Epoxy Glass Market Research, 2032

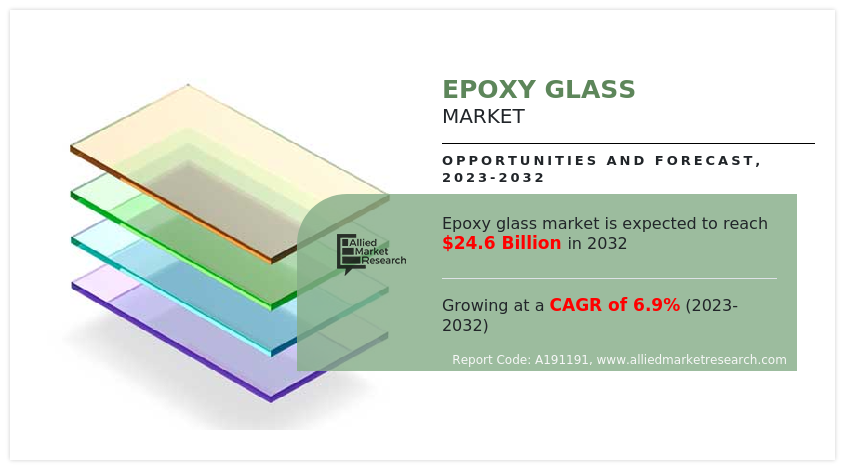

The global epoxy glass market was valued at $12.7 billion in 2022, and is projected to reach $24.6 billion by 2032, growing at a CAGR of 6.9% from 2023 to 2032.

Report Key Highlighters:

- Quantitative information mentioned in the global epoxy glass market includes the market numbers in terms of value (USD Million) with respect to different segments, annual growth rate, CAGR (2023-32), and growth analysis.

- The analysis in the report is provided based on end-use industry. The study will also contain qualitative information such as the market dynamics (drivers, restraints, opportunities, and challenges), Porter's Five Force Analysis, key regulations across the region, and value chain analysis.

- A few companies, including Axiom Materials, Inc., B.B.Chatterjee Company Private Limited, Harnawa Inc., Hexcel Corporation, Industrial Electrical Engineering Company, ISOSPORT Verbundbauteile GmbH, Panasonic Holdings Corporation, PARK AEROSPACE CORP., Shibaam Polymers, and Ventec International Group, hold a large proportion of the epoxy glass market.

- This report makes it easier for existing market players and new entrants to the epoxy glass business to plan their strategies and understand the dynamics of the industry, which ultimately helps them make better decisions.

Epoxy glass, also known as fiberglass-reinforced epoxy or FR4, is a form of composite material made from epoxy resin and woven glass fabric. When epoxy resin is embedded into woven glass fabric and then dried under controlled conditions, it produces a composite material that combines the mechanical qualities of the glass fibers with the adhesion and rigidity of the epoxy resin. It is used in various sectors such as electronics, aircraft, automotive, construction, and others, for applications requiring these properties.

The widespread utilization of epoxy glass in various end-use industries such as automotive, aerospace, electrical & electronics, marine, construction, and others drives the growth of the market. Epoxy glass composites are used in the automotive industry due to their superior mechanical properties, capacity for electrical insulation, and resistance to environmental conditions. These materials are essential for improving the durability, safety, and performance of vehicles.

In addition, epoxy glass is commonly utilized in the automotive sector to produce lightweight yet durable components. It finds uses in many different automotive structures, including body panels, chassis reinforcements, and interior parts. The excellent strength-to-weight ratio of epoxy glass helps lower the total weight of the vehicle without affecting its structural integrity. Some key players offer epoxy glass products used in the automotive industry. For instance, Axiom Materials, Inc., a composite materials manufacturer, provides a diverse range of epoxy fiberglass prepregs employed in the automotive sector. One such example is AX-3206, which is used as a high-toughness laminate for prosthetics and the race car industry.

Epoxy glass is suitable for electrical and electronic components in automobiles due to its electrical insulation characteristics. It is used to develop printed circuit boards (PCBs), sensors, connectors, and wiring harnesses. Its insulating properties reduce the possibility of short circuits or other electrical malfunctions while ensuring the reliable operation of electrical systems.

Moreover, epoxy glass composites are corrosion- and chemical-resistant, which is essential in the automotive sector where exposure to different weather conditions, road salts, and fluids is common. This resistance increases the lifespan of car parts and reduces the need for maintenance, making vehicle ownership more affordable and dependable. Owing to these factors, the epoxy glass market is expected to experience significant growth during the forecast period.

