Hydraulic Press Machines Market Outlook - 2025

The global hydraulic press machines market forecast is expected to reach $21,089.2 million by 2025 from $14,293.3 million in 2017, growing at a CAGR of 4.7% from 2018 to 2025. Hydraulic press (also known as Bramah press) is a machine that generates compressive force by utilizing liquid pressure. The working of hydraulic press machine is based on Pascals law, which states that intensity of pressure is transmitted equally in all directions through a mass of fluid at rest.

In hydraulic press machines, the pressure is generated throughout an enclosed cylinder, in which hydraulic pressure is converted into kinetic energy of piston, which in turn produces shear stress between die and punch, which cuts or presses the metal. These machines are used for transforming metallic objects into sheets and making powders for pharmaceutical & medical industries. In addition, these machines are used for various press work applications such as blanking, punching, coining, and trimming. Companies such as Schuler Group, Betenbender Manufacturing, Inc., and other leading players occupy a major share in the global hydraulic press machine industry.

There is an increase in the demand for hydraulic press machines, owing to surge in demand for high force pressing applications in various industries such as automotive and aerospace. Moreover, increase in adoption of technologically advanced automated systems in the manufacturing industry and growth in demand for fabricated metal in automotive industry are expected to drive the hydraulic press machines market growth. Furthermore, reduction in production cost within optimized time and improved rigidity & strength of machine as compared to traditional equipment are majorly expected to boost the demand for hydraulic press machines. Nonetheless, high energy efficiency using VFDs in hydraulic press machines, increase in adoption of hydraulic press machines in plastic & rubber processing industries, and development of accessible interfaces for these machines are expected to provide lucrative growth opportunities to the manufacturers in countries such as China, Germany, and India. However, increase in use of 3D printing equipment as an alternative of hydraulic press machines and uncertainty in Chinese economy are expected to hinder the growth of the hydraulic press machines market.

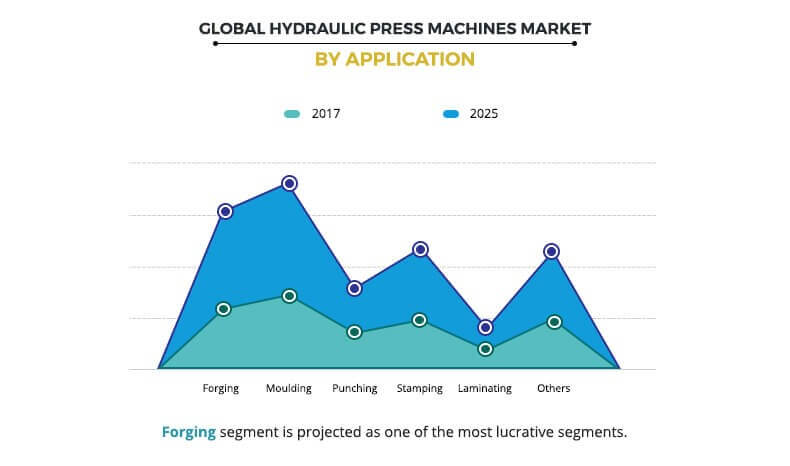

The global hydraulic press machines market analysis comprises of various segments including type, application, industry vertical, and region. Based on type, the market is divided into c-frame hydraulic press, h-frame hydraulic press, bench frame hydraulic press, 4-column hydraulic press, and others (which includes 2-column hydraulic press, gib guided, and roll frame Presses). The application segment is further classified into forging, moulding, punching, stamping, laminating, and others (clinching, deep drawing, blanking, and hot platen). The moulding segment is expected to secure leading position during forecast period.

