Machine Condition Monitoring System Market Research, 2032

The Global Machine Condition Monitoring System Market size was valued at $2.6 billion in 2022 and is projected to reach $5.4 billion by 2032, growing at a CAGR of 7.9% from 2023 to 2032. Machine condition monitoring is the technique of continuously monitoring a machine's functioning to predict mechanical wear and failure. The rapid adoption of automated condition monitoring technologies in smart factories, as well as an increase in manufacturer awareness regarding the benefits of installing condition monitoring systems on a global scale, are two significant factors driving the growth of the machine condition monitoring market.

Continuous technological innovations drive growth in industries that rely on machines and equipment. New technologies often result in more efficient, productive, and cost-effective machines, which can lead to an increase in demand for these products and services. There has been a rapid increase of machine condition monitoring systems in the manufacturing sectors due to the vast scale development of this product that requires multiple facilities for operations. Machine condition monitoring in the healthcare sector is experiencing significant growth as more healthcare providers recognize the importance of equipment reliability. This growth is driven by the demand for advanced monitoring and maintenance solutions. All these factors are projected to drive the machine condition monitoring system market growth during the forecast period.

Machine condition monitoring systems help in the prediction of mechanical wear and failure by monitoring machine conditions such as temperature, humidity, pressure, and others. Furthermore, noise, temperature, and data on vibration are important indications of equipment condition. Failure of equipment causes significant losses, which drives the use of machine condition monitoring systems in many industry verticals such as oil & gas, metal & mining, food & beverages, and automotive.

The machine condition monitoring market is increasingly being combined with other machine maintenance systems. System optimization, software upgrades, system networking, data transfers, and other technical tasks require technical expertise. Therefore, people in this industry must be trained to run new systems. This might result in a skill gap between current workers and those who have been trained. Due to a lack of educated people, industrial plant operators may be unable to implement new technologies. Machine condition monitoring systems generate determines and projections that even the most experienced operators are unsure regarding service outages, and analytics. The machine condition monitoring systems often generate vast amounts of data from various sensors. This data can be complex and require advanced analytics to extract meaningful information. Operators may struggle to understand and interpret this data effectively. All these factors are anticipated to restrict the machine condition monitoring system market share during the forecast period.

The machine condition monitoring system market is highly fragmented, with regional and local enterprises competing for a bigger market share and new entrants succeeding. As established brands are associated with better evaluations based on performance, brand identity is projected to play an important part in establishing a large consumer base. Bentley Nevada, SKF GMBH, and Meggit Sensing Systems, for example, are continually innovating by allocating significant resources to their R&D departments. Strategic purchases, such as mergers, are also used to gain crucial machine condition monitoring system market share. The competitors' strong rivalry is also projected to drive the machine condition monitoring system market toward an ongoing development cycle. In addition, the increase in the use of IIoT has driven firms to connect assets to actuators and smart sensors to accelerate industrial and manufacturing processes. Data collected in real-time from numerous IoT devices allows smooth supervision and management of plant operations. Demand for IIoT will grow across industrial verticals as stakeholders highlight business agility. For instance, in September 2022, ABB, a technological developer in automation and electrification, partnered with Samotics, a developer of asset health monitoring systems, to improve its condition monitoring services. They will use the resources of each organization to offer information on the health and energy efficiency of the equipment. ABB will begin by incorporating Samotics' plug-and-play monitoring IIoT solution into its digital portfolio.

Segment Overview

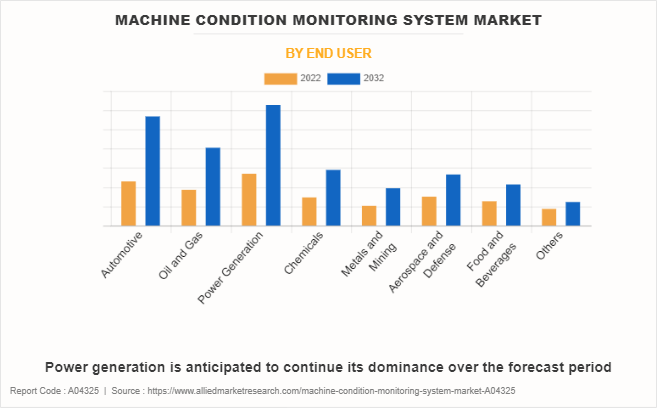

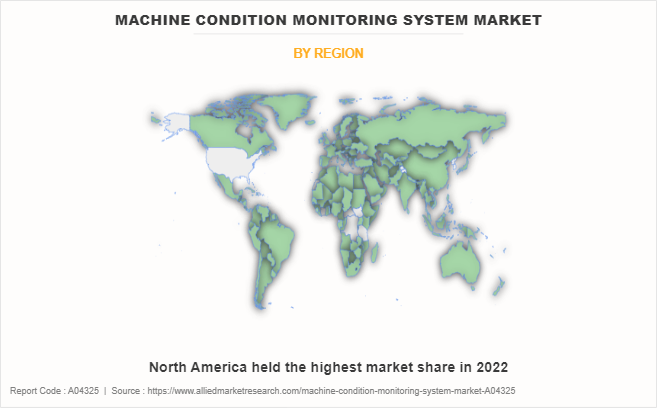

The machine condition monitoring system market outlook is segmented based on component, deployment mode, monitoring technique, end user, and region. By deployment, the machine condition monitoring system market is divided into hardware and software. By deployment mode, the machine condition monitoring system market is classified into on-premises and cloud. By monitoring technique, the market is classified into vibration monitoring, thermography, corrosion monitoring, oil analysis, ultrasound emission, and motor current analysis. By end user, the machine condition monitoring system market is classified into automotive, oil & gas, power generation, chemicals, metals & mining, aerospace & defense, food & beverages, and others. By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

