Lathe Machines Market Research: 2031

The Global Lathe Machines Market Size was valued at $12.9 billion in 2021, and is projected to reach $17.8 billion by 2031, growing at a CAGR of 3.1% from 2022 to 2031. Lathe machine is a type of stationary machine tool that is typically used to shape metal and wood workpieces. It helps remove the unwanted materials from the workpiece to produce the required shape or design.

Market Dynamics

Lathe machines can be operated manually as well as with the help of computer numerical control (CNC). These machines are also available in a wide range of configurations such as slant bed, flat bed, multi-axes, and multi-spindles. Although lathe machines are available in a wide range of configurations, they are typically made components including main bed, main spindle, sub spindle, chuck, guideway, headstock, tail stock, tool turret and CNC controller. Furthermore, lathe machines can be used for a wide range of operations such as turning, tapered turning, shoulder turning, drilling, boring, counter boring, facing, thread cutting, parting, chamfering, knurling, countersinking, and reaming. In addition, these machines are effective for producing various products such as nuts, bolts, piston, pump part, ram, train parts, gun barrels, cue sticks, wooden bowls, baseball bat, and crankshafts.

In addition, the adoption of both conventional and CNC lathe machines has increased significantly in the past few years. Conventional lathe machines are extensively used in small scale industries for manufacturing furniture, and basic metal components, whereas CNC lathe machines are used in advanced manufacturing facilities for production precise components for automotive, defense, aerospace and transportation industry. Thus, the availability of lathe machines in various configurations and wide usability of lathe machines positively influence the lathe machines market growth.

Moreover, conventional lathe machines are a cost effective machining solution, whereas CNC lathe machines offer higher precision and production efficiency. Furthermore, as conventional lathe machines are easy to manufacture, they are easily available in emerging regions. In addition, conventional lathe machines have low initial and maintenance costs. Also, the workforce of a manufacturing facility or workshop requires small training to be able to use them. Such factors are anticipated to drive the growth of the market during the forecast period.

Furthermore, the automobile sector is witnessing a considerable rise, despite the negative impact of COVID-19. For instance, the Indian automotive industry has grown by about 10% from about $100 billion in 2021 to about $110 billion in 2022. The noticeable growth is due to the development of roads, increase in standard of living, and surge in middle class population in developing regions, thus further driving the adoption of lathe machines which is used to manufacture a wide range of automotive components.

Moreover, the rise in purchasing power of masses in emerging economies has also fueled the furniture industry, thereby boosting the lathe machines market. Furthermore, the global aerospace industry has grown by about 15% since 2021 till 2022. The aerospace industry relies highly on lathe machines for delivering tight tolerance parts. Lathe machines in the aerospace industry help in the manufacture of a variety of complex components. These components are manufactured using different metals such as titanium, and other alloys others. Some of the key aerospace components manufactured using lathe machines include couplers, seat frames, fuser rollers, flanges, retainer rings, and others. Thus, growth in the aerospace industry drives the market for lathe machines.

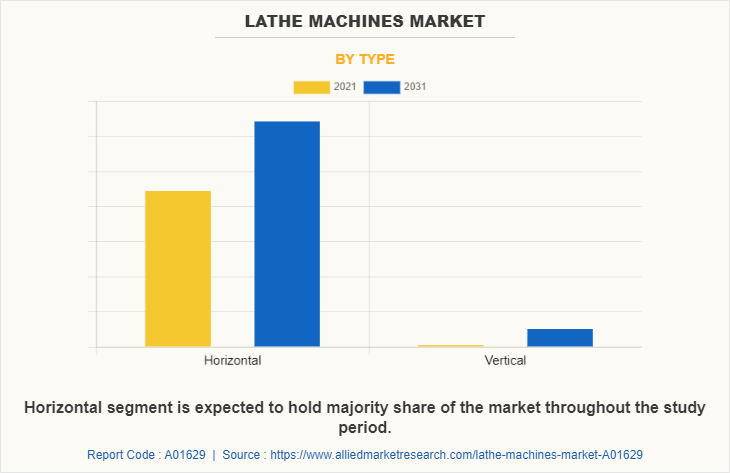

By Type:

The lathe machines market is divided into horizontal and vertical. In 2021, the horizontal segment dominated the lathe machines market, in terms of revenue, and the vertical segment is expected to maintain this trend during the forecast period.

