Graphite Recycling Market Research, 2033

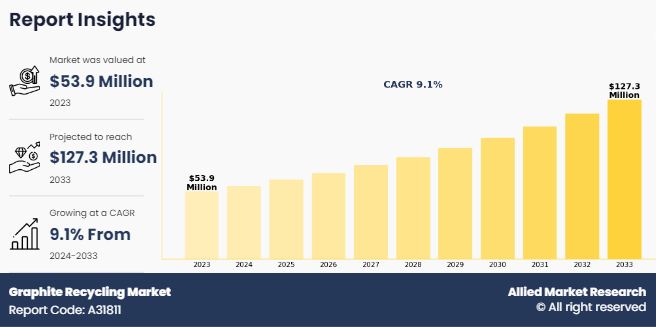

The global graphite recycling market was valued at $53.9 million in 2023, and is projected to reach $127.3 million by 2033, growing at a CAGR of 9.1% from 2024 to 2033. The adoption of smart building technologies in both commercial and residential sectors is significantly driving the demand for the electrochromic glass market. Smart buildings often integrate advanced energy management systems. Electrochromic glass can be controlled via these systems to optimize light and heat management, reducing the reliance on HVAC systems and artificial lighting.

Introduction

Graphite recycling is a process of recycling or recovering graphite from various sources such as lithium-ion batteries, electrodes, motors & crucibles, lubricants, foundry facings, arc lamps, core of nuclear reactors, and others. The spent graphite (SG) is combined with sulfuric acid curing, leaching, and calcination processes to recover or recycle graphite through graphitization, refining, and separation processes. One of the most prominent uses of graphite is in the production of lithium-ion batteries, which are essential for electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. Graphite serves as a key component in the anode material of these batteries due to its excellent conductivity, energy density, and long cycle life. With the global transition toward clean energy and electric transportation, the demand for lithium-ion batteries has skyrocketed, leading to a growing interest in graphite recycling.

Graphite is widely used in the electronics industry due to its electrical conductivity and heat dissipation properties. It is commonly found in various electronic components, such as semiconductors, electrical contacts, and heat sinks. As electronic devices are rapidly replaced by newer models, the volume of electronic waste (e-waste) is growing exponentially. Graphite recycling from electronic waste provides a solution to recovering valuable graphite materials that would otherwise end up in landfills or incinerators. Recycled graphite from electronics is used to manufacture new electrical components and devices, contributing to the circular economy. Additionally, the recycling of graphite helps reduce the environmental impact of electronic waste and minimizes the need for mining fresh resources, making electronics production more sustainable.

Key Takeaways

- The global graphite recycling market has been analyzed in terms of value ($billion). The analysis in the report is provided on the basis of application, end-use industry, 4 major regions, and more than 15 countries.

- The global graphite recycling market report includes a detailed study covering underlying factors influencing the industry opportunities and trends. The key players in the graphite recycling market are Architonic, Ascend Elements, Inc., Coidan Graphite, Duesenfeld GmbH, ECOGRAF, Graphite Sales, Inc., Lab4 Inc., Semco Carbon, Weaver Industries, and Inc., and X-BATT.

- The report facilitates strategy planning and industry dynamics to enhance decision-making for existing market players and new entrants entering the alternators industry.

- Countries such as China, the U.S., India, Germany, and Brazil hold a significant share in the global graphite recycling market.

Market Dynamics

The growth of the global graphite recycling market is driven by rapid technological advancements coupled with the emergence of artificial intelligence (AI), internet of things (IOT) and machine learning (ML) technologies which in turn have surged the demand for semiconductors used for manufacturing various kinds of electronic devices, including diodes, transistors, and integrated circuits. Recycled graphite exhibits excellent chemical, thermal stability as well as biocompatibility and achieve semiconductor-type electrical properties. This may act as one of the key drivers responsible for the growth of the graphite recycling market. Furthermore, increase in demand for consumer electronics has surged the popularity of electrochemical applications where recycled graphite is widely used as electrodes. For instance, according to a report published by National Investment Promotion and Facilitation Agency, the export of electronic devices of India is set to increase from $10 billion in 2021 to $120 billion by 2026. This may enhance the demand for recycled graphite used for electrochemical applications in the growing electronics sector; and thus boost the market growth.

