Metal Casting Market Research, 2031

The global metal casting market size was valued at $129.5 billion in 2021, and is projected to reach $226.8 billion by 2031, growing at a CAGR of 5.8% from 2022 to 2031. The growing demand in the automotive industry and technological advancements in casting processes are major drivers propelling the metal casting market growth. The automotive sector relies heavily on metal casting for the production of critical components such as engine blocks, transmission housings, and chassis parts, driven by the need for lightweight, durable, and cost-effective solutions.

Report key highlighters

- The metal casting market has been analyzed in both value and volume. The value of market is analyzed in millions while the volume is analyzed in kilotons.

- The metal casting market is consolidated in nature with few players such as Ahresty Corporation, Aisin World Corp. of America, Georg Fischer Ltd, NEMAK, and Rheinmetall Ag that hold significant share of the market.

- Countries such as China, U.S., India, Germany, and Brazil hold a significant share in the global metal casting market.

Introduction

Metal casting is a manufacturing process in which molten metal is poured into a mold to create a desired shape and then allowed to solidify before being removed from the mold. Metal casting technique is widely used for producing complex and precise parts with intricate geometries that are difficult to achieve through other manufacturing methods. Metal casting involves various methods, such as sand casting, investment casting, die casting, and lost-wax casting, depending on the material, design, and production volume. The process is commonly applied across industries such as automotive, aerospace, construction, and machinery for creating components such as engine blocks, turbine blades, and industrial machinery parts.

Market Dynamics:

Metal casting is a process that involves pouring molten metal into a mold to create a 3D metal part. The mold contains a hollow cavity of a desired geometrical shape, and the molten metal is allowed to cool down to form a solidified part. Metals such as cast iron, stainless steel, manganese, aluminum and others are widely used for metal casting process. It is employed in various end-use sectors including automotive, electrical and electronics, building and construction, heavy machinery and equipment, aerospace, and others.

Rise in population coupled with rapid urbanization have surged the growth of the architecture & construction sector in both developed and developing economies such as the U.S., China, India, and others, where metal castings are used for providing structural supports. For instance, according to a report published by National Investment Promotion and Facilitation Agency, the infrastructure activities accounted for 13% share of the total foreign direct investment (FDI) inflows in 2021. This is expected to boost the demand for metal casting in the growing architecture & construction sector.

Furthermore, factors such as surge in disposable income, technological upgrades, and spurring rise in original equipment manufacturers (OEMs) have led the automotive sector to witness a significant growth where metal castings are used to produce under hood parts, engine components, interiors, and other automotive parts. For instance, according to a report published by India Brands Equity Foundation, the domestic automobile production increased by a compound annual growth rate (CAGR) of 2.36% from 2016 to 2020 with 26.36 million vehicles being manufactured in India in 2020.

However, high investment cost associated with the production of metal castings may restrain the manufacturers with less investment potential to enter into market. This factor may hamper the growth of the metal casting market during the forecast period.

On the contrary, metal casting solutions are widely used in electronics sector for producing three-dimensional parts. Furthermore, key electronic manufacturers such as Samsung, LG, Apple, and others are using metal casting owing to its advantages such as quick yield of complexes, preciseness, and production of rigid cast parts with smooth surfaces that don't need intense secondary machining. These factors have surged the popularity of metal castings in the growing electronics sector; thus, creating remunerative opportunities for the market.

Segment Overview:

The metal casting market is segmented into process, end-use industry, and region. On the basis of process, the market is categorized into sand casting, investment casting, die casting, gravity casting, and others. By end-use industry, it is classified into automotive, heavy machinery and equipment, defense, electrical and electronics, building and construction and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

Competitive Analysis:

The major companies profiled in this report include Ahresty Corporation, Aisin World Corp. of America, Dawang Steel Casting Foundry, Dynacast International, Endurance Technologies Limited, Georg Fischer Ltd, GIBBS, Gujarat Precision Cast Pvt. Ltd., MINO Industry USA, Inc, NEMAK, Omnidex Group, Rheinmetall Ag, RFQLINE, INC, RYOBI DIE CASTING, and Sujan Industries.

