E-Coat Market Research, 2032

The global e-coat market was valued at $2.3 billion in 2022, and is projected to reach $3.7 billion by 2032, growing at a CAGR of 5.1% from 2023 to 2032.

Report Key Highlighters:

The E-coat market is fragmented in nature with few players such as C.E.D. Process Minerals, Inc, Dinglong Quartz Limited, Goldstar Powders Pvt. Ltd, Goyal Group of Minerals, GRENZEBACH GROUP, Hoben International Limited, Momentive Technologies, Quarzwerke GmbH, Sibelco, and SILMER, which hold a significant share of the market.

The report provides complete analysis of the market status across key regions and more than 15 countries across the globe in terms of value ($ Million) and volume (Tons).

Top winning strategies are analyzed by performing a thorough study of the leading players in the E-coat market. Comprehensive analysis of recent developments and growth curves of various companies helps us to understand the growth strategies adopted by them and their potential effect on the market.

The report provides competitive dynamics by evaluating business segments, product portfolios, target market revenue, geographical presence and key strategic developments by prominent manufacturers.

E-coat, short for "electrocoat" or "electrophoretic coating," is a painting or coating process that uses electrical current to deposit a protective layer of paint or other coatings onto a conductive surface. This process is widely used in various industries to provide a uniform and durable finish to metal objects and components. The e-coating process offers numerous advantages, including excellent corrosion resistance, consistent coating thickness, and the ability to coat complex shapes and hard-to-reach areas.

The automotive industry is one of the primary drivers of the e-coat market. E-coating is extensively used for automotive parts, including body panels, chassis components, and other metal parts. The process provides a uniform and durable protective layer, helping to prevent corrosion and extend the lifespan of vehicles. This factor is anticipated to drive the market during the forecast period.

However, ongoing research and development efforts are focused on improving e-coating technologies, including developments in paint formulations, application methods, and curing processes. Advancements can lead to enhanced performance, reduced energy consumption, and faster curing times. In addition, industries prioritize sustainability and eco-friendliness, e-coating is well-positioned to provide a more environmentally friendly alternative to traditional coating methods. The market can capitalize on this trend by promoting energy efficiency and reducing environmental impact of e-coating processes. This factor is projected to restrain market growth.

Ongoing research and development efforts are focused on improving e-coating technologies, including developments in paint formulations, application methods, and curing processes. Advancements can lead to enhanced performance, reduced energy consumption, and faster curing times. As industries prioritize sustainability and eco-friendliness, e-coating is well-positioned to provide a more environmentally friendly alternative to traditional coating methods. The market can capitalize on this trend by promoting energy efficiency and reducing environmental impact of e-coating processes. These factors are anticipated to offer remunerative opportunities for the e-coat market during the forecast period.

The E-coat market is segmented on the basis of type, application, and region. On the basis of type, the market is categorized into cathodic epoxy, cathodic acrylic, anodic. On the basis of application, it is divided into passenger cars, commercial vehicles, automotive parts and accessories, heavy duty equipment, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

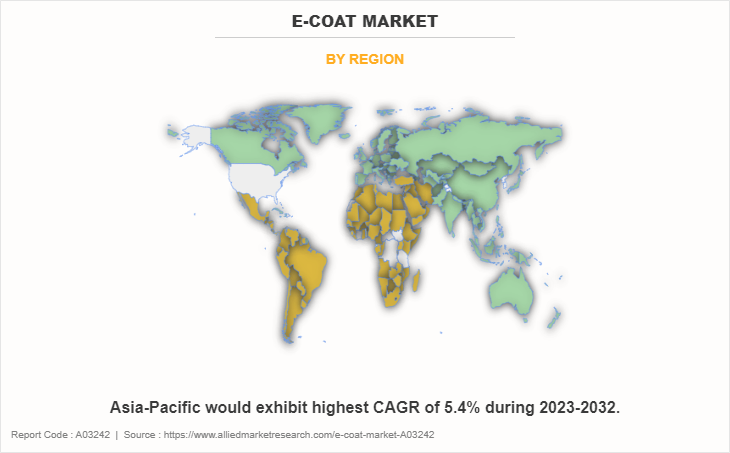

The Asia-Pacific E-coat market size is projected to grow at the highest CAGR of 5.4% during the forecast period and accounted for 57% of E-coat market share in 2022. China's robust manufacturing sector includes automotive, electronics, appliances, and more. E-coating is used in various industries to protect components from corrosion and wear. Japan is known for its automotive and electronics industries, both of which require e-coating to protect components from corrosion and maintain high-quality standards.