However, high initial investment costs is expected to restraint the growth of graphite recycling market during the forecast period. Establishing recycling facilities for graphite necessitates substantial capital investment, which can be a significant barrier to entry for many companies, particularly smaller ones. The initial costs involved in setting up these facilities include advanced machinery and equipment specifically designed for the efficient processing and purification of graphite. This machinery often incorporates new technologies that enhance the recovery rate and quality of recycled graphite, but these systems can be prohibitively expensive. In addition to machinery costs, the requirement for specialized technology further adds to the overall financial investment. Advanced recycling processes require sophisticated technology to separate graphite from other materials, such as metals and plastics, especially when sourced from complex products such as lithium-ion batteries. This technological requirement deter small and medium-sized enterprises (SMEs) from entering the market, as they lack the necessary financial resources to invest in such equipment.

On the contrary, factors such as attractive government policies for supporting emission vehicles and growth in demand for low emission commuting coupled with rise in awareness for sustainable activities, have led the electric vehicle sales to witness a significant increase. For instance, according to an article published by The Times of India in July 2022, India has reached around 5 crore electric vehicles sales in 2031. This factor has led the car battery manufacturing companies to enhance their production capacities where recycled graphite is widely used to produce anode material for various batteries. This may increase the demand for recycle graphite in the growing battery manufacturing sector; thus, creating opportunities for the graphite recycling market.

Segments Overview

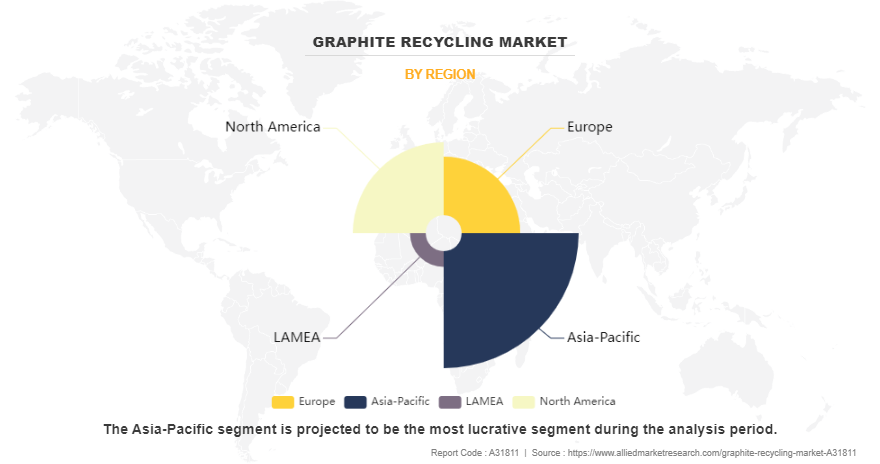

The graphite recycling market is segmented into source, form, application, and region. On the basis of source, the market is categorized into lithium-ion batteries, electrodes, motor brushes and crucibles, and others. On the basis of form, the market is bifurcated into solid chunks and powders. On the basis of application, it is divided into metal casting, batteries, lubricants, nuclear reactors, and others. On the basis of region, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

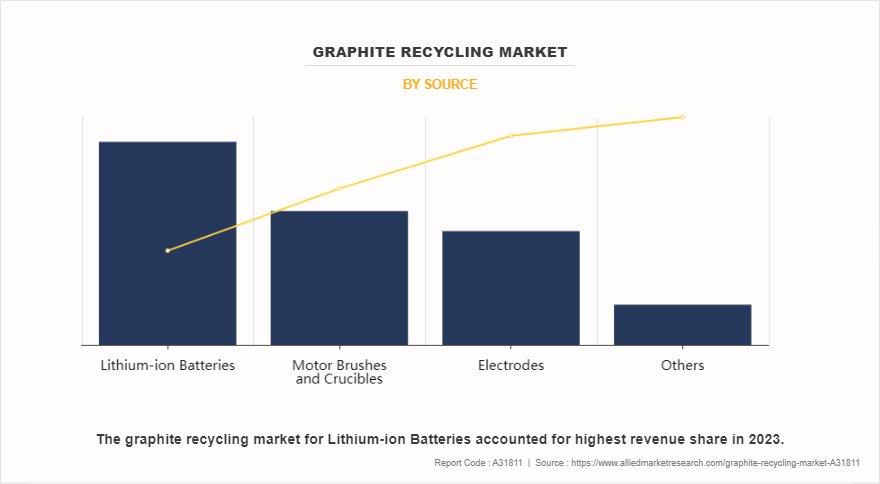

On the basis of source, the lithium-ion batteries segment was the largest revenue generator in 2023, and is anticipated to grow at a CAGR of 9.4% during the forecast period. Graphite recycling has gained significant attention in lithium-ion batteries (LIBs) due to its potential to reduce environmental impact and resource dependency. Graphite is a critical component of lithium-ion battery anodes, playing a key role in storing and releasing lithium ions during charge and discharge cycles. As the demand for lithium-ion batteries continues to surge, driven by the rise in electric vehicles (EVs), portable electronics, and renewable energy storage systems, the need for sustainable management of graphite resources has become crucial.

