Industrial 3D printing Market Research 2031

The global industrial 3d printing market was valued at $15 billion in 2021, and is projected to reach $107.7 billion by 2031, growing at a CAGR of 21.9% from 2022 to 2031. Industrial 3D printing, also known as additive printing is used for the development of 3D objects using a digital file. Industrial 3D printing uses additive processes of successive layering of material for creation of objects.

3D printing has gained acceptance in various industries for development of customized products owing to high accuracy and efficient use of materials. There is rise in adoption of 3D printing in the industrial sector owing to less material wastage and reduced production time and costs. Earlier, 3D printing was limited to rapid production of prototypes. However, 3D printing is increasingly being used for functional testing of prototypes under working conditions and development of final products, with technological advancements and increase in applications. Major application of industrial 3D printing technology is in industries like consumer goods, defense, aerospace, and automotive.

The industrial 3d printing market is segmented into Component, Technology and End-User.

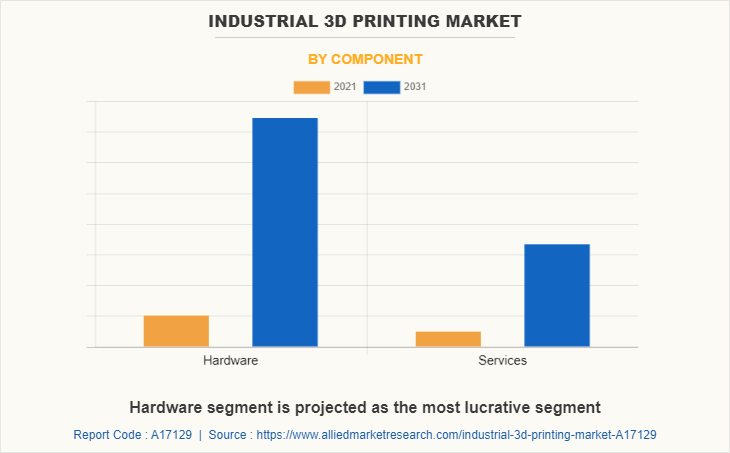

By component, the market is divided into hardware and services. The hardware segment was the highest revenue contributor to the market.

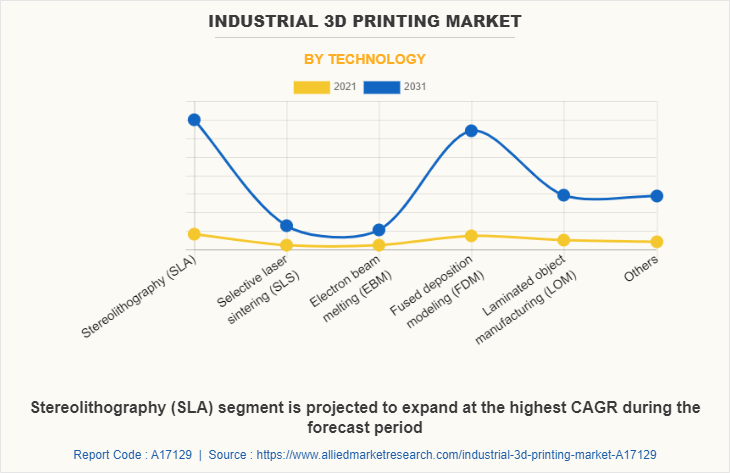

The technology segment stereolithography (SLA), selective laser sintering (SLS), electron beam melting (EBM), fused deposition modeling (FDM), laminated object manufacturing (LOM) and others.The stereolithography (SLA) segment was the highest revenue contributor to the market.

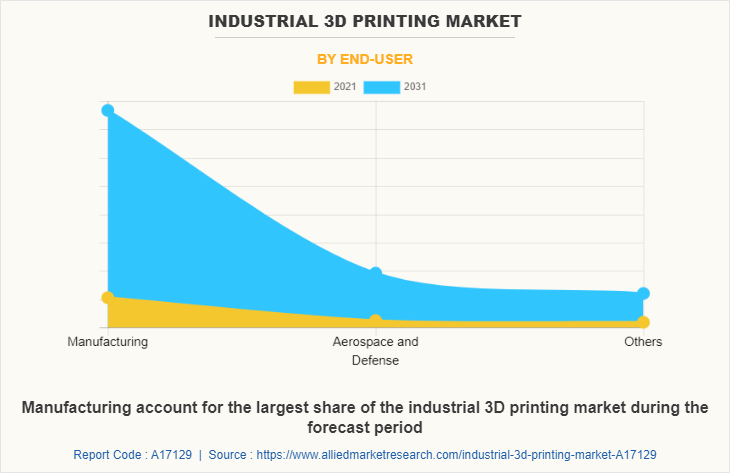

By end user, the market is segmented into manufacturing, aerospace and defense, others. The manufacturing segment was the highest revenue contributor to the market.

