Mesh Nozzle Plates Market Research, 2032

The global mesh nozzle plates market was valued at $31.6 million in 2022 and is projected to reach $57.6 million by 2032, growing at a CAGR of 6.3% from 2023 to 2032.

A mesh nozzle plate is a specialized component used in industrial applications, primarily in processes that involve the spraying or atomization of liquids. It is typically a thin plate or screen made of mesh material, such as stainless steel, brass, or other metals, featuring a pattern of small holes or openings. The purpose of a mesh nozzle plate is to regulate and control the flow of liquid as it passes through the nozzle.

Mesh nozzle plates find wide-ranging applications across various industries, including agriculture, automotive, chemical processing, coating and painting, cooling systems, pharmaceuticals, and more. They are commonly utilized in spray nozzles, atomizers, misting systems, and other devices where precise control over liquid flow and spray distribution is essential.

The mesh pattern and the size of the openings in the nozzle plate influence factors such as droplet size, spray pattern, and flow rate. By selecting an appropriate mesh size, the plate can tailor the characteristics of the sprayed liquid, ensuring optimal performance for specific applications. Overall, mesh nozzle plates play a vital role in achieving controlled and efficient liquid dispersion in industrial processes, enabling precise and uniform application of liquids in various fields.

The increasing demand from various industries for efficient and reliable filtration and separation solutions is a key driver for the growth and demand of the mesh nozzle plates industry. The oil and gas industry utilizes mesh nozzle plates for various purposes, including gas and liquid filtration, separation of impurities, and process optimization. With the increasing need for efficient extraction, refining, and processing of oil and gas, mesh nozzle plates play a crucial role in maintaining operational efficiency and ensuring product quality. Similarly in the water treatment industry, mesh nozzle plates are used in filtration systems, such as sand filters, activated carbon filters, and membrane filters. They help in the removal of suspended solids, particulate matter, and other impurities from water. With the increasing focus on water scarcity and environmental regulations, the demand for effective water treatment solutions utilizing mesh nozzle plates is on the rise.

However, one of the challenges hindering the expansion of the mesh nozzle plates market is the maintenance associated with these plates. To ensure optimal performance, mesh nozzle plates need regular cleaning and maintenance. Over time, debris, scaling, or fouling can accumulate on the plates, leading to a decrease in filtration efficiency. This necessitates frequent cleaning or in severe cases, replacement of the plates, which results in increased operational costs and downtime. The costs involve labor, cleaning agents, and potentially plate replacements. Furthermore, the cleaning and maintenance processes disrupt production schedules and workflow, leading to downtime and potential financial losses. Implementing proactive maintenance practices, such as regular inspections and efficient cleaning techniques, can help mitigate these challenges, reducing the need for frequent cleaning or replacement, minimizing operational costs, and optimizing overall productivity.

On the other hand, advancements in spray coating technologies create an excellent mesh nozzle plate market opportunity. Industries such as automotive, aerospace, electronics, and textiles rely heavily on spray coating for applying various materials such as coatings, paints, and adhesives. Mesh nozzle plates are essential components that enable the achievement of uniform and precise spray patterns, ensuring high-quality finishes. As spray coating technologies continue to progress, there is an increasing demand for high-quality mesh nozzle plates that provide improved control and efficiency. Manufacturers can leverage this opportunity by focusing on developing innovative products that meet the evolving requirements of the spray coating industry. By enhancing features such as durability, precision, and customization options, manufacturers can cater to the specific needs of different applications, establishing a competitive edge in the market and meeting the rising demand for advanced spray coating solutions.

Segment Overview

The mesh nozzle plates market is segmented into Material Type and Application.

