Fuel Cell Balance of Plant (BOP) Market Overview

The global Fuel Cell Balance of Plant (BOP) Market was valued at USD 1.9 billion in 2022, and is projected to reach USD 13.9 billion by 2032, growing at a CAGR of 22.2% from 2023 to 2032.

Key Report Highlights

- The Fuel Cell Balance of Plant (BOP) Market has been analyzed in terms of value ($million), covering more than 15 countries.

- For growth prediction, we have looked into historical trends including present and future activities of key business players.

- The report covers detailed profiling of the major 10 market players.

A fuel cell is an electrochemical device that converts the chemical energy of a fuel, typically hydrogen, directly into electricity without combustion. It is a clean and efficient energy conversion technology that offers a range of applications for power generation. The term "balance of plants" (BOP) in fuel cell refers to the collection of systems and components that support the operation of a specific technology or process. In the context of fuel cells, the balance of plants encompasses all the auxiliary systems and components required to facilitate the efficient and reliable operation of the fuel cell system itself. The specific components included in the balance of plants can vary depending on the type of fuel cell and its application.

Some common elements typically found in the balance of plants of a fuel cell system include:

- Fuel supply: This involves the storage, delivery, and conditioning of the fuel (such as hydrogen, natural gas, methanol, or others) to the fuel cell stack.

- Air supply: Provision of air or oxygen to the fuel cell stack for the electrochemical reaction to occur. This may involve air compressors, filters, and humidifiers.

- Thermal management: Fuel cells generate heat during operation, and maintaining optimal operating temperatures is crucial for efficiency and durability. Heat exchangers, coolant systems, and temperature control mechanisms are part of the thermal management system.

- Water management: Depending on the type of fuel cell, water management systems may be required to regulate the water content within the fuel cell stack. This can involve humidifiers, condensers, and water removal systems.

- Power Electronics: Converters, inverters, and other power electronic components are necessary to manage the electrical output from the fuel cell system, enabling it to interface with external electrical systems or energy storage devices.

- Controls and monitoring: Sensors, control systems, and monitoring equipment are essential for maintaining the proper operation and performance of the fuel cell system. They help regulate various parameters, detect faults, and ensure safety.

- Exhaust management: Depending on the type of fuel cell, exhaust gases may need to be treated or managed. This can involve catalysts or other devices to reduce emissions or capture byproducts.

- Balance of plant enclosure: In many cases, the balance of plants is housed within an enclosure or casing to protect the components from environmental factors and provide an integrated and compact system.

The balance of plant plays a crucial role in the overall performance, reliability, and safety of fuel cell systems. It ensures the efficient and coordinated operation of various subsystems, enabling the fuel cell stack to generate electricity effectively and reliably. The work of the balance of plants in a fuel cell system is to provide the necessary support, control, and conditioning of fuel, air, temperature, water, and electrical output to enable the efficient, reliable, and safe operation of the fuel cell stack. The growth in the requirement for clean energy, government initiatives to encourage the utilization of green energy, and the improvement of infrastructure to yield hydrogen is anticipated to facilitate the Fuel Cell Balance of Plant (BOP) Market growth.

Market Dynamics

The BOP components, such as power electronics and converters, enable efficient power conversion and management. They convert the direct current (DC) produced by the fuel cell stack into the alternating current (AC) required for various applications. This efficient power conversion minimizes energy losses and maximizes the utilization of the generated electricity. Fuel cell BOP components contribute to the environmental advantages of fuel cell technology. Fuel cells produce electricity through electrochemical reactions, emitting only water vapor and minimal pollutants.

Well-designed BOP systems can further enhance environmental benefits by incorporating efficient air filtration, exhaust gas treatment, and noise reduction measures. The BOP includes safety features and control systems to monitor and protect the fuel cell system. These systems provide safeguards against overpressure, overtemperature, and other abnormal operating conditions. They also allow for remote monitoring, diagnostics, and control of the fuel cell system, enabling efficient maintenance and troubleshooting. Therefore, the applications of the fuel cell balance of plant (BOP) are growing in several industries like automotive, military, infrastructure, and others. Balance of Plant (BOP) is critical for the efficient operation of the fuel cell. It assists to optimize the system performance and manage the complete fuel cell system. Appropriate installation of BOP components is crucial to the timely commissioning of a fuel cell. Above mentioned factors contribute to the Fuel Cell Balance of Plant (BOP) Market growth.

