Epoxy Composite Panels Market Research, 2033

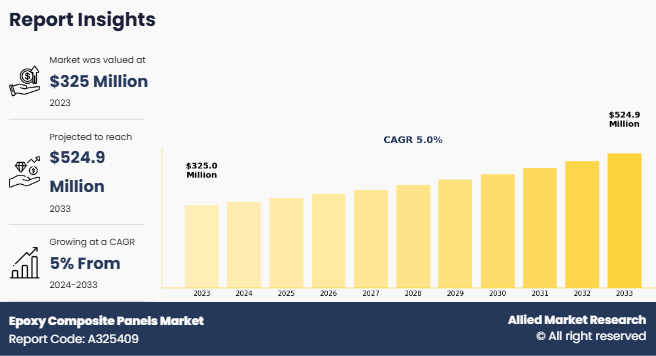

The global epoxy composite panels market was valued at $325 million in 2023, and is projected to reach $524.9 million by 2033, growing at a CAGR of 5% from 2024 to 2033.

Introduction

An epoxy composite panel is a type of engineered material that consists of multiple layers or laminates bonded together with epoxy resin. Epoxy resins are thermosetting polymers that cure to form rigid and durable structures. These resins act as the matrix, binding the reinforcing fibers and providing structural integrity. Reinforcement materials, such as carbon fibers or fiberglass, add strength and stiffness to the composite. The panels are manufactured through processes such as vacuum bagging, autoclave curing, or pultrusion, depending on the desired properties and applications. The aerospace and defense industries are among the largest consumers of epoxy composite panels. The lightweight and high-strength properties of these panels make them ideal for aircraft and spacecraft components. Key applications include fuselage structures, wings, control surfaces, and interior panels. Their excellent resistance to fatigue and environmental degradation ensures reliability and safety in critical applications.

Moreover, epoxy composite panels contribute to fuel efficiency in aircraft by reducing overall weight. In defense, these panels are used in the manufacturing of armored vehicles, protective shields, and ballistic-resistant structures. The combination of strength and lightweight characteristics enhances mobility and protection in military applications. Epoxy composite panels have gained traction in the automotive industry due to surge in demand for lightweight and fuel-efficient vehicles. These panels are used in manufacturing car body panels, chassis components, and interior parts. The reduction in vehicle weight achieved with epoxy composites leads to improved fuel economy and reduced emissions. High-performance and luxury car manufacturers use epoxy composite panels for structural and aesthetic

Key Takeaways

- The epoxy composite panels market study covers 20 countries. The research includes a segment analysis of each country in terms of value ($million) for the projected period.

- The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global epoxy composite panels market and to assist stakeholders in making educated decisions in order to achieve their most ambitious growth objectives.

- Over 3,700 product literature, annual reports, industry statements, and other comparable materials from major industry participants were reviewed to gain a better understanding of the global epoxy composite panels market.

- The key players in the epoxy composite panels market are Gurit Services AG, The Gill Corporation, Positive Composites, VDL Composites GmbH, TOPOLO New Materials, ATL Composites, Schweiter Technologies AG (3A Composites), CoreLite, Azo Composites, and Carbon-Core Corporation. They have adopted strategies such as acquisition, product launch, merger, and expansion to gain an edge in the market.

Market Dynamics

Increase in demand for lightweight materials is expected to drive the growth of epoxy composite panels market. The growing demand for lightweight materials in the transportation and aerospace industries is a significant driver for the adoption of epoxy composite panels. In the transportation sector, manufacturers of vehicles, including automobiles, trains, and buses, are under increasing pressure to meet stringent fuel efficiency and emission standards. Lightweight materials like epoxy composite panels play a crucial role in achieving these goals by reducing the overall weight of the vehicle without compromising structural integrity. This weight reduction enhances fuel efficiency, resulting in lower operational costs and decreased environmental impact, making epoxy composite panels a preferred choice. In November 2023, the Government of India approved investments totaling $360 million from 27 prominent electronics manufacturers, aiming to bolster domestic IT hardware production. Notably, epoxy composite panels are increasingly being adopted in printed circuit board (PCB) applications. Furthermore, in April 2024, the Indian government allocated approximately $9.05 million (INR 760 million) to support electronic manufacturing and introduced new incentive schemes to stimulate growth in the epoxy composite panels industry.