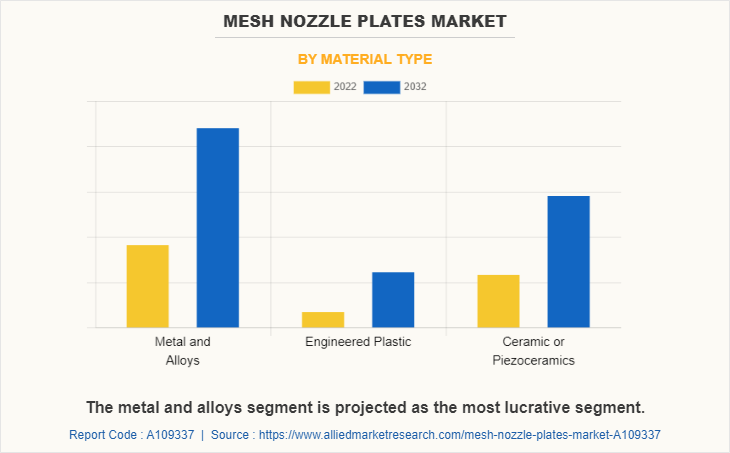

On the basis of material type, the market is divided into metal and alloys, engineered plastic, ceramic or piezoceramics. The metal and alloys segment was the highest revenue contributor to the market.

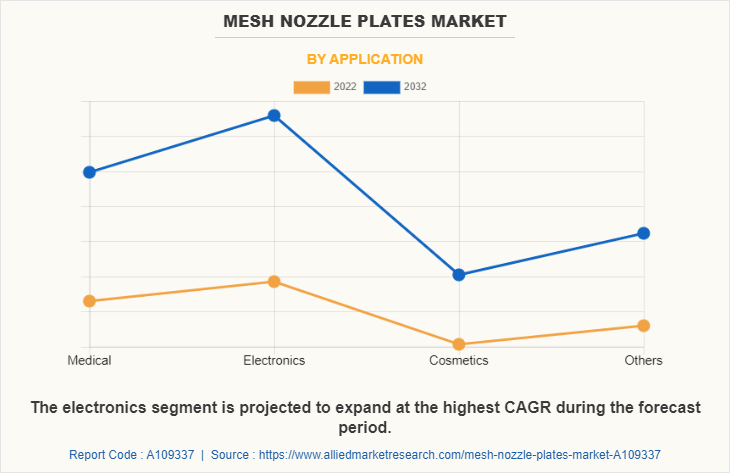

On the basis of application, the market is segregated into medical, electronics, cosmetics, and others. The electronics segment was the highest revenue contributor to the market.

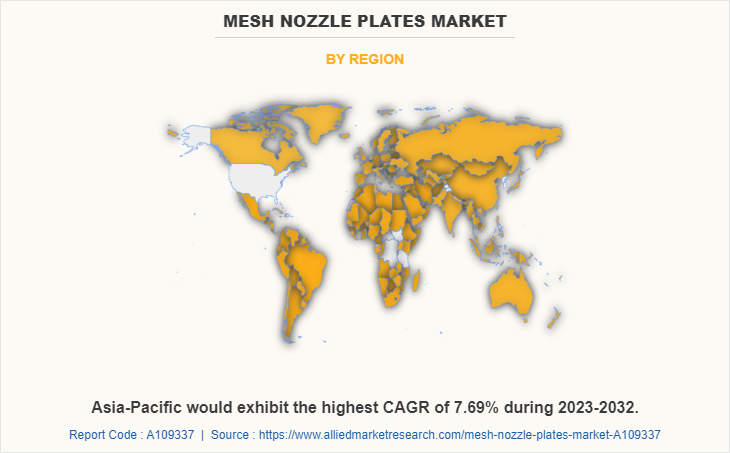

Based on region, the market is analyzed across North America (U.S., Canada, and Mexico), Europe (UK, Germany, France, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and Rest of Asia-Pacific), and LAMEA (Latin America, Middle East, and Africa).

Country-wise, the U.S. acquired a prime market share in the North American region and is expected to grow at a significant CAGR during the forecast period of 2023-2032. Several factors have contributed to this market dominance. Firstly, the U.S. is renowned for its technological advancements, particularly in research and development. This has resulted in the development of cutting-edge technologies in the spray nozzle sector, including mesh nozzle plates. Continuous innovation in materials, designs, and manufacturing processes has allowed U.S. companies to offer high-quality and efficient products, giving them a competitive edge in the market. Secondly, the strong distribution network in the U.S. plays a crucial role in its market share. The country has a well-established distribution network that ensures the widespread availability of mesh nozzle plates across different regions. This network enables manufacturers to reach a wide range of customers and industries, supporting steady market growth. The combination of technological advancements and a robust distribution network has positioned the U.S. as a leader in the North American mesh nozzle plate market.

