Flexible Manufacturing Systems For Pharmaceutical Industry Market Research, 2031

The global flexible manufacturing systems for pharmaceutical industry market size was valued at $2 billion in 2021, and is projected to reach $3.3 billion by 2031, growing at a CAGR of 5.3% from 2022 to 2031. Flexible manufacturing systems for pharmaceuticals include all the systems that are meant to quickly adapt to the changes in the market and industry conditions with regards to the pharmaceutical industry. These systems enable the pharmaceuticals producers to make effective use of their facilities, plants, and other capacities to stay profitable and competitive.

The pharmaceutical industry is highly regulated by the government policies, international trade policies and tariffs, politics, and others. Moreover, every two- or three-years new viruses are infecting people. Such factors make this industry one of the most uncertain and complex industries. Owing to such complexities, pharmaceutical producers often have to change operations, machineries, and sometimes even the entire facilities in a very short span of time, which impacts the organization negatively. To addresses this issue, pharmaceutical manufacturers make use of flexible manufacturing, as it allows changeover of system in a short span of time, without negatively affecting the organization’s profitability. Owing to this, systems involved in flexible manufacturing systems for pharmaceuticals are expected to witness a rise in the coming years.

Moreover, rising global population, especially the old-age population has significantly increased the number of patients suffering from common and rare disease. This has fueled the demand for generic and specialized drugs and other pharmaceuticals. In addition, the large investment for healthcare facilities in developed countries propels the growth in the pharmaceutical industry. Such factors are expected to positively influence the flexible manufacturing systems for pharmaceutical industry market growth.

According to World Health Organization, the number of people aged 60 years and older was 1 billion in 2019, and is expected to reach 1.4 billion by 2030 and 2.1 billion by 2050. This has increased the number of patients suffering from various chronic diseases. Furthermore, flexible manufacturing systems for the pharmaceutical industry is witnessing a rise, as various governments across the globe are increasing their expenditure on healthcare facilities. For instance, according to the U.S. Centers for Medicare & Medicaid Services, the U.S. healthcare spending reached $4.1 trillion or $12,530 per person, witnessing a rise of 9.7% in 2020, and health spending accounted for 19.7% of the U.S. GDP.

The novel coronavirus has rapidly spread across various countries and regions, causing an enormous impact on the lives of people and the overall community. It began as a human health condition and has now become a significant threat to global trade, economy, and finance. The COVID-19 pandemic increased the importance of flexible manufacturing systems for the pharmaceutical industry across the globe. Furthermore, the number of COVID-19 cases have reduced to a greater extent as the vaccine for COVID-19 is introduced in the market. This has led to the reopening of companies involved in development of flexible manufacturing systems for pharmaceutical industry. This has helped the market to recover significantly. The awareness regarding efficient operations of healthcare facilities caused by the COVID-19 pandemic is expected to positively influence the market.

The rise in global geriatic population and advancements in healthcare facilities of developing countries provides lucrative growth opportunities for the market.