The rise in awareness regarding climate change and the need to reduce greenhouse gas emissions has contributed to an increase in demand for renewable energy sources, including wind power, which drives the growth of the epoxy glass market. Wind energy is an eco-friendly source of electricity compared to fossil fuels due to its low to non-existent emissions. A wind turbine blade is composed of resins and glass or carbon fibers; hence, these epoxies, hardeners, and adhesives constitute about 25–35% of the mass of a modern wind turbine blade.

Epoxy glass composites play a significant role in the wind energy sector as they enhance the design, functionality, and durability of wind turbines. The production of wind turbine blades is a primary application of epoxy glass composites in wind energy. Wind turbine blades must be both lightweight and durable to efficiently capture wind energy and withstand various environmental stresses. Epoxy glass composites offer an ideal combination of these properties. In addition, epoxy glass's high strength-to-weight ratio enables the development of longer and aerodynamically effective blades that harness more wind energy.

Epoxy glass plays a critical role in insulating and safeguarding the electrical components of the turbine. Wind turbines feature complex electrical systems for electricity generation, control, and communication. It is used to manufacture electrical enclosures, insulating materials, and structural elements that house sensitive electronics. Its electrical insulating qualities contribute to ensuring the security and durability of these systems, which are necessary to maintain the turbine's functionality and efficiency. Owing to these factors, the surge in renewable energy has boosted the growth of the epoxy glass market.

The high production cost of epoxy glass is a significant factor that limits the market's expansion. Epoxy glass offers many benefits, including strength, electrical insulation, and durability, however, its cost prevents it from being used as widely as it could be across various industries. Epoxy resins and premium glass fabrics, both utilized in epoxy glass production, are expensive. Epoxy resin is used in the production process to impregnate glass fabric, necessitating accuracy and strict material control. The cost of acquiring these resources, particularly of superior quality, increases production costs.

Furthermore, epoxy glass is manufactured using a multi-step process that involves layup, curing, and finishing. Each of these processes require advanced machinery, a skilled workforce, and strict quality control to ensure the required properties of the epoxy glass. This complexity leads to longer manufacturing cycles and higher labor expenses, ultimately raising the overall product price. In addition, epoxy glass is customized for various applications, considering their size, shape, and performance standards. Customization often involves additional processing steps and meticulous mindfulness, potentially driving up costs. Owing to these factors, the high production cost hampers the growth of the epoxy glass market.

Significant growth opportunities for the epoxy glass market are provided by advancements in the production process, offering the potential to address some of the key problems that have historically limited the use of epoxy glass. These advances contribute to higher production, decreased costs, and expanded applications, making epoxy glass more appealing to a wide range of industries. The manufacturing process incorporates automation technology, allowing uniform and precise insertion of glass fabric impregnated with epoxy resin. Automated layup procedures increase consistency, decrease human error, and enhance overall production effectiveness.

Epoxy glass is produced continuously through techniques such as pultrusion and filament winding. These continuous production techniques enable higher production rates, less material waste, and the ability to produce complex, continuous profiles with consistent characteristics. In addition, improvements in epoxy resin formulation have resulted in resins with better curing kinetics, mechanical properties, and resistance to environmental factors. These developments provide improved adaptability of epoxy characteristics to various applications. Owing to these factors, advancements in the manufacturing process present a lucrative growth opportunity for the epoxy glass market.

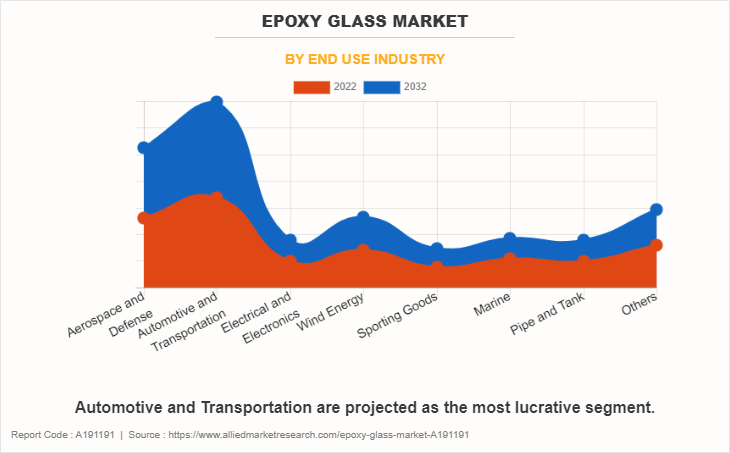

The epoxy glass market is segmented into end-use industry and region. By end-use industry, the market is classified into wind energy, aerospace & defense, sporting goods, automotive & transportation, electrical & electronics, pipe & tank, marine, and others. Region wise, the market is analyzed across North America, Europe, Asia-Pacific and LAMEA.

