Manganese Alloy Market Research, 2031

The global manganese alloy market was valued at $24.7 billion in 2021, and is projected to reach $44.0 billion by 2031, growing at a CAGR of 6% from 2022 to 2031.

Report Key Highlighters

- The report provides competitive dynamics by evaluating business segments, product portfolios, target market revenue, geographical presence and key strategic developments by prominent manufacturers.

- The manganese alloy market is consolidated in nature among companies such as Ferroglobe, Maithan Alloys Ltd., Nava Limited, Vale, Tata Steel, Hickman Williams and Company, SIMPAC Inc., and Gulf Manganese Corporation Limited.

- The study contains qualitative information such as the market dynamics (drivers, restraints, challenges, and opportunities), key regulation analysis, pricing analysis, and Porter’s Five Force Analysis across North America, Europe, Asia-Pacific, LAMEA regions.

- Latest trends in global manganese alloy market such as product development, undergoing R&D activities, and government initiatives are analyzed across 16 countries in 4 different regions.

- More than 4,500 manganese alloy-related product literatures, industry releases, annual reports, and other such documents of key industry participants along with authentic industry journals and government websites have been reviewed for generating high-value industry insights for global manganese market.

Manganese alloys are materials that consist of manganese, carbon, sulfur, and other trace elements in different ratios. Various types of manganese alloys exist such as silicomanganese, low, medium, and high carbon ferromanganese, and others. They are stronger than pure aluminum and more corrosion resistant, with no loss of workability. They are widely used in cladding and roofing materials.

Factors such as growth in prevalence of automotive industry, rise in demand from building & construction sector, and increase in penetration from electrical & electronics sector have boosted the demand for steel in recent years. Furthermore, sectors such as railways, roadways, energy, urban infrastructure, multimodal logistics parks, and affordable housing have further aided the demand for steel in both developed and developing economies.

Manganese alloy removes oxygen and sulfur when iron ore (an iron and oxygen compound) is converted into iron. It is an essential alloy that helps convert iron into steel. Moreover, as an alloy, it decreases the brittleness of steel and imparts strength. This factor has surged the demand for manganese alloy for steel fabrication purposes; thus, fueling the market growth.

Moreover, electrochemistry plays a crucial role in a wide range of important technical applications. For instance, there are several fields such as development of batteries, displays, fuel cells, sensors, and coatings, where electrochemistry holds a significant importance. Manganese alloy-based systems are considered as candidate electrocatalysts for the electrochemical oxygen evolution reaction (OER), due to their abundance in biochemical oxygen producing catalyst systems. Furthermore, it is used as an electro catalyst support in alkaline energy conversion systems and storage devices such as fuel cells, super capacitors, and lithium-ion-batteries.

The increase in demand for consumer electronics has surged the popularity of electrochemical applications, where manganese alloy is used for electrochemical oxidation. For instance, according to a report published by National Investment Promotion and Facilitation Agency, India’s export of electronic devices is set to increase from $10 billion in 2021 to $120 billion by 2026. This may enhance the demand for manganese alloy used for electrochemical applications; thus, fueling the market growth.

However, there are certain side effects associated with the use of manganese alloys. The exposure to fumes and dust of manganese alloys may cause several breathing problems such as asthma, chronic obstructive pulmonary disease (COPD), pulmonary fibrosis, pneumonia, and even lung cancer. Furthermore, prolonged exposure to dust and fumes produced during production of manganese alloys can damage the lungs, liver, and kidneys of the workers. This factor may hamper the growth of the manganese alloys market during the forecast period.

On the contrary, the aviation and aircraft sectors are experiencing significant growth in both developed and developing economies such as the U.S., Australia, China, and India. The up-gradation of jets and fighter aircrafts has surged the need for versatile magnesium alloys used for manufacturing gearboxes, covers & components, helicopter transmissions, electronic housings, flight control systems, and aircraft wheels.

Moreover, magnesium alloys is best-suited for manufacturing light multi role fighter jets due to its high thermal resistance, corrosion resistance, and other significant properties. The upcoming space and aviation-related expansion projects such as TechEdsat, Omni Role Combat Aircraft (ORCA), and HAL-DRDO Advanced Medium Combat Aircraft (AMCA) are expected to enhance the demand for manganese alloys in the growing aerospace sector; thus, creating lucrative opportunities for the manganese alloys market in the coming futures.

