in relation to the overall cost of the structure and can often be offset by savings in ridge detail and flashing costs and, for spans under approximately 25 m, by eliminating the need for an apex splice. Roof cladding on curved roof beams often does not need to be pre-curved, as many panels can follow the curvature of the roof during fixing without any special manipulation.

A curved external appearance can be produced by using faceted straight members, and by varying depth connections to the secondary members, however, the additional fabrication costs for the faceted solution generally mean that a curved solution is more cost-effective in addition to the aesthetic considerations.

One of the most popular metals utilized globally in the building industry is steel, along with its alloys. Steel is used as cladding for exterior walls and roofs. Steel is used to make a variety of products, including roofs, purlins, interior walls, ceilings, cladding, and insulating panels for exterior walls. It is widely utilized in transit facilities such as airports and metro rapid mass transportation systems in a variety of areas such as bollards, ticketing counters, seats, escalators, and canopies, which is a major factor driving the market for curved steel.

Volatility in raw material prices can be a significant restraint for the steel industry. Owing to the huge number of raw materials needed for the manufacturing of steel, changes in the worldwide demand for certain commodities might result in unexpected changes in the cost of production, reducing profitability, and perhaps resulting in losses for producers. The supply and availability of raw materials used in the production and processing of steel, such as iron ore, coal, industrial gases, ferrous scrap, and ferroalloys, affect the price of steel. These commodities' costs are extremely unstable as they are based on supply, trade agreements, and international tariffs. An increase in the prices of raw materials impacts the production costs of long steel, thereby resulting in inflated prices of finished products.

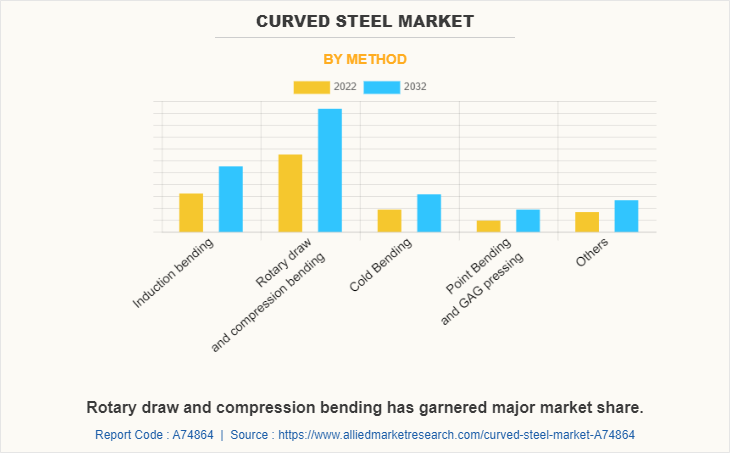

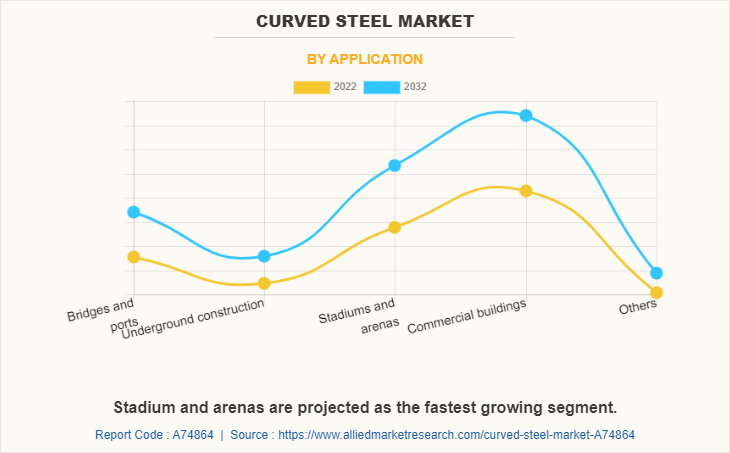

The curved steel market is segmented into method, application, and region. On the basis of the method, it is categorized into induction bending, rotary draw & compression bending, cold bending, point bending & GAG pressing, and others. By application, the market is classified into bridges & ports, underground construction, stadiums & arenas, commercial building, and others.

Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA. The major players operating in the global curved steel market include Eskate, Gerdau S/A, Outokumpu, Acerinox, FUSTEEL CO., LTD., Albina Co., Inc., Union Steel Structure Material Co., Ltd., Chicago metal rolled products, BARNSHAWS, and HUTA POKÓJ S.A.

Rotary draw and compression bending have garnered more than two-fifth of the market share. Rotary Draw Bending is by far the most popular form of tube bending as it is easiest to control, more precise, repeatable, and a relatively affordable tube bending system. Rotary bending machines have many advantages over conventional wipe-bending methods. The most advantageous feature is the simplicity of adjustment. Changes in the bend angle can be made simply by shimming or grinding the height of the assembly. The induction bending method is protected as the fastest-growing segment.

Stadium & arenas is projected as the fastest growing segment and have garnered more than one-fourth of the market share. The growing trend of gaining live experience of sports coupled with the increasing disposable income of people will result in rising expenditure on stadiums infrastructures, which in turn also is expected to fuel the growth of the market. The commercial buildings segment has garnered a major share of the market.

The Asia-Pacific region has garnered a major share of the curved steel market. The asia-Pacific region is home to many of the world’s longest bridges and has a strong pipeline of projects coming up in the future, driven by the increasing urbanization and bold infrastructure programs in the region’s developing economies.China is set to remain the key global construction and real estate market, driving regional growth over the forecast period. The expansion of the construction industry in China was aided by decades of significant Chinese investments in infrastructure projects, a growing urban population, and significant foreign direct investments (FDI) in manufacturing facilities.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the curved steel market analysis from 2022 to 2032 to identify the prevailing curved steel market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the curved steel market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global curved steel market trends, key players, market segments, application areas, and market growth strategies.

Curved Steel Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 5.7 billion |

| Growth Rate | CAGR of 4.2% |

| Forecast period | 2022 - 2032 |

| Report Pages | 279 |

| By Method |

|

| By Application |

|

| By Region |

|

| Key Market Players | BARNSHAWS, HUTA POKÓJ S.A, FUSTEEL CO.,LTD., Albina Co., Inc., Union Steel Structure Material Co., Ltd., Chicago metal rolled products, Outokumpu, eskate, Gerdau S/A, Acerinox |

Analyst Review

According to the insights of the CXOs of leading companies, the growing construction industry is the major driving factor for the curved steel market growth. Increased bridges & ports construction owing to surge in traffic is expected to further boost the demand for curve steel. The “minimum radius” to which a section can be curved without significant distortion depends on the section properties of the member and the bending methods used. Advances in technology and curving techniques mean that minimum radii continue to be reduced. This is anticipated to further boost the demand for curved steel.

Growing aesthetic appeal in the building and construction industry is the upcoming trend in the curved steel market.

The commercial building is the leading application in the curved steel market.

Asia-Pacific is the largest regional market for curved steel.

The Curved Steel Market was valued at $3.8 billion in 2022 and is estimated to reach $5.7 billion by 2032, exhibiting a CAGR of 4.2% from 2023 to 2032.

The major players operating in the global curved steel market include Eskate, Gerdau S/A, Outokumpu, Acerinox, FUSTEEL CO., LTD., Albina Co., Inc., Union Steel Structure Material Co., Ltd., Chicago metal rolled products, BARNSHAWS, and HUTA POKÓJ S.A.

Loading Table Of Content...

Loading Research Methodology...