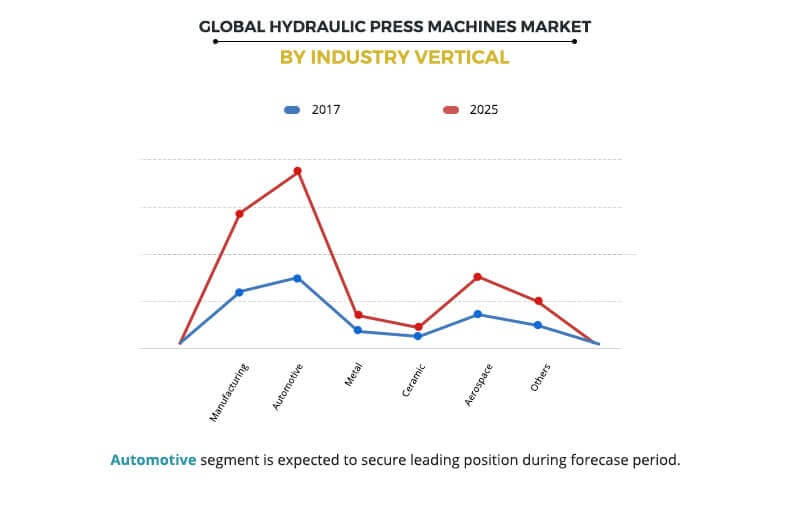

By industry vertical, the market is categorized into aerospace, manufacturing, automotive, metals, ceramic, and others (abrasives, energy & power, defense, and electrical & electronics). In 2017, the automotive segment is expected to secure highest market share.

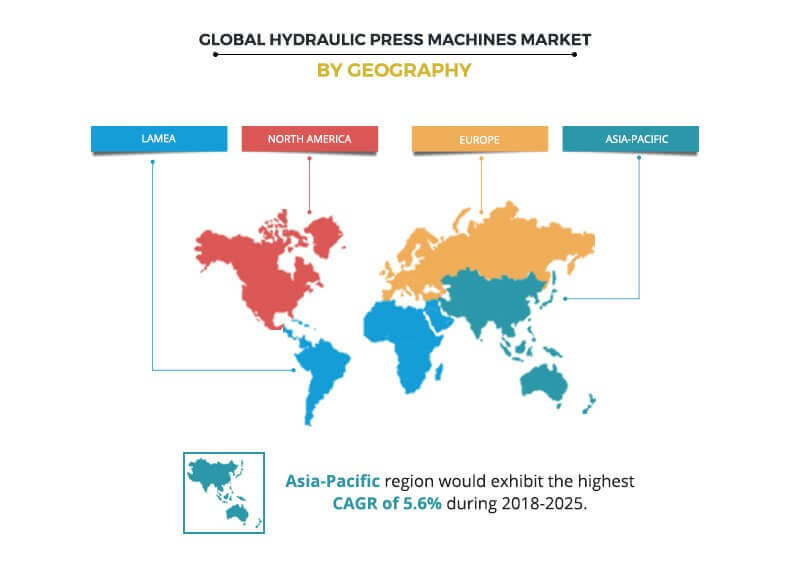

Region wise, the global hydraulic press machines market is analyzed across North America (U.S., Canada, and Mexico), Europe (UK, Germany, Russia, Italy, and others), Asia-Pacific (China, India, Japan, Korea, and others), and LAMEA (Latin America, Middle East, and Africa). Various countries covered under each region are studied and analyzed to identify the major trends demonstrated by these respective regions. Asia-Pacific dominated the hydraulic press machines market in 2017.

Top Impacting Factors

The top impacting factors for global hydraulic press machines market are upsurge in demand for high force pressing applications in various industries, growth in adoption of automated systems in the manufacturing industry, technical & economic advantages such as reduced weight, production cost and improved rigidity & strength as compared to traditional machines, and high energy efficiency using VFDs in hydraulic press machines. However, increase in usage of 3D printing machines as an alternate of these machines is expected to hinder the growth of the hydraulic press machines industry. Some of the major factors impacting on global hydraulic press machines market are given below:

Growing adoption of automated systems in manufacturing industries

The growth in automation in manufacturing sector is attributed to a high rate of industrialization rate in the developing economies. In addition, the adoption of automated systems in industrial manufacturing plants which deals with metal forming drives the hydraulic press machines market size, owing to the increased productivity & efficiency, and higher production rates with smooth operations.

Technical & economic advantages such as reduced weight, production cost and improved rigidity & strength as compared to traditional machines

The hydraulic presses are ideal machines for most of the precision applications such as metal parts forming in automobiles. Moreover, key characteristics of hydraulic press machines such as adjustable speed, pressure accuracy, lower energy consumption, lower noise level, programmable systems, and minimum maintenance are increasing the hydraulic press machines market share across various industry verticals.