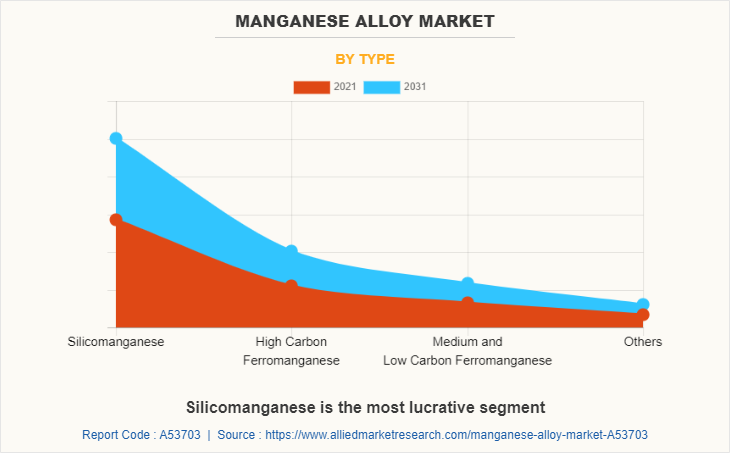

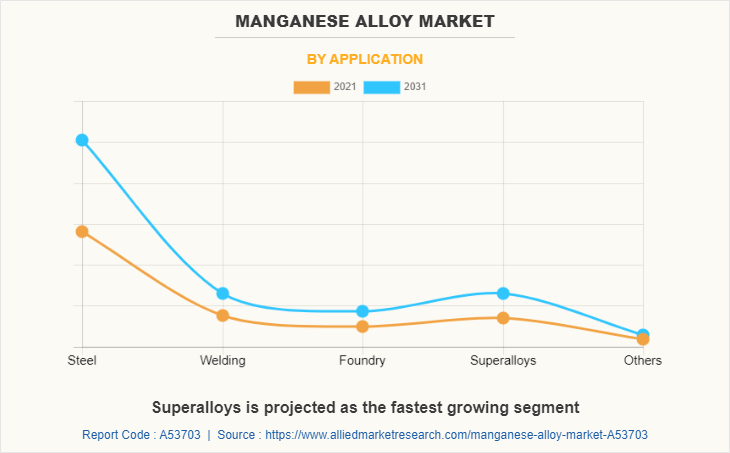

The manganese alloy industry is segmented on the basis of type, application, and region. On the basis of type, the market is categorized into silicomanganese, high carbon ferromanganese, medium & low carbon ferromanganese, and others. On the basis of application, it is divided into steel, welding, foundry, superalloys, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

In 2021, the silicomanganese segment was the largest revenue generator, and is anticipated to grow at a CAGR of 5.8% during the forecast period. Silicomanganese is a cost-effective blend of manganese and silicon and is normally the product of choice for steel manufacturers. It is consumed in all steel products and used in higher quantities in 200 series stainless steel, alloy steel, and manganese steel.

By application, the steel application segment dominated the global market in 2021 and is anticipated to grow at a CAGR of 6.1% during forecast period. Factors such as increase in government expenditure on infrastructure & construction sectors, expansion of railways, bridges, and others have surged the demand for high-quality steel. This factor has led the steel manufacturers in prominent steel manufacturing countries such as China and India to expand their production capacity, wherein manganese alloy is widely used to remove sulfur and oxygen and impart strength to steel. This factor may act as one of the key drivers responsible for the growth of the manganese alloy market for steel application.

