Honeycomb Core Materials Market Research, 2032

The global honeycomb core materials market was valued at $2.5 billion in 2022, and is projected to reach $5.2 billion by 2032, growing at a CAGR of 7.8% from 2023 to 2032.

Report key highlighters:

- The report outlines the current honeycomb core materials market trends and future scenario of the market from 2023 to 2032 to understand the prevailing opportunities and potential investment pockets.

- The global honeycomb core materials market has been analyzed in terms of value ($Million) and volume (Kilotons). The analysis in the report is provided on the basis of type, end use industry, 4 major regions, and more than 15 countries.

- The battery packaging market is fragmented in nature with few players such as Plascore, MC Gill (The Gill Corporation), Schutz Composites, Hexcel Corporation, Toray Advanced Composites, Corex Honeycomb, Argosy International, Euro-Composites, Showa Aircraft Industry Co., Ltd, Honylite, RelCore Composites Inc., REYNOARCH, and Fabrinox, which hold significant share of the market.

- The report proivdes strategy planning and industry dynamics to enhance decision making for existing market players and new entrants entering the honeycomb core materials industry.

- Countries such as China, U.S., India, Germany, and Brazil hold a significant share in the global honeycomb core materials market.

Honeycomb core material is obtained from composite materials such as glass-reinforced plastic, aluminum, meta-aramid, and paper through expansion and corrugation processes. Honeycomb cores are fabricated with a large number of hexagon-shaped cells assembled into a honeycomb structure. They have been used for several decades to manufacture composite sandwich structures, as they provide stiffness to the composite structure with minimum weight. Thus, honeycomb core materials find their application in including aerospace & defense, building & infrastructure, automotive, marine, railway, and industrial sectors.

Expansion of building and infrastructure sectors has driven the market

Rapid infrastructure development and expansion of the automotive sector have led to rise in iron & steel production in both developed and developing economies such as the U.S., China, and India, which, in turn, has boosted the demand for honeycomb core materials for use in acoustic ceiling, thermal insulation, floors, and window panels. In addition, the growing modern theme-based building & construction sector has propelled the demand for honeycomb core materials; thus, manufacturing units may experience a surge in demand. These factors are expected to notably contribute toward the growth of the honeycomb core materials market.

High cost and limited design of honeycomb core materials is expected to hinder the market growt

However, Honeycomb structures are typically produced in standard configurations and sizes. While they can be cut or shaped to some extent, they have limitations when it comes to complex or customized designs. This lack of design flexibility may restrict their use in certain applications.In addition, honeycomb structures are typically produced in standard configurations and sizes. While they can be cut or shaped to some extent, they have limitations when it comes to complex or customized designs. This lack of design flexibility may restrict their use in certain applications.

Robust demand from transportation and logistics sector is expected to offer new avenues for the market.

On the contrary, increase in the use of recyclable products such as metal containers, including tin, aluminum, and steel cans is expected to provide lucrative opportunities for the growth of the honeycomb core materials market during the forecast period. Furthermore, surge in transportation and logistics activities has led to the growth of the automotive sector, wherein honeycomb core materials are widely used for making interior and exterior body panels. Moreover, they offer high durability, strength, and corrosion resistance due to which they are highly preferred in the automotive sector.

Furthermore, the demand for renewable energy sources, such as wind and solar power, continues to grow, honeycomb core materials can play a role in enhancing the efficiency and performance of related equipment. They can be used in wind turbine blades, solar panel supports, and energy storage systems, providing lightweight and durable solutions. This factor is projected to offer lucrative opportunities for the market.