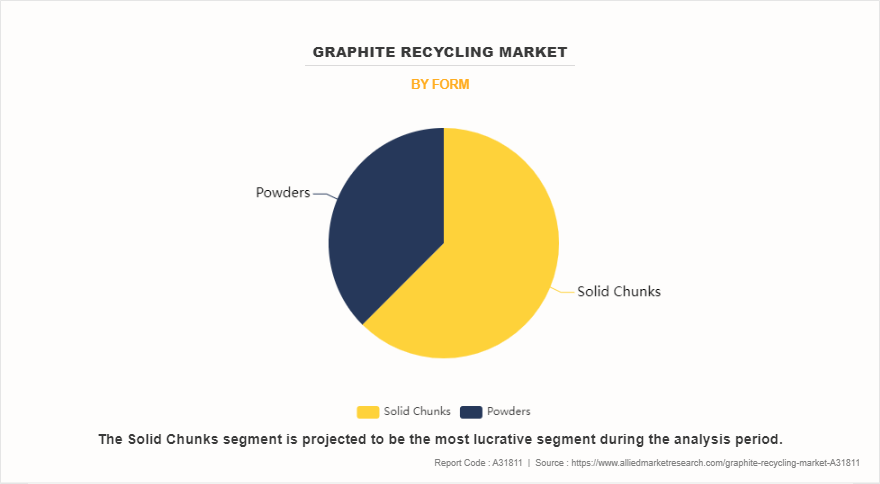

On the basis of form, the solid chunks segment is expected to dominate the graphite recycling market in 2023, and is projected to grow at the highest CAGR of 8.5% during the forecast period. Graphite recycling in solid chunk form is becoming increasingly important as industries seek to reduce waste and promote sustainability. Solid graphite chunks are typically generated as by-products in various manufacturing processes, particularly in the production of electrodes, crucibles, and molds used in high-temperature applications. The recycling process for solid graphite chunks involves sorting, cleaning, and grinding the material into usable forms. One common method is to reduce the chunks into fine powder, which then be utilized in a variety of applications, such as lubricants, batteries, and even new graphite products. Solid chunks is directly reformed into larger graphite blocks or plates for industrial use. This direct re-utilization avoids the energy-intensive process of creating new graphite from raw materials, making recycling a more energy-efficient option.