However, the availability of alternatives production is expected to hamper the growth of epoxy composite panels market. The presence of alternative materials such as aluminum and thermoplastic composites poses a significant challenge to the epoxy composite panels market growth. These materials are often more cost-effective and easier to recycle, which makes them attractive alternatives for industries focused on reducing material costs and improving sustainability. Aluminum, for instance, is widely used in sectors like construction, automotive, and aerospace due to its lightweight properties, durability, and excellent corrosion resistance. Moreover, aluminum's high recyclability reduces production costs, as recycling aluminum requires less energy compared to producing new aluminum. Similarly, thermoplastic composites offer the advantage of being easier to process and recycle. Epoxy composites, which are thermosetting and cannot be reformed once cured, thermoplastic composites is melted and reshaped, making them a more sustainable option. These materials also tend to have lower manufacturing costs due to simpler processing methods. While epoxy composites provide superior strength and thermal properties, the increasing demand for recyclable and cost-efficient alternatives such as aluminum and thermoplastic composites presents a competitive challenge, urging epoxy composite manufacturers to focus on improving their material properties and sustainability efforts.

Segments Overview

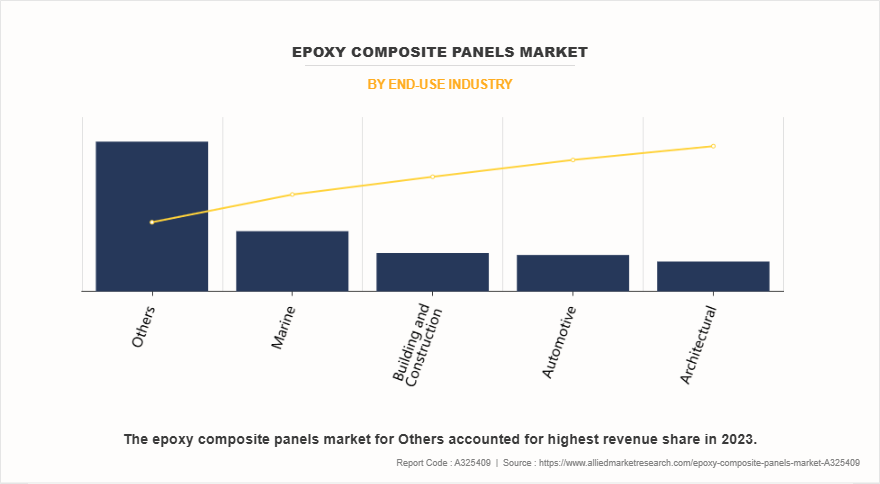

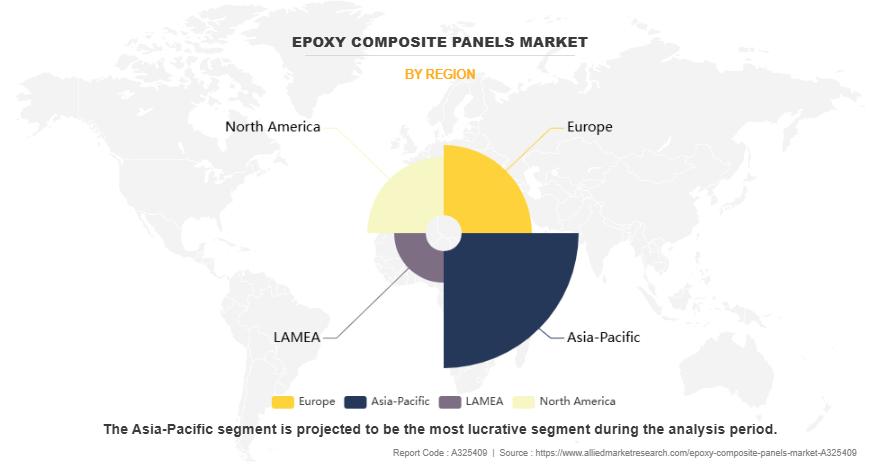

The epoxy composite panels market is segmented into end-use industry and region. On the basis of the end-use industry, the epoxy composite panels market is categorized into automotive, marine, architectural, building & construction, and others. By region, the epoxy composite panels market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

On the basis of end-use industry, the others segment was the largest epoxy composite panels market share in 2023, and is anticipated to grow at a CAGR of 5.2% during the epoxy composite panels market forecast period. The others segment of epoxy composite panels includes aerospace and defense, renewable energy, and others. These panels are extensively used in the manufacturing of aircraft structures, such as fuselages, wings, and empennages, as well as in defense vehicles and unmanned aerial systems (UAS). The reduced weight of epoxy composites improves fuel efficiency, enhances maneuverability, and contributes to the overall durability of aerospace components. In the renewable energy sector, epoxy composite panels are widely used in the construction of wind turbine blades, solar panel housings, and other energy infrastructure. These materials offer excellent resistance to environmental stressors like UV exposure, temperature fluctuations, and moisture, making them ideal for outdoor applications.

