Hot Runner Market Outlook - 2026

The global hot runner market size was $2,854.0 million in 2018, and is expected to reach $5,241.5 million by 2026, growing at a CAGR of 7.9% from 2019 to 2026.A hot runner system comprises an assembly of heated components including hot valves, nozzles, and gates that inject plastic into the cavities of an injection mold. The system usually includes a heated manifold and several heated nozzles. The manifold distributes the plastic entering the mold to the nozzles, which then meter it precisely to the injection points in the cavities.

Market players provide hot runner of various variants to meet the requirements of customers. Automotive, packaging, healthcare, and other sectors exhibit high demand for various types of hot runner. In addition, hectic lifestyle of consumers has increased the adoption of frozen foods, and thereby, the use of injection molded plastics products. This has further led to the rise in demand for hot runner. In addition, major end users, such as logistics, consumer goods, building & construction, manufacturing, and automotive, operating in the developed regions focus on the quality aspect of the hot runner nozzles; however, end users in price-sensitive economies, such as China and India, prefer low-priced systems for various applications.

The global hot runner market experiences growth owing to rapid rise in investment in the industrial sector and high demand for injection molded plastic products in the automotive and healthcare sectors. In addition, rise in movement toward automated plastic processing and packaging to accelerate productivity and efficiency drive the hot runner market growth. In addition, major players are producing electric valve gate hot runners to ensure energy efficiency, thereby fueling the growth of the market. For instance, eGate electric valve gate hot runner systems by Synventive Molding Solutions are suited for injection molding applications that require responsiveness, precision, and repeatability. Further, the augmented energy and cost saving by use of hot runners is estimated to drive the market growth. However, threat of substitutes faced by the hot runner industry is expected to hinder the growth of the hot runner market

Governments focus on maintaining political stability and providing an efficient regulatory structure and a functional legal system for growth of the economy. Furthermore, favorable government regulations and initiatives related to industrial sector development encourage domestic and international vendors to enter the lucrative markets. Hot runner manufacturers focus on expanding their base in emerging economies, such as China and India, to boost their market presence. For instance, Milacron Holdings Corp. expanded its business by completing a hot runner and control systems manufacturing facility in Kunshan City, Jiangsu, China in 2017.

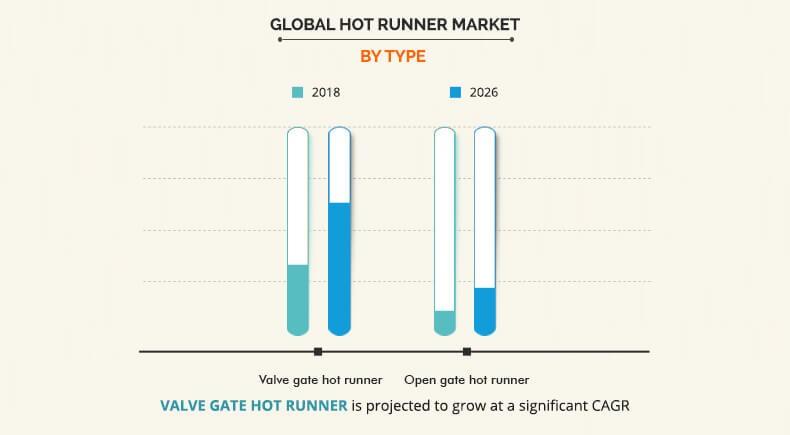

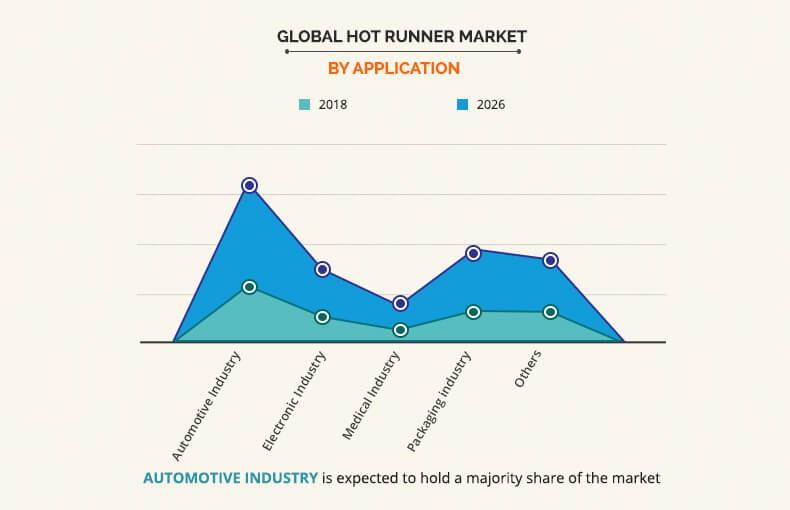

The global hot runner market is segmented based on type, application, and region. Based on type, the market is segmented into valve gate hot runner and open gate valve runner. The valve gate hot runner segment is anticipated to dominate the global hot runner market throughout the study period. Based on application, the market is categorized into various industries, namely automotive, electronics, medical, packaging, and others. The automotive segment is anticipated to dominate the global hot runner market share throughout the study period.

The global hot runner market is analyzed across four regions, which include North America (U.S., Canada, and Mexico), Europe (Germany, France, Spain, Italy, and Rest of Europe), Asia-Pacific (China, Japan, India, Indonesia, and rest of Asia-Pacific), and LAMEA (Latin America, the Middle East, and Africa). Asia-Pacific is expected to dominate the market throughout the forecast period.