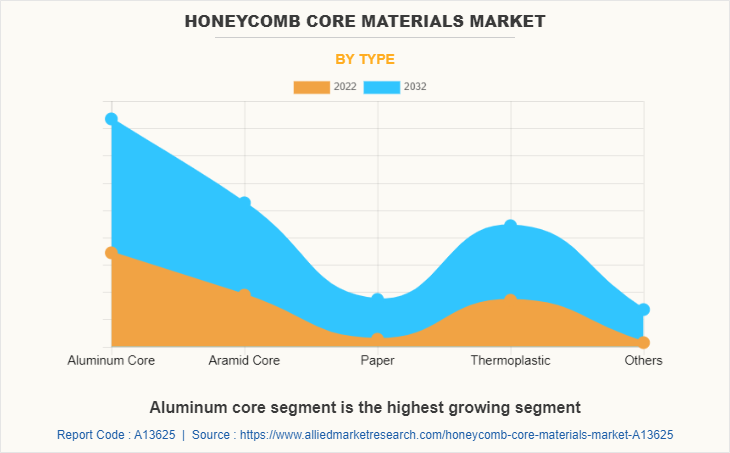

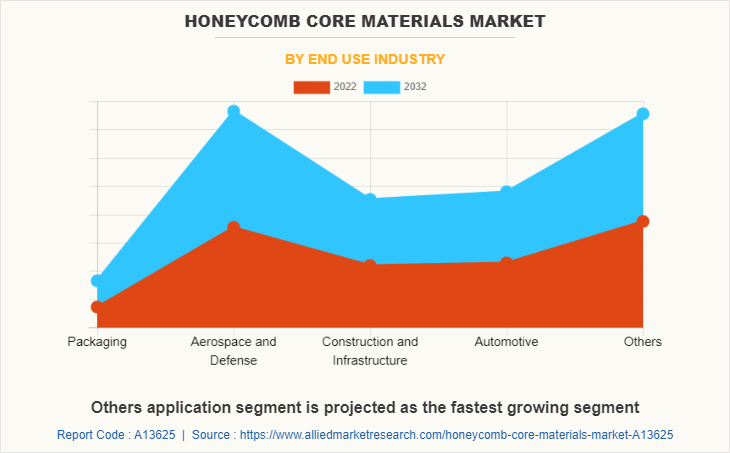

The global honeycomb core materials market is segmented into type, end-use industry, and region. By type, the market is fragmented into aluminum core, aramid core, paper, thermoplastic, and others. Depending on end-use industry, it is segregated into packaging, aerospace & defense, construction and infrastructure, automotive, and others. Region wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

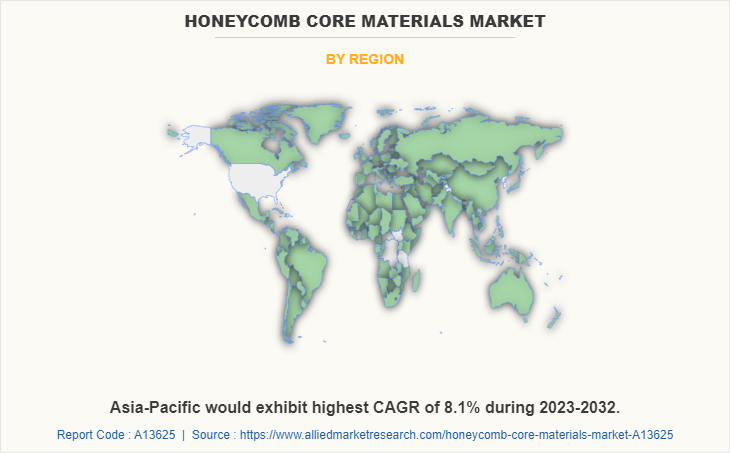

Asia-Pacific was the major shareholder in 2022, garnering 37% share in the global honeycomb core materials market, and is projected to grow at the highest CAGR during the forecast period. This is attributed to the fact that China, Japan, and India serve as the potential manufacturing hubs of automobile in Asia-Pacific with presence of major automotive giants such as Honda, Toyota, TATA, Suzuki, Ashok Leyland, and Mitsubishi. In addition, surge in demand and production of commercial and passenger vehicles across the developing economies, such China and India, has boosted the demand for honeycomb core materials as they are widely used in interior and body panels, spoilers, floors, chassis components, diffusers, and energy absorbers of automobiles.

Furthermore, North America was the second major shreolder in 2022, and growing at CAGR of 7.8% during the forecast period. This is due to the fcators such as, The construction industry in North America has been growing in response to rapid increase in housing services coupled with rise in population in Mexico and the U.S. This, in turn, has boosted the demand for honeycomb core materials, which are widely used in the construction industry for forging, pipe-in-pipe, doors, roof board, and slabs, as they exhibit low heat conduction coefficient, low density, low water absorption, high mechanical strength, and superior insulating properties. Moreover, the air transport industry in Canada is growing at a rapid pace owing to the factors such as increase in disposable income, improvement in standard of living, and rise in international trade. This has propelled the demand for honeycomb core materials in the North America region.

In 2022, the aluminum core segment was the largest revenue generator, and is anticipated to grow at a CAGR of 8.0% during the forecast period. This is attributed to the fact that, aluminum honeycomb core material is a completely recyclable, non-combustible, and lightweight building material used across several industries, including public transport, aeronautical sector, and in construction. Moreover, it makes up the central layer of the sandwich panel, and due to its superior strength to weight ratio, it is often used as flooring, ceilings, doors, partitions, and even work surfaces.

Furthermore, rise in population and increase in building & infrastructure activities have surged the demand for aluminum honeycomb core materials. This is attributed to the fact that high strength to weight ratio, resistance to corrosion, and high strength make it an ideal component in the building & construction sector. In addition, increase in application of aluminum honeycomb for making building facades, ceiling & flooring panels, clean rooms, and furniture acts as one of the key drivers of the market.

Furthermore, Aramid core type segment was the second largest revenu genrating sector growing at CAGGR of 7.7% during tjeh forecast period. The prime factor for this growth is surge in consumer demand for housing, rise in building & construction activities, and increase in disposable income have boosted the demand for aramid core fibers where they are used for acoustic insulation. Furthermore, transportation and logistics activities have spurred the demand for aramid core where it is used in auto racing bodies, train car & ship panels, and ground transportation structures

By end-use industry, The aerospace & defense segment dominated the global market, in terms of revenue in 2022 with 42% share in the global market. Honeycomb core materials are widely used in the aerospace & defense industry due to their high strength to weight ratio, resistance to compression and cuts, and superior fire protection. In addition, lightweight yet strong property makes it best suited in making aircraft and military equipment.