Japan is known for its automotive and electronics industries, both of which require e-coating to protect components from corrosion and maintain high-quality standards. Furthermore, India's industrial manufacturing landscape includes machinery, equipment, and appliances that benefit from e-coating's protective properties. As India invests in infrastructure projects, the demand for protective coatings like e-coat for infrastructure components is likely to increase.

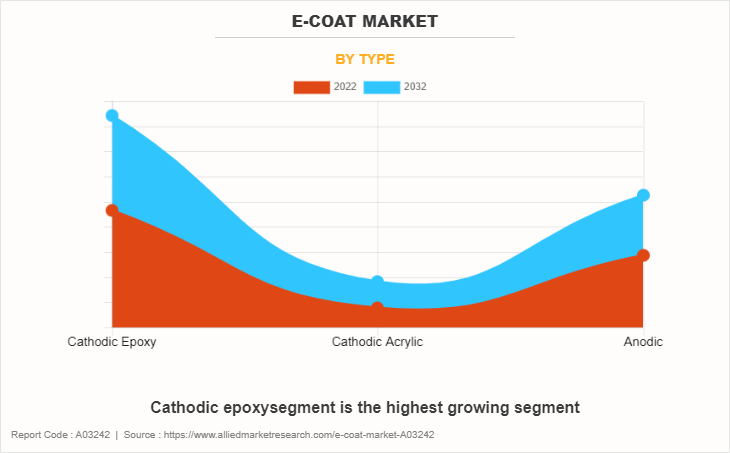

By type, the cathodic epoxy segment dominated the global market in 2022, and is anticipated to grow at a CAGR of 5.3% during forecast period. This is due to the fact that, The automotive industry is a significant driver for cathodic epoxy-based e-coat. As vehicles continue to evolve, incorporating more advanced materials and designs, the demand for effective corrosion protection becomes even more important.

Cathodic epoxy e-coat is well-suited to provide the required level of protection for automotive components. Furthermore, increasing environmental regulations have led industries to seek out more environmentally friendly coating solutions with reduced volatile organic compounds (VOCs) emissions. Cathodic epoxy-based e-coat, being water-based and low in VOCs, aligns well with these regulations.

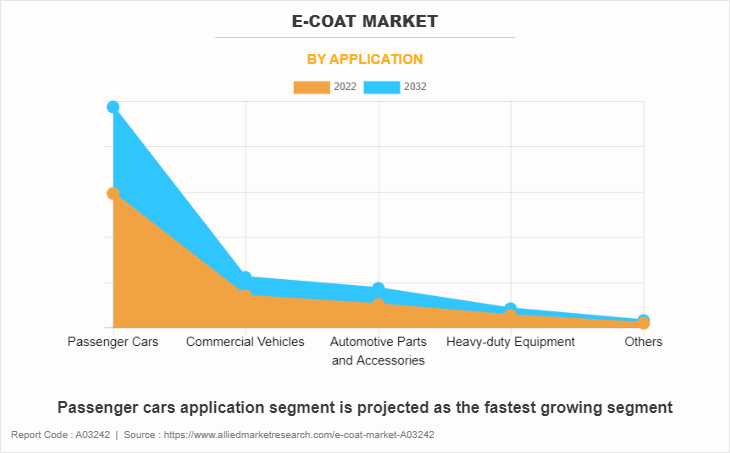

In 2022, the passenger cars segment was the largest revenue generator, and is anticipated to grow at a CAGR of 5.2% during the forecast period. Development and improvement of road networks, highways, and transportation infrastructure contribute to the convenience and accessibility of passenger cars. Better infrastructure encourages car ownership and usage.

Passenger cars offer convenience and flexibility, allowing individuals and families to travel comfortably and at their own pace. This is especially important as people seek to balance work, leisure, and family needs. E-coating is employed to protect frame components and suspension parts, such as control arms and stabilizer bars. These parts are critical for the vehicle's performance and safety, and e-coating helps maintain their integrity under varying driving conditions.