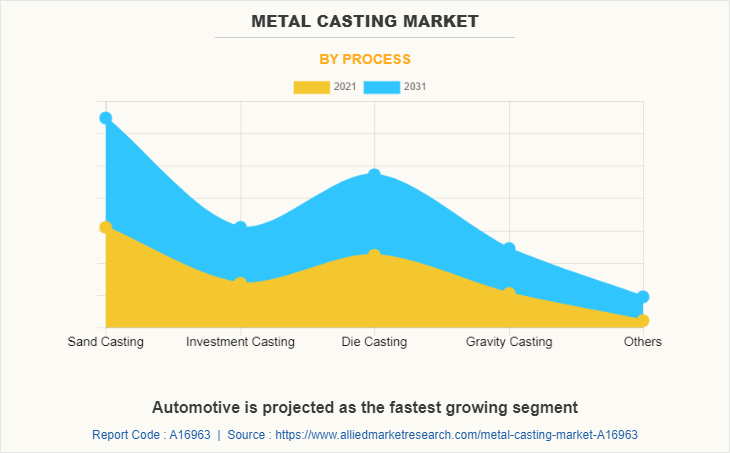

Metal Casting Market By Process

By process, the sand casting dominated the global market and is anticipated to grow at a highest CAGR of 6.2% during the forecast period. This is attributed to the increasing disposable income coupled with rise in original equipment manufacturers (OEMs) which in turn have led the automotive sector to witness a significant growth where sand casting is widely employed for producing engine crankcases, engine oil pans, bushings, and other automotive parts. Furthermore, increase in spending in both developed and developing economies for producing advanced fighter jets with modern armor facilities which in turn have surged the demand for sand castings used for producing aircraft pistons, bearings, and other aircraft parts. These factors have augmented the growth of the sand-casting process in the global metal casting market.

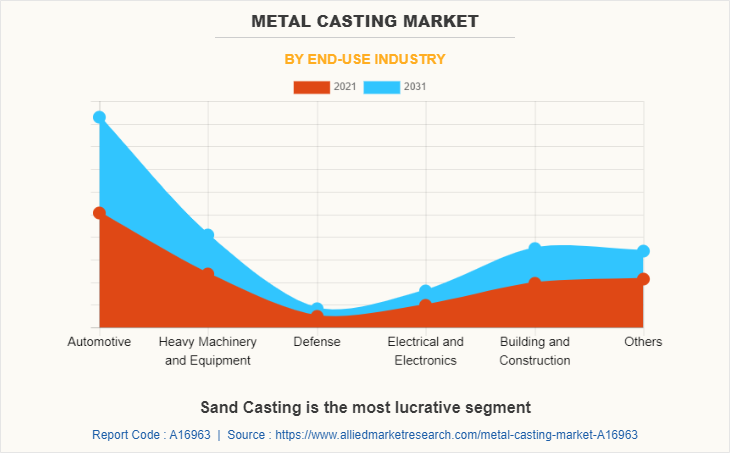

Metal Casting Market By End-use Industry

By end-use industry, the automotive segment was the largest revenue generator and is anticipated to grow at a CAGR of 6.3% during the forecast period. This is attributed to increasing disposable income coupled with spurring rise in original equipment manufacturers (OEMs), which in turn have led the automotive sector to witness a significant growth where metal casting is widely used to produce engine blocks, pistons, brake drums, carburetors, and other automotive parts. This factor has fueled the demand for metal casting for the automotive end-use industry.