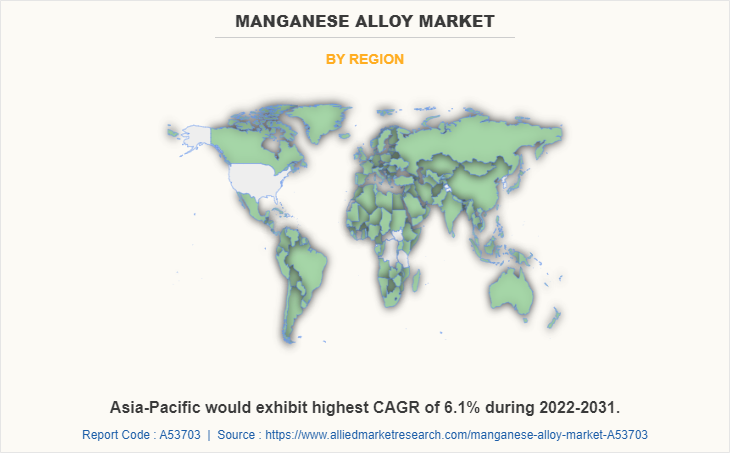

The Asia-Pacific manganese alloy market size is projected to grow at the highest CAGR of 6.1% during the forecast period and accounted for 73.5% of recycled carbon fiber market share in 2021. The rise in building & construction, transportation, industrial, and other sectors have enhanced the performance of the manganese alloy market in Asia-Pacific. China's industrial sector is growing rapidly, which in turn, has enhanced the performance of the manganese alloy market in the region. According to a report published by the United Nations Statistics Division, China witnessed around 28.7% of the global manufacturing output for consumer goods in 2019.

Moreover, countries such as India and Australia have witnessed a rapid increase in automotive & transportation sectors, where manganese alloy is used to produce various lightweight automotive components. For instance, according to a report published by the Indian Ministry of Commerce and Industry, the transportation sector in India is expected to grow at a CAGR of 5.9% owing to the development of highways, widespread railway networks, aviation ports, and waterways structure. This may enhance the performance of the manganese alloy market in Asia-Pacific.

The global manganese alloy market profiles leading players that include Ferroglobe, Maithan Alloys Ltd., Nava Limited, Eramet, Vale, Tata Steel, Hickman Williams and Company, SIMPAC Inc., Gulf Manganese Corporation Limited, and MOIL. The global manganese alloy market report provides in-depth competitive analysis as well as profiles of these major players.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the manganese alloy market analysis from 2021 to 2031 to identify the prevailing manganese alloy market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the manganese alloy market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global manganese alloy market trends, key players, market segments, application areas, and market growth strategies.

Manganese Alloy Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 44 billion |

| Growth Rate | CAGR of 6% |

| Forecast period | 2021 - 2031 |

| Report Pages | 484 |

| By Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | Eramet, MOIL, Maithan Alloys Ltd., Tata Steel, Hickman Williams & Company, SIMPAC Inc., Nava Limited, Gulf Manganese Corporation Limited, Ferroglobe, Vale |

Analyst Review

According to CXOs of leading companies, the global manganese alloy market is expected to exhibit high growth potential during the forecast period. Manganese alloys are used in a variety of end-use sectors such as automotive, electrical & electronics, aerospace & defense, and building & construction for production of various parts and equipment. Automotive sector that requires finished, lightweight, and high-strength metallic components for producing various vehicle parts that made by using manganese alloy.

In addition, manganese alloy is used in foundry for removing oxygen and sulfur when iron ore is converted into iron. Furthermore, it also is an essential alloy that helps convert iron into steel. As an alloy, it decreases the brittleness of steel and imparts strength. These factors altogether have boosted the potential application of manganese alloy in metal fabrication sector. Furthermore, factors such as rise in building & construction activities has fostered the popularity of manganese alloys used for producing high-quality construction grade steels. CXOs further added that sustained economic growth and development of the steel fabrication have increased the popularity of manganese alloys

Increase in demand for electrochemical applications, increase in demand for manganese alloy among automotive and transportation sector, and escalating demand from steel fabrication sector are the upcoming trends of manganese alloy market.

Steel, welding, foundry, superalloys, and others are the leading application of manganese alloy market.

Asia-Pacific is the largest regional market for manganese alloy market.

The global manganese alloy market was valued at $24.7 billion in 2021, and is projected to reach $44.0 billion by 2031, growing at a CAGR of 6% from 2022 to 2031.

Ferroglobe, Maithan Alloys Ltd., Nava Limited, Eramet, Vale, Tata Steel, Hickman Williams and Company, SIMPAC Inc., Gulf Manganese Corporation Limited, and MOIL are the top companies that hold significant share in the manganese alloy market.

Loading Table Of Content...

Loading Research Methodology...