CNC Lathes are automatic machine tools that allow for precise operation of stored programmable commands. In conventional machines, an operator decides and adjusts various machines parameters like feed and depth of cut depending on the type of job and controls the slide movements by hand. In a CNC machine, motors using computer programs control functions and slide movements. The demand for CNC lathe machines is being spurred by the rising adoption of CNC cutting, which reduces the production time and element of human error to a great extent.

Through the adoption of CNC machines, enterprises are gaining significant competitive advantages. Due to the R&D efforts undertaken in the CNC machines market over the last couple of decades, CNC manufacturing offers a wide variety of benefits. Essentially, CNC cutting enables precise cutting of a metal while considering various design requirements. On the other hand, a conventional lathe machine requires a highly skilled technician to operate the machine. Thus, increasing demand for CNC machines boosts the lathe machines industry.

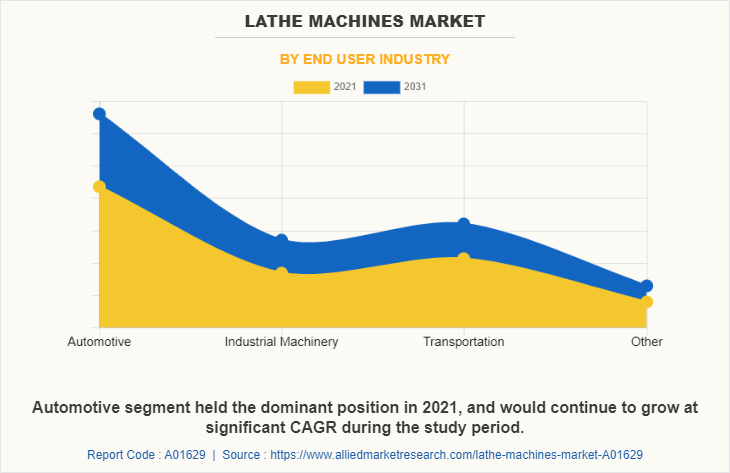

By End User Industry:

The lathe machines market is divided into automotive, industrial machinery, transportation and other. In 2021, the automotive segment dominated the lathe machines market, in terms of revenue, and is expected to maintain this trend during the forecast period.

In addition, the availability of lathe machines in horizontal and vertical configurations, further enhance its usability. Horizontal and vertical lathes are typically made of the same components. A vertical lathe is extensively used if there as space constrictions in the manufacturing facility. A vertical lathe rotates the workpiece in a vertical plane and the machinist works the workpiece in a top to down fashion, conversely a horizontal lathe rotates the workpiece in a horizontal plane and the machinist works the workpiece in a side to side fashion. Thus, wide usability of lathe machines is anticipated to drive the market growth throughout the forecast period.

However, the global economic slowdown limits the growth of the market. Industrial economies in North America, Europe, and Asia are witnessing slow economic growth while the manufacturing growth of a number of emerging industrial economies is also decreasing. Uncertainty caused by Russia Ukraine conflict has affected the growth prospects of many of the European economies. Among other emerging industrial economies, China’s growth slowdown and there has been a serious manufacturing downturn in Latin America. This uncertainty in the global manufacturing sector can hamper the growth of the lathe machines market.

The novel coronavirus has rapidly spread across various countries and regions, causing an enormous impact on the lives of people and the overall community. It began as a human health condition and later became a significant threat to global trade, economy, and finance. The COVID-19 pandemic had halted the production of many components of lathe machines due to lockdown. The economic slowdown initially resulted in reduced spending on automotives sales and government spending on public transportation projects. However, owing to introduction of various vaccines, the severity of COVID-19 pandemic has significantly reduced. As of end of 2022, the number of COVID-19 cases have diminished significantly. This has led to the full-fledged reopening of lathe manufacturing companies at their full-scale capacities. Furthermore, it has been more than two years since the outbreak of this pandemic, and many companies have already shown notable signs of recovery.