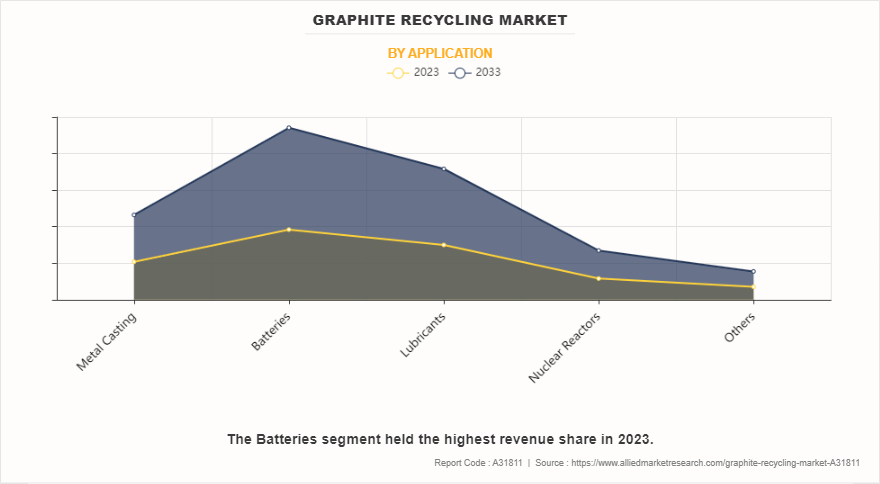

On the basis of application, batteries segment is expected to dominate the graphite recycling market in 2023, growing with the CAGR of 9.5% during the forecast period. Graphite recycling in batteries is becoming increasingly important due to the rising demand for electric vehicles (EVs) and energy storage systems, which rely on lithium-ion batteries. These batteries use graphite as the primary material for the anode, making up around 10-30% of the total battery weight. Recycling graphite from spent batteries offers both economic and environmental benefits, reducing reliance on natural graphite extraction and lowering the carbon footprint of battery production. The process of graphite recycling typically involves the recovery of graphite from end-of-life batteries through mechanical, chemical, or thermal methods. During recycling, the battery components are broken down, and the graphite is separated from other materials such as metals (like lithium, cobalt, and nickel) and electrolytes. Once purified, recycled graphite is reconditioned and used in new batteries or other industrial applications.

Region wise Asia-Pacific is expected to dominate the graphite recycling market in 2023. The rise in use of recycled graphite to manufacture coated steel and iron casting drives the growth of the graphite recycling market. The growth of the graphite recycling market in Asia-Pacific is majorly driven by the largest economies such as India and China and this is attributed to rise in the steel industry, electronics, and the automotive market in the Asia-Pacific region. There is a rapid increase of the electronic sector in China which has forced the graphite recycling manufacturers to produce high-quality recycled graphite in the region. According to a report published by the United Nations Statistics Division, China witnessed around 28.7% of the global manufacturing output for consumer electronic products in 2019. In addition, countries such as Japan and Taiwan have a large electronics industry base and consumer electronics appliances industry which in turn may boost the performance of graphite recycling market in the Asia-Pacific region.

Competitive Analysis

The major players operating in the graphite recycling market include Architonic, Ascend Elements, Inc., Coidan Graphite, Duesenfeld GmbH, ECOGRAF, Graphite Sales, Inc., Lab4 Inc., Semco Carbon, Weaver Industries, and Inc., and X-BATT.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the graphite recycling market analysis from 2023 to 2033 to identify the prevailing graphite recycling market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the graphite recycling market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global graphite recycling market trends, key players, market segments, application areas, and market growth strategies.

Graphite Recycling Market Report Highlights

| Aspects | Details |

| Market Size By 2033 | USD 127.3 million |

| Growth Rate | CAGR of 9.1% |

| Forecast period | 2023 - 2033 |

| Report Pages | 386 |

| By Form |

|

| By Source |

|

| By Application |

|

| By Region |

|

| Key Market Players | Duesenfeld GmbH, Weaver Industries, Inc., Semco Carbon, Lab4 Inc., Architonic, X-BATT, Graphite Sales, Inc., Ascend Elements, Inc., Coidan Graphite, ECOGRAF |

Analyst Review

According to the opinions of various CXOs of leading companies, the graphite recycling market is expected to witness significant growth in the upcoming years. This is attributed to the rise in use of recycled graphite in end use such as power, lubrication, transportation, electric vehicles, and electronics. In addition, mainstream applications of graphite recycling such as lubrication of metal, metal casting, anti-seize agent, release agent, and dry lubrication of materials propel the growth of the market. Key players opt for product innovations as their developmental strategies to strengthen their foothold in the competitive market and build sector expertise.

The electric vehicle batteries sector is predicted to dominate the global graphite recycling market during the forecast period, due to an upsurge in the use of recycled graphite as a positive anode material in automotive batteries. In addition, recycled graphite is used on steel and iron tools which in turn helps to control the seizure between tool and workpiece and can enhance the life of a metal-forming die.

Furthermore, the use of recycled graphite materials in the metal casting industry benefits both metal casting manufacturers and their clients due to the lower cost of recycled graphite compared to original graphite materials. This factor has surged the popularity of recycled graphite among metallurgical sectors. CXOs further added that sustained economic growth and a rise in transportation activities have increased the popularity of recycled graphite as a dry lubricant.

The global graphite recycling market was valued at $53.9 million in 2023, and is projected to reach $127.3 million by 2033, growing at a CAGR of 9.1% from 2024 to 2033.

Asia-Pacific is the largest regional market for graphite recycling.

Lithium-ion batteries is the leading source of graphite recycling market.

The surge in demand for EV and energy storage systems are the upcoming trends of graphite recycling market.

The major players operating in the graphite recycling market include Architonic, Ascend Elements, Inc., Coidan Graphite, Duesenfeld GmbH, ECOGRAF, Graphite Sales, Inc., Lab4 Inc., Semco Carbon, Weaver Industries, and Inc., and X-BATT.

Loading Table Of Content...

Loading Research Methodology...