Die Bonder Equipment Market Research, 2032

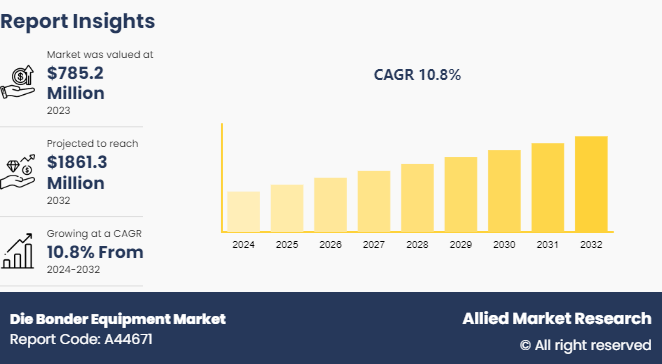

The global die bonder equipment market was valued at $785.2 million in 2023, and is projected to reach $1,861.3 million by 2032, growing at a CAGR of 10.8% from 2024 to 2032.

Market Introduction and Definition

Die bonding involves attaching the semiconductor die to either its package or a substrate. The process begins by selecting the die from a wafer or waffle tray, typically done by pushing the die from the tape with a pin. Alternatively, the tape can be removed from the die using a vacuum. The die is then picked up by a vacuum tool, aligned to a target pad on the carrier or substrate, and finally securely attached using various die bonding methods. Moreover, the global die bonder equipment market is experiencing a surge in growth owing to several factors. The introduction of stacked die technology in Internet of Things (IoT) enabled products, the growing demand for semiconductor integrated circuits, the rising usage of hybrid laptops, and the popularity of high-definition television are all contributing to this positive trend.

Key Takeaways

The die bonder equipment market study covers 20 countries. The research includes a segment analysis of each country in terms of value for the projected period.

More than 1, 500 product literatures, industry releases, annual reports, and other such documents of major die bonder equipment industry participants along with authentic industry journals, trade associations' releases, and government websites have been reviewed for generating high-value industry insights.

The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and to assist stakeholders in making educated decisions to achieve their most ambitious growth objectives.

Key Market Dynamics

The semiconductor sector witnessed a surge in the adoption of die bonder equipment market analysis owing to the growing need for high-performance computing (HPC) applications such as artificial intelligence (AI) and machine learning (ML) . The demand for precision die bonder equipment is being driven by the increased need for semiconductor components with higher processing power to handle complex algorithms and massive datasets efficiently using advanced computing technologies. Assembly process of semiconductor devices, guaranteeing precise positioning and bonding of small semiconductor components onto substrates. The rising demand for miniaturized electronic devices presents a significant Die Bonder Equipment Market Opporunity. The increasing intricacy and miniaturization of semiconductor devices, along with the expanding utilization of AI and ML in sectors such as healthcare, automotive, and finance, intensify the need for enhanced die bonder equipment. Innovations in technology have allowed smaller companies to gain a foothold and expand their die bonder equipment market share.

Furthermore, progress in semiconductor manufacturing technology, such as the creation of smaller and more efficient chips, requires die bonders capable of handling reduced form factors and achieving stricter tolerances. The Die Bonder Equipment Market Growth is driven by the increasing demand for advanced semiconductor devices. This advancement is driving manufacturers to procure cutting-edge die bonder equipment to fulfill the demanding performance standards of contemporary semiconductor devices. For Instance, In November 2023, The RFID inlay die bonder provides rapid, precise, and flexible solutions for retail and aerospace sectors, making a substantial impact on manufacturing. ITEC’s ADAT3 XF Tagliner stands out as an RFID inlay die bonder known for its exceptional speed and precision. It can achieve placement speeds of up to 48, 000 Units Per Hour (UPH) , with positional and rotational accuracies of less than 9 micrometres and 0.67º at one sigma. This outstanding performance sets it apart from other die-bonding machines. The equipment boasts a low total cost of ownership in its category and has the potential to lower production expenses. It is well-suited for a range of RFID uses across different industries, such as retail and automotive labels, access control setups, railway and airline ticketing, as well as shipping container tracking. The report indicates that the die bonder equipment market size is expected to grow significantly during forecasted period.

Market Segmentation

The die bonder equipment market is segmented into type, bonding technique, application, and region. On the basis of type, the market is divided into manual die bonder, semiautomatic die bonder, and fully automatic die bonder. On the basis of bonding technique, the market is bifurcated into epoxy, eutectic, UV, others. As per operation mode, the market is segregated into consumer electronics, automotive, industrial, telecommunications, and others. Region wise, the market is analyzed across North America, Europe, Asia-Pacific, LA, and MEA.