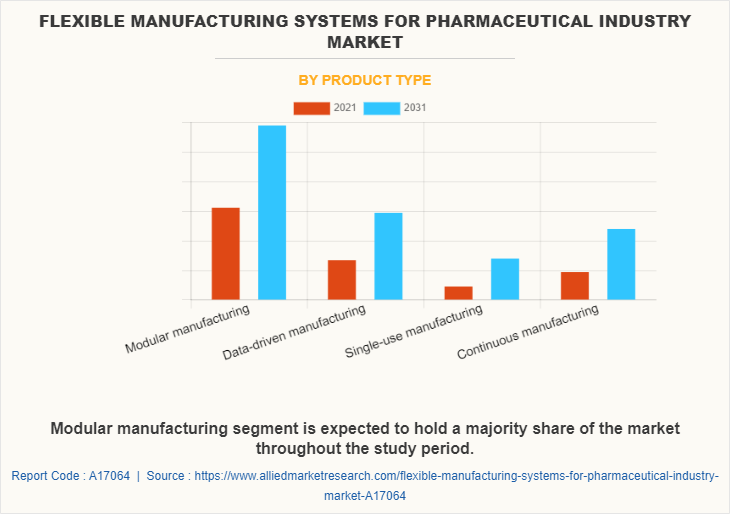

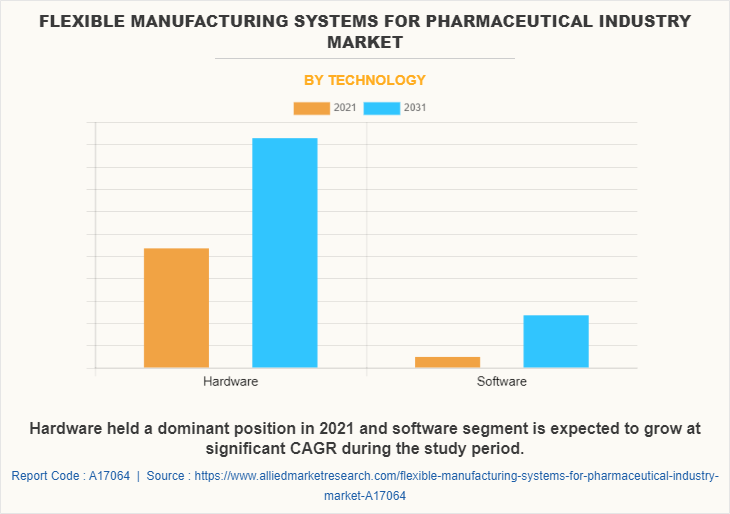

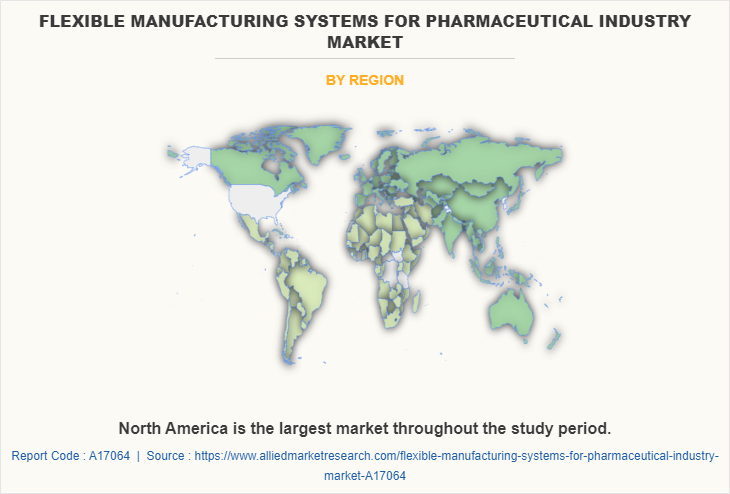

The flexible manufacturing systems for pharmaceutical industry market is segmented into Product Type, Technology and End User Industry. By type, the market is categorized into modular manufacturing, data-driven manufacturing, single-use manufacturing, and continuous manufacturing. On the basis of technology, it is segmented into software and hardware. By end user, it is bifurcated into large pharmaceutical manufacturers and medium and small pharmaceutical manufacturers. Region-wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. North America held the largest flexible manufacturing systems for pharmaceutical industry market share in 2021, accounting for the highest share. However, Asia-Pacific is anticipated to maintain this trend throughout the forecast period. This is attributed to increase in population and rise in spending of healthcare facilities.

Competition Analysis

Key companies profiled in the flexible manufacturing systems for pharmaceutical industry market forecast report include, Angstrom Technology, Biologics Modular, LLC, Chempharm, Cytiva, ESC (Environmental Systems Corporation), Exyte GmbH, G-CON Manufacturing, Germfree Laboratories Inc., IPM Technologies, KeyPlants Ab, ModuleCo Ltd., Modwave LLC, Nicomac Srl, NNE, Pharmadule Morimatsu AB, PR Pharma, and Engineers Pvt. Ltd., and Univercells Technologies

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the flexible manufacturing systems for pharmaceutical industry market analysis from 2021 to 2031 to identify the prevailing flexible manufacturing systems for pharmaceutical industry market opportunity.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the flexible manufacturing systems for pharmaceutical industry market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global flexible manufacturing systems for pharmaceutical industry market trends, key players, market segments, application areas, and market growth strategies.

Flexible Manufacturing Systems for Pharmaceutical Industry Market Report Highlights

| Aspects | Details |

| By Product Type |

|

| By Technology |

|

| By End User Industry |

|

| By Region |

|

| Key Market Players | Exyte GmbH, PR Pharma Engineers Pvt. Ltd., Cytiva, Chempharm, Univercells Technologies, ModuleCo Ltd., NNE, IPM Technologies, Biologics Modular, LLC, Modwave LLC, Germfree Laboratories Inc., Pharmadule Morimatsu AB, ESC (Environmental Systems Corporation), KeyPlants Ab, Angstrom Technology, Nicomac Srl, G-CON Manufacturing |

Analyst Review

The flexible manufacturing systems for pharmaceutical industry have witnessed significant growth in past few years, owing to surge in global population and everchanging nature of pharmaceutical industry.

The pharmaceutical industry is highly volatile and uncertain. Governments across the world impose varying tariffs on general and life-saving drugs. Moreover, drug safety associations in their respective countries across the globe keep a tight control over pharmaceuticals, and drugs from one country might not get approval in another country. Such uncertainties drive the demand for flexible manufacturing systems for pharmaceutical industry. In addition, flexible manufacturing systems help in economical, and effective utilization of the resources of a manufacturer. Furthermore, rise in number of elderly population across the world, especially in the European regions, is expected to drive the demand in pharmaceutical sector, thereby driving the demand for flexible manufacturing systems for pharmaceutical industry.

In addition, pharmaceutical industry is growing rapidly in emerging nations such as India and Kenya, owing to relatively easy government guidelines and a cheap workforce. This is expected to provide lucrative opportunities for flexible manufacturing systems for pharmaceutical industry growth

Development of flexible manufacturing systems that enhance machine and volume flexibility is a major trend in the market.

The Flexible Manufacturing Systems for Pharmaceutical Industry Market is expected to reach $3,319.7 Million by 2031.

North America is the largest regional market for Flexible Manufacturing Systems for Pharmaceutical Industry.

$1,962.2 Million is the estimated industry size of Flexible Manufacturing Systems for Pharmaceutical Industry in 2021.

Angstrom Technology, Biologics Modular, LLC, Chempharm, Cytiva and ESC (Environmental Systems Corporation are some of the top companies to hold the market share in Flexible Manufacturing Systems for Pharmaceutical Industry.

The company profile has been selected on factors such as geographical presence, market dominance (in terms of revenue and volume sales), various strategies and recent developments.

Based on product type, Modular manufacturing holds the maximum market share of the Flexible Manufacturing Systems for Pharmaceutical Industry in 2021.

Latest version of global Flexible Manufacturing Systems for Pharmaceutical Industry report can be obtained on demand from the website.

Loading Table Of Content...