In Europe, Germany, dominated the mesh nozzle plates market share, in terms of revenue, in 2022 and is expected to follow the same trend during the forecast period. Several factors contribute to Germany's strong market position in the region one is manufacturing excellence, Germany is renowned for its manufacturing excellence and precision engineering. The country has a strong industrial base and expertise in various sectors, including automotive, chemical processing, pharmaceuticals, and food processing. This expertise translates into the production of high-quality mesh nozzle plates that meet the stringent requirements of industries. Furthermore, Germany has strict environmental regulations and a strong commitment to sustainability. Mesh nozzle plates offer advantages in terms of reduced waste, optimized material usage, and controlled spray distribution, aligning with the country's sustainability goals. Manufacturers that provide environmentally friendly solutions gain a competitive edge in the German market.

In the Asia-Pacific region, China is anticipated to become a prominent market for the mesh nozzle plates industry. One noteworthy trend driving this growth is the growing manufacturing sector, China's manufacturing sector has witnessed significant expansion in recent years. The country is known as the "world's factory" due to its large-scale production capabilities across various industries such as automotive, electronics, chemicals, and textiles. The demand for efficient spraying solutions, including mesh nozzle plates, is on the rise to optimize manufacturing processes and improve productivity. Furthermore, China has a significant agricultural sector that relies on efficient spraying solutions for crop protection, fertilization, and irrigation. Mesh nozzle plates provide uniform spray coverage, droplet control, and reduced drift, ensuring the effective application of agrochemicals. The agricultural sector's demand for advanced spraying technologies is fuelling the mesh nozzle plates market growth in China

In the LAMEA region, the Middle East dominated the mesh nozzle plates market share, in terms of revenue, in 2022 and is expected to follow the same trend during the forecast period. This dominance is primarily driven by the region's robust industrial growth, propelled by sectors such as oil and gas, petrochemicals, construction, and manufacturing. These industries rely on efficient spraying solutions for a range of applications, including cooling, cleaning, dust suppression, and chemical processes. The precision spray patterns and control offered by mesh nozzle plates make them indispensable for these industrial operations. Furthermore, the Middle East has witnessed significant infrastructure development, with the construction of major projects like airports, highways, residential complexes, and industrial zones. Mesh nozzle plates play a vital role in applications such as dust control, fire protection, and landscaping, contributing to the region's infrastructure development efforts and driving the demand for these products.

Top Impacting Factors

The expansion of the chemical and petrochemical industry, driven by urbanization, industrialization, and economic growth, is a significant driver of the mesh nozzle plates market. These plates are extensively used in critical processes such as catalytic cracking, refining, and gas separation, providing precise control over fluid flow and optimizing chemical processes. Additionally, the market is propelled by environmental concerns and sustainability initiatives, as industries prioritize eco-friendly filtration solutions that improve air and water quality. However, the high initial investment required for adopting mesh nozzle plates can be a restraint on market expansion, particularly for large-scale applications. Nevertheless, the growing demand for filtration in industries such as water treatment, oil and gas, and food and beverage presents a significant opportunity for the market's growth.

Competitive Analysis

The mesh nozzle plates market is highly competitive, owing to the strong presence of existing vendors. Vendors of the mesh nozzle plates market with extensive technical and financial resources are expected to gain a competitive advantage over their competitors because they can cater to market demands. The competitive environment in this market is expected to increase as agreements, partnerships, collaborations, expansions, product approvals, and investments such as different strategies adopted by key vendors increase. Competitive analysis and profiles of the major mesh nozzle plates market players that have been provided in the report include Temicon GmbH, Veco B.V., MicroBase Technology Corp., Aerogen, Koninklijke Philips N.V., Entero Healthcare, OMRON HEALTHCARE Co., Ltd., Tekceleo, APC International, Ltd., and MedPlus Health Services Limited.