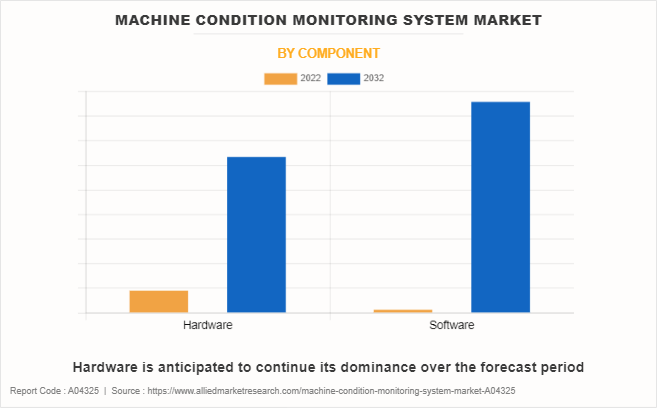

By component, the hardware sub-segment dominated the machine condition monitoring system market in 2022. The increase in usage of infrared sensors, ultrasonic detectors, vibration analyzers, accelerometers, and others can be attributed to the larger share. Condition monitoring technologies have a specific understanding of places where different types of failure could take place. Manufacturers of hardware or sensors provide their products in two variants, static and dynamic, based on the varied frequencies the hardware or sensors have. Furthermore, this allows manufacturers to reduce machine downtime and successfully implement predictive maintenance. Hardware manufacturers strive hard to design and produce durable sensors and other technologies that enable end customers to remotely monitor the condition of machines. Proximity probes, vibration sensors, tachometers, infrared sensors, spectrometers, ultrasonic detectors, corrosion probes, and other forms of hardware are available from vendors. These are predicted to be the major factors driving the machine condition monitoring market size during the forecast period.

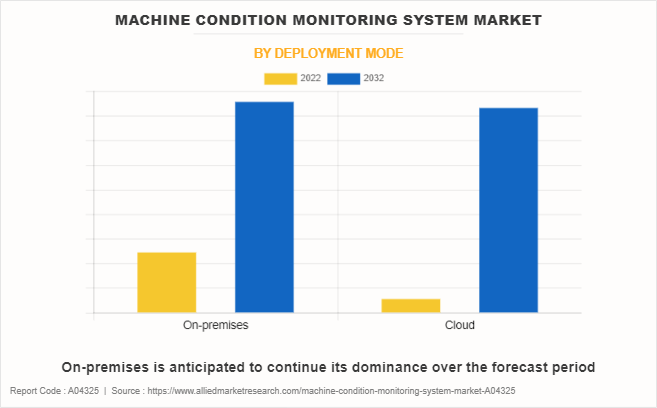

By deployment mode, the on-premises sub-segment dominated the global machine condition monitoring systems market share in 2022. The increase in the use of on-premises across many industrial verticals to ensure that the machines function correctly, monitor the status, and immediately inform teams about long-running or inefficient machines is accelerating the growth of this segment. On-premises is frequently managed or self-hosted and ensures that enterprises satisfy unique market needs, allowing teams to minimize their workload and build a more configurable environment. Engineers must be able to maintain track of and monitor the state of machines for teams to readily identify long-running or inefficient machines. All these factors are projected to drive the on-premises segment growth during the forecast period.

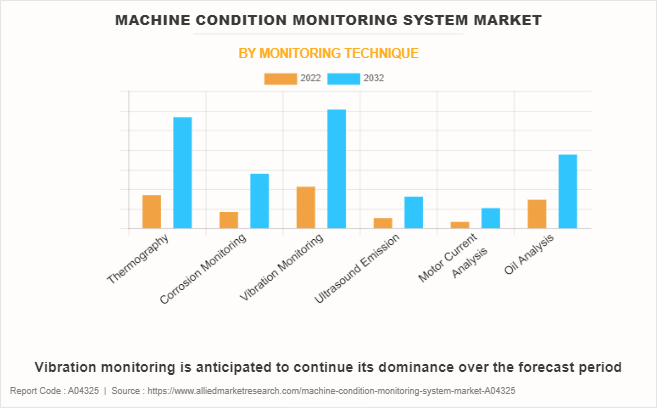

By monitoring technique, the vibration monitoring sub-segment dominated the global machine condition monitoring market share in 2022. The use of vibration monitoring enables the identification and documentation of typical vibration values and operating parameters. It provides real-time information that may be used to evaluate the health of the equipment and identify operational problems. Vibration-based monitoring is critical for predictive maintenance procedures since it detects faults at an early stage. The use of vibration monitoring allows for the identification and documentation of typical vibration values and operating parameters. It provides real-time information that may be used to analyze the condition of the equipment and identify operational problems. Vibration monitoring is the most extensively utilized machine condition monitoring technology in a wide range of industries. Vibration monitoring comprises using vibration sensors to measure and analyze vibration patterns in equipment, allowing technicians to identify potential problems before they become costly. Vibration monitoring is especially important for identifying defects in rotating machinery such as motors, pumps, and gearboxes.