The BOP of a fuel cell system can be complex and require careful design and integration. The presence of additional components, such as power electronics, cooling systems, and control systems, increases the complexity of the overall system. This complexity can result in higher costs, increased maintenance requirements, and potential challenges in system optimization and troubleshooting. The BOP components add to the overall cost of a fuel cell system. Components such as power electronics, cooling systems, and control systems can be expensive to manufacture and integrate. The cost of these additional components can make fuel cell systems more expensive compared to conventional power generation technologies, which may limit their widespread adoption. These factors act as major restraining forces for the fuel cell balance of plant market growth.

There is significant potential for cost reduction in BOP components, such as power electronics, cooling systems, and control systems. Research and development efforts focused on improving manufacturing techniques, materials selection, and system integration can help drive down costs, making fuel cell systems more competitive with conventional power generation technologies. These factors are expected to drive potential growth for Fuel Cell Balance of Plant (BOP) Market.

Segment Overview

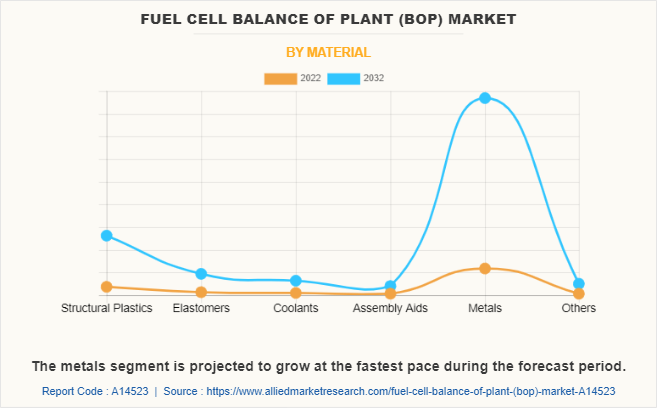

The fuel cell balance of plant market size is studied on the basis of material, component, and region.

Based on material, the market is divided into structural plastics, elastomers, coolants, assembly aids, metals, and others. Structural plastics can be employed in non-critical components or enclosures within the BOP to provide structural support, protection, and insulation. Some examples of where structural plastics might be used in a fuel cell system include enclosures or housings, ducts & conduits, and mounting or support structures. For choosing structural plastics, factors such as mechanical strength, chemical resistance, thermal stability, and any specific requirements for the fuel cell system are considered vital. They have been compatible with the operational conditions and ensure the overall performance, reliability, and safety of the fuel cell system.

Elastomers play a key role in the balance of plants in fuel cell systems. In fuel cell systems, elastomers are used in various sealing and gasket applications due to their flexibility and ability to withstand demanding operating conditions. Some common elastomers used in fuel cell systems include silicone, fluorocarbon (Viton), and perfluoro elastomers (Kalrez). These elastomers are chosen for their chemical resistance, thermal stability, and compatibility with the specific operating environment of fuel cells.