Moreover, Aerospace and defense industry accounted for second highest revenue generating segment which hold 43% of market share. The aerospace and defense industry plays a significant role in the growth of the honeycomb core materials market. Furthermore, the upsurge in international passengers and freight trafficking has led to rise in demand for aircraft. These factors are expected to eventually boost the demand for honeycomb core materials.

The major companies profiled in this report include Plascore, MC Gill (The Gill Corporation), Schutz Composites, Hexcel Corporation, Toray Advanced Composites, Corex Honeycomb, Argosy International, Euro-Composites, Showa Aircraft Industry Co., Ltd, Honylite, RelCore Composites Inc., REYNOARCH, and Fabrinox.

COVID-19Impact Analysis:

The COVID-19 pandemic negatively impacted the global honeycomb core materials market. Furthermore, the building and construction industry was adversely impacted in 2020 due to rise in cases of COVID-19 and the imposition of lockdown and disruption in the supply chain in the second quarter of 2020, which, in turn, had hampered the honeycomb core materials market.

In addition, the falling income of customers and international travel restrictions led to decline in the demand for honeycomb core materials in the automotive, aerospace, commercial, industrial sectors. In addition, COVID-19 temporarily halted various infrastructure projects, which, in turn, reduced the demand for honeycomb core materials.

However, the building & construction, aerospace, and automotive industries are projected to get back on track and start functioning at full capacity post the COVID-19 period, which in turn is expected to enhance the performance of the honeycomb core material market in 2023. This factor will increase potential sales of the honeycomb core material market in the upcoming years.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the honeycomb core materials market analysis from 2022 to 2032 to identify the prevailing honeycomb core materials market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the honeycomb core materials market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global honeycomb core materials market trends, key players, market segments, application areas, and market growth strategies.

Honeycomb Core Materials Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 5.2 billion |

| Growth Rate | CAGR of 7.8% |

| Forecast period | 2022 - 2032 |

| Report Pages | 671 |

| By Type |

|

| By End Use Industry |

|

| By Region |

|

| Key Market Players | TCCORE APPLIED HONEYCOMB TECHNOLOGY CO., LTD., fabrinox, Toray Advanced Composites, Euro-Composites, Hexcel Corporation, Argosy International, Plascore, RelCore Composites Inc., Schtz GmbH & Co. KGaA, Corex Honeycomb, Honylite, Showa Aircraft Industry Co., Ltd, The Gill Corporation |

Analyst Review

According to CXOs of leading companies, the global honeycomb core materials market is expected to exhibit high growth due to rise in demand for lightweight, high-strength materials across various end-use industries such as aerospace & defense, automotive, and building & construction. Moreover, surge in demand for lightweight, fuel-efficient cars is encouraging automotive manufacturers to adopt honeycomb core materials.

Honeycomb cores enable the manufacturers to considerably reduce the weight of the vehicle without compromising on strength. The product is being utilized to produce a variety of automotive components, including interior body panels, floors, chassis components, diffusers, and spoilers.

The CXOs further added that aerospace-grade honeycomb core materials are progressively replacing traditional materials, including laminated panels and aluminum sheets on account of their lightweight and high-strength attributes. The product is being increasingly adopted in the production of a variety of aerospace components such as helicopter blades, fuselage components, aircraft flooring, and antennas. Thus, the rapid expansion of the automotive and aerospace industries across the developing economies, such as China, India, and Brazil, is expected to significantly contribute toward the growth of the global honeycomb core materials market during the forecast period.

Ongoing research and development efforts were aimed at improving the performance and manufacturing processes of honeycomb core materials. Advancements in material science and manufacturing techniques could lead to enhanced properties, cost reductions, and wider applications.

The honeycomb core materials market was valued at $2.5 billion in 2022, and is estimated to reach $5.2 billion by 2032, growing at a CAGR of 7.8% from 2023 to 2032.

Aerospace and defense segment is the leading in honeycomb core materials market.

Plascore, MC Gill (The Gill Corporation), Schutz Composites, Hexcel Corporation, Toray Advanced Composites, Corex Honeycomb, Argosy International, Euro-Composites, Showa Aircraft Industry Co., Ltd, Honylite, RelCore Composites Inc., REYNOARCH, and Fabrinox.

Asia-Pacific is the largest regional market for honeycomb core materials.

The global honeycomb core materials market is segmented into type, end-use industry, and region. By type, the ma end-use industry, it is segregated into packaging, aerospace & defense, construction and infrastructure, automotive, and others. Region wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

Honeycomb core material is obtained from composite materials such as glass-reinforced plastic, aluminum, meta-aramid, and paper through expansion and corrugation processes. Honeycomb cores are fabricated with a large number of hexagon-shaped cells assembled into a honeycomb structure. They have been used for several decades to manufacture composite sandwich structures, as they provide stiffness to the composite structure with minimum weight. Thus, honeycomb core materials find their application in including aerospace & defense, building & infrastructure, automotive, marine, railway, and industrial sectors.

Loading Table Of Content...

Loading Research Methodology...