By end user, the power generation sub-segment dominated the global machine condition monitoring systems market share in 2022. Power production facilities, including power plants, wind farms, and solar farms, rely largely on vast and sophisticated machinery and equipment that must be regularly monitored to maintain reliable operation and minimize unscheduled downtime. Machine condition monitoring systems are critical for spotting possible issues and allowing maintenance crews to solve them before they cause equipment failure and expensive downtime. The segment growth is driven by the increasing use of renewable energy sources, necessitating advanced monitoring solutions and the adoption of predictive maintenance strategies to optimize costs.. Machine condition monitoring systems detect possible problems such as equipment wear and corrosion, allowing maintenance personnel to fix them.

By region, North America dominated the global machine condition monitoring system market in 2022. The demand for machine condition monitoring systems is increasing in North America due to factors such as the emphasis that manufacturing companies are placing on optimum asset and resource utilization, stringent regulations governing workplace and employee safety, and high standards for quality control that organizations in the chemicals, oil & gas, and food & beverage industries must meet. The increase in power generator producers is contributing to the expansion of the machine condition monitoring system market share in the region. The U.S. holds the largest share in the machine condition monitoring market due to a strong emphasis on effective plant asset management and the prominence of many important firms in the region, including Rockwell Automation, Emerson Electric, and General Electric.

Competitive Analysis

The key players profiled in this report include Amphenol, Inc., Meggitt PLC, Parker Hannifin Corporation, National Instruments Corporation, Honeywell International Inc., Rockwell Automation, Inc., Analog Devices, Inc., Emerson Electric Co., SKF AB, and General Electric. Investment and agreement are common strategies followed by major machine condition monitoring system market players. For instance, in November 2022, Advantech and Actility announced the launch of a revolutionary integrated AI-based solution to aid machine operation teams in the implementation of machine prognostics and status monitoring. It enables users to monitor the status of several devices simultaneously.

Key Benefits for Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the machine condition monitoring system market from 2022 to 2032 to identify the prevailing machine condition monitoring system market opportunity.

- The machine condition monitoring system market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders to make profit-oriented business decisions and strengthen their supplier-buyer network.

- An in-depth analysis of the machine condition monitoring system market forecast segmentation assists in determining the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes an analysis of the regional as well as global machine condition monitoring system market trends, key players, market segments, application areas, and market growth strategies.

Machine Condition Monitoring System Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 5.4 billion |

| Growth Rate | CAGR of 7.9% |

| Forecast period | 2022 - 2032 |

| Report Pages | 290 |

| By Component |

|

| By Deployment Mode |

|

| By Monitoring Technique |

|

| By End User |

|

| By Region |

|

| Key Market Players | Analog Devices, Inc., Meggitt PLC, Honeywell International Inc., Emerson Electric Co., Rockwell Automation, Inc., General Electric, Amphenol, Inc., Baker Huges, SKF, National Instruments Corporation |

The rise of Industry 4.0 and the Industrial Internet of Things (IIoT) has driven the adoption of MCMS. These systems are integral to the data-driven decision-making and remote monitoring capabilities of modern manufacturing. As new industries and sectors emerge, the need for effective condition monitoring increases. Rising demand for highly secure cloud computing solutions that provide real-time condition monitoring, surging adoption of wireless technology in machine condition monitoring, and rising use of predictive maintenance techniques are factors anticipated to create excellent opportunity for the market growth during the forecast period.

The major growth strategies adopted by machine condition monitoring system market players are product innovation and development.

Asia-Pacific is projected to provide more business opportunities for the global machine condition monitoring system market in the future.

Amphenol, Inc., Parker Hannifin Corporation, Analog Devices, Inc., Rockwell Automation, Inc., SKF AB, Meggitt PLC, General Electric, Honeywell International Inc., National Instruments Corporation, and Emerson Electric Co. are the major players in the machine condition monitoring system market.

The hardware sub-segment of the component acquired the maximum share of the global machine condition monitoring system market in 2022.

Manufacturing and automotive industries are the major customers in the global machine condition monitoring system market.

The report provides an extensive qualitative and quantitative analysis of the current trends and future estimations of the global machine condition monitoring system market from 2022 to 2032 to determine the prevailing opportunities.

The integration of MCMS with the Internet of Things (IoT) and Industry 4.0 concepts will continue to grow. MCMS will become a part of interconnected smart ecosystem, enabling real-time data sharing, advanced analytics, and more precise predictive maintenance strategies, which is anticipated to boost the machine condition monitoring system market in the upcoming years.

Loading Table Of Content...

Loading Research Methodology...