Increase in usage of 3D printing machines as an alternate of hydraulic press machines

Development of 3D printing technology is one of the major factors affecting the growth of hydraulic press machines market. The metal 3D printing technology is flexible with the mechanical properties of metal, which offers ability to produce many desired configurations of metal components.

Competition Analysis

Competitive analysis and profiles of the major hydraulic press machines market players, such as Greenerd Press & Machine Co., Beckwood Press, Schuler Group, Betenbender Manufacturing, Inc., DORST Technologies GmbH & Co. KG, Enerpac (Actuant Corporation), Fujian Haiyuan Automatic Equipments, Japan Automatic Machine Co., Ltd., P.J.Hare Limited, and French Oil Mill Machinery are provided in this report. Other prominent players in the market include Worcester Presses, Yoshizuka Seiki, Sutherland, Macrodyne, Osterwalder, Dake, Hefei Metalforming Machine Tools, and others.

Key Benefits for Hydraulic Press Machines Market:

- The report provides an extensive analysis of the current & emerging market trends and dynamics in the global hydraulic press machines market.

- In-depth analysis is conducted by constructing market estimations for the key market segments between 2018 and 2025.

- Extensive analysis of the market is conducted by following key product positioning and monitoring of the top competitors within the market framework.

- A comprehensive analysis of all regions is provided to determine the prevailing opportunities in these geographies.

- Key market players within the hydraulic press machines market are profiled in this report and their strategies are analyzed thoroughly, which help to understand the competitive outlook of the market.

Hydraulic Press Machines Key Market Segments:

By Type

- C-Frame Hydraulic Press

- H-Frame Hydraulic Press

- Bench Frame Hydraulic Press

- 4-Column Hydraulic Press

- Others

By Application

- Forging

- Molding

- Punching

- Stamping

- Laminating

- Others

By Industry Vertical

- Aerospace

- Manufacturing

- Automotive

- Metals

- Ceramic

- Others

By Region

- North America

- U.S.

- Canada

- Mexico

- Europe

- UK

- Germany

- Russia

- Italy

- Rest of Europe

- Asia-Pacific

- China

- India

- Japan

- Korea

- Rest of Asia-Pacific

- LAMEA

- Latin America

- Middle East

- Africa

Key Players

- Greenerd Press & Machine Co.

- Beckwood Press

- Schuler Group

- Betenbender Manufacturing, Inc.

- DORST Technologies GmbH & Co. KG

- Enerpac (Actuant Corporation)

- Fujian Haiyuan Automatic Equipments

- Japan Automatic Machine Co., Ltd.

- P.J.Hare Limited

- French Oil Mill Machinery

Hydraulic Press Machines Market Report Highlights

| Aspects | Details |

| By Type |

|

| By Application |

|

| By Industry verticals |

|

| By Region |

|

Analyst Review

The hydraulic press machines market is projected to depict a prominent growth during the forecast period, owing to various factors, such as increase in demand for high force pressing applications in various industries, growth in adoption of technologically advanced automated systems in manufacturing industry, and rise in demand for fabricated metal in automotive industry.

Hydraulic press machines are widely used in various press work applications such as blanking, punching, coining, trimming, and others. High energy efficiency using VFDs in hydraulic press machines, increase in adoption of hydraulic press machines in plastic & rubber processing industries, and development of accessible interfaces for these machines are expected to provide lucrative growth opportunities to the manufacturers in countries such as China, Germany, and India. Moreover, wide presence of automotive and manufacturing companies in China and Japan drive the demand for hydraulic press machines in Asia-Pacific.

Various leading manufacturers such as Greenerd Press & Machine Co., Beckwood Press, Schuler Group, Betenbender Manufacturing, Inc., DORST Technologies GmbH & Co. KG, Enerpac (Actuant Corporation), Fujian Haiyuan Automatic Equipments, Japan Automatic Machine Co., Ltd., P.J.Hare Limited, and French Oil Mill Machinery Companies occupy a prominent revenue share in the hydraulic press machines market.

Loading Table Of Content...