On the basis of region, Asia-Pacific dominated the epoxy composite panels market size. Epoxy composite panels are used in the construction of building facades due to their weather-resistant properties and aesthetic appeal. Countries such as China, India, and Japan are adopting these panels in the construction of modern, high-rise buildings and commercial complexes. In countries like Japan and South Korea, epoxy composite panels are used in the production of lightweight and durable automotive interiors. These panels are favored for dashboard components, door panels, and interior trim. The marine industry in countries such as China, South Korea, and Japan uses epoxy composite panels for building hulls, decks, and other parts of boats and ships. These panels provide resistance to corrosion, reducing maintenance costs and improving the longevity of marine vessels.

Competitive Analysis

The major players operating in the epoxy composite panel market include Gurit Services AG, The Gill Corporation, Positive Composites, VDL Composites GmbH, TOPOLO New Materials, ATL Composites, Schweiter Technologies AG (3A Composites), CoreLite, Azo Composites, and Carbon-Core Corporation.

In March 2022, Swancor introduced two cutting-edge solutions, "EzCiclo" and "CleaVER," designed to revolutionize the recycling and reuse of wind turbine blades. EzCiclo is a recyclable and reusable epoxy resin integrated with glass or carbon fiber composites, which can be efficiently recycled and degraded using the CleaVER technology, a breakthrough developed in collaboration with leading epoxy composite panels industry experts.

In November 2021, Westlake Chemical Corporation announced the acquisition of Hexion Inc.'s global epoxy business for approximately $1.2 billion. This strategic acquisition, with its headquarters in Rotterdam, Netherlands, aimed to strengthen Westlake's footprint in the epoxy market.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the epoxy composite panels market analysis from 2023 to 2033 to identify the prevailing epoxy composite panels market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the epoxy composite panels market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global epoxy composite panels market trends, key players, market segments, application areas, and market growth strategies.

Epoxy Composite Panels Market Report Highlights

| Aspects | Details |

| Market Size By 2033 | USD 524.9 million |

| Growth Rate | CAGR of 5% |

| Forecast period | 2023 - 2033 |

| Report Pages | 217 |

| By End-use Industry |

|

| By Region |

|

| Key Market Players | CoreLite, SCHWEITER TECHNOLOGIES AG (3A Composites), VDL Composites GmbH, TOPOLO New Materials, The Gill Corporation, Positive Composites, AZO Composites, SL, Gurit Services AG, Carbon-Core Corporation, ATL Composites |

Analyst Review

According to the opinions of various CXOs of leading companies, the epoxy composite panel market is expected to witness significant growth in the upcoming years. The increase in demand for aluminum bare wire conductors in India is driven by the rapid development of renewable energy projects, particularly in the solar and wind sectors. India has set a goal to achieve 500 GW of renewable energy capacity by 2030, driving the need for extensive transmission infrastructure to connect new power sources to the grid. Aluminum conductors, known for their lightweight, cost-effectiveness, and corrosion resistance, are widely used for transmitting electricity over long distances. In the solar sector, particularly in states such as Rajasthan, Gujarat, and Tamil Nadu, large-scale solar farms contribute to the country's renewable energy output. Aluminum conductors are ideal for these projects due to their high conductivity and ease of installation, efficiently transporting electricity from remote areas to urban and industrial centers. Similarly, wind farms, often located in coastal regions and areas with high wind potential, require durable and cost-effective transmission lines to handle variable energy output. Aluminum conductors offer a reliable solution, balancing performance and affordability for long-distance power transmission.

However, competition from copper conductors is expected to hinder the growth of India aluminum bare wire conductor market during the forecast period. One of the key challenges that the aluminum bare wire conductor market faces is competition from copper conductors. Despite cost advantages of aluminum, copper remains the preferred choice in many applications due to its superior electrical conductivity and mechanical durability. Despite the cost advantages of aluminum, copper remains the preferred choice in many applications due to its superior electrical conductivity and mechanical durability. Copper’s conductivity is about 40% higher than aluminum, which allows it to carry more current through a smaller cross-sectional area. This makes copper particularly advantageous in applications where space is limited, or higher electrical efficiency is required. In addition, copper’s strength and resilience make it less prone to stretching or breaking under mechanical stress, a feature that is critical in many demanding industrial environments.

The global epoxy composite panels market was valued at $325 million in 2023, and is projected to reach $524.9 million by 2033, growing at a CAGR of 5% from 2024 to 2033.

The major players operating in the epoxy composite panel market include Gurit Services AG, The Gill Corporation, Positive Composites, VDL Composites GmbH, TOPOLO New Materials, ATL Composites, Schweiter Technologies AG (3A Composites), CoreLite, Azo Composites, and Carbon-Core Corporation.

Asia-Pacific is the largest regional market for epoxy composite panels.

Other segment aerospace and defense, renewable energy, and others are the the leading end-use industry of epoxy composite panels market

The integration of smart materials and sensors with epoxy composites are the upcoming trends of epoxy composite panels market.

Loading Table Of Content...

Loading Research Methodology...