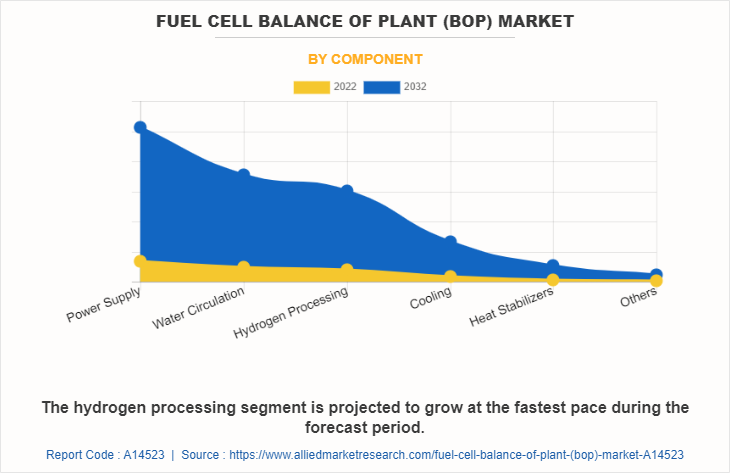

Depending on the component, the fuel cell balance of plants (BOP) market is divided into power supply, water circulation, hydrogen processing, cooling, heat stabilizers, and others. The power supply segment dominated the fuel cell balance of plant market share. However, the hydrogen processing segment is projected to grow at a higher CAGR during the fuel cell balance of plant market forecast. Power supply components in the balance of plants (BOP) of a fuel cell system are responsible for managing and delivering electrical power to various subsystems and components within the system. These components ensure proper operation and control of the fuel cell system. They include DC-DC converters, inverters, energy storage systems, power distribution & protection, control & monitoring units, and power management & control units.

The proper design, integration, and control of power supply components in the BOP are essential for achieving efficient power conversion, stable operation, and reliable performance of the fuel cell system. These components enable power delivery to the load, grid connection, energy storage, and power management, ensuring the optimal utilization of the electrical energy generated by the fuel cell stack. Water circulation is an important aspect of the balance of plants (BOP) in a fuel cell system, particularly for fuel cell technologies that require precise water management. The water circulation system ensures proper hydration of the fuel cell stack and helps maintain optimal operating conditions. It involves processes such as water supply & purification, humidification, water vapor management, water recirculation, water removal & purging, and water quality monitoring.

Region-wise, fuel cell balance of plant market analysis is done across North America, Europe, Asia-Pacific, and LAMEA (Latin America, the Middle East, and Africa). Asia-Pacific region is projected to dominate the Fuel Cell Balance of Plant (BOP) Market growth during the forecast period. North America has a well-established fuel cell industry and a robust supply chain for fuel cell components, subsystems, and balance of plant equipment. This includes manufacturers of fuel cell stacks, power electronics, hydrogen storage systems, and balance of plant components. North America has specific regulations and policies that impact the deployment and operation of fuel cell systems. These include federal, state, and local regulations related to safety, environmental standards, and energy policies.

Understanding and complying with these regulations is essential for the successful implementation of fuel cell BOP in North America. The region offers significant Fuel Cell Balance of Plant Market opportunities for fuel cell systems across various sectors. Many countries in the Asia-Pacific region have implemented policies and incentives to promote the adoption of fuel cells. Governments provide financial support, grants, tax incentives, and feed-in tariffs to encourage the development and deployment of fuel cell systems. Understanding the specific policies and support mechanisms in each country is essential for implementing fuel cell BOP in Asia-Pacific.

Key Market Players

The key players operating in the fuel cell balance of plant industry are INN Balance, Cummins Inc., Hydrogenics Corporations, Ballard Power Systems, Bloom Energy, SFC Energy AG, Doosan Fuel Cell America, Inc., HORIBA Group, Elcogen AS, and Dana Limited. The industry players adopted several startegies such as business expansion and collaboration to sustain competition in Fuel Cell Balance of Plant (BOP) Market.

Recent Market Strategies

Cummins, Inc. opened a new facility in Herten, Germany. This facility initially focuses on the assembly of fuel cell systems, with plans to expand in the future to support fuel cell stack refurbishment.

Cummins, Inc., and Hyundai collaborated on hydrogen fuel cell technology. They signed an MOU to jointly develop and commercialize electric and fuel cell powertrains combining Hyundai fuel cell systems and Cummins' electric powertrain, battery, and control technologies.

Doosan Fuel Cell Co., Ltd. signed a business collaboration agreement with Kolon Global at the Doosan Tower in Dongdaemun. This helps Doosan Fuel Cell Co., Ltd. to develop a hydrogen fuel cell business model using biogas with Kolon Global.

Doosan Fuel Cell Co., Ltd. signed a large-scale supply contract where hydrogen fuel cells are supplied to China's ZKRG Smart Energy Technology Co. Ltd. (hereinafter referred to as ZKRG) and establish a joint venture (JV) with ZKRG.