Regional/Country Market Outlook

The demand for die bonder equipment is increasing in North America due to various factors and regional advancements. Silicon Valley in California, Phoenix in Arizona, and Austin in Texas, which are key regions, are witnessing a surge in demand. These areas serve as centers for prominent semiconductor companies and startups, creating a vibrant atmosphere for technological innovation and advanced manufacturing. North America's focus on research and development in semiconductor technology, along with substantial investments, further contribute to this trend. Intel's recent $20 billion investment in new semiconductor facilities in Arizona highlights the region's significant contribution to the demand for advanced die bonder equipment. This expansion of production capabilities, along with initiatives including the U.S. CHIPS and Science Act, marking the importance of efficient die bonding technology in supporting high-precision manufacturing processes and driving innovation across various sectors, including consumer electronics, automotive, and aerospace industries. The Die Bonder Equipment Market Forecast indicates that North America will continue to dominate the market share.

Competitive Landscape

The major players operating in the die bonder equipment market include ASM Pacific Technology, Kulicke & Soffa Industries, Inc., MRSI Systems, Mycronic, Palomar Technologies, West·Bond, Inc., MicroAssembly Technologies, Ltd., Finetech GmbH & Co. KG, TRESKY GmbH, Hybond Inc., and Shibuya Corporation.

Recent Key Strategies and Developments

In May 2024, ITEC introduced an innovative flip-chip die bonder that revolutionizes the industry. The flagship machine swiftly picks, flips, and places the die with precision. Unlike conventional linear motion systems, this bonder features two rotating heads ('TwinRevolve') to minimize inertia and vibration. This advancement enables chipmakers to enhance the speed and accuracy of their high-volume wire-bonded products, making the transition to flip chips seamless.

In September 2024, MRSI Systems, a prominent member of the Mycronic Group, introduced the MRSI-705HF high force die bonder. This advanced version of the well-established MRSI-705 platform showcases their expertise in manufacturing fully automated, high-precision, high-speed, and flexible die bonding and epoxy dispensing systems. In addition, the MRSI-705HF features a heated bond head capable of exerting 500N of force when bonding, along with top heating up to 400°C. This tool is perfect for high-level applications such as sintering in power semiconductors and thermocompression bonding in IC packaging.

Key Sources Referred

U.S. Department of Commerce

National Association of Manufacturers

Taiwan Semiconductor Industry Association

Japan External Trade Organization

Key Benefits for Stakeholders

This report provides a quantitative analysis of the die bonder equipment market segments, current trends, estimations, and dynamics of the market analysis from 2023 to 2032 to identify the prevailing market opportunities.

The market research is offered along with information related to key drivers, restraints, and opportunities.

Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

In-depth analysis of the die bonder equipment market segmentation assists to determine the prevailing market opportunities.

Major countries in each region are mapped according to their revenue contribution to the global die bonder equipment market statistics.

Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

The report includes the analysis of the regional as well as global die bonder equipment market trends, key players, market segments, application areas, and market growth strategies.

Die Bonder Equipment Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 1861.3 Million |

| Growth Rate | CAGR of 10.8% |

| Forecast period | 2024 - 2032 |

| Report Pages | 315 |

| By Type |

|

| By Bonding Technique |

|

| By Application |

|

| By Region |

|

| Key Market Players | ASM Pacific Technology, MRSI Systems, Kulicke & Soffa Industries, Shibuya Corporation, West·Bond, Inc., MicroAssembly Technologies, Ltd., Mycronic, Palomar Technologies, Finetech GmbH & Co. KG, Hybond Inc., TRESKY GmbH |

The global Die Bonder Equipment market is valued at $1,861.3 million by 2032, registering a CAGR of 10.8% from 2024 to 2032.

The forecast period in the Die Bonder Equipment market report is 2024 to 2032.

The top companies analyzed for Die Bonder Equipment market report are ASM Pacific Technology, Kulicke & Soffa Industries, Inc., MRSI Systems, Mycronic, Palomar Technologies, West·Bond, Inc., MicroAssembly Technologies, Ltd., Finetech GmbH & Co. KG, TRESKY GmbH, Hybond Inc., and Shibuya Corporation.

The base year calculated in the Die Bonder Equipment market report is 2023.

The Epoxy segment is the most influential segment in the Die Bonder Equipment market.

Loading Table Of Content...