The global E-coat market profiles leading players that include PPG Industries, Inc., BASF SE, Nippon Paint Holdings Co., Ltd., Kansai Paint Co., Ltd, AXALTA COATING SYSTEMS, LTD, B.L DOWNEY COMPANY LLC., KCC Corporation, The Sherwin-Williams Company, TATUNG FINE CHEMICALS CO., and Parker Trutec, Inc. The global E-coat market report provides in-depth competitive analysis as well as profiles of these major players.

Impact of Russia Ukraine War on the E-coat Market:

Conflict leads to broader economic repercussions; it could affect consumer purchasing power and overall economic growth. This, in turn, could impact industries that utilize e-coating in their manufacturing processes.

In response to geopolitical events, countries might alter their trade policies, regulations, and standards. Changes in regulations could influence the e-coating industry's operations and market dynamics. Public awareness about the importance of transitioning to sustainable and renewable energy sources have enhanced the E-coat market during the forecast period.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the e-coat market analysis from 2022 to 2032 to identify the prevailing e-coat market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the e-coat market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global e-coat market trends, key players, market segments, application areas, and market growth strategies.

E-Coat Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 3.7 billion |

| Growth Rate | CAGR of 5.1% |

| Forecast period | 2022 - 2032 |

| Report Pages | 349 |

| By Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | Nippon Paint Holdings Co., Ltd., B.L DOWNEY COMPANY LLC., KCC CORPORATION., The Sherwin-Williams Company, PPG Industries, Inc., BASF SE, AXALTA COATING SYSTEMS, LTD, TATUNG FINE CHEMICALS CO., Kansai Paint Co., Ltd., Parker Trutec, Inc. |

| Other Key Market Players | AUTOTECH PRODUCTION SERVICES, INC., BEACON INDUSTRIES, INC., BROSE GROUP, DC COATERS, INC., ELECTROPRIME GROUP LLC., GEORGE KOCH SONS LLC., MAX COATING, INC., MID WEST COATINGS |

Analyst Review

According to CXOs of leading companies, the global E-coat market is expected to exhibit high growth potential. E-coating is extensively used for automotive parts, including body panels, chassis components, and other metal parts. The process provides a uniform and durable protective layer, helping to prevent corrosion and extend the lifespan of vehicles. Transportation and industrial equipment that require high strength, corrosion protection, and abrasion resistant properties can be accomplished with the use of E-coats.

In addition, e-coat possesses excellent significant properties such as high mechanical strength, adhesion to metals, thermal resistance, chemical resistance, and corrosion resistance that makes it best suited for automotive coating applications. It serves as a protective coating in under hood parts and engine components owing to its scratch resistance property. Furthermore, factors such as flexibility in operation, ease of application, and minimal or no volatile organic compounds (VOCs) levels enhance performance of E-coats in several end-use industries.

CXOs further added that sustained economic growth and development of the building & construction sector have increased the popularity of E-coat.

E-coat, short for "electrocoat" or "electrophoretic coating," is a painting or coating process that uses electrical current to deposit a protective layer of paint or other coatings onto a conductive surface. This process is widely used in various industries to provide a uniform and durable finish to metal objects and components. The e-coating process offers numerous advantages, including excellent corrosion resistance, consistent coating thickness, and the ability to coat complex shapes and hard-to-reach areas.

Innovations in e-coat chemistry aimed at improving properties like hardness, flexibility, and resistance to chemicals and UV exposure were being developed to expand the application range of e-coatings.

PPG Industries, Inc., BASF SE, Nippon Paint Holdings Co., Ltd., Kansai Paint Co., Ltd, AXALTA COATING SYSTEMS, LTD, B.L DOWNEY COMPANY LLC., KCC Corporation, The Sherwin-Williams Company, TATUNG FINE CHEMICALS CO., and Parker Trutec, Inc

The E-coat market is segmented on the basis of type, application, and region. By type, it is categorized into cathodic epoxy, cathodic acrylic, and anodic. By application, it is segregated into passenger cars, commercial vehicles, automotive parts and accessories, heavy duty equipment, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA

The global e-coat market was valued at $2.3 billion in 2022, and is projected to reach $3.7 billion by 2032, growing at a CAGR of 5.1% from 2023 to 2032.

Passenger cars is the leading application of E-coat market.

Asia-Pacific is the largest regional market for E-coat market.

Loading Table Of Content...

Loading Research Methodology...