The key players profiled in hot runner market report include Barnes Group Inc., CACO Pacific Corporation, EWIKON Molding Technologies, Inc., Fast Heat UK Limited, Fisa Corporation, Günther Heisskanaltechnik, Husky Injection Molding Systems Ltd., INCOE Corporation, INglass Group, Milacron, Seiki Corporation, and Yudo Group.

By Type

By type, the market is segmented into valve gate hot runner and open gate hot runner. Among these, the valve gate hot runner segment is expected to dominate the market and is expected to grow at a significant growth rate during the forecast period, owing to varied benefits offered by the valve gate hot runner system such as perfect finishing on the injection point, lower pressure, less shearing of plastic material, and better injection flow.

By Application

By application, the hot runner market is segmented into automotive, electronics, medical, packaging, and others. Among these, the automotive industry segment is projected to dominate and is expected to grow at a significant growth rate during the forecast period.

By Region

The hot runner market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. Among these, Asia-Pacific accounted for a significant share in the global hot runner market in 2018 and is projected to grow at a significant CAGR, due to several small and mid-level players effective in economies such as China and India.

Key Benefits for Hot Runner Market:

- The study provides an in-depth global hot runner market analysis along with the current trends and future estimations to elucidate the imminent investment pockets.

- Information about the key drivers, restraints, and opportunities and their impact analyses on the market is included in the study.

- Porter’s five forces analysis illustrates the potency of the buyers and suppliers operating in the industry.

- The quantitative analysis of the global hot runner market from 2019 to 2026 is provided to determine its potential.

Hot Runner Key Market Segment:

By Type

- Valve gate hot runner

- Open gate hot runner

By Application

- Automotive Industry

- Electronic Industry

- Medical Industry

- Packaging Industry

- Others

By Region

- North America

- U.S.

- Canada

- Mexico

- Europe

- Germany

- Italy

- France

- Spain

- Rest of Europe

- Asia-Pacific

- China

- India

- Japan

- Indonesia

- Rest of Asia-Pacific

- LAMEA

- Latin America

- Middle East

- Africa

Key Market Players Profiled in the Report

- Barnes Group Inc.

- CACO Pacific Corporation

- EWIKON Molding Technologies, Inc.

- Fast Heat UK Limited

- Fisa Corporation

- Günther Heisskanaltechnik

- Husky Injection Molding Systems Ltd.

- INCOE Corporation

- INglass Group

- Milacron Inc.

- Seiki Corporation

- Yudo Group

Hot Runner Market Report Highlights

| Aspects | Details |

| By Type |

|

| By APPLICATION |

|

| By Region |

|

| Key Market Players | BARNES GROUP INC., EWIKON MOLDING TECHNOLOGIES, INC., HUSKY INJECTION MOLDING SYSTEMS LTD., MILACRON, FISA CORPORATION, SEIKI CORPORATION, FAST HEAT UK LIMITED, CACO PACIFIC CORPORATION, INCOE CORPORATION, GÜNTHER HEISSKANALTECHNIK |

Analyst Review

Hot runner systems are required by injection molds to transfer liquefied plastic material from the machine nozzle into the cavity. These systems comprise nozzles, manifolds, flow control, connections, and hot halves, using which the individual system is created. Manufacturers have incorporated energy saving means to reduce power consumption and intensify functioning efficiency without negotiating on the quality and performance of the injection molding machines. Thus, processing costs are lowered and better filling & packing environments are achieved with the use of hot runners in injection molding machines.

A key benefit of using hot runner system is that it can use diverse types of plastic concurrently to produce injection molded plastic parts of optimal quality. Producers can use thermosetting, thermoplastics, and a combination of polymers to achieve the output with definite properties. In addition, the improvement in heat control and melt-flow analysis has increased the adoption of hot runners. The installation of a hot runner eliminates the need of high-speed, high-cavitation molding operations, and regrinding. Moreover, hot runner molds facilitate automatic cycling, which further ensures improved molding system efficiency. Thus, many hot runner manufacturers and mold makers collectively design, produce, and install their systems in the molds they create to meet the ever-increasing demand from the end users

The factors driving the growth of the hot runner market are rapid rise in investment in the industrial sector and high demand for injection-molded plastic products in the automotive and healthcare sectors.

The market share of the global hot runner market in 2018 was $2,854.0 million.

The report sample for hot runner market report can be obtained on demand from the website.

The leading players profiled in the hot runner market report include Barnes Group Inc., CACO Pacific Corporation, EWIKON Molding Technologies, Inc., Fast Heat UK Limited, Fisa Corporation, Günther Heisskanaltechnik, Husky Injection Molding Systems Ltd., INCOE Corporation, INglass Group, Milacron, Seiki Corporation, and Yudo Group.

Business Expansion and Product Launch are some of the key growth strategies adopted by the hot runner market players.

The statistical data of the top market players of hot runner market can be obtained from the company profile section mentioned in the report. This section includes analysis of top ten player’s operating in the hot runner industry.

The key trends in the hot runner market are the rise in the movement toward automated plastic processing and packaging to accelerate productivity and efficiency in addition to technological advancements.

Asia-Pacific will provide more business opportunities for hot runner in the future.

In terms of application, the automotive industry is expected to lead the hot runner market.

The potential customers of the hot runner industry are the automotive and packaging industries.

Loading Table Of Content...