Logistics Robotics Market Summary

The global logistics robotics market was valued at $6.3 billion in 2021 and is projected to reach $27.8 billion by 2031, growing at a CAGR of 16.2% from 2022 to 2031. This is driven by increasing demand for automation, efficiency, and accuracy in warehouse and supply chain operations. Rising e-commerce activities, labor shortages, and advancements in AI and machine learning further accelerate adoption. Robotics enhances productivity, reduces costs, and improves order fulfillment across various logistics sectors.

Market Dynamics & Insights

- The logistics robotics industry in Asia-Pacific held a significant share of over 50.4% in 2021.

- The logistics robotics industry in the U.S. is expected to grow significantly at a CAGR of 17.6% from 2022 to 2031.

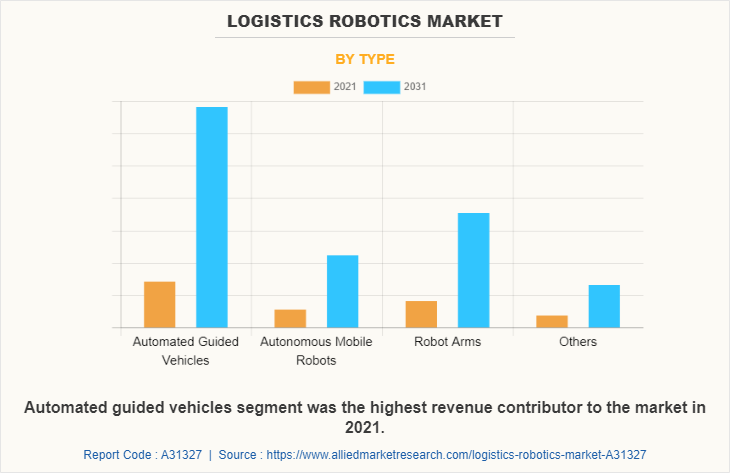

- By type, the Automated Guided Vehicles segment is one of the dominating segments in the market and accounted for the revenue share of over 45.2% in 2021.

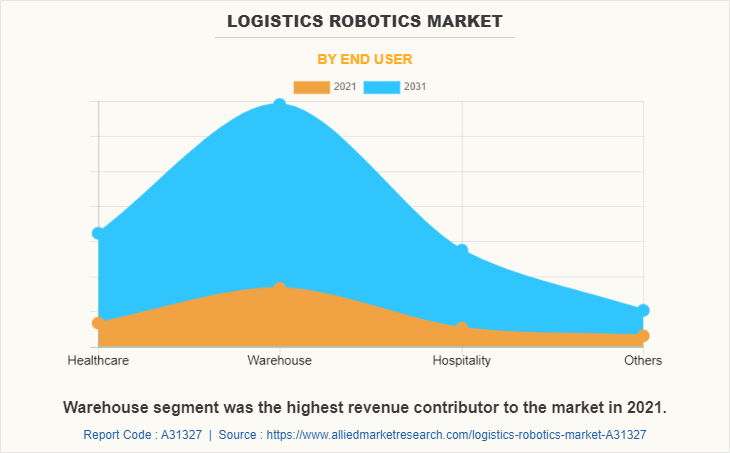

- By end-user, the hospitality segment is the fastest-growing segment in the market.

Market Size & Future Outlook

- 2021 Market Size: $6.3 Billion

- 2031 Projected Market Size: $27.8 Billion

- CAGR (2022-2031): 16.2%

- Asia-Pacific: Largest market in 2021

- North America: Fastest growing market

Robotics technology is a combination of machine tools and computer applications used for various activities that include designing and manufacturing. The use of robotics technology allows consumers to automate processes, increase productivity, enhance quality, and reduce human errors. Logistics robots are automated machines that improve the efficiency of logistics operations. The use of robots in logistics networks serves as an efficient alternative to the customary belt-based transportation system. Logistics robots are intelligent devices equipped with sensors, manipulators, control systems, power supplies, and software to perform tasks with increased efficiency.

Segment Overview:

The logistics robotics market is segmented into Type, Function, and End User.

By type, the market is divided into automated guided vehicles, autonomous mobile robots, robot arms, and others. The automated guided vehicles segment was the highest revenue contributor to the market in 2021.

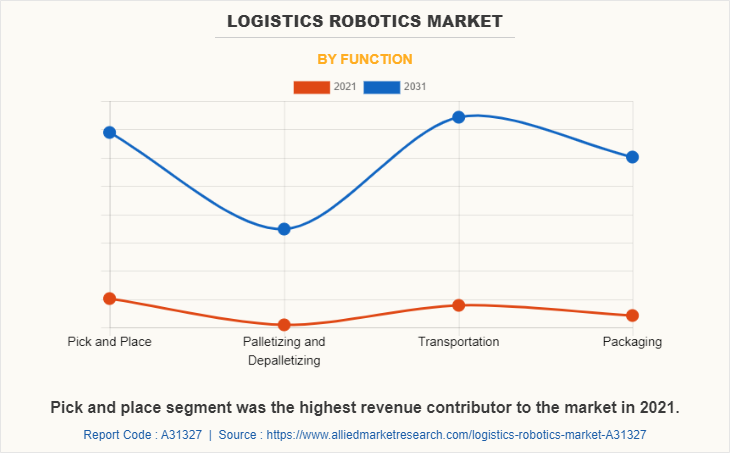

By function, the market is classified into pick & place, palletizing & depalletizing, transportation, and packaging. The pick & place segment was the highest revenue contributor to the market in 2021.