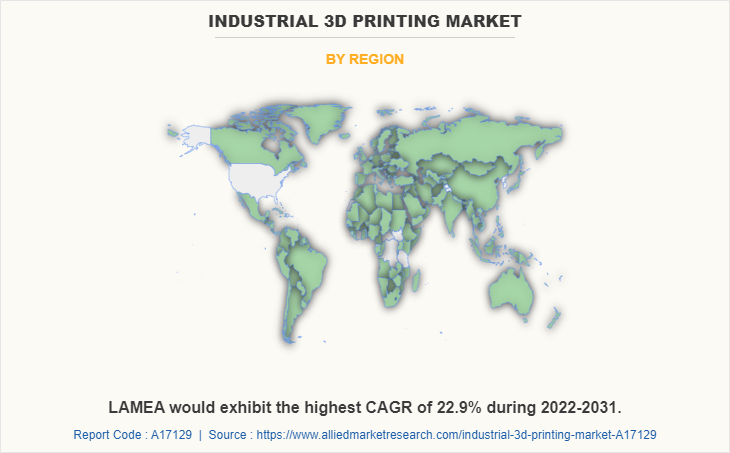

Region wise, the industrial 3D printing market trends are analyzed across North America (the U.S., Canada, and Mexico), Europe (the U.K., Germany, France, Italy, Spain, Russia, Poland and rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, Philippines, Indonesia and rest of Asia-Pacific) and LAMEA (Latin America, the Middle East, and Africa). North America, specifically the U.S., remains a significant participant in the global industrial 3D printing industry. Major organizations and government institutions in the country are intensely putting resources into the technology.

Industries including automotive and aerospace are increasingly using 3D printing for manufacturing of affordable, complex and lighter components. The major driving factors of the industrial 3D printing market growth include efficient use of materials, minimized human errors, customization of products, and reduced production time and costs. Application in diverse industry verticals, and additional choice of materials is projected toprovide numerous growth opportunities for the industrial 3D printing market. The initiatives taken by the major players in the technological development of industrial 3D printing and for research and development accelerates the adoption of technology across the globe.

Significant factors that impact the growth of the industrial 3D printing industry include growing demand for customization of products to gain competitive edge. Moreover, rapid increase in adoption of multiple materials for printing is expected to drive growth of the industrial 3D printing market share. However, high cost related to 3D printing, along with requirement for skilled professionals is acting as a prime barrier for early adoption, which hampers the growth of the market. On the contrary, increasing applications in various industries and improved manufacturing processes is offering potential growth opportunity for the industrial 3D printing market size during the forecast period.

The key players profiled in this report include 3D Systems, Arcam Ab (General Electric), Autodesk Inc, Canon Inc., Envisiontec, Inc., Eos GmbH. ExOne Company, General Electric Company,GE Additive. HOGANAS AB, HP Inc., Materialise. OPTOMEC INC, Organovo Holdings, Inc., Protolabs, SLM Solutions. Stratasys Ltd. and Voxeljet AG. These key players have adopted strategies, such as product portfolio expansion, mergers & acquisitions, agreements, regional expansion, and collaborations to enhance their market penetration.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the industrial 3d printing market analysis from 2021 to 2031 to identify the prevailing industrial 3D printing market opportunity.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the industrial 3d printing market outlook assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global industrial 3d printing market trends, key players, market segments, application areas, industrial 3D printing market forecast and market growth strategies.

Industrial 3D printing Market Report Highlights

| Aspects | Details |

| By Component |

|

| By Technology |

|

| By End-User |

|

| By Region |

|

| Key Market Players | Envisiontec, Inc., voxeljet ag, General Electric Company, GE Additive (US), Organovo Holdings Inc, Stratasys, Ltd., Eos GmbH (Germany), arcam ab, HOGANAS AB, protolabs, CANON INC., ExOne Company, HP Inc. (US), Materialise (Belgium), Optomec Inc., 3D Systems, SLM Solutions (Germany), Autodesk, Inc. |

Analyst Review

According to insights of the CXOs of leading companies, there is substantial increase in usage of additive manufacturing solutions across various applications such as consumer products, industrial products, defense, aerospace, automotive and others. The industrial 3D printing market is expected to grow rapidly, owing to the increased adoption of 3D printing in automotive, defense, and consumer products sectors.

The industrial 3D printing market provides numerous growth opportunities to the market players. This market is in its nascent stage but is expected to witness rapid growth in the future owing to its growing application in diverse industries. In addition, reduction in human error, efficient use of raw materials, technological advancements, and use of multiple materials for printing would lead to the rapid growth of industrial 3D printing market during the forecast period.

Apart from 3D printing companies operating in the market, service providers are the key participants and largely contribute to the growth of overall 3D printing market. Service providers use different technologies and materials to provide customized 3D printed products. The key players profiled in the report include industrial 3D printing market players, such as 3D Systems, Arcam Ab (General Electric), Autodesk Inc, Canon Inc., Envisiontec, Inc., Eos GmbH. ExOne Company, General Electric Company,GE Additive. HOGANAS AB, HP Inc., Materialise. OPTOMEC INC, Organovo Holdings, Inc., Protolabs, SLM Solutions. Stratasys Ltd. and Voxeljet AG.

The leading application of Industrial 3D printing Market is considered to be manufacturing.

North America is expected to be the largest regional market for Industrial 3D printing.

The global industrial 3D printing market size was valued at $15.01 billion in 2021.

The major players in the Industrial 3D printing market are 3D Systems, Arcam Ab (General Electric), Autodesk Inc, Canon Inc., Envisiontec, Inc., Eos GmbH. and others.

The Industrial 3D printing Market is expected to grow at 21.9 % CAGR from 2022 - 2031.

Loading Table Of Content...