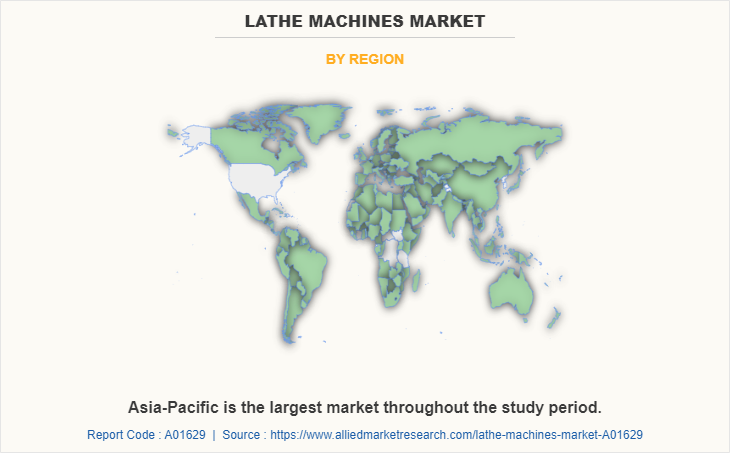

By Region:

The lathe machines market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. In 2021, Asia-Pacific held the highest lathe machines market share, due to extensive demand in from the automotive industry.

The lathe machines market is segmented into Type, Operation and End user industry. By type, the market is categorized into horizontal and vertical. By operation, the market is bifurcated into conventional and CNC. By end-user industry, the market is categorized into automotive, industrial machinery, transportation and other. Region wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. Asia-Pacific dominated the market in 2021, accounting for the largest lathe machines market share. LAMEA is anticipated to grow with the highest CAGR throughout the forecast period. This is attributed to high growth rate of disposable income of the region and a significantly large untapped market.

Competition Analysis

The major players profiled in the lathe machines market forecast report include Dalian Machine Tool Group Corporation, DMG Mori Co., Ltd., Ellison technologies, Haas Automation, Inc., Hardinge Inc., HMT Machine Tools Limited, JTEKT Machinery Americas Corporation, Okuma Corporation, SMEC CO., LTD. and Yamazaki Mazak Pvt. Ltd.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the lathe machines market analysis from 2021 to 2031 to identify the prevailing lathe machines market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the lathe machines market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global lathe machines market trends, key players, market segments, application areas, and market growth strategies.

Lathe Machines Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 17.8 billion |

| Growth Rate | CAGR of 3.1% |

| Forecast period | 2021 - 2031 |

| Report Pages | 185 |

| By Type |

|

| By Operation |

|

| By End user industry |

|

| By Region |

|

| Key Market Players | Haas Automation, Inc., Hardinge Inc., DMG Mori Co., Ltd., HMT Limited, Samsung Electronics Co., Ltd. (SMEC Machine Tools), Yamazaki Mazak Corporation, Ellison Technologies, TEKT Corporation, Okuma Corporation, Dalian Machine Tool Group Corporation |

Analyst Review

The lathe machines market has witnessed significant growth in the past few years, owing to a surge in automotive and infrastructure development activities. The rise in demand for cost effective and precise machining tools in countries such as the U.S., Canada, the UK, Germany, and China has fueled the growth of the lathe machines market.

Apart from these positive factors, the market is negatively impacted by slowdown in global manufacturing industry. However, integration of latest advanced technologies are providing lucrative opportunities for the growth of the market.

Growth of automotive industry and advancements in technology are some of the upcoming trends of Lathe Machines Market in the world

Lathe machines are extensively used in automotive, industrial machinery, and transportation for manufacturing various components.

Asia-Pacific is the largest regional market for Lathe Machines.

$12,937.6 Million is the estimated industry size of Lathe Machines in 2021.

Dalian Machine Tool Group Corporation, DMG Mori Co., Ltd., Ellison technologies, and Haas Automation are some of the top companies to hold the market share in Lathe Machines

The Lathe Machines market is projected to reach $17,798.6 million by 2031.

The company profile has been selected on factors such as geographical presence, market dominance (in terms of revenue and volume sales), various strategies and recent developments.

Latest version of global Lathe Machines market report can be obtained on demand from the website.

Loading Table Of Content...

Loading Research Methodology...