By end user, the market is fragmented into healthcare, warehouse, hospitality, and others. The warehouse segment was the highest revenue contributor to the market in 2021.

Region-wise, the logistics robotics market trends are analyzed across North America (the U.S., Canada, and Mexico), Europe (the UK, Germany, France, Italy, Spain, Russia, Netherlands, Belgium, Poland, and the rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, Malaysia, Thailand, Philippines, Indonesia, and rest of Asia-Pacific), and LAMEA (Latin America, the Middle East, and Africa).

Integration of warehouse and robotics technology has helped ensure that there is accuracy and automation while increasing the warehouse storage space and operational efficiency. For instance, an autonomous mobile robot can adapt to the changes in surroundings and the application of robotics in warehousing, which is expected to increase the efficiency in delivering the merchandise from the shelf to the workstation and can maximize the use of the storage area. Logistics robotics projects are enduring worldwide with an emphasis on end-to-end process automation. Adapting existing tools, implementing commercial mechanisms, and loading & unloading pallets are the factors that pave the way to build viable robots.

The industrial sector has experienced a revolutionary technological transformation from tangibly managed activities to automation technologies, on account of increasing global export activity. The evolution of robotics in warehousing, as per business requirements, has reduced the associated time losses and theft intimidation. Factors such as an increase in the need for safety among workers in the workplace and a rise in demand from online retailers are expected to drive the growth of the logistics robotics market in the future. However, high initial acquisition costs and challenges faced while working in untested environments act as major barriers and hamper the logistics robotics industry. Furthermore, factors such as the emergence of Industry 4.0 in logistics and warehousing and the growth of logistics robots in emerging economies are expected to offer lucrative opportunities for the market globally.

Significant factors that impact the logistics robotics market growth include an increase in the need for safety among workers in the workplace. Moreover, the rapid rise in demand from online retailers is also expected to drive the market opportunity. However, the high initial cost of acquisition is projected to hamper the growth of the market. On the contrary, the emergence of Industry 4.0 in logistics and warehousing is offering potential growth opportunities for the logistics robotics market share during the forecast period.

The key players profiled in the report include ABB, Toyota Industries Corporation, Kawasaki Heavy Industries, Ltd., Fanuc Corporation, Vecna Robotics, KUKA AG, Yaskawa America, Inc., Toshiba Corporation, Dematic and OMRON Corporation are provided in this report.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the logistics robotics market from 2021 to 2031 to identify the prevailing logistics robotics market opportunity.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders to make profit-oriented business decisions and strengthen their supplier-buyer network.

- An in-depth analysis of the logistics robotics market outlook assists in determining the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes an analysis of the regional as well as global logistics robotics market trends, key players, market segments, application areas, logistics robotics market forecast, and market growth strategies.

Logistics Robotics Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 27.8 billion |

| Growth Rate | CAGR of 16.2% |

| Forecast period | 2021 - 2031 |

| Report Pages | 294 |

| By Type |

|

| By Function |

|

| By End User |

|

| By Region |

|

| Key Market Players | Toshiba Corporation, KUKA AG, Kawasaki Heavy Industries, Ltd., Omron Corporation, Toyota Industries Corporation, Yaskawa America, Inc., Vecna Robotics, ABB, Dematic, FANUC CORPORATION |

Analyst Review

The global logistics robotics market has high potential for the warehouse sector. The market growth is also attributed to increase in R&D investments by the large players to deploy enhanced specifications in the product portfolio. Moreover, companies are projected to indulge in mergers, collaborations, and partnerships to make the most use of technology, which is further projected to propel the market growth.

The logistics robotics market has gained traction, owing to the rise in need for safety among workers in the workplace, increase in demand for online retailers, emergence of industry 4.0 into logistics and warehousing among others, which positively influences its growth. Among the analyzed geographical regions, Asia-Pacific exhibits the highest adoption of logistics robotics and has been experiencing massive expansion of the market.

On the other hand, Asia-Pacific is expected to grow at a faster pace, predicting lucrative growth due to emerging countries such as China, Japan, and India, investing in these technologies. Regions such as the Middle East and Africa, are expected to make way for new opportunities in the logistics robotics market in the future. The key players profiled in the report include logistics robotics market players, such ABB, Toyota Industries Corporation, Kawasaki Heavy Industries, Ltd., Fanuc Corporation, Vecna Robotics, KUKA AG, Yaskawa America, Inc., Toshiba Corporation, Dematic, and OMRON Corporation.

The major applications of Logistics Robotics Market are considered to be Logistics Robotics Market.

Asia-Pacific is expected to be the largest regional market for Logistics Robotics.

The global logistics robotics market was valued at $6,270.2 million in 2021.

The key players to hold the major share of Logistics Robotics Market are ABB, Toyota Industries Corporation, Kawasaki Heavy Industries, Ltd., Fanuc Corporation, Vecna Robotics and others.

The Logistics Robotics Market is anticipated to grow at a CAGR of 16.17% during the forecast period.

Loading Table Of Content...