Key Developments/ Strategies

According to the latest mesh nozzle plates market outlook, OMRON Healthcare, Inc., Koninklijke Philips N.V., MedPlus Health Services Limited, Aerogen, and Temicon GmbH are the top 5 key players in the mesh nozzle plates market. Top market players have adopted various strategies, such as agreements, partnerships, collaborations, expansions, product approvals, and investments to expand their foothold in the mesh nozzle plates market.

In May 2023, Omron, a leading Japanese company, announced plans to invest 1.28 billion Indian rupees ($15.5 million) in establishing its first medical device factory in Tamil Nadu, a southern state in India. The decision marks another significant step taken by a foreign manufacturer to establish operations in the region. Omron's decision to invest in India highlights the country's attractiveness as a global manufacturing hub and reinforces its position in the medical technology sector.

In August 2022, Tekceleo, a leading technology company, achieved a significant milestone in the development of a new nozzle design capable of sustaining long-duration aerosolization with highly corrosive liquids. Utilizing their patented Micronice technology, which incorporates a piezo-amplified vibrating mesh, Tekceleo has successfully manufactured a fully compatible nozzle for substances like H2O2, Peracetic Acid, Ammonia, Ethanol, and Acetone.

In December 2021, Aerogen, a leading global medical device and drug delivery company, and Nuance Pharma, a specialty care-focused biopharmaceutical company, announced an exclusive agreement to jointly develop an advanced and non-invasive approach for the treatment of Respiratory Distress Syndrome (RDS). This life-threatening condition primarily affects preterm infants and can lead to long-term lung health issues in survivors.

Key Benefits for Stakeholders

This study comprises an analytical depiction of the mesh nozzle plates market size along with the current trends and future estimations to depict the imminent investment pockets.

The overall mesh nozzle plates market analysis is determined to understand the profitable trends to gain a stronger foothold.

The report presents information related to key drivers, restraints, and opportunities with a detailed impact analysis.

The mesh nozzle plates market forecast is quantitatively analyzed from 2022 to 2032 to benchmark financial competency.

Porter’s five forces analysis illustrates the potency of the buyers and suppliers in the mesh nozzle plates market.

The report includes the share of key vendors and mesh nozzle plates market trends.

Mesh Nozzle Plates Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 57.6 million |

| Growth Rate | CAGR of 6.3% |

| Forecast period | 2022 - 2032 |

| Report Pages | 201 |

| By Material Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | Veco B.V., Aerogen, MicroBase Technology Corp., Temicon GmbH, Koninklijke Philips N.V., MedPlus Health Services Limited, Entero Healthcare, OMRON Healthcare, Inc, APC International, Ltd., Tekceleo |

Analyst Review

The global mesh nozzle plates market is projected to experience significant growth in the coming years due to various factors. Firstly, the increased demand for mesh nebulizers and humidifiers in the medical industry, along with the rising adoption of micromanufacturing methods such as electroforming, will contribute to market expansion. Additionally, the market is projected to grow at a healthy rate due to research and technological advancements. The demand for high precision products and the emergence of additive manufacturing processes will also play a role in driving market growth. The wide range of applications of mesh nozzle plates in industries such as electronics, cosmetics, medicine, and agriculture further propel market expansion. Key players in the industry are focusing on implementing cost-effective manufacturing techniques and driving product innovation to stay competitive in the market.

The Mesh Nozzle Plates Market is expected to grow at a CAGR of 6.28% from 2023-2032.

Electronics is the leading application of Mesh Nozzle Plates Market.

North America is the largest regional market for Mesh Nozzle Plates.

The estimated industry size of Mesh Nozzle Plates Market is $31.62 million in 2022.

OMRON Healthcare, Inc., Koninklijke Philips N.V., MedPlus Health Services Limited, Aerogen, and Temicon GmbH are the top 5 key players in the mesh nozzle plates market.

Loading Table Of Content...

Loading Research Methodology...