The key players that operate in the global epoxy glass market are Axiom Materials, Inc., B.B.Chatterjee Company Private Limited, Harnawa Inc., Hexcel Corporation, Industrial Electrical Engineering Company, ISOSPORT Verbundbauteile GmbH, Panasonic Holdings Corporation, PARK AEROSPACE CORP., Shibaam Polymers, and Ventec International Group. These players have adopted agreement as their key strategy to increase their market shares.

By end-use industry, the apparel segment held the largest market share in 2022. A key trend is the adoption of epoxy glass composites for making lightweight vehicles. With stringent emission regulations and a growing emphasis on fuel efficiency, automakers are increasingly turning to these composites to reduce the weight of vehicles without compromising structural integrity. Epoxy glass materials offer an exceptional strength-to-weight ratio, resulting in lighter components that contribute to improved fuel economy and reduced emissions. This trend is especially relevant in the electric vehicle (EV) sector, where lightweight materials are crucial for maximizing battery range.

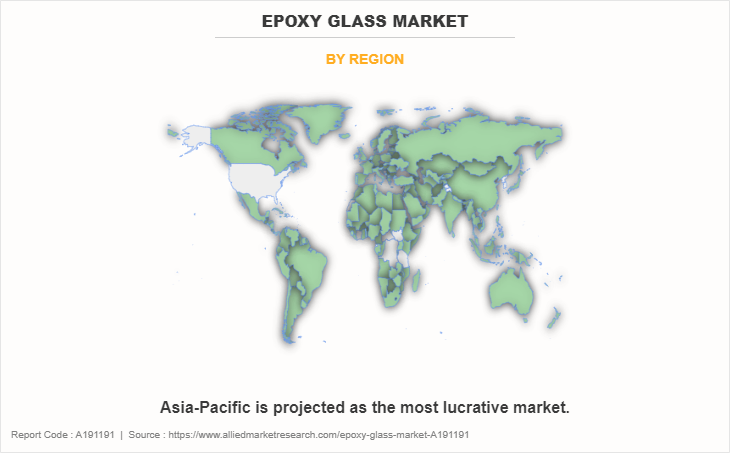

By region, the market is categorized into North America, Europe, Asia-Pacific, and LAMEA. The Asia-Pacific region is one of the fastest-growing regions in the world. the region's burgeoning electronics industry is fueling the adoption of epoxy glass. With the increasing demand for electronic devices, there is a parallel need for high-performance materials to create reliable circuit boards and electronic components. Epoxy glass offers excellent electrical insulation properties, making it invaluable for manufacturing printed circuit boards (PCBs) and semiconductor packaging, thus driving its incorporation in the electronics supply chain.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the epoxy glass market analysis from 2022 to 2032 to identify the prevailing epoxy glass market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the epoxy glass market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global epoxy glass market trends, key players, market segments, application areas, and market growth strategies.

Epoxy Glass Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 24.6 billion |

| Growth Rate | CAGR of 6.9% |

| Forecast period | 2022 - 2032 |

| Report Pages | 206 |

| By End Use Industry |

|

| By Region |

|

Analyst Review

According to the opinions of various CXOs of leading companies, epoxy glass is a type of composite material comprised of epoxy resin and woven glass fabric, commonly called fiberglass-reinforced epoxy or FR4. Epoxy resin produces a composite material that combines the mechanical properties of glass fibers with the adhesion and stiffness of epoxy resin when it is inserted into woven glass fabric and then cured under regulated conditions.

The wide usage of epoxy glass in various industries such as automobile, aerospace, marine, construction, and electronics drive the market growth. It is used in a wide range of industries owing to its excellent mechanical properties, high electrical insulation, and resistant to corrosion. In addition, expansion of residential & commercial developments and rise in demand for renewable energy stimulate the growth of the market. However, availability of substitutes such as carbon fibers and high production cost to create epoxy glass hamper the market growth. Rise in technological advancements in the manufacturing process presented an excellent growth opportunity for the epoxy glass market.

The growth of industries like automotive, aerospace, and renewable energy was driving the demand for epoxy glass laminates with improved high-temperature resistance. This was especially important in applications where electronic components are subjected to elevated temperatures.

Automotive and Transportation application are the potential customers of Epoxy Glass market industry

Asia-Pacific region will provide more business opportunities for Epoxy Glass market in coming years

The market players are adopting various growth strategies and also investing in R&D extensively to develop technically advanced unique products which are expected to drive the market size.

Axiom Materials, Inc., B.B.Chatterjee Company Private Limited, Harnawa Inc., Hexcel Corporation, Industrial Electrical Engineering Company, ISOSPORT Verbundbauteile GmbH, Panasonic Holdings Corporation, Park Aerospace Corp are the top players in Epoxy Glass market.

Loading Table Of Content...

Loading Research Methodology...