Most BOP components are similar to components in a regular Internal Combustion Engine (ICE). Some of the key regulations in Fuel Cell Balance of Plant (BOP) Market are:

GMW3172

GM Worldwide (GMW) standards are based on ASTM, ISO standards.

ASTM D4728

IEC 60068-2-1, IEC 60068-2-14, IEC 60068-2-27, IEC 60068-2-29, IEC 60068-2-30, IEC 60068-2-38, IEC 60068-2-52, IEC 60068-2-64, IEC 60068-2-78

ISO 8820, ISO 12103-1, ISO 16750-2, ISO 16750-3, ISO 16750

Safety standards applicable to fuel cell BOP include the National Fire Protection Association (NFPA) 2, NFPA 70 (National Electrical Code), and the International Electrotechnical Commission (IEC) 62282 series.

IEC 62282 series for fuel cell technologies, ISO 16111 for fuel cell systems in transportation, and ISO 14687 for hydrogen fuel quality.

Key Benefits For Stakeholders

This report provides a quantitative analysis of the Fuel Cell Balance of Plant (BOP) Market segments, current trends, estimations, and dynamics of the fuel cell balance of plant market analysis from 2022 to 2032 to identify the prevailing fuel cell balance of plant market opportunities.

The research is offered along with information related to key drivers, restraints, and opportunities.

Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make to profit-oriented business decisions and strengthen their supplier-buyer network.

In-depth analysis of the fuel cell balance of plant market segmentation assists to determine the prevailing market opportunities.

Major countries in each region are mapped according to their revenue contribution to the global market.

Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

The report includes the analysis of the regional as well as global fuel cell balance of plant market trends, key players, market segments, application areas, and market growth strategies.

Fuel Cell Balance of Plant (BOP) Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 13.9 billion |

| Growth Rate | CAGR of 22.2% |

| Forecast period | 2022 - 2032 |

| Report Pages | 244 |

| By Material |

|

| By Component |

|

| By Region |

|

| Key Market Players | INN Balance, Dana Limited, Doosan Fuel Cell Co., Ltd., Ballard Power Systems, Elcogen AS, HORIBA FuelCon GmbH, SFC Energy AG, Hydrogenics Corporation, Bloom Energy, Cummins, Inc. |

Analyst Review

According to insights from the CXOs, the market is expected to offer significant opportunities for fuel cell systems across various sectors. This is attributed to the efficient power conversion benefits of the fuel cell balance of plants (BOP) systems. In addition, there is growing interest and support for clean energy technologies, including fuel cells, in applications such as stationary power generation, transportation, and portable power, which contributes toward the growth of the market. Moreover, the availability of supportive infrastructure is important for the BOP of fuel cell systems. However, additional components can make fuel cell systems more expensive compared to conventional power generation technologies and thus hamper the growth of the fuel cell balance of plants (BOP) industry.

The CXOs further added the implementation of extensive measures for decarbonization for cleaner and more sustainable energy. Further, cross-border collaboration in fuel cell development and initiatives such as the Hydrogen Energy Supply-Chain Technology Research Association (HySTRA) and collaborations between Japan, South Korea, and other countries foster joint research, demonstration projects, and knowledge sharing. Thus, these factors are anticipated to offer lucrative opportunities for the expansion of the global market during the forecast period.

$13.9 billion is the estimated industry size of Fuel Cell Balance of Plant (BOP).

Efficient power conversion, environmental benefits, and improved safety & control systems are the upcoming trends of Fuel Cell Balance of Plant (BOP) Market in the world.

Power Supply is the leading component of Fuel Cell Balance of Plant (BOP) Market.

Asia-Pacific is the largest regional market for Fuel Cell Balance of Plant (BOP).

INN Balance, Cummins Inc., Hydrogenics Corporations, Ballard Power Systems, Bloom Energy, SFC Energy AG, Doosan Fuel Cell America, Inc., HORIBA Group, Elcogen AS, and Dana Limited are the top companies to hold the market share in Fuel Cell Balance of Plant (BOP).

Loading Table Of Content...

Loading Research Methodology...