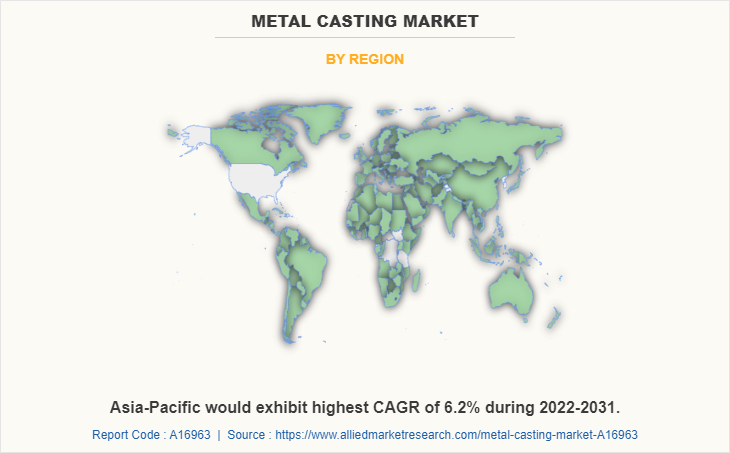

Metal Casting Market By Region

The Asia-Pacific metal casting market is projected to grow at the highest CAGR of 6.2% during the forecast period and accounted for 63.8% of the metal casting market share in 2021. This is attributed to the rise in building & construction, automotive, electronics, and other sectors, have enhanced the performance of the market in the Asia-Pacific region. In addition, China's industrial sector is increasing rapidly, which in turn has enhanced the performance of the market in the region. Furthermore, countries such as India, Australia, Indonesia, and Malaysia, have witnessed a rapid increase in building & construction sector where metal casting are employed to provide structural supports to both residential and commercial building & construction sites, such as hotels, hospitals, homes, flats, warehouses, showrooms, garages, and offices.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the metal casting market analysis from 2021 to 2031 to identify the prevailing metal casting market opportunities.

- Market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the metal casting market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the metal casting market players.

- The report includes the analysis of the regional as well as global metal casting market trends, key players, market segments, application areas, and market growth strategies.

Metal Casting Market, by Process Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 226.8 billion |

| Growth Rate | CAGR of 5.8% |

| Forecast period | 2021 - 2031 |

| Report Pages | 352 |

| By End-use Industry |

|

| By Process |

|

| By Region |

|

| Key Market Players | MINO Industry USA, Inc, Sujan Industries, Rheinmetall Ag, Aisin World Corp. of America, GIBBS, ahresty corporation, Gujarat Precision Cast Pvt. Ltd., Dynacast International, RFQLINE, INC, Dawang Steel Casting Foundry, Nemak, Georg Fischer Ltd., Ryobi Die Casting (USA), Inc., Endurance Technologies Limited, Omnidex Group |

Analyst Review

According to CXOs of leading companies, the global metal casting market is expected to exhibit high growth potential during the forecast period. Metal castings are used in a variety of end-use sectors such as automotive, electrical and electronics, defense, building and construction, and others, for designing and production of various parts and equipment. Automotive sector that requires finished metallic products of definite dimensions can be accomplished with the use of metal casting.

In addition, sand casting and investment casting serve as an excellent process used for maintaining the finish and dimension of equipment by using relatively less energy. Furthermore, factors such as rise in building & construction activities coupled with increase in sales of automotive vehicles, have surged the popularity of metal casting for producing a wide range of interior and exterior metallic components. CXOs further added that sustained economic growth and development of the automotive sector have increased the popularity of metal casting.

Nowadays, metal casting solutions are widely used in electronics sector for producing three-dimensional parts. Furthermore, key electronic manufacturers such as Samsung, LG, Apple, and others are using metal casting owing to its advantages such as quick yield of complexes, preciseness, and production of rigid cast parts with smooth surfaces that don't need intense secondary machining.

Metal casting finds its major applications in automotive industry. This is attributed to increasing disposable income coupled with spurring a rise in original equipment manufacturers (OEMs)

Asia-Pacific is the largest metal casting market across the globe. This is attributed to the rise in building & construction, automotive, electronics, and other sectors, which have enhanced the performance of the metal casting market in the Asia-Pacific region.

The global metal casting market is projected to reach $226.8 billion by 2031, growing at a CAGR of 5.8% from 2022 to 2031.

The major companies profiled in this report include Ahresty Corporation, Aisin World Corp. of America, Dawang Steel Casting Foundry, Dynacast International, Endurance Technologies Limited, Georg Fischer Ltd, GIBBS, Gujarat Precision Cast Pvt. Ltd., MINO Industry USA, Inc, NEMAK, Omnidex Group, Rheinmetall Ag, RFQLINE, INC, RYOBI DIE CASTING, and Sujan Industries.

Loading Table Of Content...