Isostatic Pressing Market Outlook - 2027

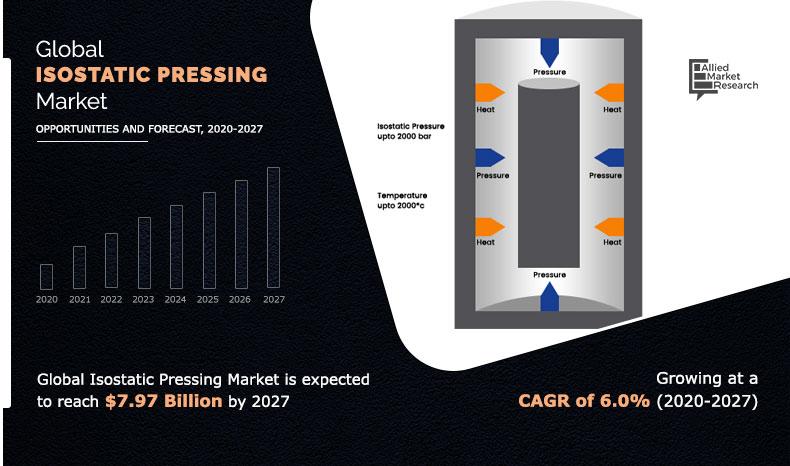

The global isostatic pressing market size was valued at $5.81 billion in 2019 and is projected to reach $7.97 billion by 2027, registering a CAGR of 6.0% from 2020 to 2027.

Isostatic pressing is a system designed to use fluid (such as water or oil) or a gas (generally argon (Ar)) pressure to modify materials by uniformly pressuring them in all directions to achieve maximum uniformity of density. The isostatic pressing process can be done at high temperatures as well as room temperature (cold).

Cold isostatic pressing is used to produce very large and complex spare parts where the initial cost is unjustified. Hot isostatic pressing is similar to cold isostatic pressing but is conducted at high temperatures. In addition, uniform density distribution acts as a key driver for the growth of isostatic pressing systems globally. Moreover, the isostatic pressing technique enables the removal of human error, which reduces any pressing flaws.

Isostatic pressing is popular for use in automotive, healthcare, and aerospace & defense industries, owing to the demand for low-penetrability material in 3D printed parts. Moreover, isostatic pressing can increase the density of metals and lower tooling costs. Furthermore, isostatic pressing offers a large range of ceramic products such as balls, tubes, fuse tubes, lighting tubes, and spark plug insulators. A rise in demand for products with a short development cycle is expected to propel the isostatic pressing market growth in the coming years.

The isostatic pressing industry is expected to witness growth during the forecast period, owing to a rapid rise in demand for products with short production cycles in the healthcare sector. Moreover, the rise in demand for additive manufacturing or 3D printing technology in the automotive sector, owing to the surge in demand for low-cost spare parts manufacturing techniques drives growth of the global isostatic pressing market growth. However, hot isostatic pressing comprises five major components such as pressure vessels and electrical systems, which require high initial investments. This, in turn, hampers demand for isostatic pressing in developing countries.

Risks regarding competition with global players in the isostatic pressing market act as a major challenge for small isostatic pressing manufacturers in developing countries. An increase in the use of additive manufacturing technology in the defense sector is expected to provide significant opportunities for isostatic pressing technology.

Segmentation Overview

The isostatic pressing market share is analyzed by offering, type, HIP capacity, CIP process type, application, and region. Based on offering, it is fragmented into services and systems. The systems segment dominated the market, in terms of revenue in 2019, and is expected to follow the same trend during the forecast period. Based on type, it is segregated into hot isostatic pressing (HIP) and cold isostatic pressing (CIP). The hot isostatic pressing (HIP) segment dominated the market, in terms of revenue in 2019, however, the cold isostatic pressing (CIP) segment is projected to witness a significant market share during the forecast period.

By Offering

Services segment is projected as one of the most lucrative segments.

By HIP capacity, it is divided into small-sized HIP, medium-sized HIP, and large-sized HIP. The global isostatic pressing market share of the large-sized HIP segment accounted highest in 2019 and is expected to follow the same trend during the forecast period. By CIP process type, it is bifurcated into dry-bag pressing and wet-bag pressing. The dry-pressing bag segment accounted for a major share in the global isostatic pressing market in 2019, however, the wet-bag pressing segment is expected to witness the highest CAGR during the forecast period.

By Application

Automotive segment is expected to secure leading position during forecast period.

By application, the market is segregated into automotive, aerospace & defense, medical, precision machine manufacturing, energy & power, and others. The aerospace & defense segment accounted for the major share in the global isostatic pressing market in 2019, however, the automotive segment is expected to witness highest CAGR during the forecast period. By region, the isostatic press market trends are analyzed across North America, Europe, Asia-Pacific, and LAMEA. North America dominated the market, in terms of revenue in 2019, and is expected to follow the same trend during the forecast period.

By Region

Asia-Pacific would exhibit the highest CAGR of 7.7% during 2020-2027

Top Impacting Factors

Significant factors that impact the growth of the global isostatic pressing industry include a surge in demand for hip coupled with other heat treatment processes, a rise in demand for products with short development cycles, and a rise in demand for additive manufacturing techniques. However, high initial investments in hot isostatic pressing and isostatic pressing machinery require a professional workforce to operate, which hampers the growth of the market. On the contrary, the surge in demand for low-cost titanium alloys in the automotive sector, and growth in the need for low-cost medical applications in the healthcare industry are anticipated to provide lucrative opportunities for the isostatic pressing market during the forecast period.

Competition Analysis

Competitive analysis and profiles of the major global isostatic pressing market players such as American Isostatic Presses (API), DORST Technologies GmbH & Co.KG, Bodycote PLC, Engineered Pressure Systems (EPSI), Fluitron, Inc., Kobe Steel, Ltd., Nikkiso Co. Ltd., Pressure Technology, Inc., Shanxi Golden Kaiyuan Co. Ltd. are provided in this report.

Covid 19 Impact Analysis

The COVID-10 outbreak has declined growth rate in production and manufacturing sectors in 2020, and the market is estimated to witness relatively slow growth till the end of 2021. Moreover, COVID-19 has caused a significant and protracted drop in traveling bans and facilities, keeping the workforce out of their factories; thus, influencing the isostatic pressing market share. Furthermore, markets such as automotive, healthcare, and aerospace were primarily hit by several obstacles created amid the COVID-19 pandemic. However, industries such as healthcare and energy & power have witnessed considerable growth during the COVID-19 outbreak, which is expected to propel demand for the isostatic pressing market in the coming year.

Key Benefits for Stakeholders

- This study comprises an analytical depiction of the global isostatic pressing market size along with the current trends and future estimations to depict the imminent investment pockets.

- The overall global isostatic pressing market analysis is determined to understand the profitable trends to gain a stronger foothold.

- The report presents information related to key drivers, restraints, and opportunities with a detailed impact analysis.

- The current global isostatic pressing market forecast is quantitatively analyzed from 2019 to 2027 to benchmark financial competency.

- Porter’s five forces analysis illustrates the potency of the buyers and suppliers in the global isostatic pressing market.

- The report includes the global isostatic pressing market share of key vendors and market trends.

Isostatic Pressing Market Report Highlights

| Aspects | Details |

| By Offering |

|

| By Type |

|

| By Hip Capacity |

|

| By Cip Process Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | PRESSURE TECHNOLOGY, INC., DORST TECHNOLOGIES GmbH & CO. KG, ENGINEERED PRESSURE SYSTEMS (EPSI), KOBE STEEL, LTD., NIKKISO CO., LTD., ARCONIC, SHANXI GOLDEN KAIYUAN CO., LTD., FLUITRON, INC., AMERICAN ISOSTATIC PRESSES (AIP), .BODYCOTE PLC |

Analyst Review

Isostatic pressing is a traditional forming process in powder metallurgy. However, with advancements in technology and emergence of additive manufacturing, commonly known as 3D printing, the isostatic pressing market has gained momentum. Moreover, integration of heat treatment processes with isostatic pressing leverages manufacturing process, which saves time and cost to produce any component.

Market players are striving to gain maximum opportunities from growing isostatic pressing market by planning their strategies meticulously. Strategic partnership, collaboration, and product launches are some of the prominent strategies adopted by key market players of the isostatic pressing market. For instance, Quintus Technologies, a leading manufacturer in high pressure technology developed world’s fastest fan-driven hot isostatic press (HIP) for Italy’s PRES-X to meet post-production needs of 3D printed metal components.

The market players are expanding their business to new industry verticals by developing new isostatic presses to reach new customer base. For instance, Spanish high-pressure processing (HPP) equipment supplier, Hiperbaric expanded its business to additive manufacturing segment with introduction of a hot isostatic pressing (HIP) system that is specifically designed for metal 3D printing.

The key players profiled in the report include American Isostatic Presses (API), DORST Technologies GmbH & Co.KG, Bodycote PLC, Engineered Pressure Systems (EPSI), Fluitron, Inc., Kobe Steel, Ltd., Nikkiso Co. Ltd., Pressure Technology, Inc., Shanxi Golden Kaiyuan Co. Ltd.

Loading Table Of Content...